Method for preparing aluminum oxide coated modified lithium nickel cobalt manganese oxygen cathode material

A lithium-nickel-cobalt-manganese oxide cathode, alumina technology, applied in battery electrodes, manganate/permanganate, electrical components, etc. The use of large isopropyl alcohol and other problems can improve the cycle performance and safety performance, improve the surface stability, and inhibit the agglomeration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) According to the molecular formula Li(Ni 1 / 3 co 1 / 3 mn 1 / 3 )O 2 The proportion of transition metals to prepare NiSO 4 、CoSO 4 , MnSO 4 mixed aqueous solution, the cation concentration is 2mo1 / L;

[0038] 2) Add the mixed solution in step 1), 2mol / L NaOH solution and 3mol / L ammonia solution dropwise into the reaction vessel, control the pH of the system at 11.0, and heat to 50°C in a water bath. After reacting for 12 hours, filter, wash, and vacuum dry at 120°C for 8 hours to obtain the precursor (Ni 1 / 3 co 1 / 3 mn 1 / 3 )(OH) 2 ;

[0039] 3) The precursor (Ni 1 / 3 co 1 / 3 mn 1 / 3 )(OH) 2 , aluminum nitrate nonahydrate and urea nonahydrate in molar ratio precursor: Al: urea = 100: 0.5: 8.35 ratio, respectively weigh 50g precursor, 3.67g aluminum nitrate nonahydrate and 5.35g urea dispersant, dissolve in 250mL deionized In water, stir to disperse evenly;

[0040] 4) Warm up the dispersion solution obtained in step 3) to 70°C, keep stirring for 1 hour, and fil...

Embodiment 2-5

[0045] The steps of embodiment 2-5 are basically the same as the steps of embodiment 1, the difference is that in step 3) of embodiment 2-5, the precursor quality, aluminum salt, aluminum salt concentration, precursor: aluminum element: all The powder molar ratio and alumina coating ratio are shown in the following table:

[0046]

[0047]

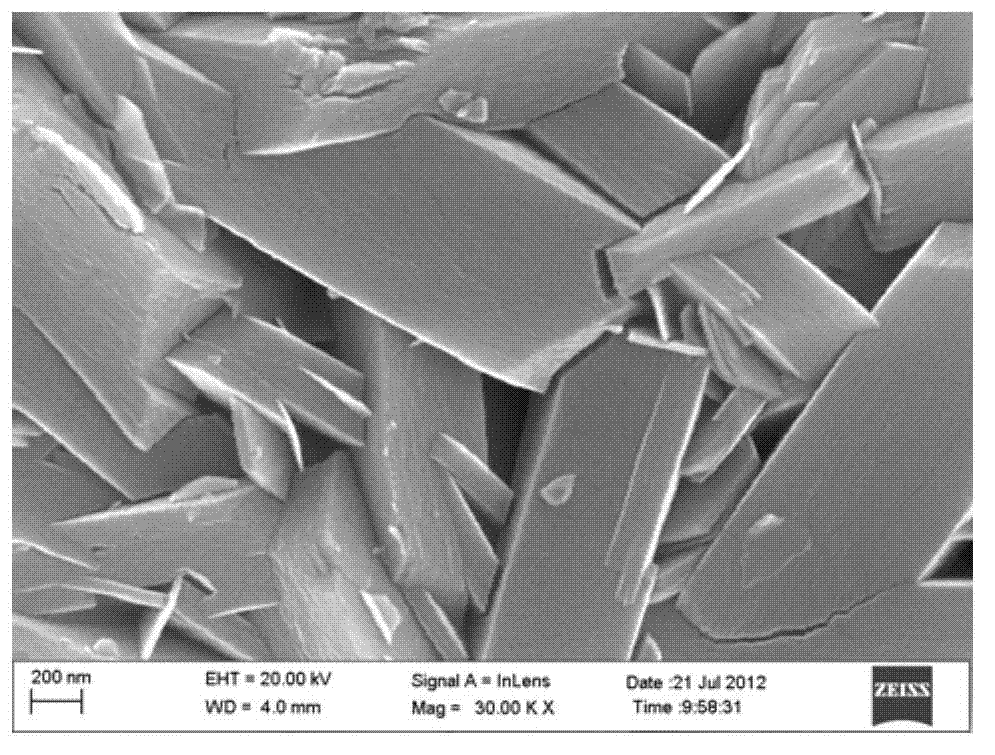

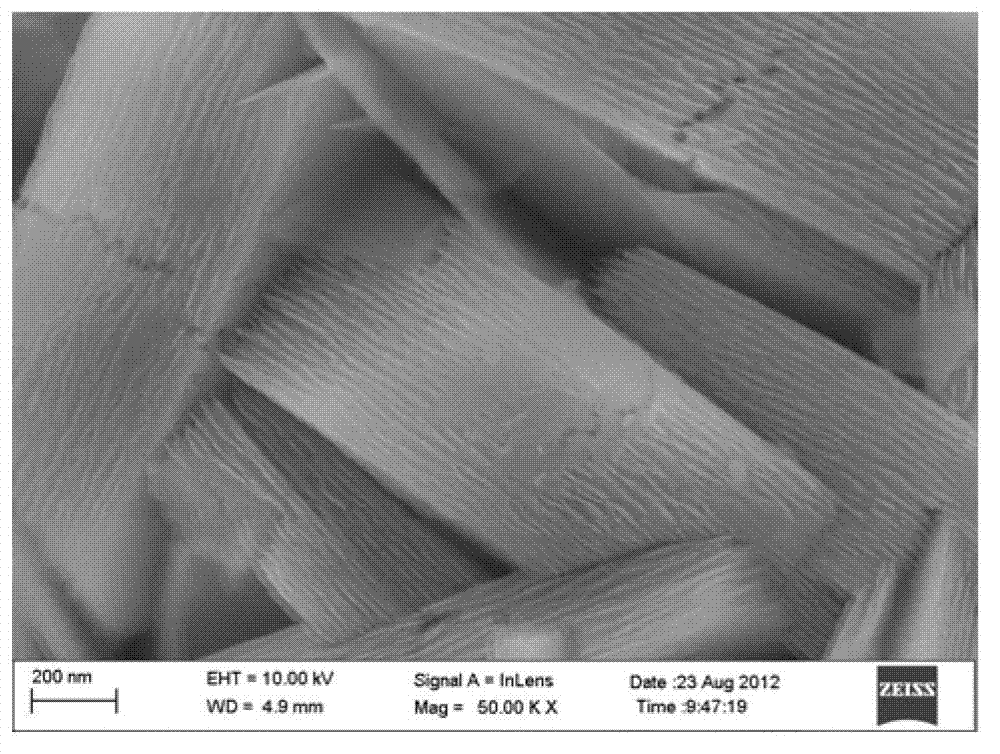

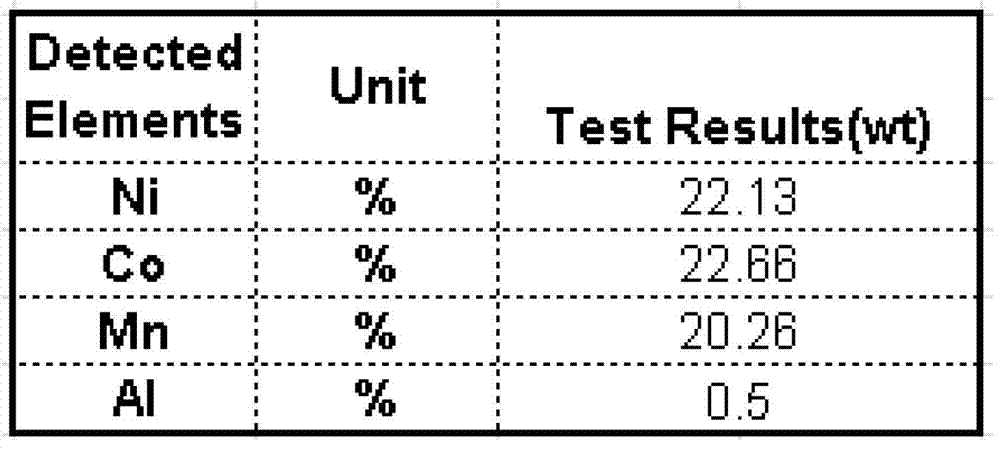

[0048] figure 1 and figure 2 They are the morphology of the precursor alumina in Example 2 before and after coating. It can be seen from the figure that the uniformity of the coated alumina in the embodiment of the present invention is very good; image 3 Shown is the ICP result graph of the precursor coated alumina prepared in Example 2 of the present invention. It can be seen from the figure that the aluminum content coated in the embodiment of the present invention is consistent with the designed amount, indicating that the coating method The practicability is better.

[0049] Electrochemical Performance Analysis

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com