Clean environment-friendly dimethyl carbonate diesel and preparation method thereof

A kind of dimethyl carbonate, clean and environment-friendly technology, applied in the field of clean and environment-friendly dimethyl carbonate diesel and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

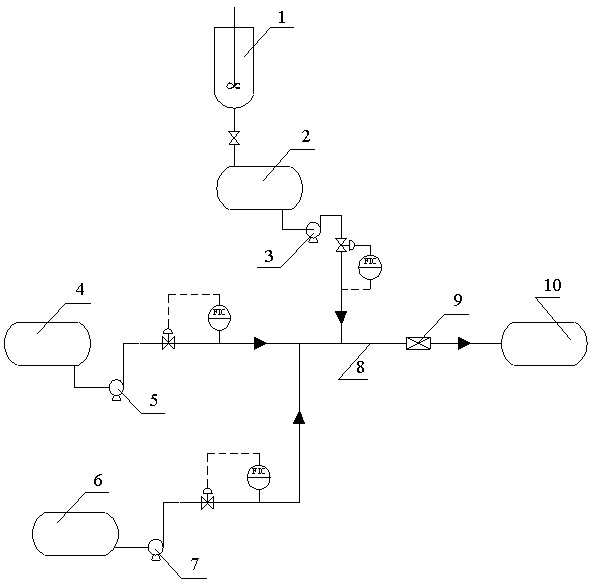

Method used

Image

Examples

Embodiment 1

[0025] 1. The clean and environment-friendly dimethyl carbonate diesel oil of the present embodiment is composed of the following components by weight percentage:

[0026] 2,6-tert-butyl-p-cresol 50~300ppm

[0027] Tris(2,4-di-tert-butylphenyl)phosphite 10~200 ppm

[0028] Thiadiazole or benzotriazole 10~200 ppm

[0029] Isooctyl nitrate or ethyl nitrate 10~500ppm

[0030] Lubricity improver 100~500ppm

[0031] Dimethyl carbonate 9.98~29.83%

[0032] Diesel 70~90%.

[0033] 2. Preparation method:

[0034] (1) 2,6-tert-butyl-p-cresol, tris(2,4-di-tert-butylphenyl) phosphite, thiadiazole or benzotriazole, isooctyl nitrate or ethyl nitrate and lubricity improver are added to part of the dimethyl carbonate according to the formula, stirred at normal temperature and pressure until completely dissolved, and the dimethyl carbonate solution I is prepared; the amount of dimethyl carbonate used accounts for the total amount of dimethyl carbonate added 1~10%.

[0035] (2) Mix die...

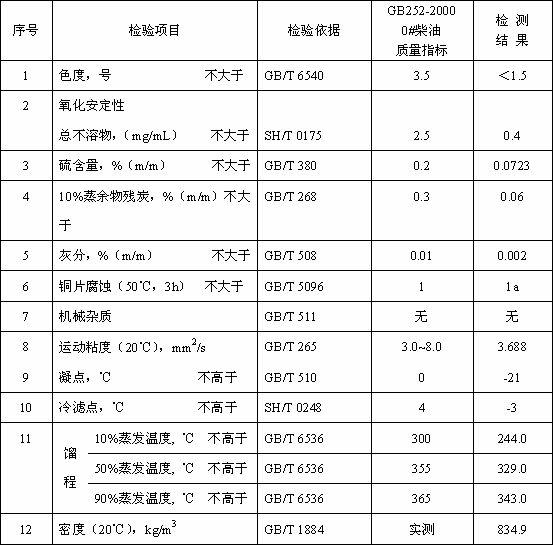

Embodiment 2

[0042] 1. The clean and environment-friendly dimethyl carbonate diesel oil of the present embodiment is composed of the following components by weight percentage:

[0043] 2,6-tert-butyl-p-cresol 100ppm

[0044] Tris(2,4-di-tert-butylphenyl)phosphite 50 ppm

[0045] Thiadiazole or benzotriazole 50 ppm

[0046] Isooctyl nitrate or ethyl nitrate 200ppm

[0047] Lubricity improver 300ppm

[0048] Dimethyl carbonate 14.93%

[0049] Diesel 85%.

[0050] 2, preparation method: preparation method is with the preparation method of embodiment 1.

Embodiment 3

[0052] 1. The clean and environment-friendly dimethyl carbonate diesel oil of the present embodiment is composed of the following components by weight percentage:

[0053] 2,6-tert-butyl-p-cresol 50ppm

[0054] Tris(2,4-di-tert-butylphenyl)phosphite 10 ppm

[0055] Thiadiazole or Benzotriazole 150 ppm

[0056] Isooctyl nitrate or ethyl nitrate 300ppm

[0057] Lubricity improver 100ppm

[0058] Dimethyl carbonate 29.94%

[0059] Diesel 70.0%.

[0060] 2, preparation method: preparation method is with the preparation method of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com