High-voltage lithium ion battery

A lithium-ion battery and electrolyte technology, applied in secondary batteries, battery electrodes, secondary battery repair/maintenance, etc., can solve problems such as deteriorating battery performance, inhibit reduction and decomposition, improve high-temperature storage and high-temperature cycle performance, The effect of slowing down the occurrence of side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A high-voltage lithium-ion battery comprising a positive electrode, a diaphragm, a negative electrode and an electrolyte, the positive electrode comprising LiCoO coated with a layer of tungsten trioxide nanoparticles on the surface 2 active material, the LiCoO 2 Based on the total mass of tungsten trioxide, the mass percentage of said tungsten trioxide is 0.05%;

[0028] The negative electrode comprises graphite / SiO composite active material,

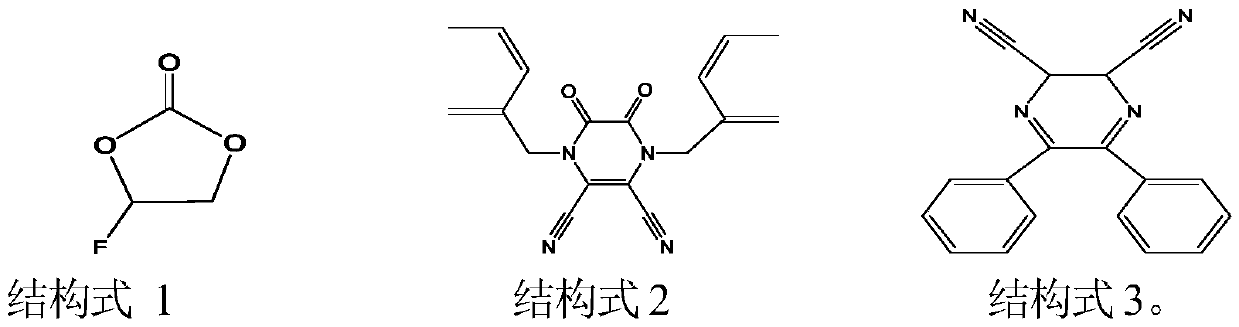

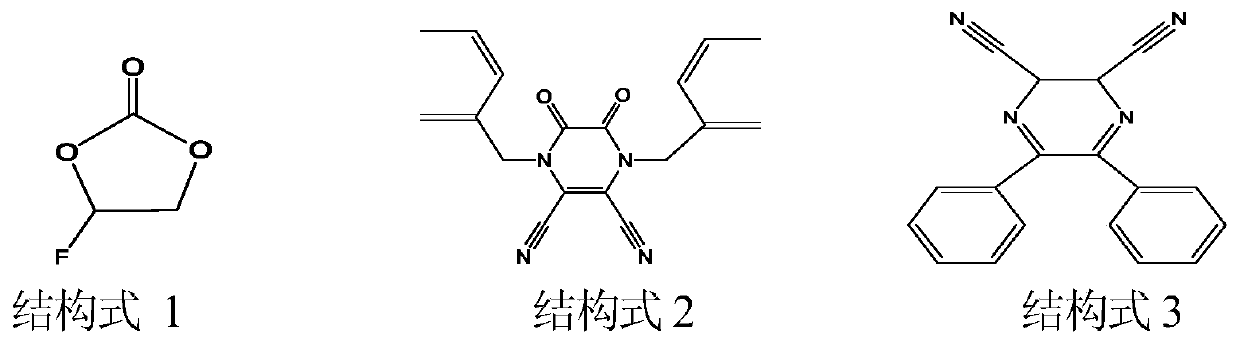

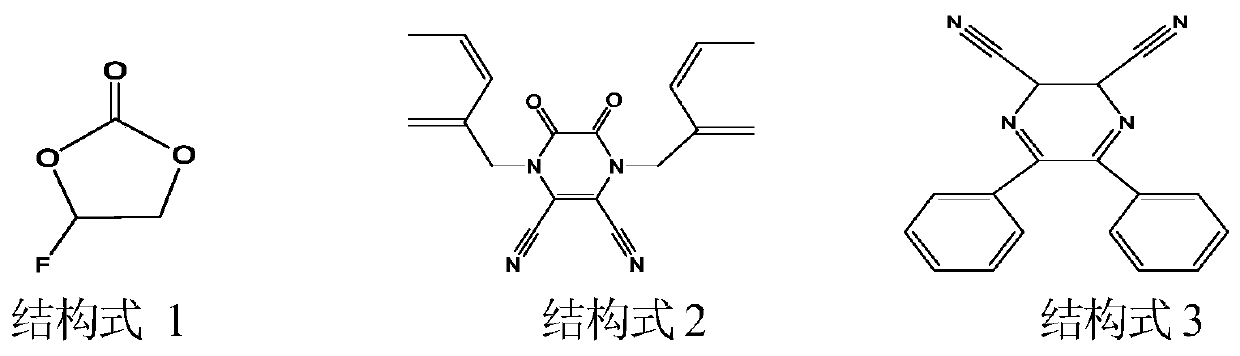

[0029] The electrolyte comprises organic solvent, lithium salt and additives shown in structural formula 1, structural formula 2 and structural formula 3, the additive shown in structural formula 1 accounts for 5% of the total mass of the electrolyte, and the additive shown in structural formula 2 accounts for 1% of the total mass of the electrolyte %, the additive shown in structural formula 3 accounts for 1% of the total mass of the electrolyte,

[0030] The charging cut-off voltage of the lithium ion battery is greater than ...

Embodiment 2~15 and comparative example 1~18

[0045] Embodiments 2-15 and Comparative Examples 1-18 are used to illustrate the lithium ion battery disclosed by the present invention and the preparation method thereof, including most of the operating steps in Example 1. The difference is: 1) the electrolyte Preparation: the types and mass ratios of organic solvents, the types and mass percentages of additives are listed in Table 1. 2) Preparation of cathode material: LiCoO 2 The types and mass percentages of the coating layer on the surface are listed in Table 1. 3) Preparation of negative electrode material: See Table 1 for SiO mass percentage content.

[0046] Battery performance test:

[0047] The following performance tests were performed on the batteries prepared and formed in Comparative Examples 1-18 and Examples 1-15 above:

[0048] Battery cycle performance test at 45°C

[0049] 45°C cycle performance test: After the formed battery was stored in an oven at 45°C for 6 hours, it was charged to 4.45V at a constan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compaction density | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com