Nitrile rubber/modified silica-gel powder blend and preparation method thereof

A technology of nitrile rubber and silica gel powder, which is applied in the field of nitrile rubber/modified silica gel powder blend and its preparation, can solve the problems that the modification effect of silica gel powder is not obvious, and the molecular structure and chemical properties of silica gel powder are changed. , to achieve the effect of small mechanical properties, improved low temperature resistance, high temperature resistance and excellent aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

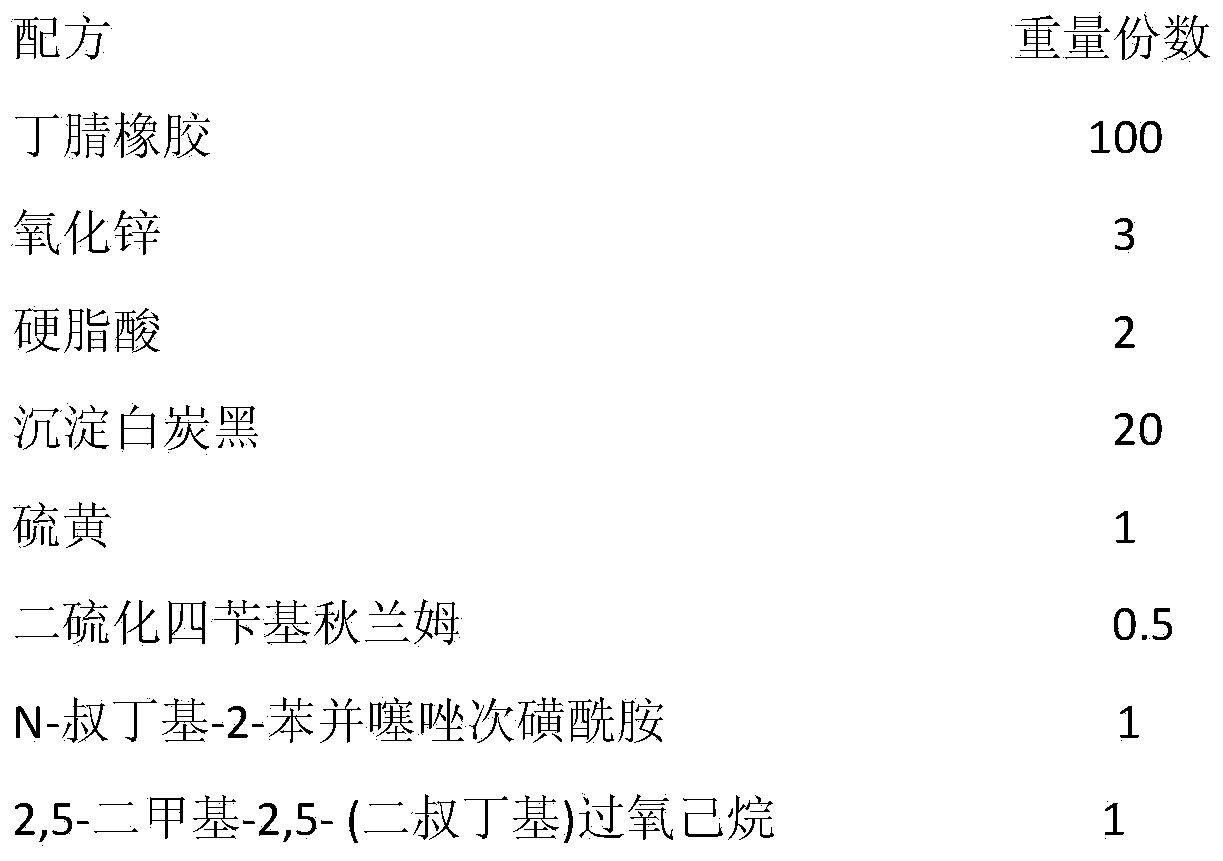

Embodiment 1

[0029]

[0030]In the formula of Example 1, the nitrile rubber was first masticated in an open mill or an internal mixer for 3 minutes, then zinc oxide, stearic acid and precipitated white carbon black were added, and finally sulfur and tetrabenzylqiuran disulfide were added. Ammonium, N-tert-butyl-2-benzothiazole sulfenamide and 2,5-dimethyl-2,5-(di-tert-butyl) peroxyhexane, the mixing temperature is controlled at 40°C, and the mixing The time is 15 minutes. Then the blend obtained above was placed in a flat vulcanizer for compression molding, the vulcanization temperature was controlled at 200° C., and the vulcanization time was 10 minutes.

[0031] The properties of the obtained pure nitrile rubber compound without silica gel powder are shown in Table 1.

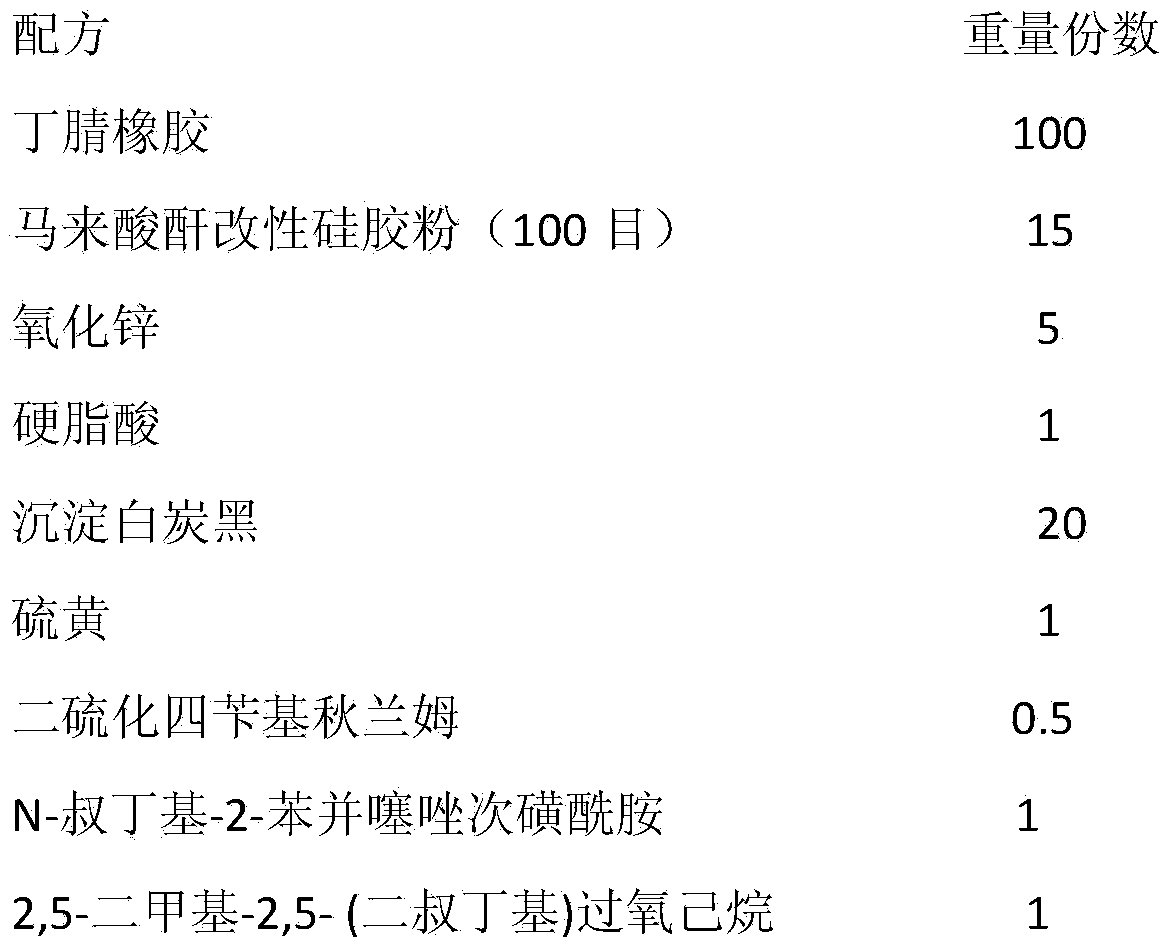

Embodiment 2

[0033]

[0034] In the formula of Example 2, in parts by weight, first place 100 parts of 100 mesh silica gel powder in an internal mixer or a Haake rheometer, add 0.5 parts of dibenzoyl peroxide and 5 parts of maleic anhydride, Heat to 80°C, shear and mix for 25 minutes to prepare maleic anhydride modified silica gel powder.

[0035] Masticate nitrile rubber in an open mill or internal mixer for 3 minutes, add zinc oxide, stearic acid and precipitated silica, then add modified silica gel powder, and finally add sulfur, tetrabenzylthiuram disulfide , N-tert-butyl-2-benzothiazole sulfenamide, 2,5-dimethyl-2,5-(di-tert-butyl) hexane peroxide, the mixing temperature is controlled at 40°C, the mixing time for 30 minutes. Then the blend obtained above was molded in a flat vulcanizer, the vulcanization temperature was 200° C., and the vulcanization time was 10 minutes.

[0036] The properties of the obtained nitrile rubber / modified silica gel powder blend are shown in Table 1. ...

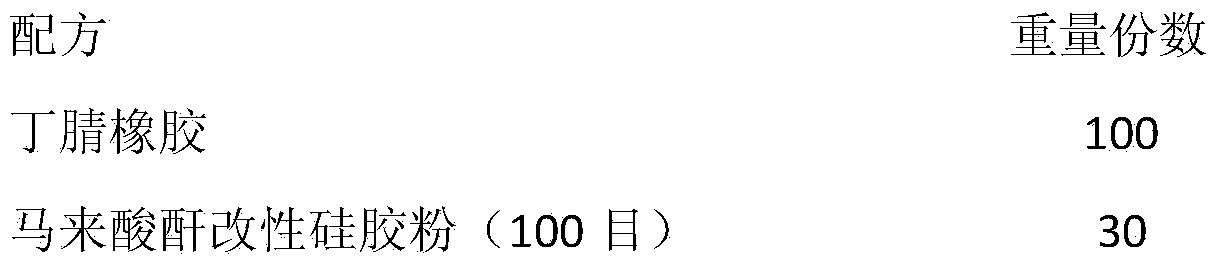

Embodiment 3

[0038]

[0039]

[0040] In the formula of Example 3, in terms of parts by weight, first place 100 parts of 100 mesh silica gel powder in an internal mixer or a Haake rheometer, add 1.0 parts of dibenzoyl peroxide and 5 parts of maleic anhydride, Heat to 80°C, shear and mix for 25 minutes to prepare maleic anhydride modified silica gel powder.

[0041] First, masticate the nitrile rubber in an open mill or internal mixer for 3 minutes, add zinc oxide, stearic acid and precipitated white carbon black, then add modified silica gel powder, and finally add sulfur, tetrabenzylqiuran disulfide Mu, N-tert-butyl-2-benzothiazole sulfenamide, 2,5-dimethyl-2,5-(di-tert-butyl) hexane peroxide, the mixing temperature is controlled at 40°C, and the mixing The time is 25 minutes. Then the blend obtained above was molded in a flat vulcanizer, the vulcanization temperature was 150° C., and the vulcanization time was 30 minutes.

[0042] The properties of the prepared nitrile rubber / mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com