Dispersion equipment for coating production

A dispersing and coating technology, applied in the directions of dissolving, mixing machines, chemical instruments and methods, etc., can solve the problems of raw material waste, poor coating dispersion quality, low work efficiency, etc., to improve quality, improve dispersion efficiency and dispersion quality, The effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

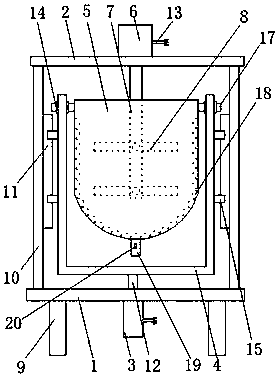

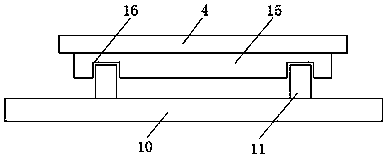

[0017] as attached figure 1 and 2 Shown: a kind of dispersing equipment for coating production, including bottom plate 1, top plate 2, cylinder 3, bearing frame 4, dispersion barrel 5, motor 6, transmission shaft 7 and stirring rod 8, it is characterized in that, described bottom plate 1 is set On the bracket 9, a vertical plate 10 is provided on the base plate 1, and a vertical stop block 11 is provided on the vertical plate 10. The top plate 2 is arranged on the vertical plate 10, and the cylinder 3 is provided On the base plate 1, a power cord 13 and a piston rod 12 are arranged on the cylinder 3, and the bearing frame 4 is arranged on the piston rod 12, and a bearing 14 and a fixed block 15 are arranged on the carrier frame 4. Both sides of the dispersing bucket 5 are provided with connecting rods 17, and the connecting rods 17 are arranged in the bearings 14, the described motor 6 is arranged on the top plate 2, and a power cord 13 is arranged on the motor 6, and the des...

Embodiment 2

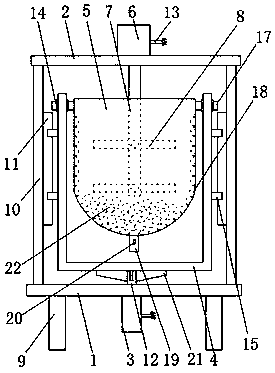

[0023] as attached image 3 Shown: a kind of dispersing equipment for coating production, including bottom plate 1, top plate 2, cylinder 3, bearing frame 4, dispersion barrel 5, motor 6, transmission shaft 7 and stirring rod 8, it is characterized in that, described bottom plate 1 is set On the bracket 9, a vertical plate 10 is provided on the base plate 1, and a vertical stop block 11 is provided on the vertical plate 10. The top plate 2 is arranged on the vertical plate 10, and the cylinder 3 is provided On the base plate 1, a power cord 13 and a piston rod 12 are arranged on the cylinder 3, and the bearing frame 4 is arranged on the piston rod 12, and a bearing 14 and a fixed block 15 are arranged on the carrier frame 4. Both sides of the dispersing bucket 5 are provided with connecting rods 17, and the connecting rods 17 are arranged in the bearings 14, the described motor 6 is arranged on the top plate 2, and a power cord 13 is arranged on the motor 6, and the described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com