Composite anti-corrosive primer of epoxy phytic acid salt and preparation method thereof

A technology of epoxy phytate and anti-rust primer, which is applied in the direction of epoxy resin coating, anti-corrosion coating, coating, etc., can solve the problems of poor anti-rust effect, loss of competitiveness, high energy consumption, etc., and achieve anti-rust Good effect, simple process, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

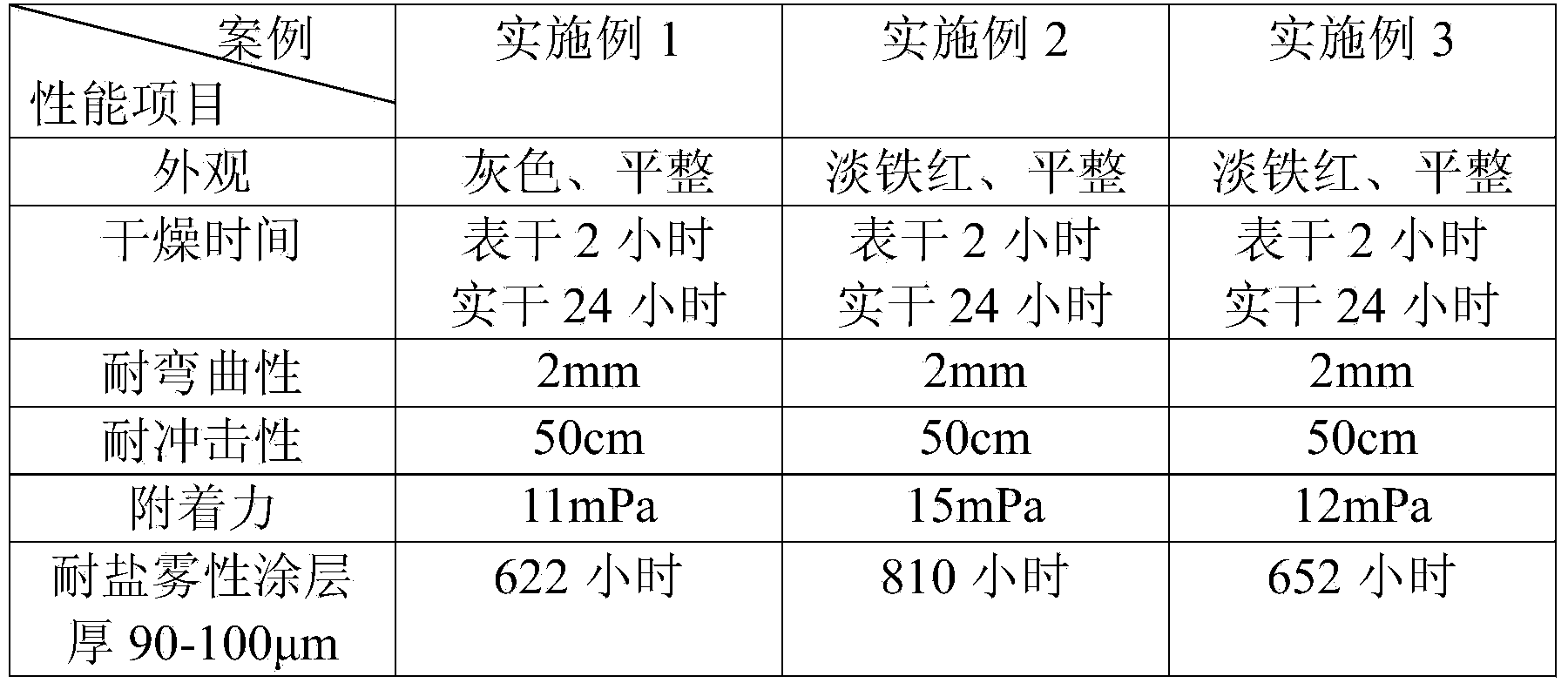

Examples

Embodiment 1

[0026] a. Take 20 kg of epoxy resin with an epoxy equivalent of 190-600, 5 kg of petroleum resin, 15 kg of phytate composite anti-rust pigment, 3 kg of titanium dioxide, 20 kg of feldspar powder, 5 kg of mica powder, and anti-nano II 2.2 kg of silicon oxide, 15.3125 kg of xylene, 6.125 kg of butanol, 3.0625 kg of cyclohexanone, 24.5 kg of xylene, butanol and cyclohexanone;

[0027] b. Add epoxy resin and petroleum resin with an epoxy equivalent of 190-600 to xylene, butanol, and cyclohexanone to dissolve evenly, then add a wetting and dispersing agent, and use nano-silica at 1000-2000 rpm Stir evenly at high speed, then add phytate composite anti-rust pigment and feldspar powder in sequence, stir evenly at a high speed of 1000-2000 rpm, then grind in a grinder until the fineness is ≤50μm, and finally add mica powder and stir well , to obtain anti-rust primer A component, standby;

[0028] c. Take 4 kg of polyamide with an amine value of 200-300, 2 kg of cashew nut shell oil m...

Embodiment 2

[0033] a. Take 25 kg of epoxy resin with an epoxy equivalent of 190-600, 7 kg of xylene resin, 12 kg of phytate composite antirust material, 4 kg of titanium dioxide, 10 kg of feldspar powder, 15 kg of iron oxide red, aluminum 7 kilograms of powder, 1 kilogram of organic bentonite, 11.58 kilograms of xylene, 5.26 kilograms of butanol, 3.16 kilograms of cyclohexanone, 20 kilograms of xylene, butanol, and cyclohexanone;

[0034] b. Add epoxy resin and xylene resin with an epoxy equivalent of 190-600 to xylene, butanol, and cyclohexanone to dissolve evenly, then add wetting and dispersing agent and bentonite, and use 1000-2000 rpm Stir at a high speed, then add iron oxide red, phytate composite antirust pigment, and feldspar powder in sequence, stir evenly at a high speed of 1000-2000 rpm, then enter the grinder, grind to a fineness of ≤50μm, and finally add aluminum silver The slurry is fully stirred evenly to obtain the anti-rust primer component A, which is set aside;

[0035...

Embodiment 3

[0040] a. Get 30 kilograms of epoxy resins with an epoxy equivalent of 190-600, 10 kilograms of coumarone resins, 10 kilograms of phytate composite antirust materials, 5 kilograms of titanium dioxide, 15 kilograms of feldspar powder, and 10 kilograms of iron oxide red, 10 kilograms of potassium aluminum silicate, 3 kilograms of polyamide wax, 16.36 kilograms of xylene, 8.18 kilograms of butanol, 5.46 kilograms of cyclohexanone, 30 kilograms of xylene, butanol, and cyclohexanone;

[0041] b. Add epoxy resin and coumarone resin with an epoxy equivalent of 190-600 to xylene, butanol and cyclohexanone to dissolve evenly, then add wetting and dispersing agent, polyamide wax at 1000-2000 rpm Stir evenly at a speed of 1 minute, then add iron oxide red, phytate composite antirust pigment, and feldspar powder at a speed of 1000-2000 rpm, stir evenly at a high speed, then enter the grinder, grind to a fineness of ≤50 μm, and finally Add potassium aluminum silicate and stir well to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com