Water-based industrial detergent capable of self-defoaminng at normal temperature and preparation method thereof

A cleaning agent and defoaming technology, which is applied in the direction of detergent compounding agent, detergent composition, chemical equipment and methods, etc., can solve the problems of polluting the environment, application restrictions, reducing defoaming effect, etc., and achieves simple preparation method and easy use The method is simple and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The raw materials of the embodiments of the present invention are all commercially available raw materials.

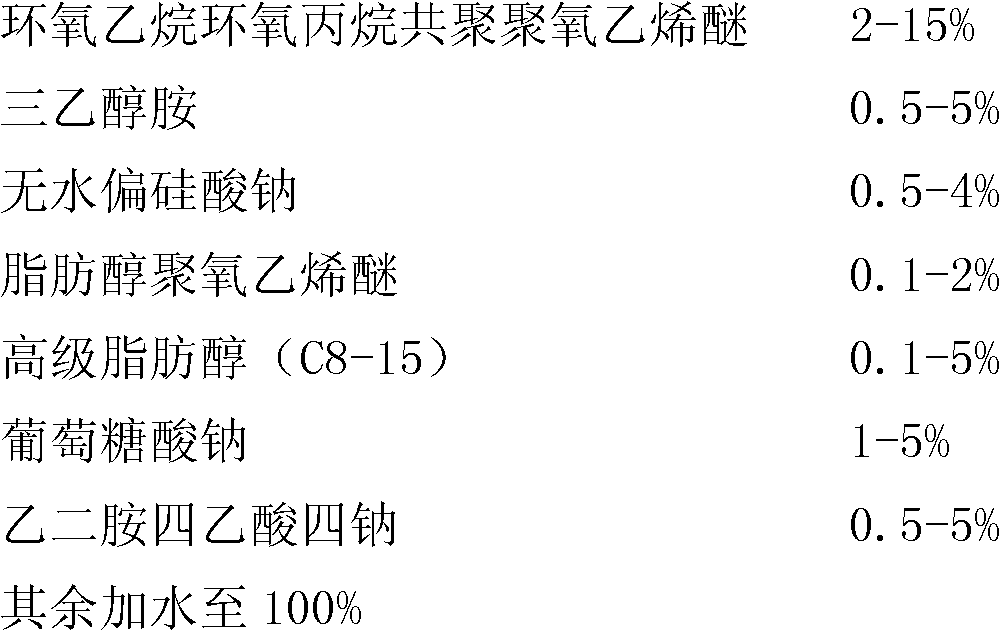

[0020] The composition of a normal temperature self-defoaming water-based industrial cleaning agent is (taking 1000g water-based rust inhibitor as an example):

[0021]

[0022] The steps of a kind of preparation method of self-defoaming water-based industrial cleaning agent at normal temperature are as follows:

[0023] (1) Add the reaction amount of water into the reaction kettle, add the reaction amount of anhydrous sodium metasilicate, sodium gluconate, and tetrasodium edetate at 25-40°C and stir, and keep the reaction for 20 minutes.

[0024] (2) Add the reaction amount of ethylene oxide propylene oxide copolymer polyoxyethylene ether and triethanolamine to the reaction kettle and stir until completely dissolved, then add fatty alcohol polyoxyethylene ether and higher fatty alcohol (C8-15), and continue Stir for 30 minutes until the solution is clear an...

Embodiment 2

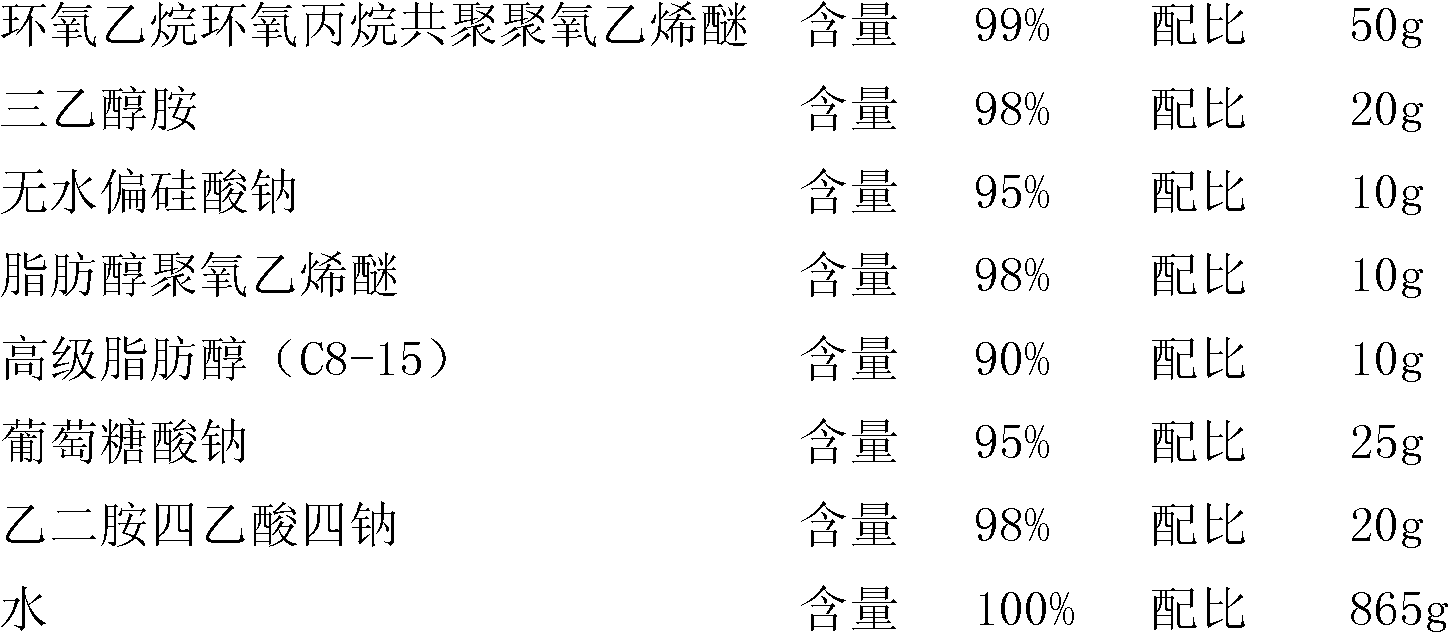

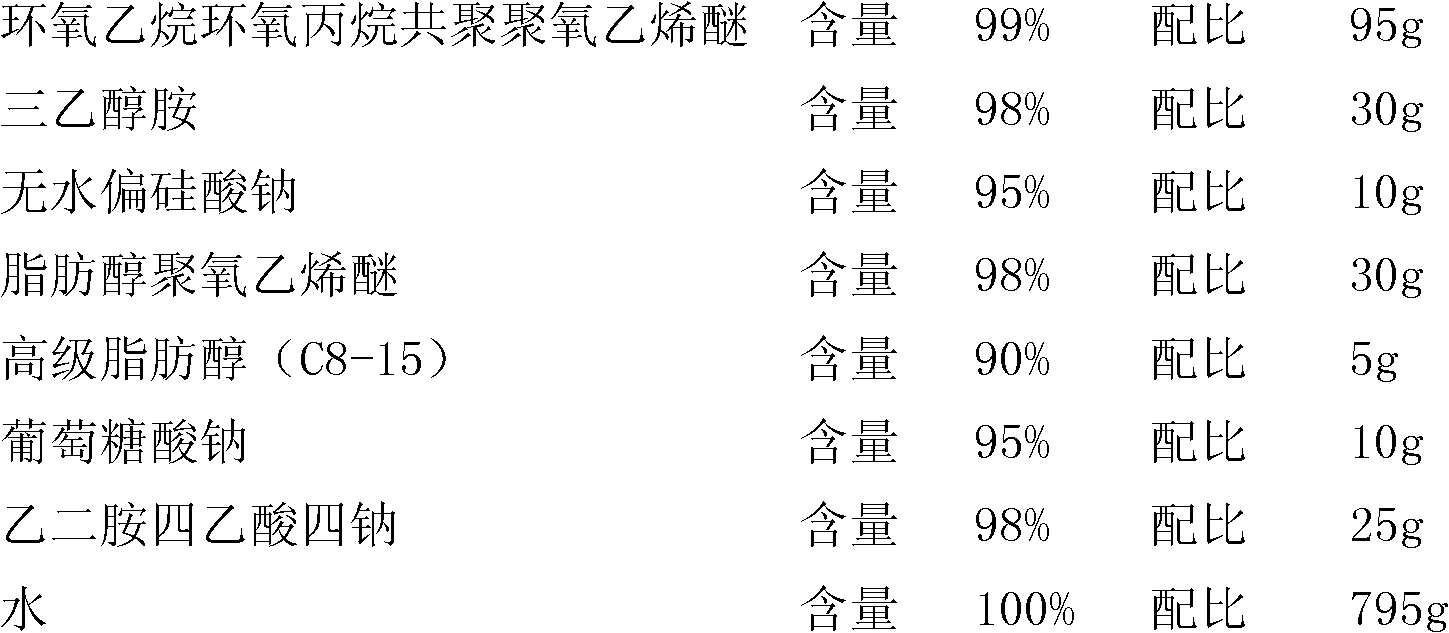

[0027] The composition of a normal temperature self-defoaming water-based industrial cleaning agent is (taking 1000g water-based rust inhibitor as an example):

[0028]

[0029] The steps of its preparation method are the same as in Example 1.

[0030] Mechanism of action of the present invention:

[0031] The present invention mainly adopts the joint action of the lipophilic group propylene oxide in the ethylene oxide propylene oxide copolymer polyoxyethylene ether, the lipophilic group in the system and industrial oil stains to reduce the foam strength of the foam generated in the cleaning process, The principle of self-defoaming is achieved at room temperature. Through the synergistic effect of various components, the cleaning and anti-rust effects are both optimal. At the same time, the synergistic effect of various surfactants has significantly improved the defect that inorganic salts are easy to form white spots on the surface of the workpiece. .

[0032] Applicatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com