High voltage lithium ion battery and its electrolyte

A lithium-ion battery, high-voltage technology, applied in secondary batteries, secondary battery repair/maintenance, circuits, etc., can solve the problem of SEI film rupture or gradual dissolution, increase the internal pressure of lithium-ion batteries, and reduce the cycle performance of lithium-ion batteries To achieve the effects of inhibiting oxidation and decomposition to produce gas, improving cycle performance at room temperature, and improving the interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

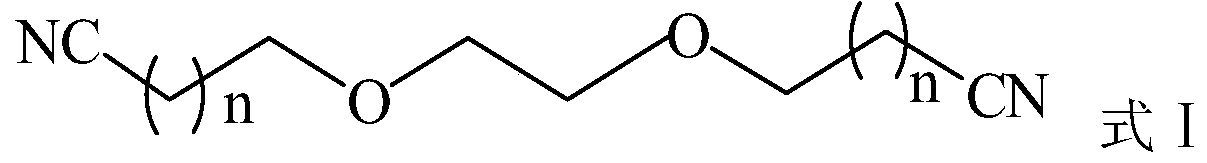

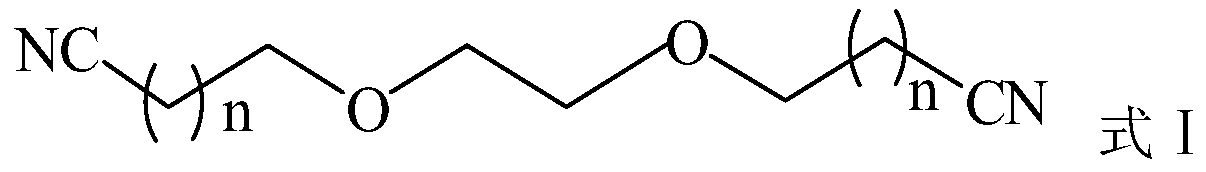

Method used

Image

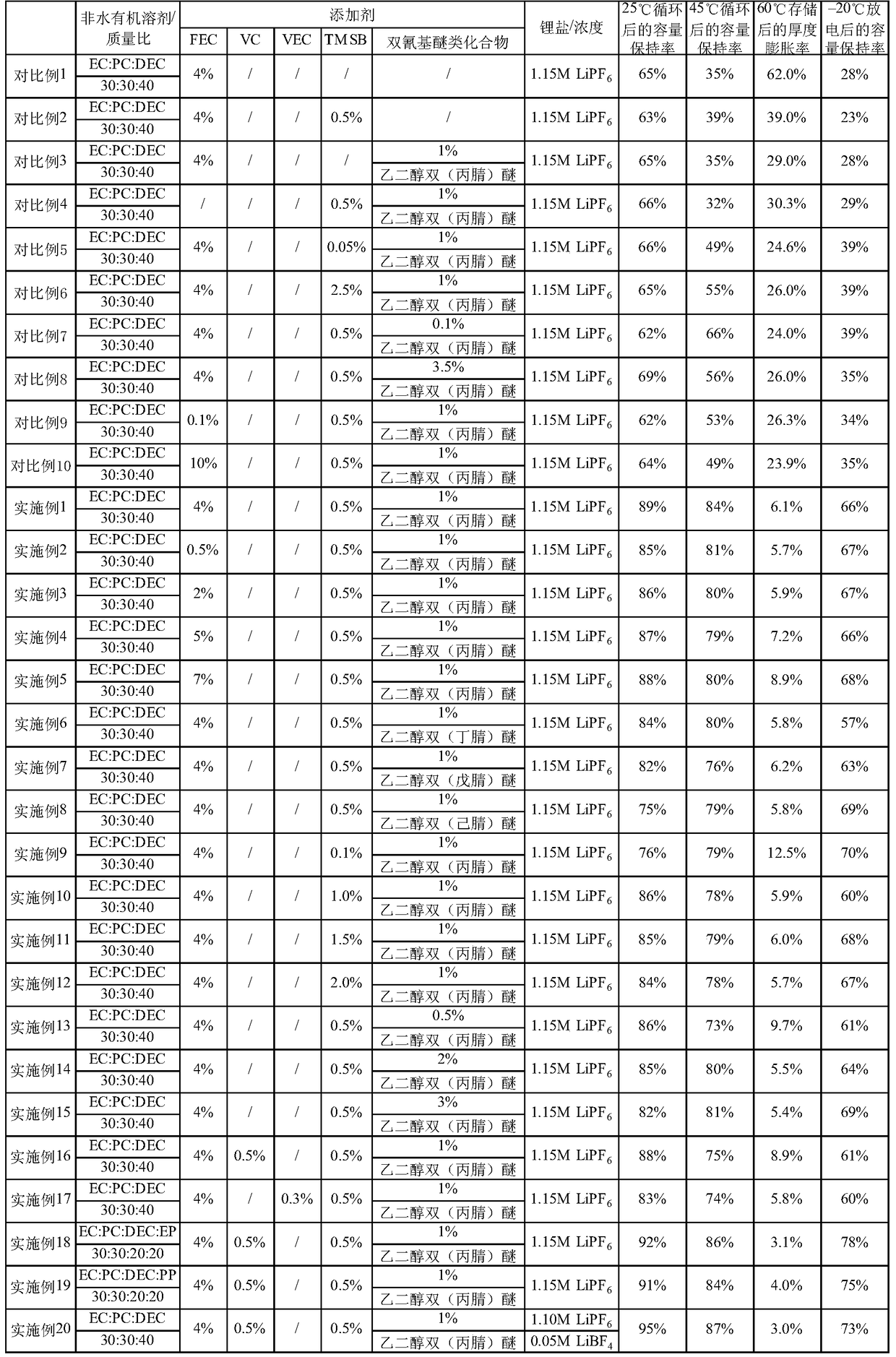

Examples

Embodiment 1

[0068] Lithium-ion batteries were prepared according to the method of Comparative Example 1, except for the following differences:

[0069] (1) prepare the electrolytic solution of lithium-ion battery: additive is that the mass percent composition in electrolytic solution is 4% fluoroethylene carbonate (FEC), the mass percent composition in electrolytic solution is 0.5% three ( trimethylsilane) borate (TMSB) and 1% ethylene glycol bis(propionitrile) ether in mass percent in the electrolyte.

Embodiment 2

[0071] Lithium-ion batteries were prepared according to the method of Comparative Example 1, except for the following differences:

[0072] (1) prepare the electrolytic solution of lithium-ion battery: the additive is that the mass percent composition in electrolytic solution is 0.5% fluoroethylene carbonate (FEC), the mass percent composition in electrolytic solution is 0.5% three ( trimethylsilane) borate (TMSB) and 1% ethylene glycol bis(propionitrile) ether in mass percent in the electrolyte.

Embodiment 3

[0074] Lithium-ion batteries were prepared according to the method of Comparative Example 1, except for the following differences:

[0075] (1) prepare the electrolytic solution of lithium-ion battery: additive is that the mass percent composition in electrolytic solution is 2% fluoroethylene carbonate (FEC), the mass percent composition in electrolytic solution is 0.5% three ( trimethylsilane) borate (TMSB) and 1% ethylene glycol bis(propionitrile) ether in mass percent in the electrolyte.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com