Patents

Literature

54results about How to "Good anti-rust effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

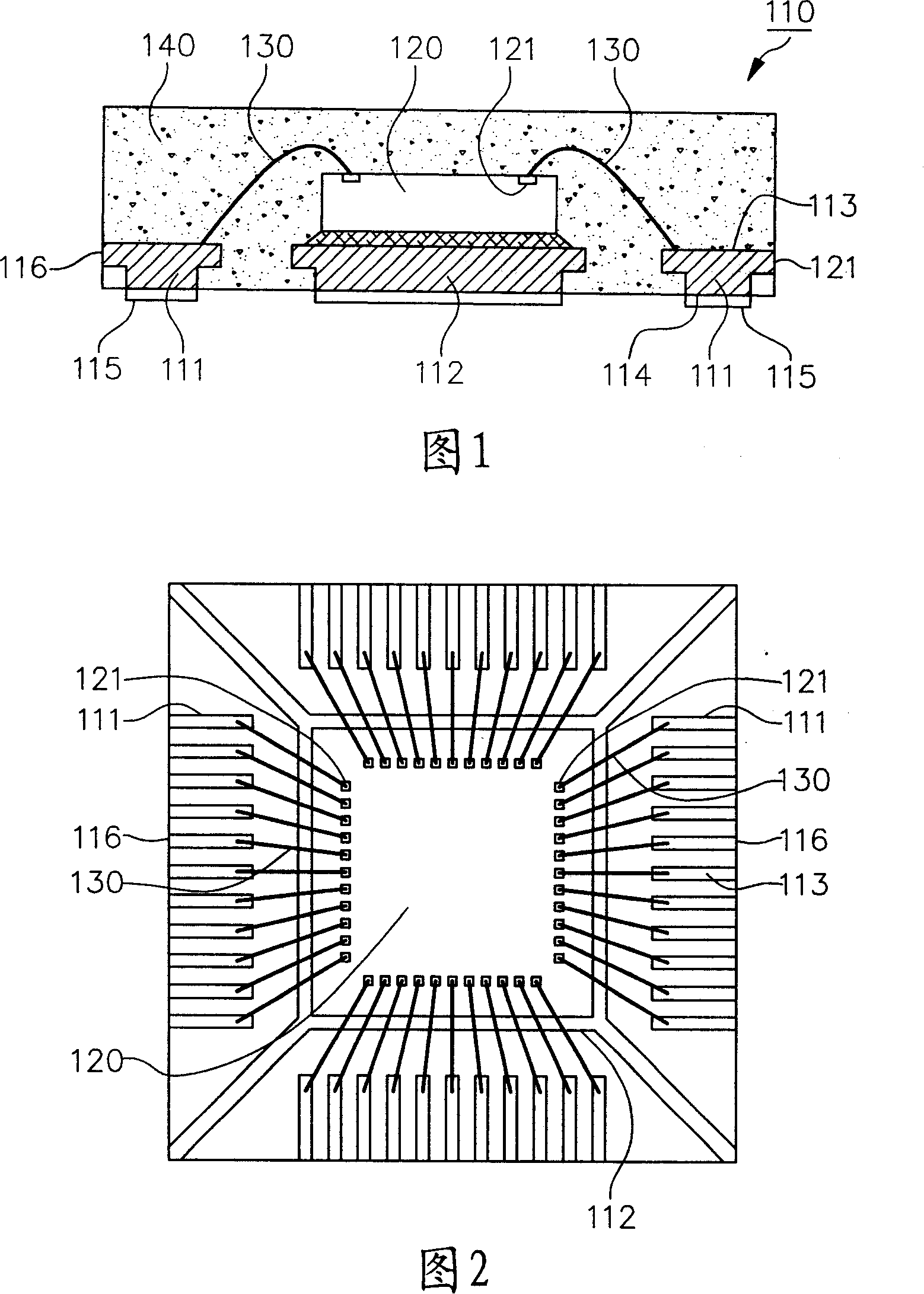

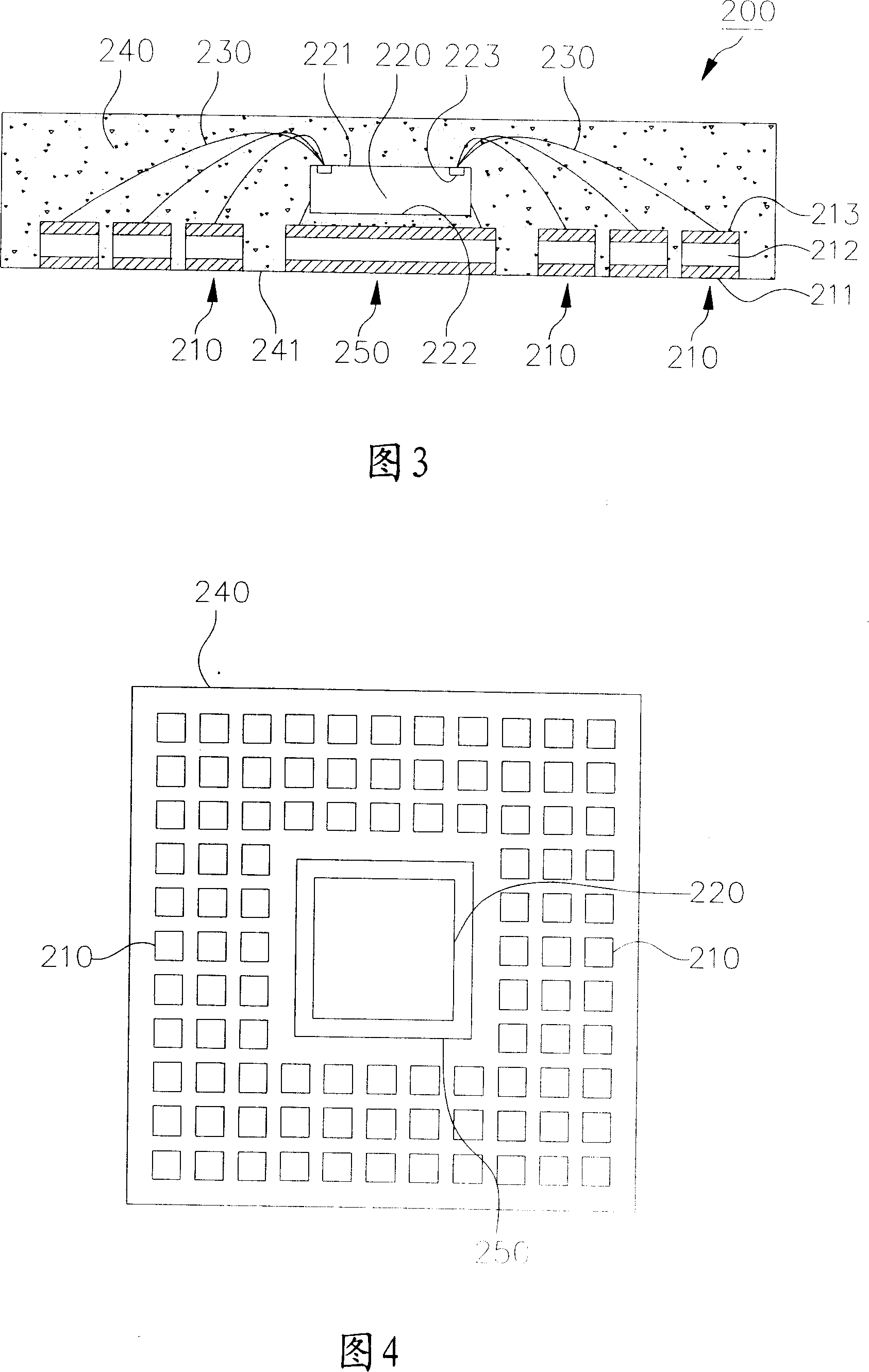

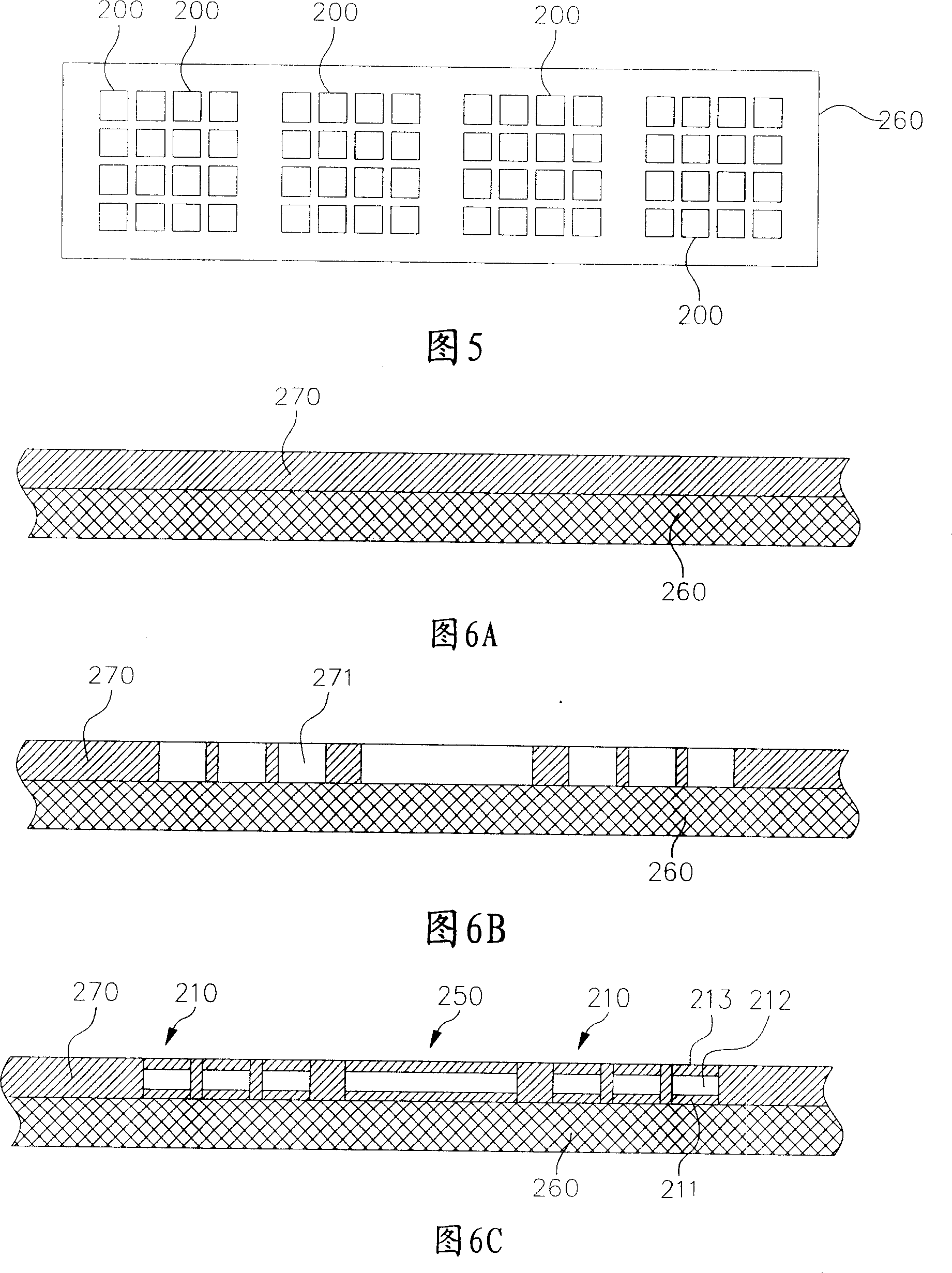

Wafer packaging construction with array connecting pad and method of manufacturing the same

InactiveCN101131980AHigh densityPrevent rustSemiconductor/solid-state device detailsSolid-state devicesHigh densityEngineering

The present invention relates to a wafer packaging with array pads and its processing method. The wafer packaging mainly includes even numbers of wire-bonded pads, a wafer, even numbers of welding line and a sealing colloid. An upper and a lower combination layers are separately formed on cores of the wire-bonded pads, in which materials of the cores include copper. These welding lines electric connect the wafer with the upper combination layer of the wire-bonded pads. The sealing colloid seals these welding lines, cores and upper combination layers, in which only the lower combination layers are exposed out of the sealing colloid. The present invention can solve the former rusting problem of exposed cutting surface of pins in non-external-pin wafer packaging of conductor frame substrate, and has array pads which can achieve high density of wafer packaging. The processing method of the present invention keeps using a rigid conductive mold in packaging process to carry steps of electroforming, wafer attaching, wire bonding and packaging to achieve coherence of the packaging process.

Owner:CHIPMOS TECH INC

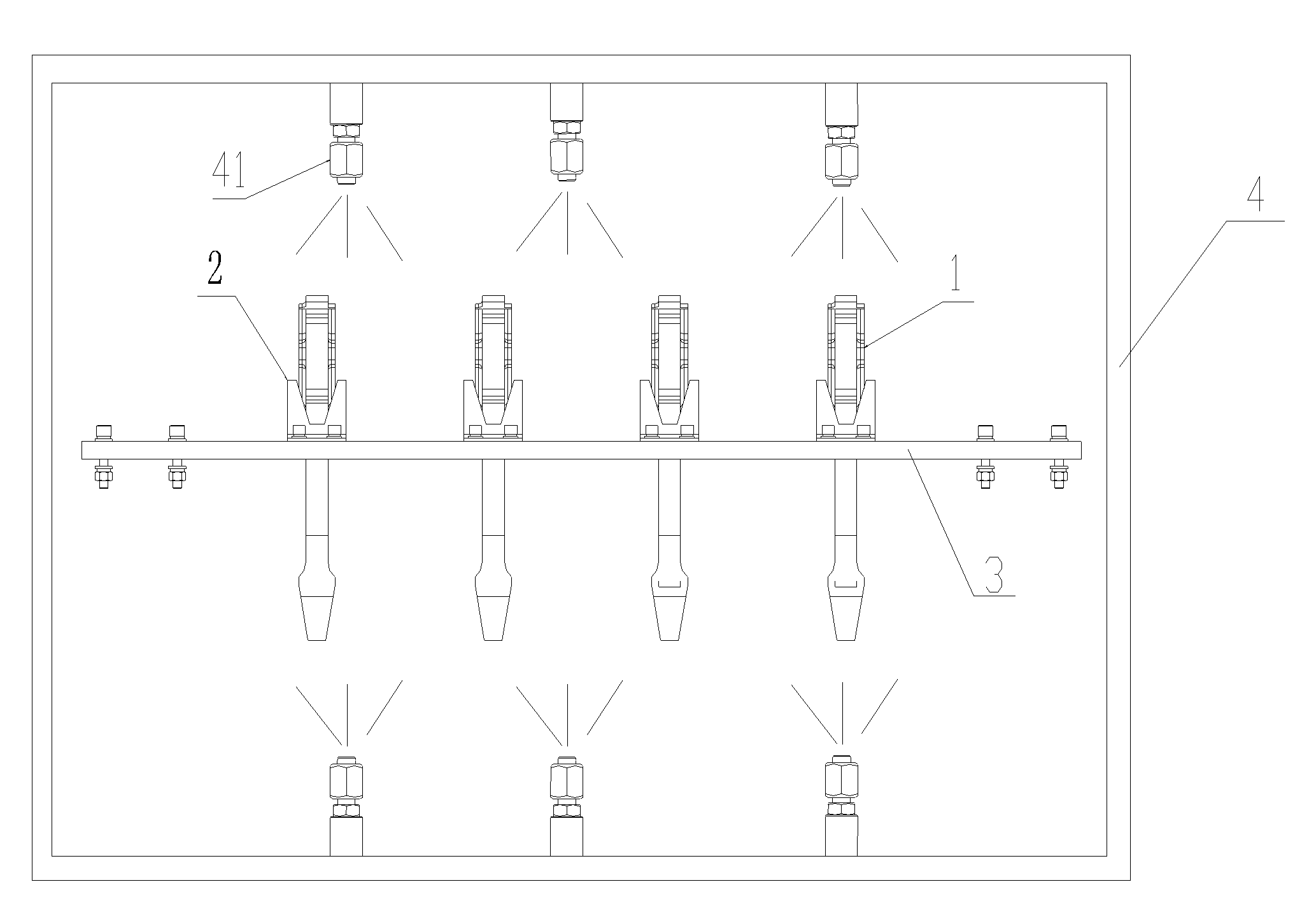

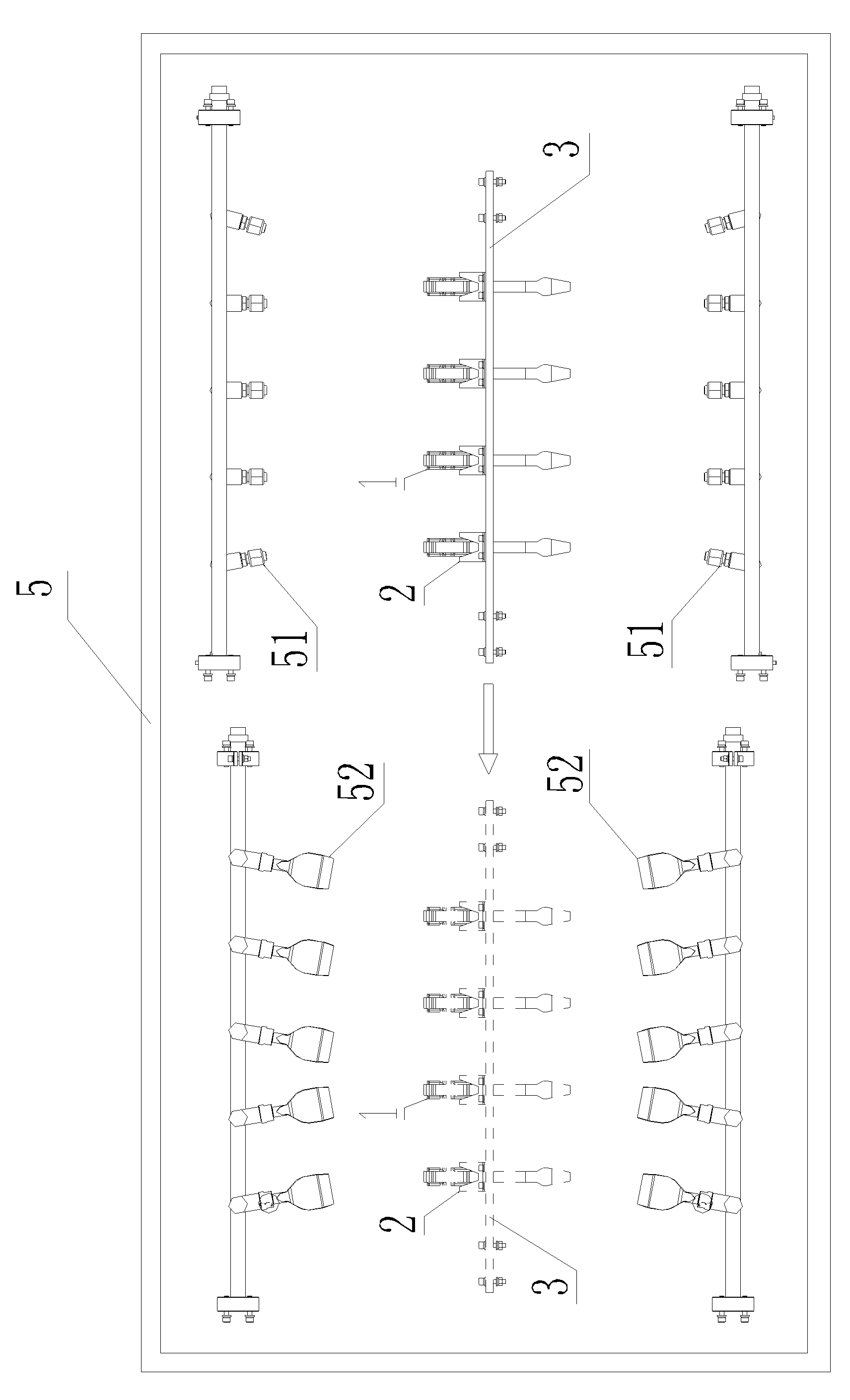

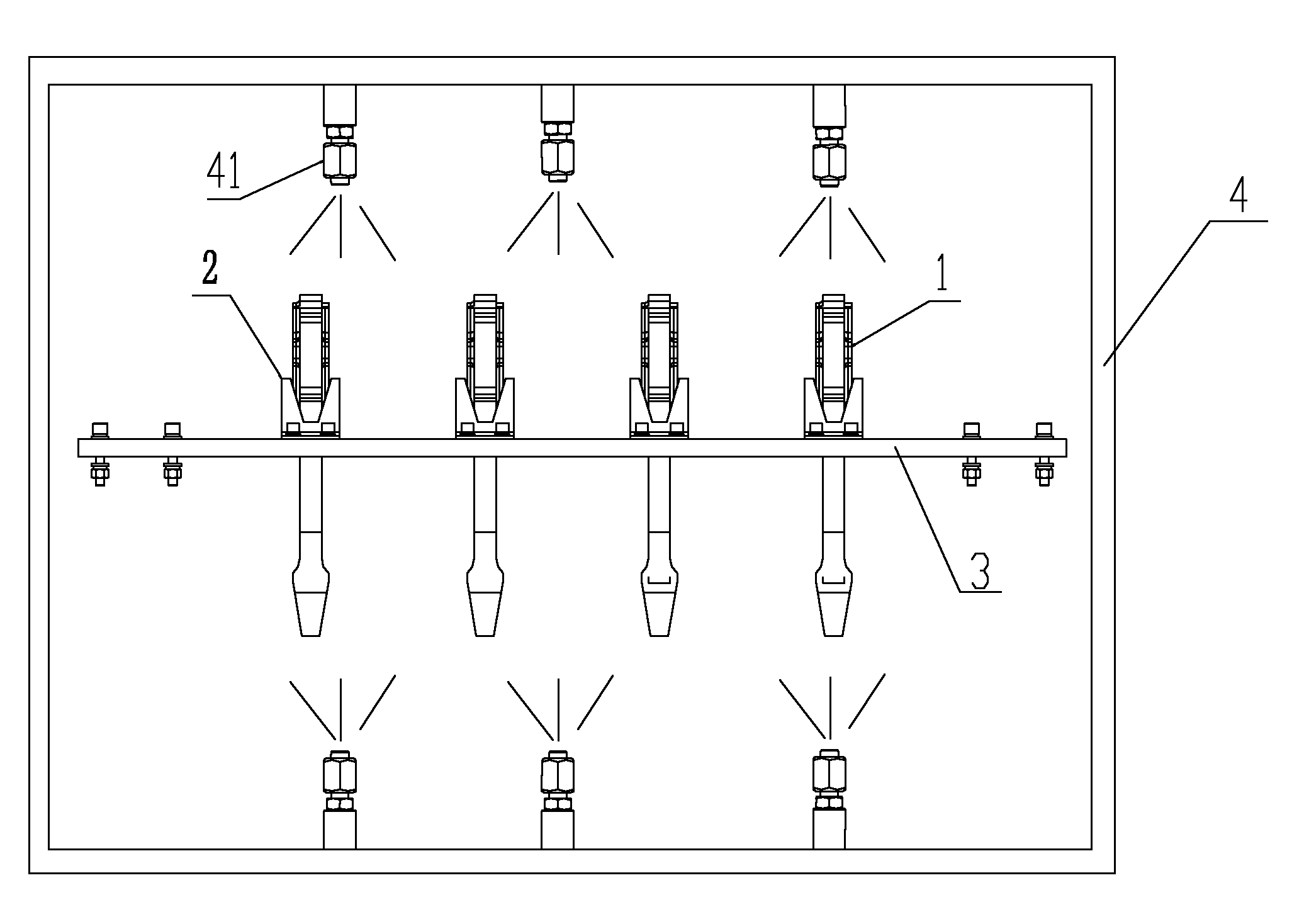

Antirust process for connecting rod of automotive engine

InactiveCN102430493AGood anti-rust effectSimple and efficient operationConnecting rodsPretreated surfacesWater contentScrap

The invention relates to an antirust process for a connecting rod of an automotive engine. The antirust process comprises the following steps of: cleaning the connecting rod in a cleaning room to remove oil dirt and scrap iron on the surface of the connecting rod; rinsing the connecting rod in a rinsing room and primarily oiling the connecting rod by using an antirust oil-doped cleaning solution; baking the connecting rod in a baking room, and evaporating excessive water content on the surface of the connecting rod, and coating atomized antirust oil on the connecting rod in a spraying and coating room. In the invention, the connecting rod is put in a material channel in a vertical manner, and is cleaned and oiled in a passageway in a spraying manner so as to keep a certain cleanness and a good antirust effect through the process of the four steps. The antirust process is simple and convenient to operate, and has an obvious effect; and when the antirust process is adopted, the requirement for the automated process is met, labor cost is reduced, and many costs for materials are also saved.

Owner:SHANGHAI JIAOYUN AUTOMOTIVE POWER SYST

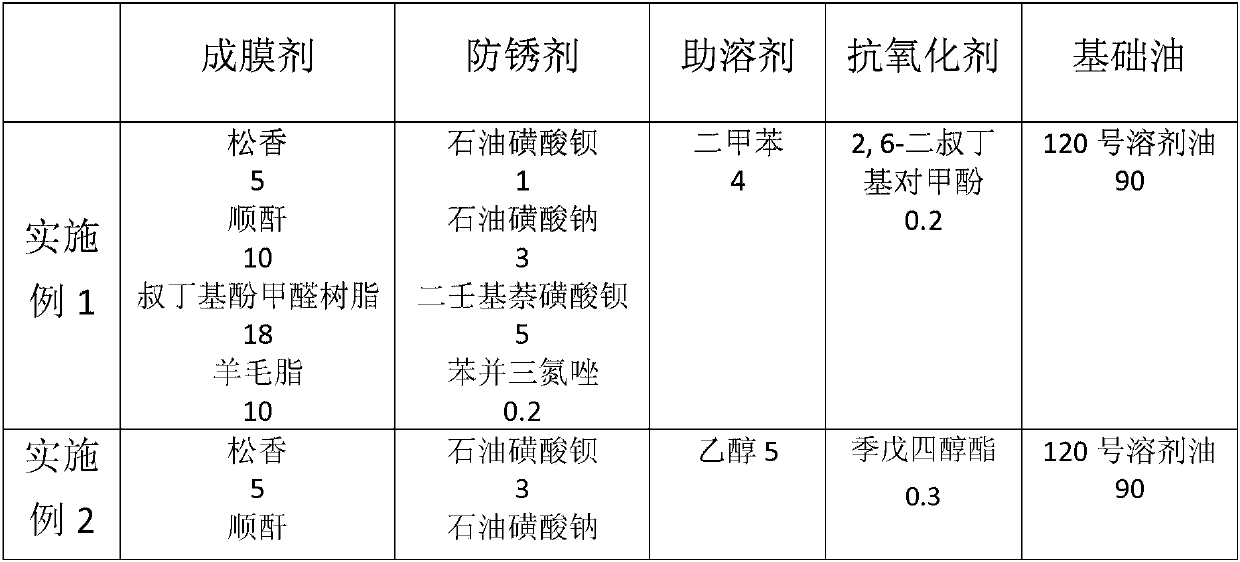

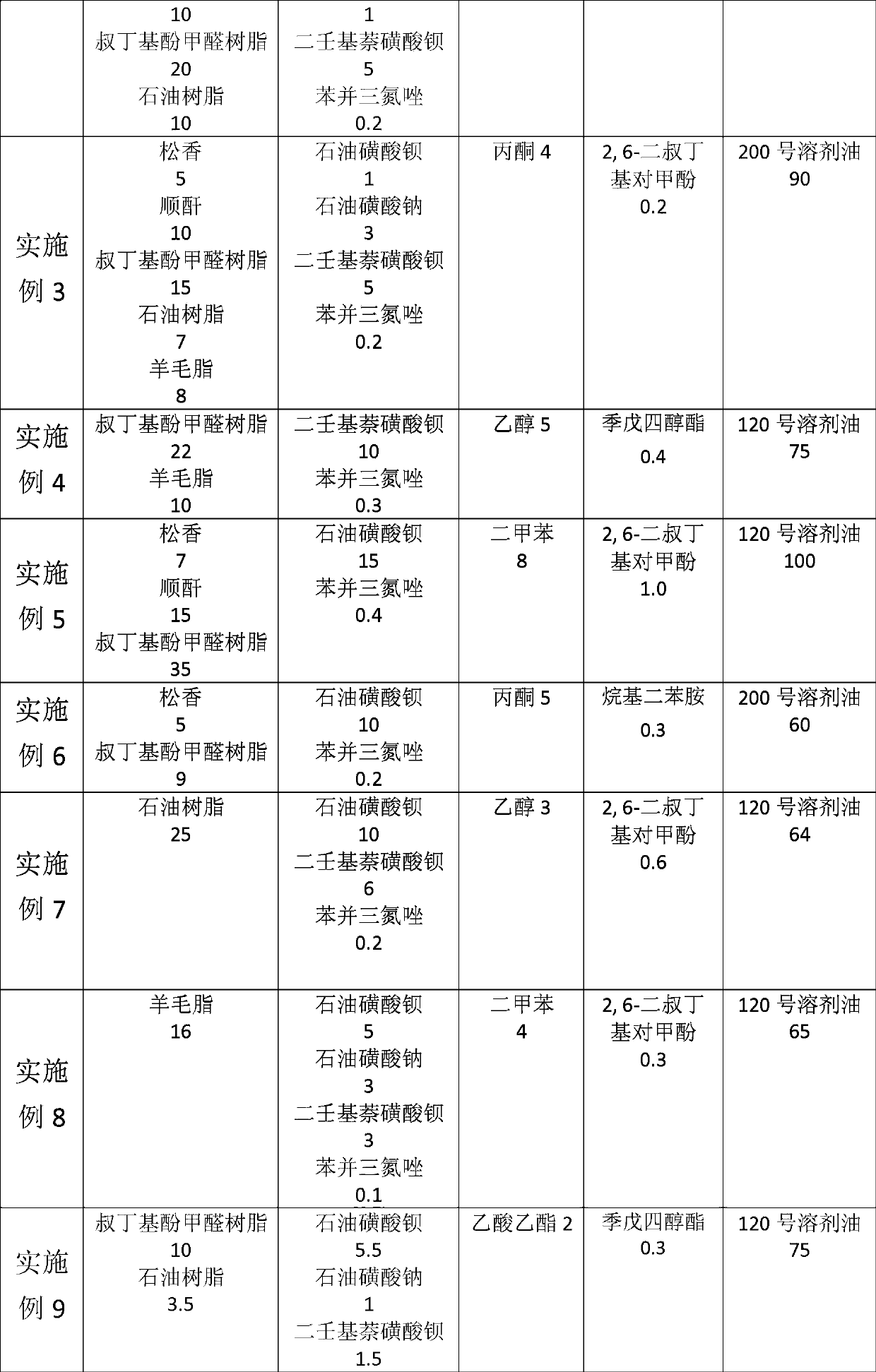

Antirust oil and preparation method thereof

The invention relates to antirust oil and a preparation method thereof. The antirust oil is prepared from the following components by weight percent: 20 to 35 percent of film forming agent, 5 to 15 percent of antirust agent, 0.1 to 5 percent of co-solvent, 0.1 to 2 percent of antioxidant and 40 to 75 percent of basic oil. The preparation method comprises the following steps: preparing all raw materials according to the components and the weight ratio, adding the basic oil into a reactor, heating and stirring, when the temperature is increased to 90 to 120 DEG C, adding the antirust agent, theco-solvent and the antioxidant, sufficiently stirring, completely dissolving, lowering the temperature in the reactor to 50 to 80 DEG C, then slowly adding the film forming agent and the residual basic oil, sufficiently stirring, completely dissolving, cooling to the room temperature, detecting, discharging the material, thus obtaining the antirust oil. The antirust oil of the invention is high inactually completely drying speed and has good antirust effects for the long-term storage and transportation of various metals such as iron, copper, aluminum, magnesium alloy and the like.

Owner:上海有道新能源技术有限公司 +1

Aqueous antirust agent

The invention discloses an aqueous antirust agent, which comprises the following components in parts by weight: 40 to 50 parts of 1-hydroxybenzotriazole, 35 to 42 parts of 1,2-diethoxyl silyl ethane, 5 to 10 parts of inositol hexaphosphate, 5 to 8 parts of triethylamine, 1 to 4 parts of sodium acetate and 0.02 to 1 part of oxalic acid. According to the aqueous antirust agent, the characteristic of cleanliness of the aqueous antirust agent is ensured; compared with a conventional aqueous antirust agent, the aqueous antirust agent has a good antirust effect, and is stable and long in antirust life.

Owner:珠海市金宜科环保材料有限公司

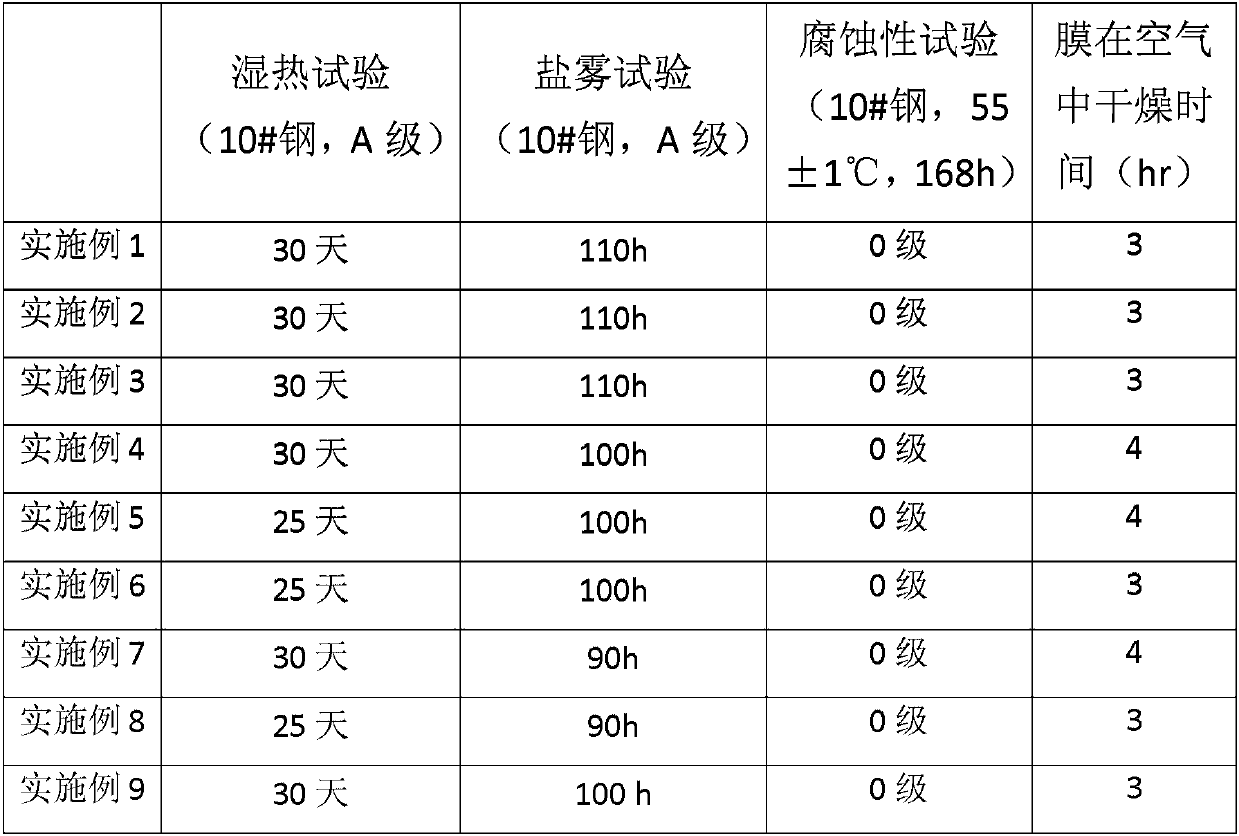

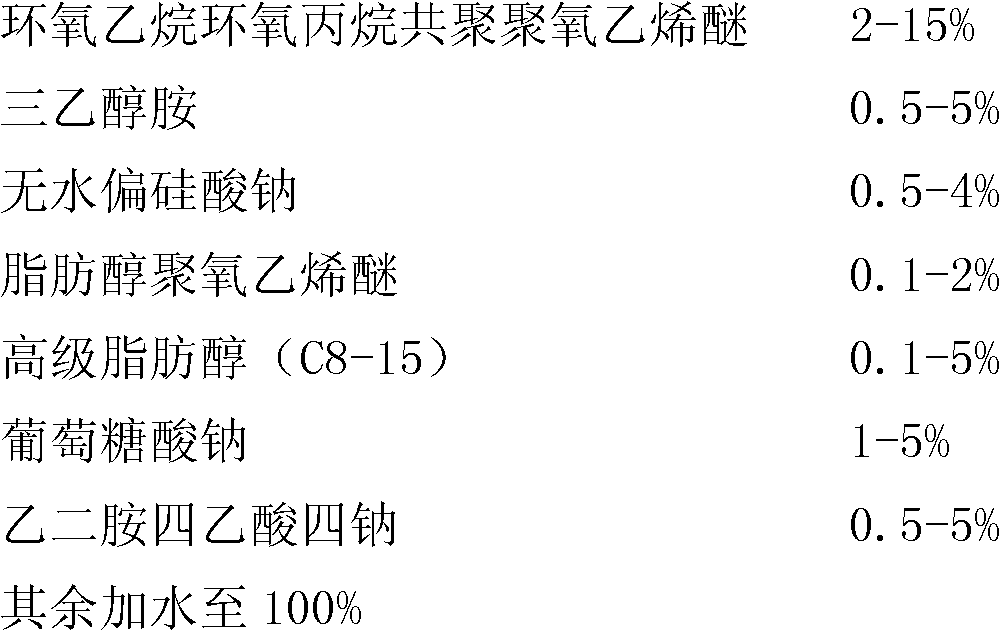

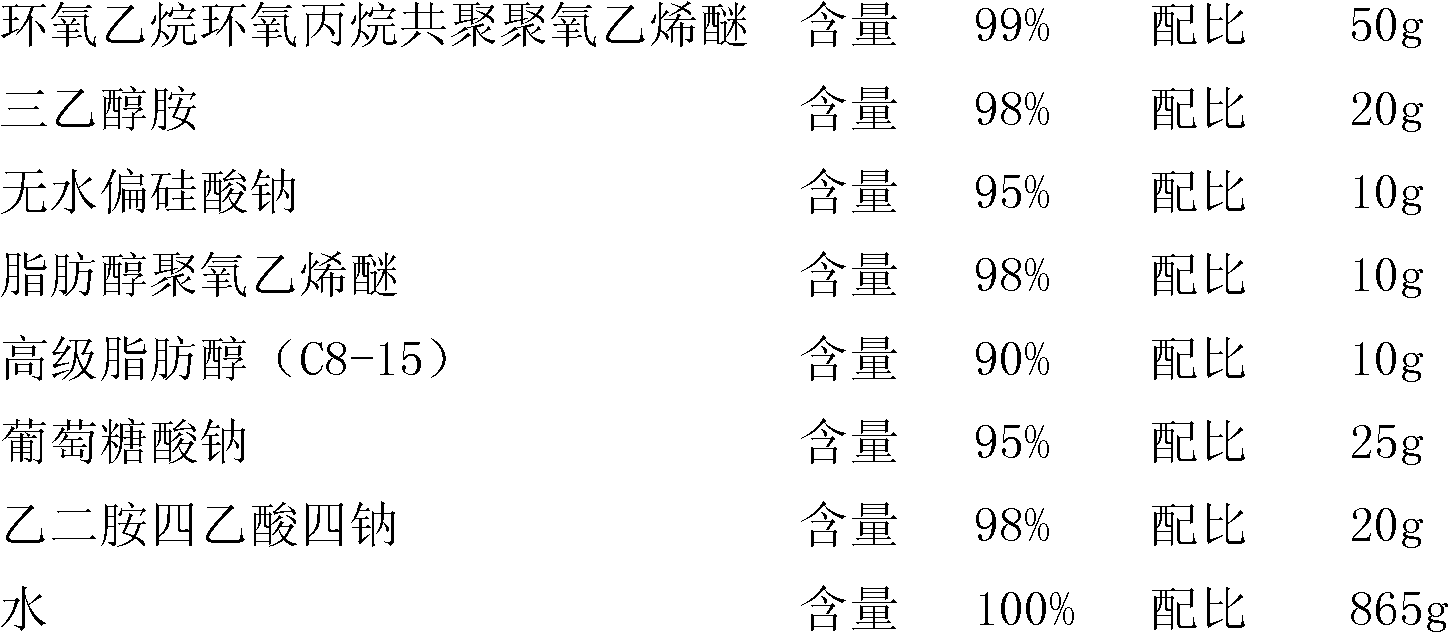

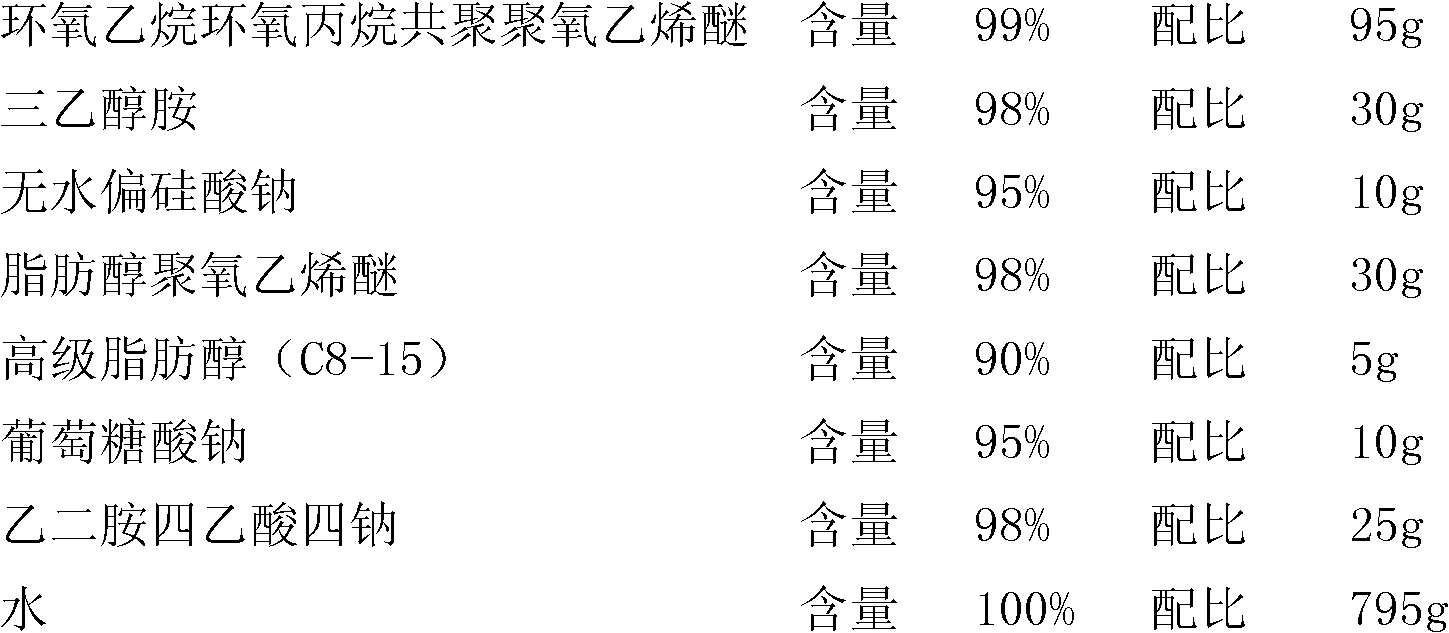

Water-based industrial detergent capable of self-defoaminng at normal temperature and preparation method thereof

InactiveCN102161939AReduce intensityThe principle of achieving self-defoamingInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsWater basedSodium metasilicate

The invention relates to a water-based industrial detergent capable of self-defoaming at normal temperature and a preparation method thereof. The detergent comprises the following components in percentage by weight: 2-15% of ethylene oxide epoxypropane copolymerized polyoxyethylene, 0.5-5% of triethanolamine, 0.5-4% of sodium metasilicate anhydride, 0.1-2% of fatty alcohol-polyxyethylene ether, 0.1-5% of advanced fatty alcohol (C8-15), 1-5% of sodium gluconate, 0.5-5% of ethylene diamine tetraacetic acid and the balance of water. The preparation method mainly comprises the following steps: dissolving the sodium metasilicate anhydride, the sodium gluconate and the ethylene diamine tetraacetic acid in the water; and then adding the ethylene oxide epoxypropane copolymerized polyoxyethylene, the triethanolamine, the fatty alcohol-polyxyethylene ether, the advanced fatty alcohol (C8-15) and the like in sequence, and mixing to finally obtain the industrial detergent. In the invention, based on the combined action of lipophilic group epoxypropane in the ethylene oxide epoxypropane copolymerized polyoxyethylene and lipophilic group in the system as well as industrial oil stain, the intensity of foam generated in the process of cleaning is reduced so as to realize the self-defoaming effect; through the synergistic effect of various components, optimal cleaning and antirust effects are achieved; simultaneously, through the synergistic effect of various surfactants, the defect that inorganic salts always form white spots on the surface of a workpiece is obviously improved.

Owner:华阳新兴科技(天津)集团有限公司

Metal part anti-rust technology

ActiveCN105441921ABroad application prospectsGood anti-rust effectMetallic material coating processesCorrosion resistantMetal

The invention discloses a metal part anti-rust technology. Cleaning is executed in two steps. On one hand, degreasing fluid can be washed out, and on the other hand, influences of other ions on the surface of steel to film formation can be removed. According to the composition and ratio and the preparing method of a phosphating solution, a phosphating film formed by phosphating of a metal part is ideal in anti-rust effect, and the application prospect is wide. Saponification treatment is carried out after passivation, the long-term anti-rust and anti-corrosion effects can be achieved, the anti-rust technology is adopted, the beneficial effects of being good in anti-rust effect and good in corrosion resistance are achieved, the market potential is giant, and the prospect is wide.

Owner:台州和兴锻造有限公司

Rust-proof water-based cutting fluid

InactiveCN105567407AGood cooling and lubricating propertiesGood anti-rust effectLubricant compositionChemistryDodecylsulfonic acid

The invention discloses a rust-proof water-based cutting fluid, which consists of the following raw materials by weight: 10-12 parts of alkyl phosphate, 15-18 parts of sodium dodecylsulphate, 3-5 parts of polyethylene glycol, 3-5 parts of triethanolamine, 0.5-1 part of nano calcium carbonate, 1-3 parts of potassium borate, 0.5-1 part of borax, 5-8 parts of sodium petroleum sulfonate, 2-4 parts of sodium silicate, 0.5-1 part of phosphatidic acid, 1-3 parts of glyceryl monostearate, 0.5-1 part of vinyl acetate maleate, 0.05-0.1 part of t-butyl chromate, 0.01-0.04 part of methyl isobutyl ketone, 1-2 parts of tetramer castor ester, 3-5 parts of 4-methyl salicylate, 1-3 parts of a corrosion inhibitor, 2-6 parts of a rust inhibitor and 30-40 parts of deionized water. The cutting fluid has good cooling and lubrication performances, sterilization, antibiosis and good antirust effect.

Owner:QINGDAO WENSHENG AUTOMOBILE COMPONENTS & PARTS

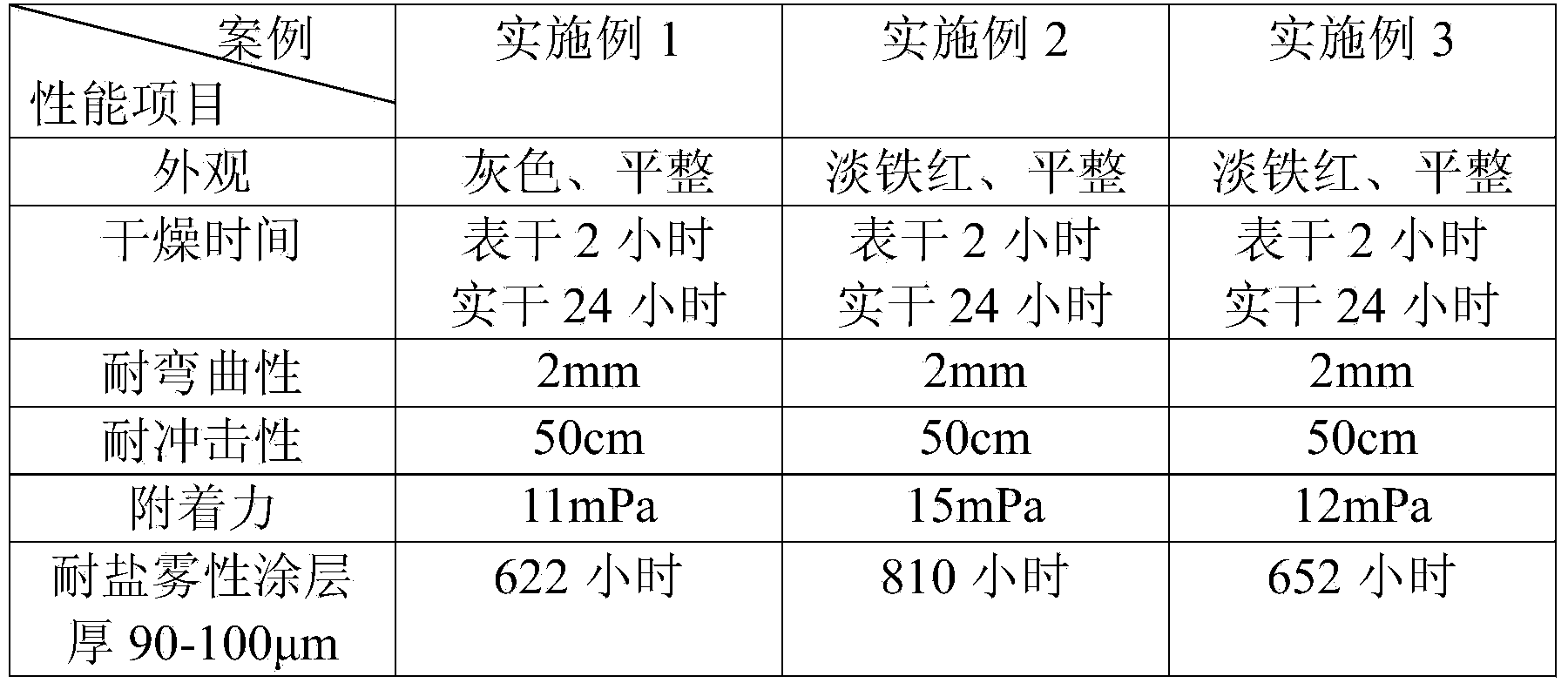

Polyurethane resin-acrylic resin antirust paint

InactiveCN102372999AGood anti-rust effectShort drying timeAnti-corrosive paintsPolyurea/polyurethane coatingsDiamineIron oxide

The invention discloses a polyurethane resin-acrylic resin antirust paint, prepared by stirring the following ingredients: 70 weight portions of polyurethane resin, 36 weight portions of ethene diamine, 45 weight portions of acrylic resin, 12 weight portions of sodium potassium silicate, 5 weight portions of triethanolamine, 15 weight portions of iron oxide red, 10 weight portions of turpentine, 65 weight portions of water, 2 weight portions of antiseptic, 15 weight portions of kaolin, and 3 weight portions of thickening agent. The paint has the advantages of safety, no toxicity, water resistance, oxygen resistance, good anti-rust effect, short drying time and the like.

Owner:SUZHOU MEIYAMEI CONSTR COATINGS

Coating for preventing surface rusting of color steel plate of solar water tank

InactiveCN106590358AExtended service lifeImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsAcrylic resinSolar water

The invention relates to the technical field of solar equipment, in particular to a coating for preventing surface rusting of a color steel plate of a solar water tank. Most of solar water tanks are made of color steel plates, the installation environment of the solar water tanks is adverse, and the easiness in corrosion and rusting of the color steel plates by water, temperature and air pollution of surrounding environment is caused; the color steel plate is thinner, and the easiness in breaking is caused. The coating comprises the following raw materials of modified vinyl resin, thermosetting acrylic resin, bisphenol-A-type epoxy resin, talcum powder, glass powder, precipitated barium sulfate, nanometer material, compound ferric and titanium powder, zeolite, tributyl phosphate, ammonia water, solvent, pigment, synergist, flatting agent, dispersant and antirust agent. The coating has the advantages that by adding the nanometer material, the film forming density of the coating is improved, the hardness of a paint film is improved, and the hand feel is improved; the anti-rust property and anti-corrosive property are good, the adhesion force of a coating film is strong, and the pollution-resistant property and the acid and alkaline-resistant property are good.

Owner:钦州太平电子科技有限公司

Emulsion-type derusting antirust liquid and preparation method thereof

The invention discloses an emulsion-type derusting antirust liquid which is prepared from the following raw materials in parts by weight: 2-3 parts of potassium dihydrogen phosphate, 10-12 parts of isopropanol, 1-2 parts of zinc oxide, 1-2 parts of thiourea, 4-6 parts of polyisobutene, 1-2 parts of sodium dodecyl benzene sulfonate, 9-12 parts of inositol hexaphosphate, 10-12 parts of dipentaerythritol hexaacrylate, 1-2 parts of a silane coupling agent KH560, 1-2 parts of EDTA disodium, 4-5 parts of an auxiliary agent, and 300 parts of water. The derusting antirust liquid can strongly remove rust on the surface of a metal, at the same time, because of containing resin and the chelating agent, the derusting antirust liquid can form a thin film on the surface of the metal, thereby playing a role of isolating air; besides, because of the resin having an anti-oxidation effect and in addition of containing an antirust agent, the derusting antirust liquid has quite excellent antirust effect; and the antirust film can be immediately removed by water washing, thereby saving manpower.

Owner:MINGGUANG CITY LIUXIANG PUMP IND

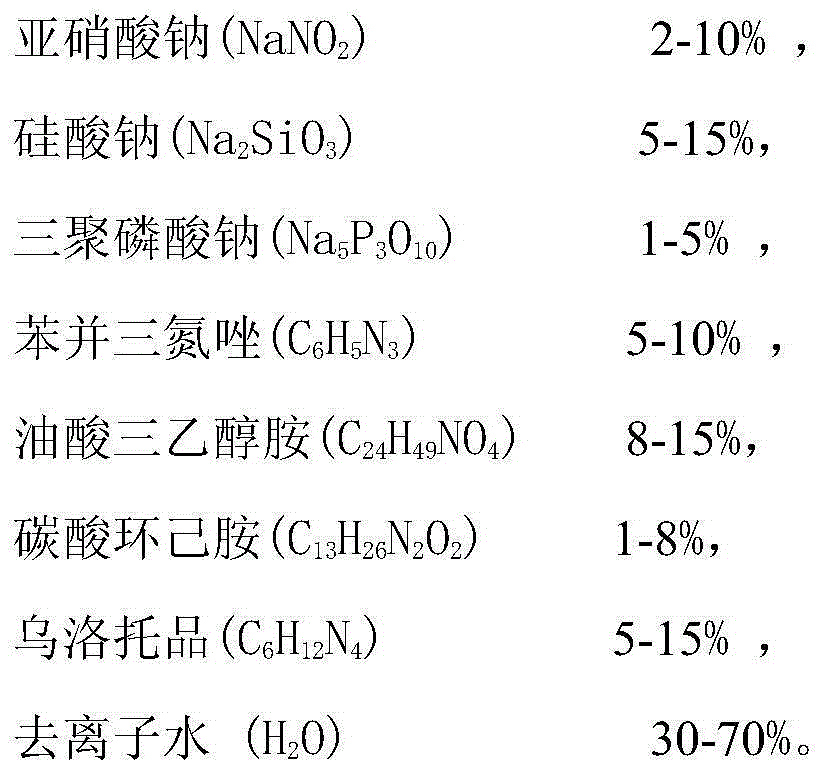

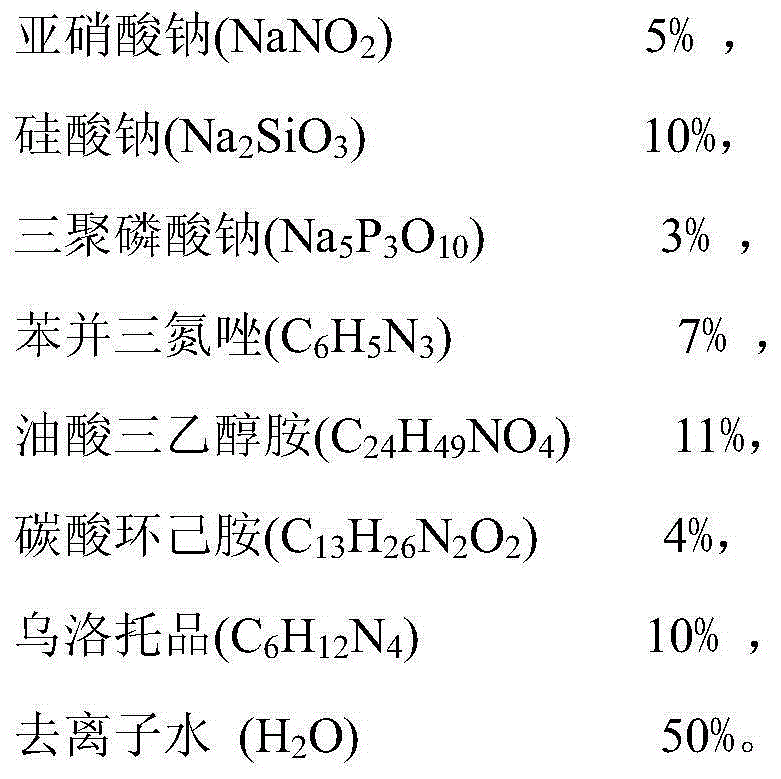

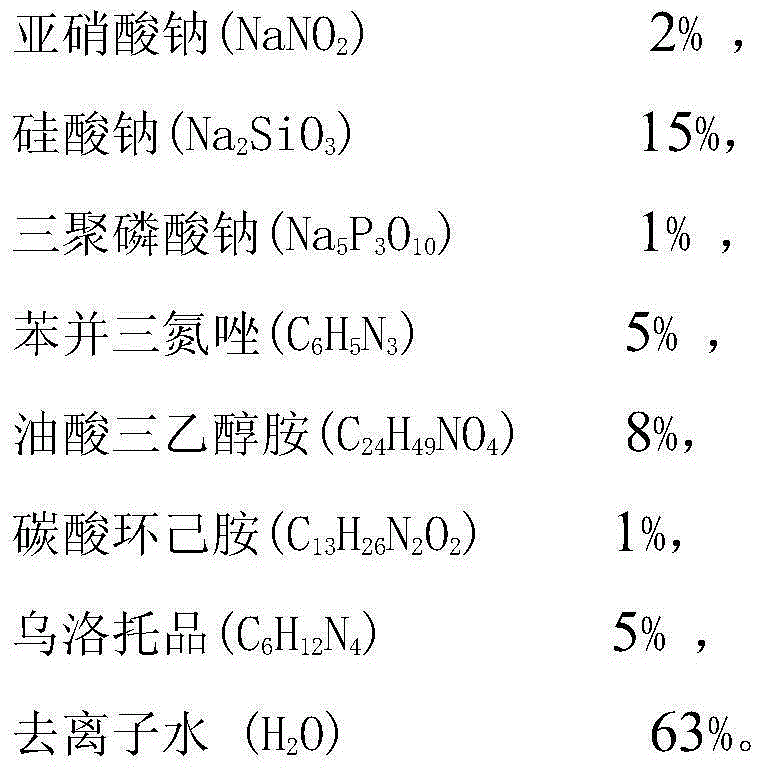

Novel black metal antirust agent and preparation method thereof

The invention relates to a novel black metal antirust agent and a preparation method thereof. The metal antirust agent comprises, by weight, 2%-10% of sodium nitrite, 5%-15% of sodium silicate, 1%-5% of sodium tripolyphosphate, 5%-10% of benzotriazole, 8%-15% of triethanolamine oleate, 1%-8% of cyclohexylamine carbonate, 5%-15% of urotropine and 30%-70% of deionized water. The black metal antirust agent is excellent in performance, high in anti-rust property, low in cost, convenient to operate, capable of not damaging the original color and luster of the surface of a machine part, and high in rust preventing and membrane forming speed, thereby being an effect optimum product for medium-short-term rust prevention.

Owner:江门市三清环境技术工程有限公司

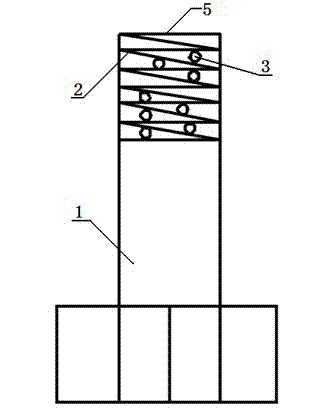

Antirust bolt

Provided is an antirust bolt. The antirust bolt comprises a bolt body. A connecting thread is arranged in one end of the bolt body, and at least one oil outlet is arranged in a groove of the connecting thread and communicated with an oil filling hole which is arranged in the bolt body and disposed along the axial direction. An oil inlet of the oil filling hole is arranged in the bolt top end, and bolt loosen fluid or lubricant is filled into the oil filling hole along the oil inlet under certain pressure and enters into the connecting thread along the oil filling hole through the oil outlet so as to remove rust and loose the connecting thread and a clamp nut. The antirust bolt has the advantages of being simple in structure, convenient to maintain and good in antirust effect.

Owner:XIAN HUIKE GEOLOGICAL TECH SERVICES

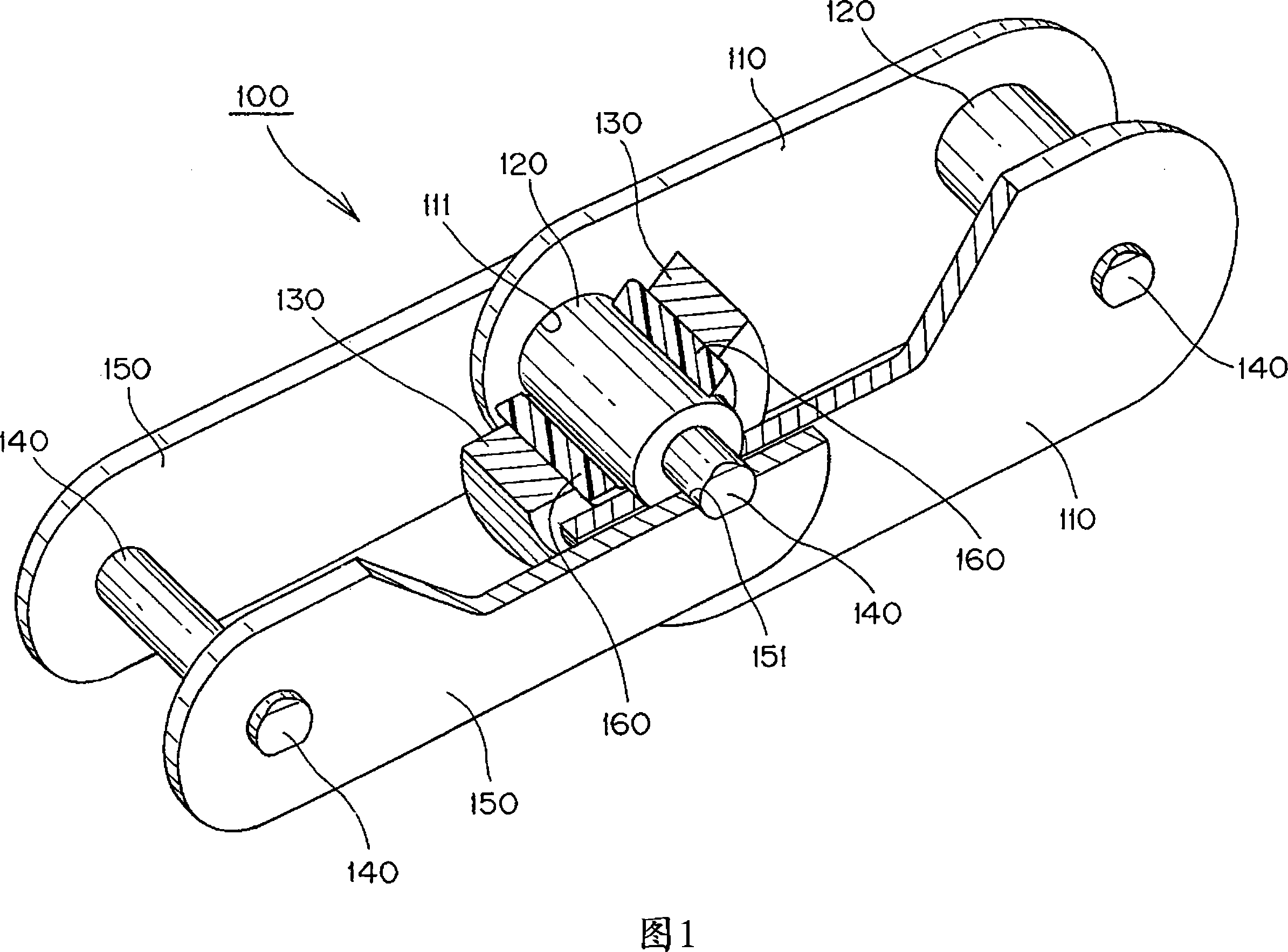

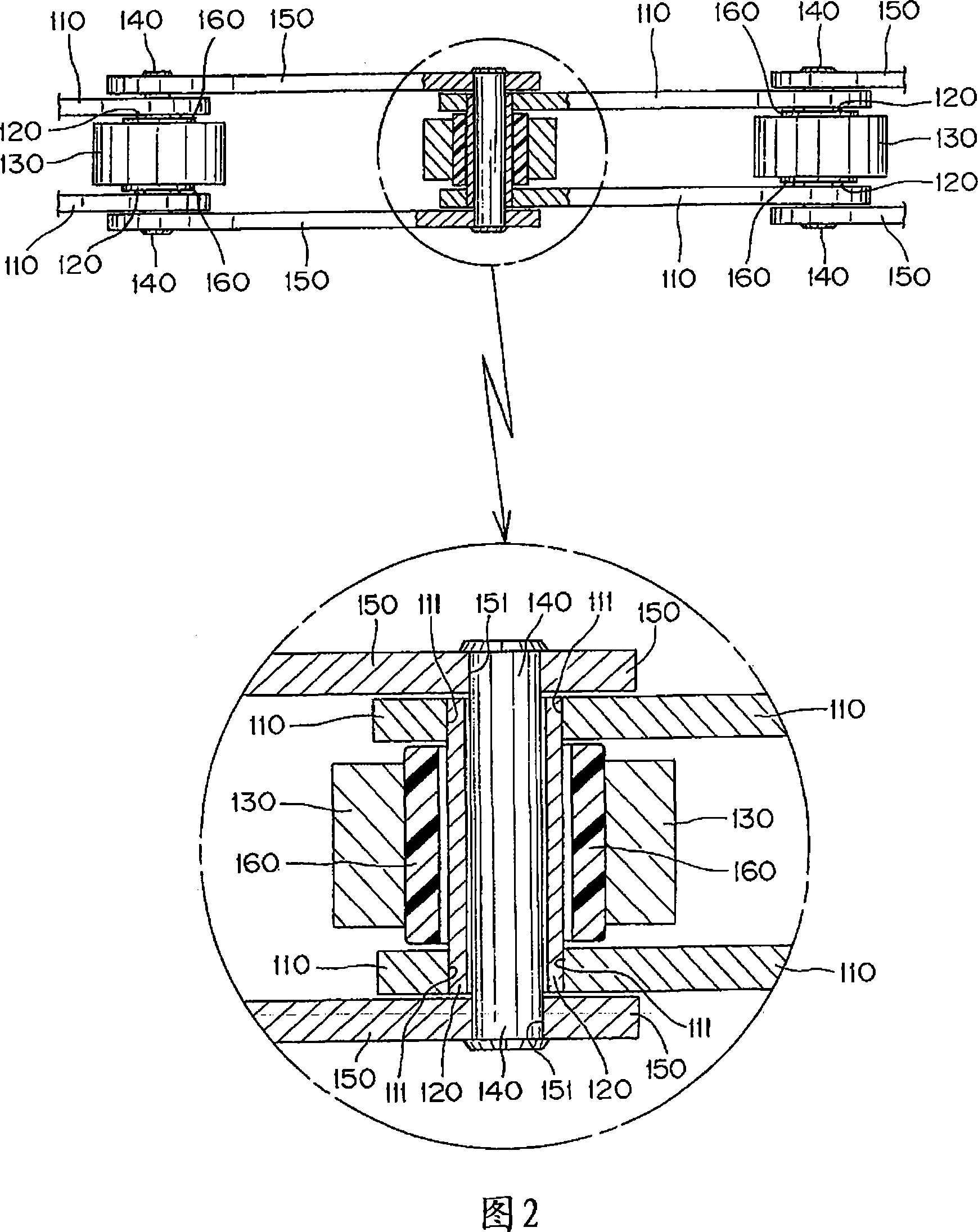

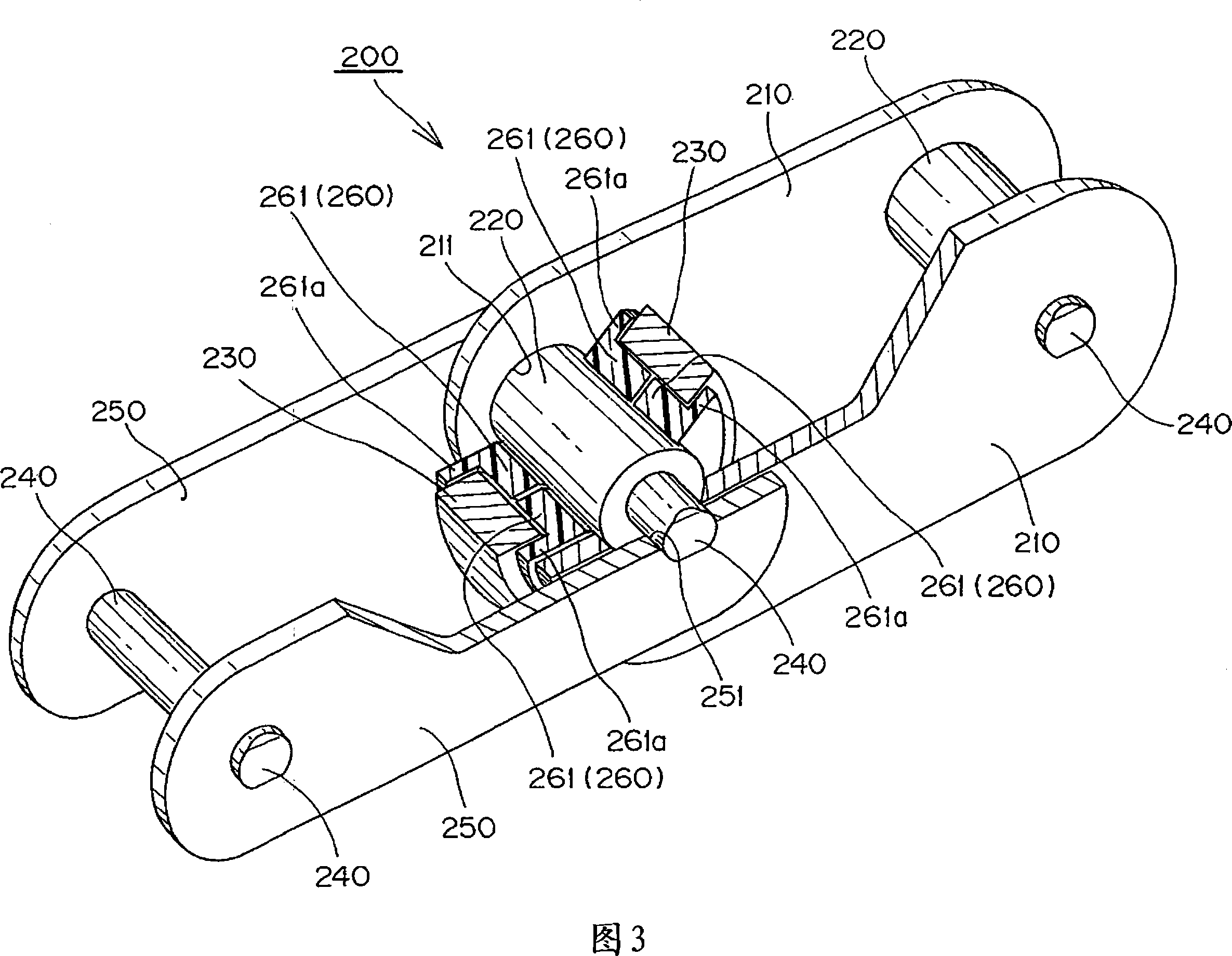

Wear resistant, heat resistant conveyor chain

InactiveCN101100235AQuiet working environmentAvoid sliding contactConveyorsPackagingWear resistantHeat resistance

Owner:TSUBAKIMOTO CHAIN CO

Anti-rust oil for indoor temporary sealing and storage

The invention discloses an anti-rust oil for indoor temporary sealing and storage. The anti-rust oil is composed of, by weight, 40-60 parts of transformer oil, 10-20 parts of petroleum sodium sulfonate, 6-10 parts of lanolin and 20-30 parts of petroleum barium sulfonate. The anti-rust oil solves the problems in the prior art. The anti-rust oil for indoor temporary sealing and storage has good anti-rust effects, reduces loss of companies, has strong practicability, and is suitable for wide application of related industries.

Owner:QIDONG TIANDI MACHINERY MFG

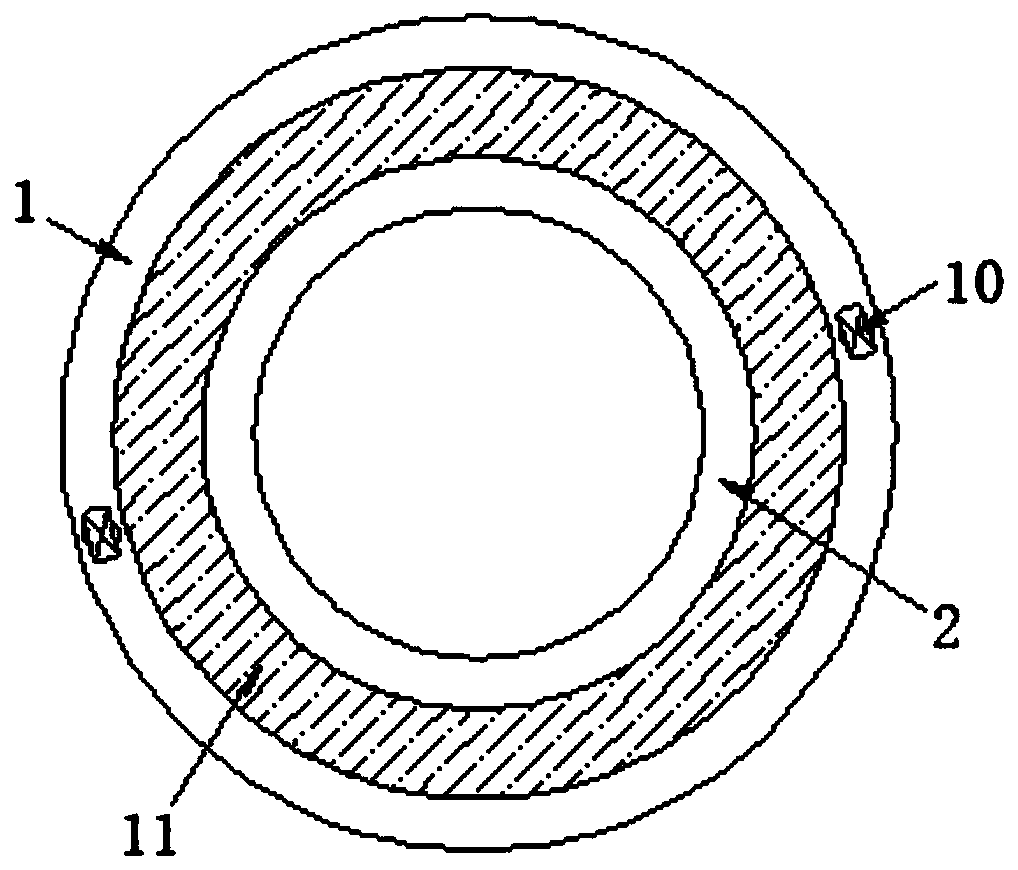

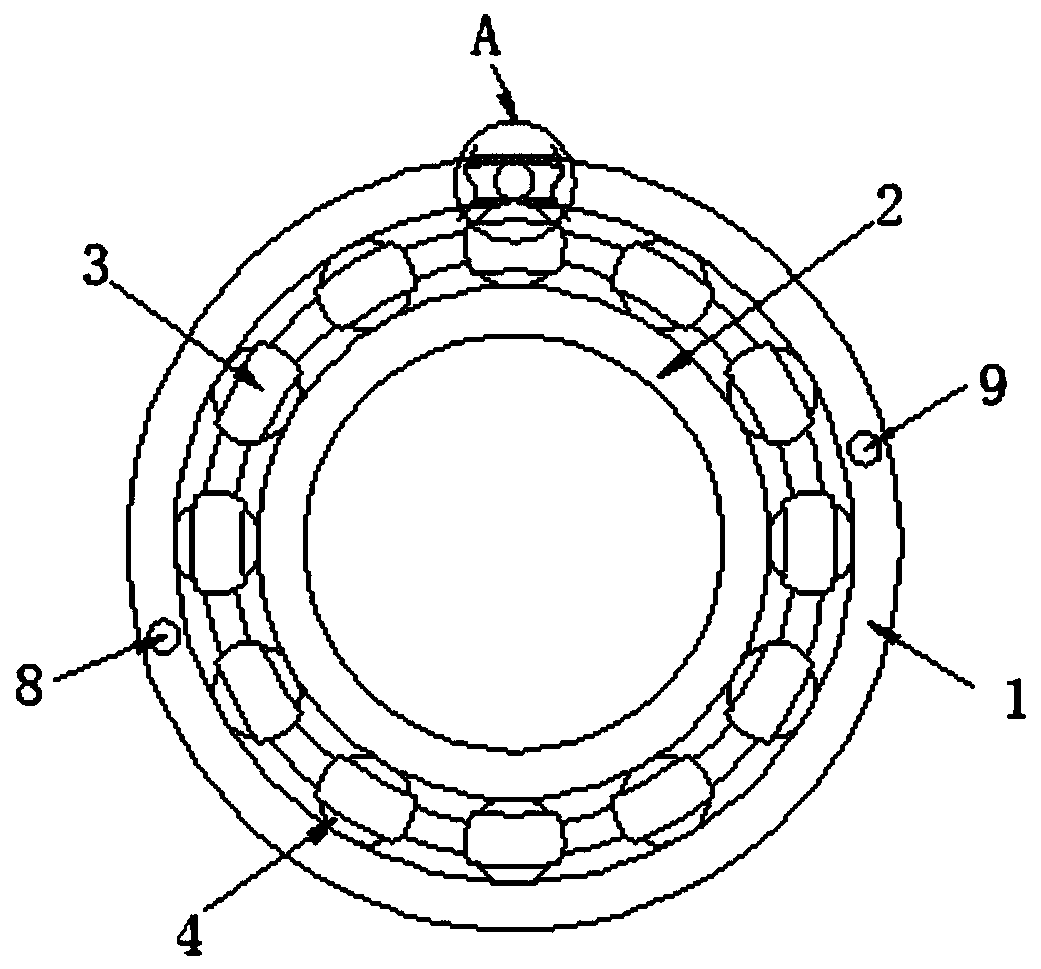

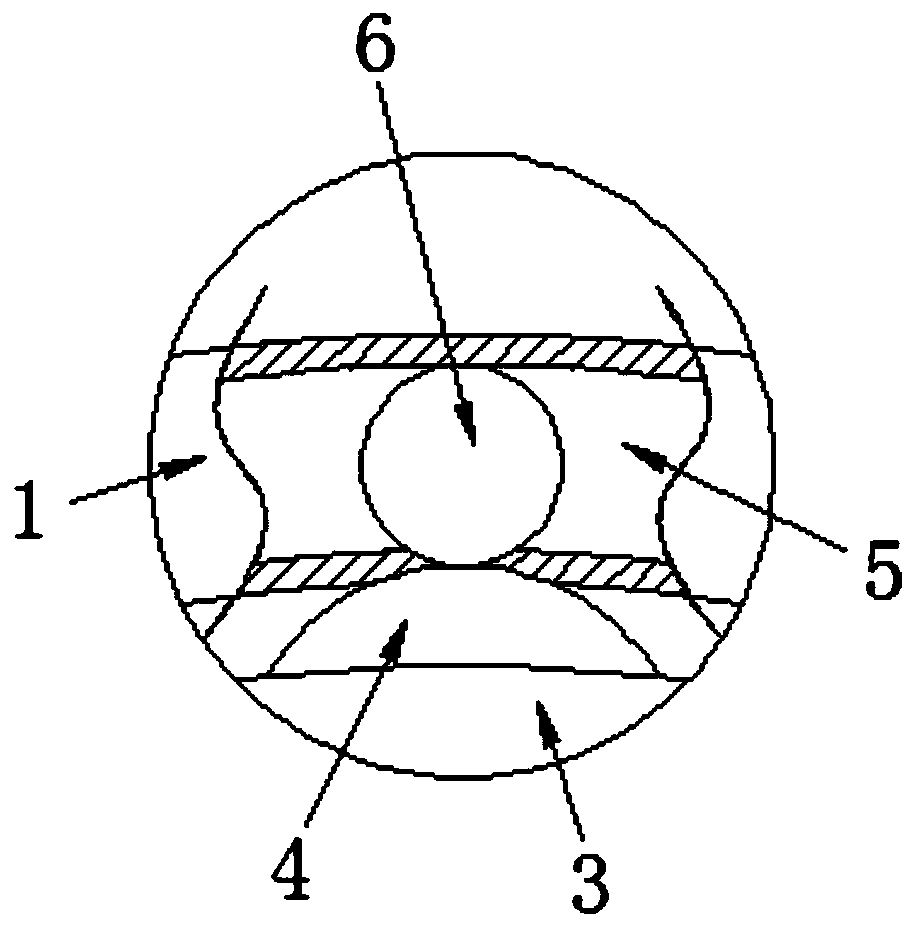

Deep groove ball bearing with good rust prevention effect and machining method thereof

InactiveCN109812495AExtended service lifeSolve easy rustBall bearingsBearing componentsBall bearingSalt spray test

The invention discloses a deep groove ball bearing with good rust prevention effect and a machining method thereof, and relates to the technical field of deep groove ball bearings. The deep groove ball bearing comprises a bearing outer ring, a bearing inner ring and a retainer; the inner surface of the retainer is rotatably connected with balls; one sides of the outer surfaces of the balls are movably connected with the outer surface of the bearing inner ring; the other sides of the outer surfaces of the balls are movably connected with the inner surface of the bearing outer ring; an arc groove is formed in the bearing outer ring; and oil beads are rotatably connected with the interior of the arc groove. According to the deep groove ball bearing with the good rust prevention effect and themachining method thereof, rust prevention oil is introduced into the arc groove by feeding the oil through an oil inlet, so that the problems that the balls are prone to rusting and difficult to rotate and loud in noise can be effectively solved, the amount of the rust prevention oil is reasonably controlled, and the cost is reduced; and the bearing outer ring, the bearing inner ring and the retainer are all treated with a nickel coating technology and are not rusted after 72 hours of salt spray test, so that the service life of the deep groove ball bearing is prolonged.

Owner:宁波市镇海甬明轴承有限公司

Water-based rust inhibitor for steel surfaces and preparation method thereof

InactiveCN104356828AGood anti-rust effectGood environmental effectAnti-corrosive paintsActive agentFormamides

The invention discloses a water-based rust inhibitor for steel surfaces and a preparation method thereof. The preparation method comprises the following steps: proportionally adding polyisobutylene, triethanolamine, N,N-bis(2-cyanoethyl)formamide, dimethylamino-p-phenol, polyacrylate and deionized water into a stainless steel reaction kettle, heating to 130+ / -5 DEG C, starting stirring, adding surfactant, sebacic acid, glycerol, zinc dihydrogen phosphate, thickener and sorbitol, heating to 185-195 DEG C at the rate of 10-15 DEG C / hour, reacting for 2-3 hours, stopping heating, adding ammonium gluconate, potassium persulfate and borax, and dissolving by evenly mixing. The rust inhibitor has excellent antirust effect for steel, and can form an ultrathin antirust film on the surface to prevent the corrosion from the outside. The water-based rust inhibitor for steel surfaces is nontoxic and harmless to the human body, and has favorable environment-friendly effect; and the antirust time can reach 6-8 months. The method has the advantages of simple technique, wide component sources and low price.

Owner:WUXI EPIC TECH

Composite anti-corrosive primer of epoxy phytic acid salt and preparation method thereof

ActiveCN104017462AGood anti-rust effectLow toxicityAnti-corrosive paintsEpoxy resin coatingsChemistryPolyamide

The invention discloses a composite anti-corrosive primer of an epoxy phytic acid salt and a preparation method thereof. The composite anti-corrosive primer of the epoxy phytic acid salt comprises independently packaged anti-corrosive primer component A and anti-corrosive primer component B, wherein the anti-corrosive primer component A and the anti-corrosive primer component B need to be mixed and stirred into a whole well in use; the anti-corrosive primer component A comprises epoxy resin of which the epoxide equivalent is 190-600, hydrocarbon resin, a phytate composite anti-corrosive paint, titanium dioxide, feldspar powder, a laminated filler, a precipitation agent and a first organic solvent; the anti-corrosive primer component B comprises polyamide of which the amine value is 200-300, cashew nut shell oil modified amine and a second organic solvent. The composite anti-corrosive primer of the epoxy phytic acid salt disclosed by the invention has the advantages of being good in anti-corrosive effect, small in toxicity, free of pollution and the like, and the preparation method disclosed by the invention has the advantages of being simple and feasible in process, small in energy consumption and the like.

Owner:江苏云湖新材料科技有限公司

Anticorrosive paint with rust for ships and preparation method thereof

InactiveCN108531004AGood anti-rust effectEnvironmentally friendlyAnti-corrosive paintsEpoxy resin coatingsWeather resistanceEmulsion

The invention discloses anticorrosive paint with rust for ships, which is used for directly coating the surface of a ship corroded steel product. A formula of the anticorrosive paint with the rust forthe ships comprises the following components in percentage by mass: 20 to 25 percent of styrene-acrylic emulsion, 15 to 20 percent of epoxy resin, 5 to 20 percent of modified acrylic resin, 3 to 5 percent of rust stabilizing agent, 10 to 50 percent of filler, 0.1 to 0.3 percent of dispersant, 0.1 to 0.4 percent of de-foaming agent and 1 to 3 percent of coupling agent. The invention also disclosesa preparation method of the anticorrosive paint with the rust for the ships. The anticorrosive paint with the rust for the ships, disclosed by the invention, can be directly brushed and coated on thesurface of the ship corroded steel product and is applicable to rust prevention of ship steel product surfaces with rust-corroded and hard oxidized skin layers or old paint films; in a coating process, the anticorrosive paint can permeate a rust layer and seal the whole rust layer; the anticorrosive paint has strong permeability, high coating attachment force and good antirust effect, can be usedunder bad conditions and has relatively good durability and weather resistance.

Owner:WISON NANTONG HEAVY IND

Mono-component high-adhesion epoxy modified acrylic anticorrosive coating material

InactiveCN108587415AGood anti-rust effectThe surface is smooth and beautifulAnti-corrosive paintsEpoxy resin coatingsBrown iron oxideEthyl acetate

The invention provides a mono-component high-adhesion epoxy modified acrylic anticorrosive coating material. The mono-component high-adhesion epoxy modified acrylic anticorrosive coating material is prepared from the following ingredients in parts by weight: 40-60 parts of water-soluble epoxy acrylate resin, 5-15 parts of iron oxide red, 5-10 parts of ferrotitanium powder, 8-12 parts of titanium white powder, 0.4-0.6 part of dispersant, 0.1-0.3 part of antifoamer, 3-8 parts of ethyl acetate, 2-5 parts of butyl glycol ether, 3-6 parts of xylene, 0.1-0.3 part of leveling agent, 0.6-1.2 parts ofanti-settling agent, 0.6-1.2 parts of dust preventive and 30-50 parts of deionized water.

Owner:FOSHAN KANGDONG LIGHTING TECH CO LTD

Antibacterial and insect-repelling water-based antirust agent for surface treatment of seeder and preparation method for antibacterial and insect-repelling water-based antirust agent

InactiveCN106048583AGood anti-rust effectLasting effectMetallic material coating processesDamp environmentPolyaspartic acid

The invention discloses an antibacterial and insect-repelling water-based antirust agent for surface treatment of a seeder. The antibacterial and insect-repelling water-based antirust agent is prepared from the following raw materials in parts by weight: 34-36 parts of phytic acid, 7-8 parts of polyaspartic acid, 9-11 parts of waste polystyrene foam plastics, 4-6 parts of Chinese prickly ash seed oil, 2-3 parts of diethylenetriamine, 1-2 parts of myristic acid, 1.5-1.8 parts of gamma-mercaptopropyl trimethoxy silane, 0.7-0.9 part of sodium alginate, 6-7 parts of orange peel extract, 2.2-2.4 parts of nano silicon dioxide, 3.2-3.5 parts of polyethylene glycol, 4.2-4.5 parts of polyvinyl alcohol and the balance of deionized water. The phytic acid and polyaspartic acid are adopted as main components; the polyethylene glycol and polyvinyl alcohol are adopted as macromolecular film-forming agents; the modified waste polystyrene foam plastics is added as a waterproof agent; meanwhile, the other agents are added, so that the antirust agent prepared with optimized formation can effectively prevent performance degradation of metal caused by rusting in a damp environment; the antibacterial and insect-repelling water-based antirust agent has excellent antibacterial and insect-repelling performance; and metal products are endowed with excellent antibacterial performance.

Owner:张卫东

Emulsified-type metal antirust agent

InactiveCN106191832ASalt spray anti-rust periodGood anti-rust effectMetallic material coating processesChemistryN-butyl acrylate

The invention provides an emulsified-type metal antirust agent. The emulsified-type metal antirust agent comprises, by weight, 1-5 parts of monobasic acid, 4-10 parts of dibasic acid, 2-6 parts of tribasic acid, 4-10 parts of monoethanolamine, 2-6 parts of diethanol amine, 40-50 parts of triethanolamine, 10-20 parts of polyacrylate, 20-30 parts of butyl acrylate, 10-20 parts of tricresyl phosphate, 30-50 parts of olefin succinic acid, 20-30 parts of dodecyl phenyl succinic acid, 30-40 parts of Octadecylamine N-oleoyl Sarcosinate and 600-700 parts of water. The emulsified-type metal antirust agent is resistant to salt mist, long in rust-proof life and good in rust-proof effect. The rust-proof life can reach 1-4 months. Moreover, the source of the raw materials is wide, production cost can be effectively reduced, and the emulsified-type metal antirust agent is particularly suitable for large-scale industrial production.

Owner:施美

Compound iron oxide red rust resisting pigment

InactiveCN101760050AStrong weather resistanceGood anti-rust effectPigmenting treatmentWeather resistanceBrown iron oxide

The invention discloses a compound iron oxide red rust resisting pigment, which contains the following components in percentage by weight: 20-80 percent of ferric oxide and 20-80 percent of iron phosphate. The invention has the following advantages that: firstly, the invention integrates the chemical rust resisting characteristics of iron oxide red physical shielding rust resistance and phosphates, has strong weather resistance and good rust resistance and is particularly suitable for metal rust resistance in relatively-severe environment; secondly, the invention can utilize industrial waste residue so as to save resources and reduce the production cost; and in addition, the no pollution generates in the production process and products have no toxicity and are green and environment-friendly.

Owner:湘潭市双马世纪新材料有限公司

Antirust detergent for metal equipment

The invention relates to an antirust detergent for metal equipment, which is prepared from the following raw materials in parts by weight: 4-6 parts of coco fatty acid diethanol amide, 3.5-8 parts of fatty alcohol polyethenoxy ether, 1-4 parts of sodium gluconate, 1.5-4 parts of bromoalkyldimethyl benzylamine, 2.2-5 parts of undecanedioic acid, 1.6-3.5 parts of surfactant, 5.5-10 parts of sodium polyepoxysuccinate, 1.5-6 parts of sodium ethylene diamine tetracetate, 2.5-4.8 parts of methacrylic acid and 2.1-3.8 parts of ammonium persulfate. The detergent has the advantages of favorable deoiling and stain cleaning effects, favorable antirust effect, low equipment corrosivity and low use cost.

Owner:QINGDAO QIYUAN ZHENDONG ELECTRIC

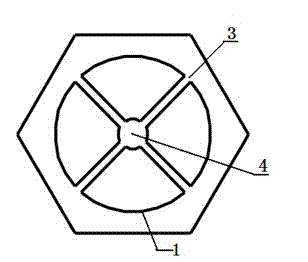

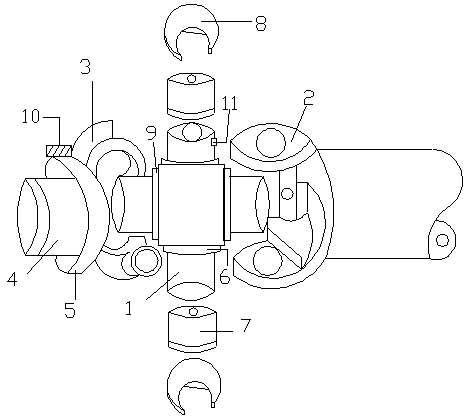

Cross axle-type rigid universal joint

PendingCN107842561ASimple structureGood anti-rust effectYielding couplingAnti stressAgricultural engineering

The invention relates to a cross axle-type rigid universal joint. The cross axle-type rigid universal joint comprises a cross axle. The cross axle is equipped with an oil hole. The right side of the cross axle is equipped with a driving shaft fork. The driving shaft fork is connected with a sleeve fork matching the driving shaft fork. A silica gel separation pad is arranged between the driving shaft fork and the sleeve fork. The left side of the sleeve fork is provided with a sleeve equipped with a steel belt hoop. The steel belt hoop is provided with a locking sleeve. A bearing of the cross axle is connected with a bearing outer ring through a reinforcing rib. The outside of the bearing outer ring is equipped with a clamp ring. The cross axle-type rigid universal joint is simple in structure and good in rust-proof effect. Through application of the separation pad, the structure is more compact. Therefore, a skidding phenomenon is prevented. The shock resistance effect of the structureis enhanced. The reinforcing rib helps effectively increase compressive resistance such that the structure is firmer and is more stable. The locking sleeve helps effectively improve locking effect ofthe steel belt hoop such that the structure becomes firmer. The oil hole is filled with lubricating oil conveniently. Friction and noise are reduced. The service lifetime is prolonged.

Owner:XINGHUA SANCHENG PRECISION FORGING

Water-based antirust agent for surface treatment of flame-retardant seeder and preparing method of water-based antirust agent

InactiveCN106191833AGood anti-rust effectLasting effectMetallic material coating processesRosinChemistry

The invention discloses a water-based antirust agent for surface treatment of a flame-retardant seeder. The water-based antirust agent is prepared from, by weight, 39-40 parts of phytic acid, 7-9 parts of polyaspartic acid, 10-12 parts of waste polystyrene foam plastic, 1-2 parts of rosin amine, 2-3 parts of petroleum barium sulfonate, 3-4 parts of aminotri-methylene phosphonic acid, 1.8-2.1 parts of inositol hexaphosphoric acid, 1.5-1.8 parts of 3-aminopropyltriethoxysilane, 5-7 parts of a honeysuckle extract, 2-3 parts of sericin powder, 2.4-2.7 parts of nano-magnesium hydroxide, 3.4-3.7 parts of polyethylene glycol, 4.4-4.7 parts of polyvinyl alcohol and the balance deionized water. According to the water-based antirust agent, the phytic acid and the polyaspartic acid serve as main ingredients, polyethylene glycol and polyvinyl alcohol serve as macromolecule film-forming agents, and the modified waste polystyrene foam plastic is added to serve as a waterproof additive. Meanwhile, the other additives are added, and the antirust agent prepared according to the optimized formula is good in antirust effect, strong in flame-retardant effect, low in production cost, low in viscosity and easy to coat.

Owner:张卫东

Anti-corrosion coating

InactiveCN104327734AGood anti-rust effectGood qualityRosin coatingsAnti-corrosive paintsOxideAntistatic agent

The invention discloses an anti-corrosion coating. The anti-corrosion coating is prepared from ester gum, a pigment and filler, an antirust agent, a lubricating agent, a dispersing agent, an antistatic agent and an anti-settling agent, wherein the pigment and filler is wollastonite; the antirust agent is zinc oxide; the lubricating agent is oleamide; the dispersing agent is potassium citrate; the antistatic agent is ethyoxyl lauryl amine; and the anti-settling agent is organobentonite. The anti-corrosion coating disclosed by the invention is prepared from the ester gum, the pigment and filler, the antirust agent, the lubricating agent, the dispersing agent, the antistatic agent and the anti-settling agent, so that the prepared product is good in antirust effect, antistatic, high in quality, long in storage time, long in protective time and good in service effect.

Owner:江苏博腾新材料股份有限公司

Antirust agent for steel

The invention discloses an antirust agent for steel, and belongs to the field of antirust technologies for metal. The antirust agent comprises, by weight, 10-15 parts of sodium gluconate, 1-3 parts of ammonium molybdate, 1-5 parts of boric acid, 5-10 parts of sodium benzoate, 5-8 parts of triethanolamine, 1-2 parts of sodium carbonate, 0.5-1 part of fatty acid, 15-20 parts of acrylate emulsion and 30-45 parts of water. Compared with antirust agents sold in current markets, the antirust agent has the advantages of high pertinence and obvious antirust effects for steel products.

Owner:赵冯

Turning cutting fluid

InactiveCN104830476AGood anti-rust effectExtended service lifeLubricant compositionCoconut oilPhosphate

A turning cutting fluid is composed of the following raw materials in parts by weight: 6 to 14 parts of poly(alpha-olefin), 1.5 to 3.2 parts of petroleum calcium sulfonate with a medium alkali value, 2.5 to 3.5 parts of emulsifier, 5 to 8 parts of oleic acid gylcol ester, 2.4 to 3.4 parts of sulfur-molybdenum phosphate, 3 to 6.2 parts of water-soluble resin, 23 to 46 parts of glycol, 18 to 24 parts of dibutyl sodium naphthalene sulfonate, 25 to 30 parts of sodium sulfide, 3.6 to 4.8 parts of sulfurized cotton seed oil, 4.2 to 5.6 parts of dispersant, 2.2 to 4.4 parts of sulfurized castor oil, 8 to 12 parts of coconut diethanol amide, and 4 to 7 parts of synthesized antirust agent. The turning cutting fluid has the advantages of excellent antirust effect, no degradation, no odor, and long service life.

Owner:QINGDAO DEXITUOCHUANG HIGH TECH CO LTD

Environmentally friendly grease and preparation method thereof

InactiveCN108285818AAffect the service lifeHigh kinematic viscosityAdditivesWorking environmentViscosity

The invention provides environmentally friendly grease. The grease is characterized in that the grease is prepared from, by weight, 20-50% of environmentally friendly grease precursor and 50-80% of poly castor oil acid ester. According to the grease, beeswax has a pleasant and fragrant smell and can be used for improving a working environment, the beeswax reacts with borate to generate organic borate, the organic borate has better friction reducing and rust resisting effects, the poly castor oil acid ester has higher kinematic viscosity, the poly castor oil acid ester does not easily escape from a grease structural system to affect the service life of the grease, and the components of the grease are obtained from natural raw materials, so that the grease is good in environmental protectionperformance.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

Lubricating oil for freezer compressor

The invention discloses lubricating oil for a freezer compressor. The lubricating oil is prepared from 15-25 parts of anti-wear agent, 6-10 parts of anti-oxidation and anti-corrosion agent, 12-20 parts of antifoaming agent, 8-10 parts of antirust agent and 5-8 parts of refined cleaning agent, and preferably is prepared from 20 parts of anti-wear agent, 8 parts of anti-oxidation and anti-corrosion agent, 15 parts of antifoaming agent, 9 parts of antirust agent and 6 parts of refined cleaning agent. According to the lubricating oil for the freezer compressor, raw materials are low in cost and easy to purchase on the market, the anti-wear, anti-oxidation and antirust effects are good, and the lubricating effect is remarkable.

Owner:常熟市制冷压缩机铸件厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com