Antirust agent for steel

A technology of anti-rust agent and iron and steel, which is applied in the field of anti-rust agent for iron and steel. It can solve the problems that the anti-rust agent is not very targeted and the anti-rust effect of steel products is not very ideal, and achieve the effect of significant anti-rust effect and strong pertinence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

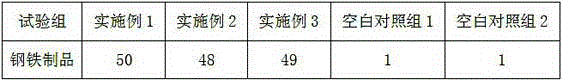

Examples

Embodiment 1

[0015] The iron and steel rust inhibitor is made of the following components: 1.0kg sodium gluconate, 0.3kg ammonium molybdate, 0.5kg boric acid, 0.5kg sodium benzoate, 0.8kg triethanolamine, 0.1kg sodium carbonate, 0.1kg fatty acid, acrylate emulsion 1.5kg and 4.5kg of water.

[0016] The preparation method is as follows: adding sodium gluconate, ammonium molybdate, boric acid, sodium benzoate, triethanolamine, sodium carbonate and fatty acid into water, stirring well, and then adding acrylate emulsion, stirring evenly.

Embodiment 2

[0018] This iron and steel rust inhibitor is made of the following components: 1.5kg sodium gluconate, 0.1kg ammonium molybdate, 0.1kg boric acid, 1.0kg sodium benzoate, 0.5kg triethanolamine, 0.2kg sodium carbonate, 0.05kg fatty acid, acrylate emulsion 2.0kg and water 3.0kg.

[0019] The preparation method is as follows: adding sodium gluconate, ammonium molybdate, boric acid, sodium benzoate, triethanolamine, sodium carbonate and fatty acid into water, stirring well, and then adding acrylate emulsion, stirring evenly.

Embodiment 3

[0021] This iron and steel rust inhibitor is made of the following components: 1.2kg sodium gluconate, 0.2kg ammonium molybdate, 0.4kg boric acid, 0.8kg sodium benzoate, 0.6kg triethanolamine, 0.15kg sodium carbonate, 0.08kg fatty acid, acrylate emulsion 1.6kg and 4.0kg of water.

[0022] The preparation method is as follows: adding sodium gluconate, ammonium molybdate, boric acid, sodium benzoate, triethanolamine, sodium carbonate and fatty acid into water, stirring well, and then adding acrylate emulsion, stirring evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com