High-nickel ternary positive electrode material containing active oxygen removing agent and preparation method thereof

A high-nickel ternary material and cathode material technology, applied in the field of lithium-ion batteries, can solve the problems of serious gas production and impedance increase, and achieve the effects of eliminating residual lithium, easy operation, and reducing surface residual alkali

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

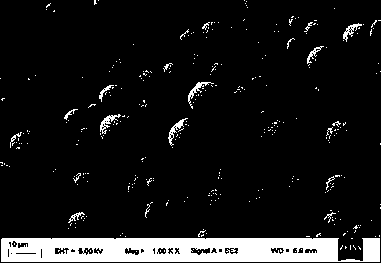

Image

Examples

Embodiment 1

[0025] (1) Preparation of high-nickel ternary cathode material LiNi0.8Co0.1Mn0.1O2, the preparation method of which is similar to Comparative Example 1.

[0026] (2) Dissolve LiNi0.8Co0.1Mn0.1O2 and active oxygen removal agent CoS2 in step (1) in absolute ethanol at a mass ratio of 100:1, ultrasonically disperse for 10 min, and vacuum the sample at 100°C after filtration Dry it for 12 hours, then place it in a muffle furnace for calcination at 700°C for 5 hours in an oxygen-free atmosphere, then cool it to room temperature, and sieve it to obtain CoS2-coated LiNi0.8Co0.1Mn0.1O2 with a mass fraction of 1%.

[0027] (3) The CoS2-coated LiNi0.8Co0.1Mn0.1O2 material prepared in step (2) with a mass fraction of 1% was used as the positive electrode, and the graphite was used as the negative electrode to prepare a pouch battery. The preparation method was similar to Comparative Example 1.

[0028] Test Example 1 Preparation of 1% CoS2-coated high-nickel ternary positive electrode ma...

Embodiment 2

[0030] (1) Preparation of high-nickel ternary cathode material LiNi0.8Co0.1Mn0.1O2, the preparation method of which is similar to Comparative Example 1;

[0031] (2) Dissolve LiNi0.8Co0.1Mn0.1O2 and active oxygen removal agent CoS2 in step (1) in absolute ethanol at a mass ratio of 50:1, ultrasonically disperse for 10 min, and vacuum the sample at 100°C after filtration Dry it for 12 hours, then place it in a muffle furnace for calcination at 700°C for 5 hours in an oxygen-free atmosphere, then cool it to room temperature, and sieve it to obtain CoS2-coated LiNi0.8Co0.1Mn0.1O2 with a mass fraction of 2%.

[0032] (3) The CoS2-coated LiNi0.8Co0.1Mn0.1O2 material prepared in step (2) with a mass fraction of 2% was used as the positive electrode, and the graphite was used as the negative electrode to prepare a pouch battery. The preparation method was similar to Comparative Example 1.

[0033]Test Example 2 prepares the high-nickel ternary positive electrode material containing 2...

Embodiment 3

[0035] (1) Preparation of high-nickel ternary cathode material LiNi0.8Co0.1Mn0.1O2, the preparation method of which is similar to Comparative Example 1;

[0036] (2) Dissolve LiNi0.8Co0.1Mn0.1O2 and active oxygen removal agent CoS2 in step (1) in absolute ethanol at a mass ratio of 20:1, ultrasonically disperse for 10 min, filter and vacuum the sample at 100°C Dry it for 12 hours, then place it in a muffle furnace for calcination at 700°C for 5 hours in an oxygen-free atmosphere, then cool it to room temperature, and sieve it to obtain CoS2-coated LiNi0.8Co0.1Mn0.1O2 with a mass fraction of 5%.

[0037] (3) The CoS2-coated LiNi0.8Co0.1Mn0.1O2 material prepared in step (2) with a mass fraction of 5% was used as the positive electrode, and the graphite was used as the negative electrode to prepare a pouch battery. The preparation method was similar to Comparative Example 1.

[0038] The content of residual lithium on the surface of the high-nickel ternary positive electrode mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com