Patents

Literature

34results about How to "No oil stains" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel composite aluminium alloy plates and prepn. method

This invention discloses a method for manufacturing a new type of aluminum alloy composite sheets, and solves the problems of low mechanical properties and low yield existing with present aluminum alloy composite sheets. The sheets are composed of three parallel sheets. The top and the bottom sheets are composed of Si 9.4-10 wt.%, Fe 0.4 wt.%, Cu 0.2 wt.%, Mn 0.1 wt.%, Mg 1.2-1.8 wt.%, Zn 0.2 wt.% and Al as balance. The middle sheet is composed of Si 0.4 wt.%, Fe 0.4-0.6 wt.%, Cu 0.07-0.15 wt.%, Mn 1.1-1.3 wt.%, Ti 0.02-0.03 wt.% and Al as balance. The thickness ratio of the three sheets from top to bottom is 1:2.5~13:1. The sheets are manufactured by: smelting the three alloy ingots, casting into sheets, heating and rolling the top and the bottom sheets, chemically washing and welding, hot-rolling, cold-rolling and annealing the intermediate products to obtain the final products. The aluminum alloy composite sheets have good mechanical properties, and the yield of the final products is increased by more than 15%.

Owner:NORTHEAST LIGHT ALLOY CO LTD

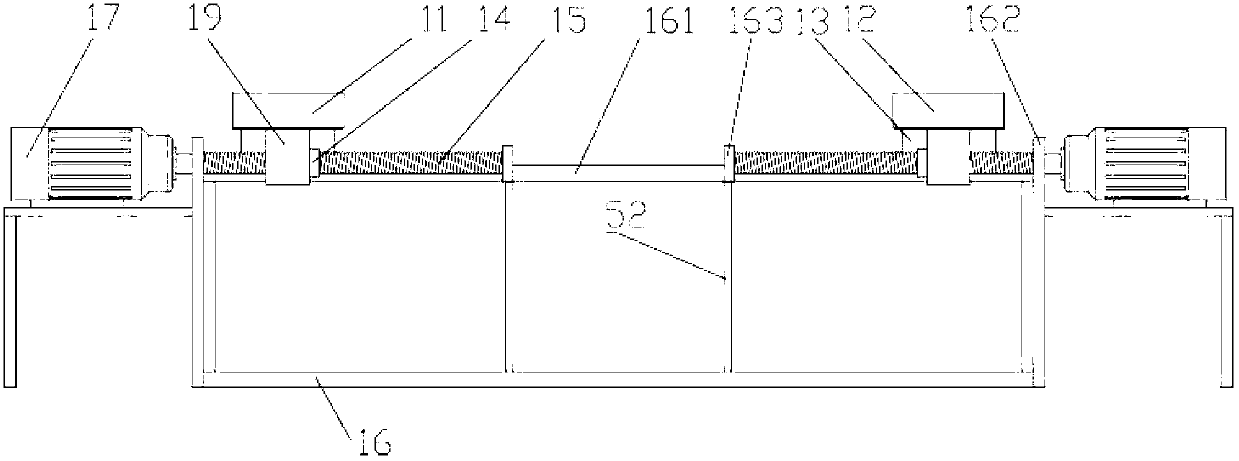

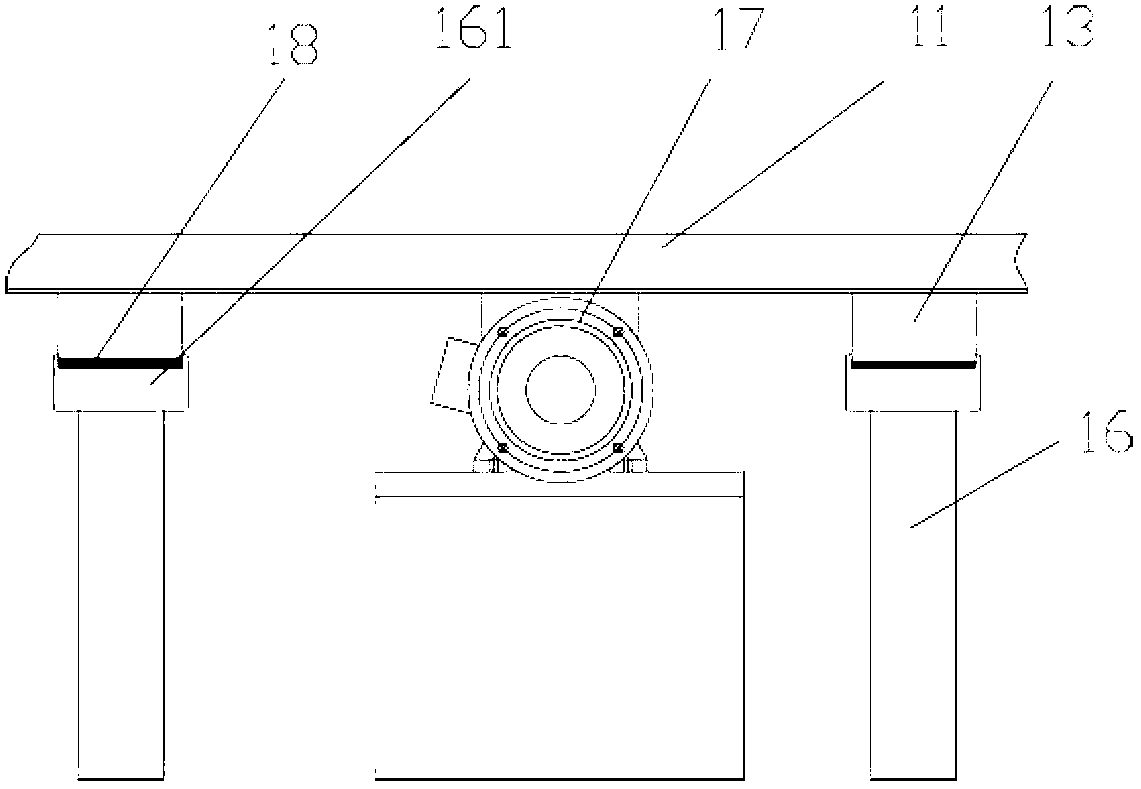

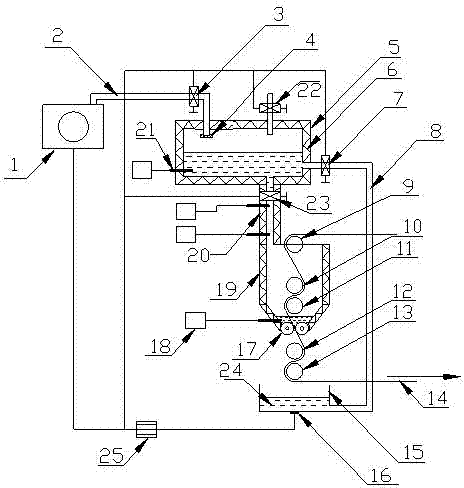

Novel stentering setting machine

InactiveCN102733133AEasy to adjustEnsure the quality of stenter settingStretchingGraphiteMechanical engineering

The invention provides a novel stentering setting machine comprising a guide device, a drawing mechanism, an operation platform and a cropping device, wherein the cropping device is arranged behind the drawing mechanism and the operation platform is placed between the guide device and the drawing mechanism; the drawing mechanism comprises a feeding rail, an oven and a heat exchange device; the feeding rail passes through the oven and the heat exchange device is arranged above the oven; a waste gas outlet pipe of the oven is communicated with a waste gas inlet pipe of the heat exchange device; a hot air outlet pipe of the heat exchange device is communicated with a hot air inlet pipe of the oven; a guide rail adjusting device is additionally arranged between two guide rails, so that the distance between a left guide rail and a right guide rail can be accurately adjusted and each guide rail is respectively adjustable; the novel stentering setting machine is suitable for machining a plurality of types of cloth; meanwhile, cloth tongs slide on graphite and do not generate oil stains; the two connected cloth tongs can be finely adjusted to ensure the stentering setting quality; and an adjustable range of a wrap angle of spreading rolls and a textile is large and the two spreading rolls can be adjusted, so that the spreading effect is good.

Owner:ZHEJIANG RILI INDAL

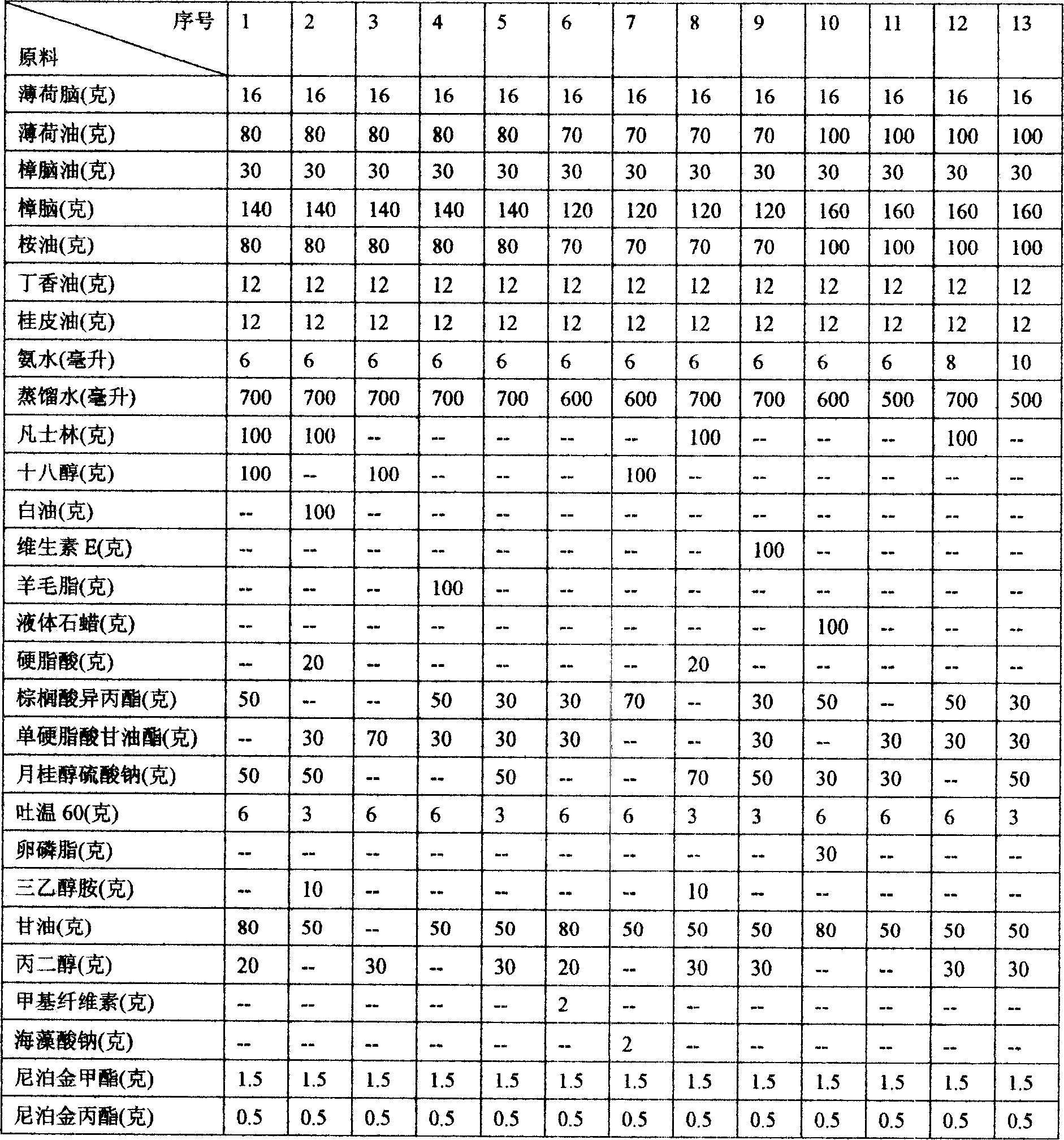

Cool cream

InactiveCN1579431AGood lookingReduce pollutionAntipyreticDigestive systemMedicineAdditive ingredient

The invention relates to a cool cream which can be used as medicine healthy keeping product, its applied symptom and functions are same to the cool oil. The effective ingredients of cool oil is added with emulsifying agent, distilled water and other accessories and forms the water-packaging-oil type cream, when it maintains the excellent functions of the cool oil, it overcomes the oil sense of cool oil and the contamination to cloth, the effective ingredients can be decomposed quickly, thus the effect can be displayed quickly.

Owner:崔名全

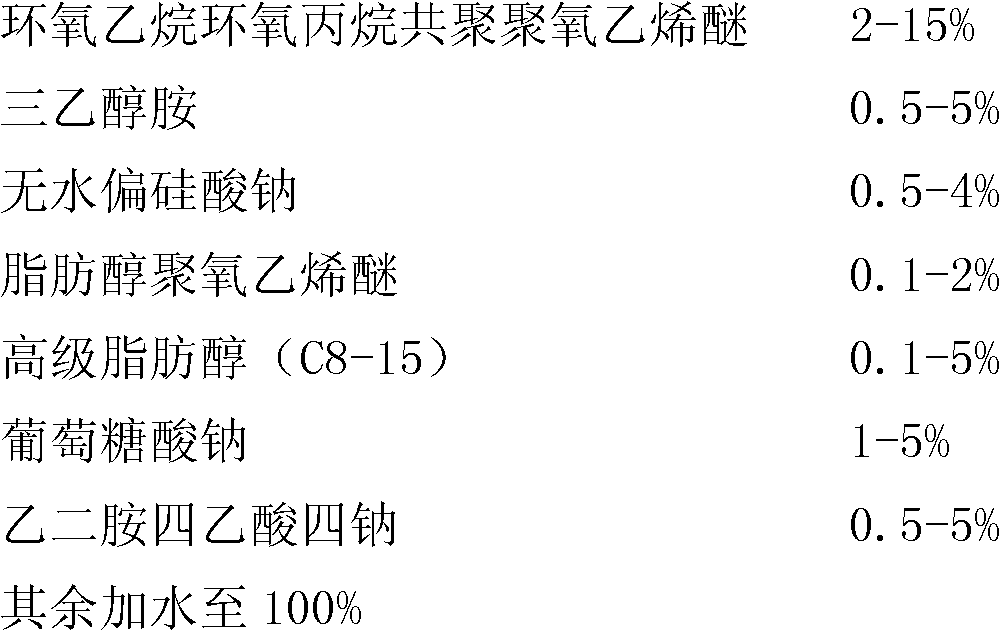

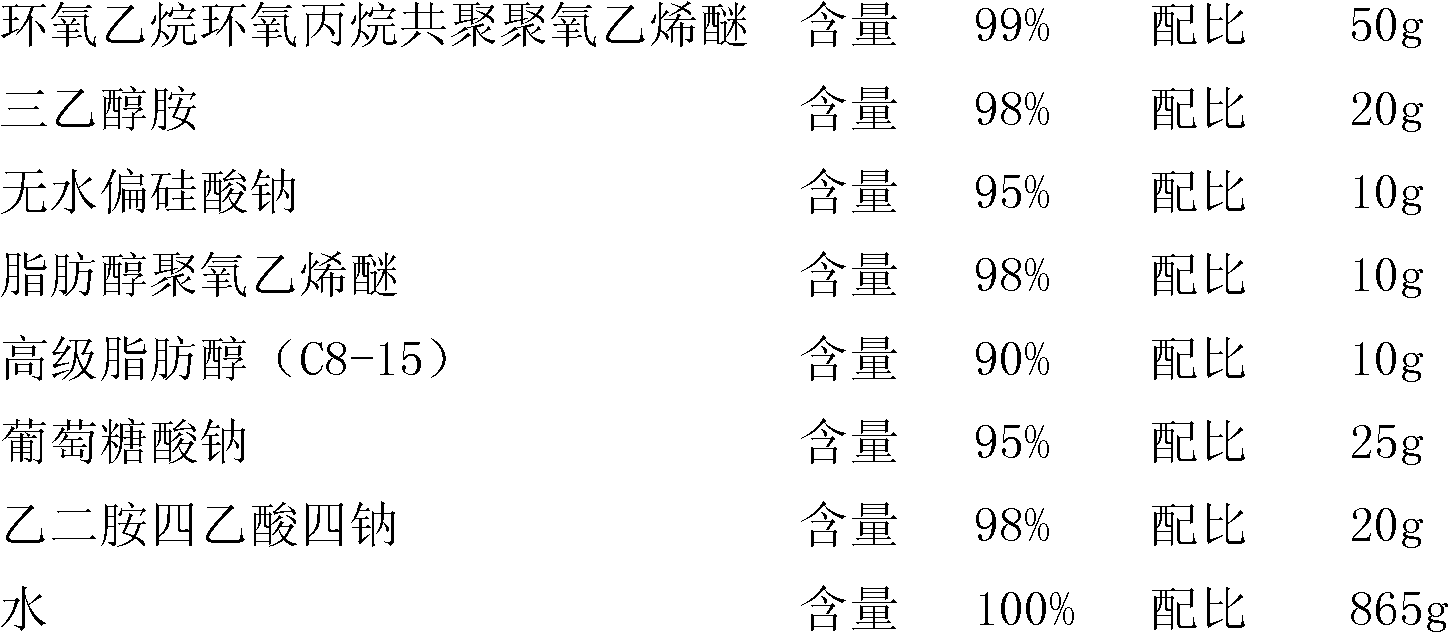

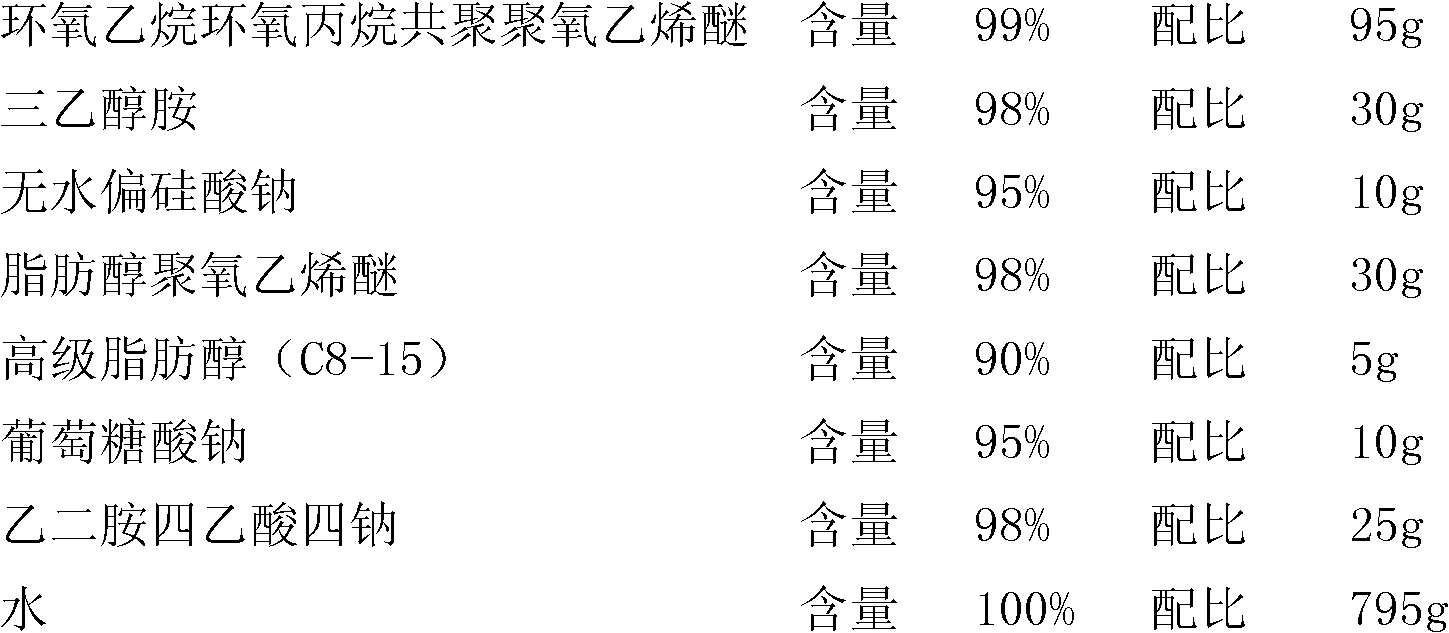

Water-based industrial detergent capable of self-defoaminng at normal temperature and preparation method thereof

InactiveCN102161939AReduce intensityThe principle of achieving self-defoamingInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsWater basedSodium metasilicate

The invention relates to a water-based industrial detergent capable of self-defoaming at normal temperature and a preparation method thereof. The detergent comprises the following components in percentage by weight: 2-15% of ethylene oxide epoxypropane copolymerized polyoxyethylene, 0.5-5% of triethanolamine, 0.5-4% of sodium metasilicate anhydride, 0.1-2% of fatty alcohol-polyxyethylene ether, 0.1-5% of advanced fatty alcohol (C8-15), 1-5% of sodium gluconate, 0.5-5% of ethylene diamine tetraacetic acid and the balance of water. The preparation method mainly comprises the following steps: dissolving the sodium metasilicate anhydride, the sodium gluconate and the ethylene diamine tetraacetic acid in the water; and then adding the ethylene oxide epoxypropane copolymerized polyoxyethylene, the triethanolamine, the fatty alcohol-polyxyethylene ether, the advanced fatty alcohol (C8-15) and the like in sequence, and mixing to finally obtain the industrial detergent. In the invention, based on the combined action of lipophilic group epoxypropane in the ethylene oxide epoxypropane copolymerized polyoxyethylene and lipophilic group in the system as well as industrial oil stain, the intensity of foam generated in the process of cleaning is reduced so as to realize the self-defoaming effect; through the synergistic effect of various components, optimal cleaning and antirust effects are achieved; simultaneously, through the synergistic effect of various surfactants, the defect that inorganic salts always form white spots on the surface of a workpiece is obviously improved.

Owner:华阳新兴科技(天津)集团有限公司

Once grinding technology of steel ball for high-grade car transmission shaft

InactiveCN101514726AReduce surface defectsGood cutting effectOther chemical processesLapping machinesLiquid waterDrive shaft

The invention discloses a once grinding technology of a steel ball for a high-grade car transmission shaft, which includes cold heading process, smooth grinding process, heat treatment process, hard grinding process, reinforcement process, secondary hard grinding process and fine grinding process, and is characterized in that two fine grinding processes after the secondary hard grinding process are combined into one fine grinding process. The fine grinding process includes steps of adjusting the present once grinding technology to standard of G10 grade ball, carrying out circulation liquid water grinding on a grinder, and increasing grinding amount to the steel ball to 30MM-35MM. Stage of steel ball produced by employing the technology reach to G28, so that the steel ball is suitable for high-grade car transmission shaft, and the two processes are modified to one process by the processing technology, thereby increasing production efficiency.

Owner:JIANGSU LIXING GENERAL STEEL BALL

Long-acting antirust oil and preparation method thereof

The invention discloses long-acting antirust oil and a preparation method thereof. The long-acting antirust oil comprises the following components in parts by weight: 60-70 parts of base oil, 3-8 parts of petroleum barium sulfonate, 0.5-1 part of dodecenylsuccinic acid, 0.2-1 part of sorbitan monooleate, 2-6 parts of wool fat, 0.2-0.8 part of tert-butyl p-cresol, 0.5-1 part of benzotriazole, 0.5-1 part of stearic acid and 0.5-1 part of industrial lecithin. The preparation method comprises the steps of adding the base oil into a container, heating and then adding the petroleum barium sulfonate and the benzotriazole into the container; continuously heating and stirring to enable machine oil to be completely dehydrated; cooling and then adding the dodecenylsuccinic acid and the wool fat; stirring, dissolving and then continuously cooling; adding the rest components, and evenly stirring and mixing; filtering impurities to obtain the long-acting antirust oil. After a metal plate is treated by the long-acting antirust oil, a performance test is carried out on the metal plate, and the result proves that the long-acting antirust oil disclosed by the invention has the protection function for a long time.

Owner:吴江市宝鑫机械有限公司

Water washing resistant bovine hide clothing leather processing process

InactiveCN107164584AImprove mechanical propertiesWashableTanning treatmentPre-tanning chemical treatmentPulp and paper industryStain

The invention belongs to the technical field of clothing fabric processing, and provides a water washing resistant bovine hide clothing leather processing process. The process comprises the steps of: bovine hide pretreatment; soaking; deliming; pickling; tanning; retanning; rinsing; dyeing and fat-liquoring; drying; wetting back; milling and finishing. Prepared bovine hide clothing leathers have the advantages of water washing resistance, no smell, no oil stains and high mechanical strength; the tanning process is environmentally friendly and pollution-free; the cost in the production process is low; and the process is simple.

Owner:HEFEI YUANKE GARMENT DESIGN CO LTD

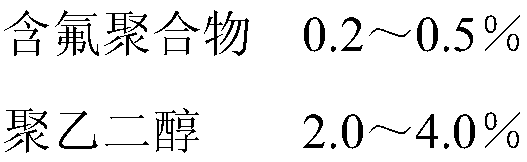

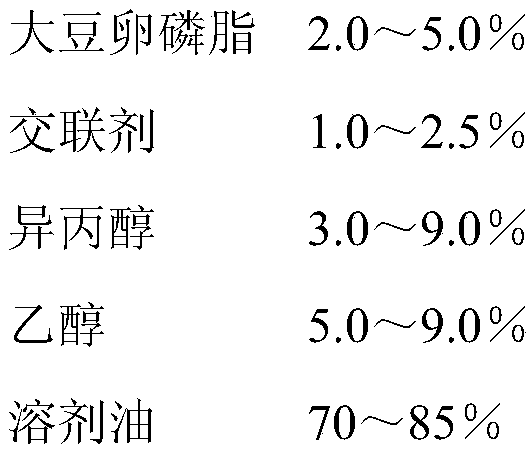

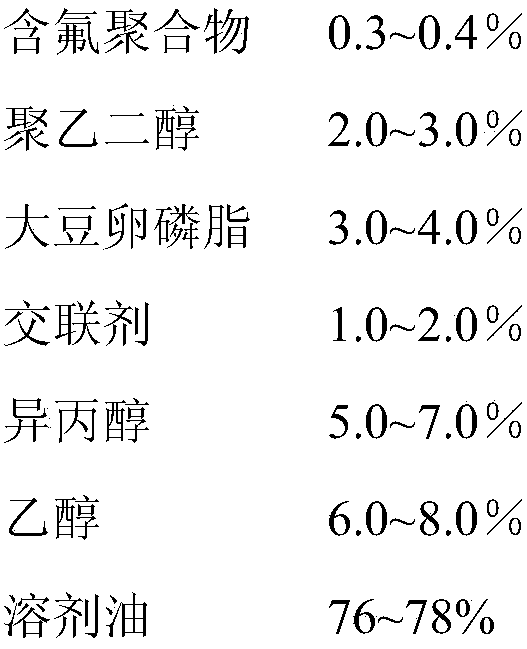

Fluorine-containing dry demoulding agent and preparation method thereof

The invention discloses a fluorine-containing dry demoulding agent and a preparation method thereof. The fluorine-containing dry demoulding agent of the invention consists of the following componentsin percentages by weight: 0.2-0.5% of fluorine-containing polymer, 2.0-4.0% of polyethylene glycol, 2.0-5.0%of soybean lecithin, 1.0-2.5% of a cross-linking agent, 3.0-9.0% of isopropanol, 5.0-9.0% ofethanol, and 70-85% of solvent oil. The fluorine-containing dry demoulding agent is prepared by the method comprising the following steps: dissolving the fluorine-containing polymer in isopropanol tobe used as a component A; dissolving polyethylene glycol in isopropanol and ethanol to be used as a component B; and adding the component A and component B into the solvent oil, conducting stirring for dissolving, and finally adding the cross-linking agent, and performing stirring. The preparation method of the invention is simple, and the obtained fluorine-containing dry demoulding agent has nooil marks on the surfaces of the injection moulded parts due to the fluorine-containing ingredients, and does not affect the subsequent surface processing at all; because of the formation of a high-strength isolation film on the surface of the mould, the number of demoulding times is doubled.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

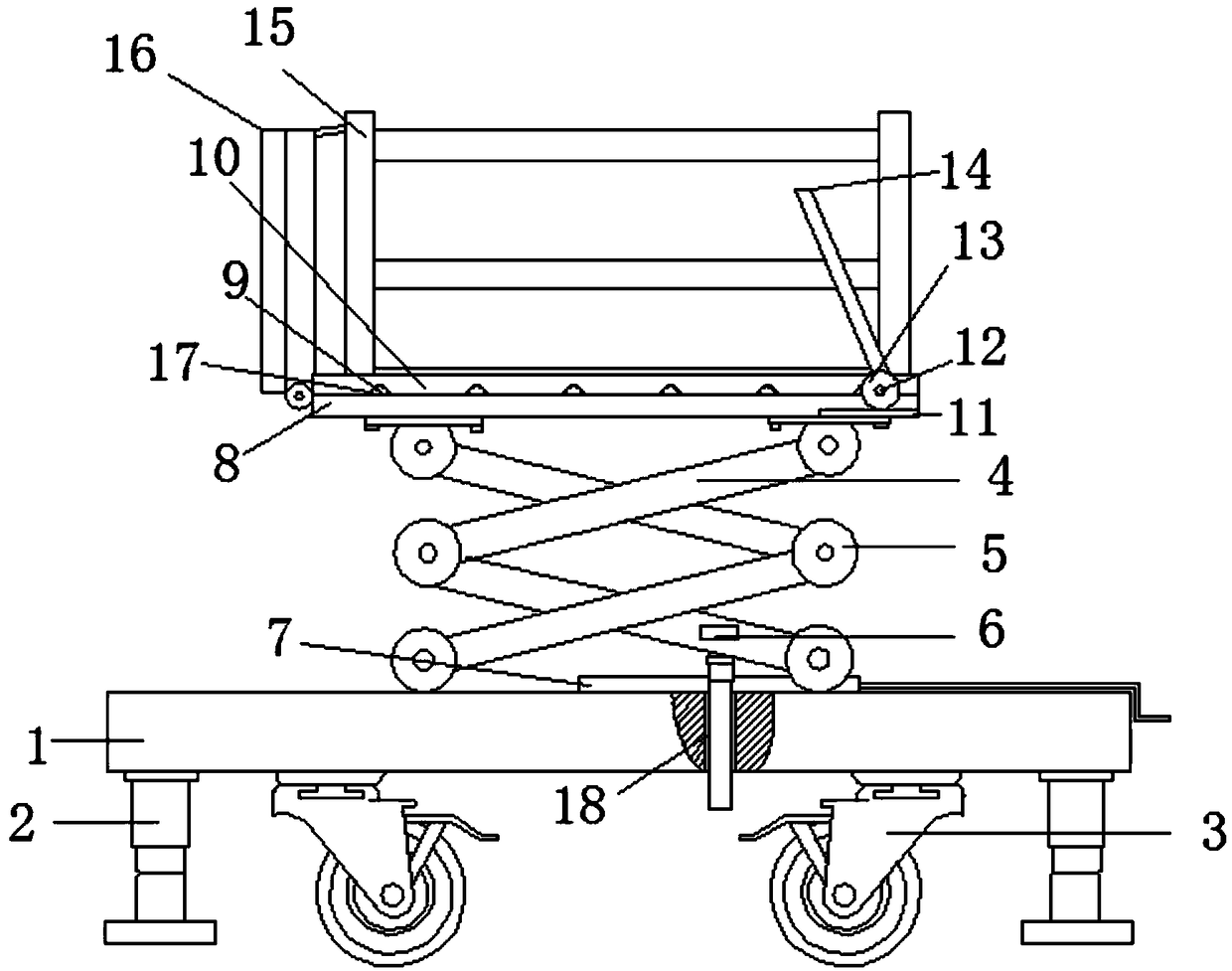

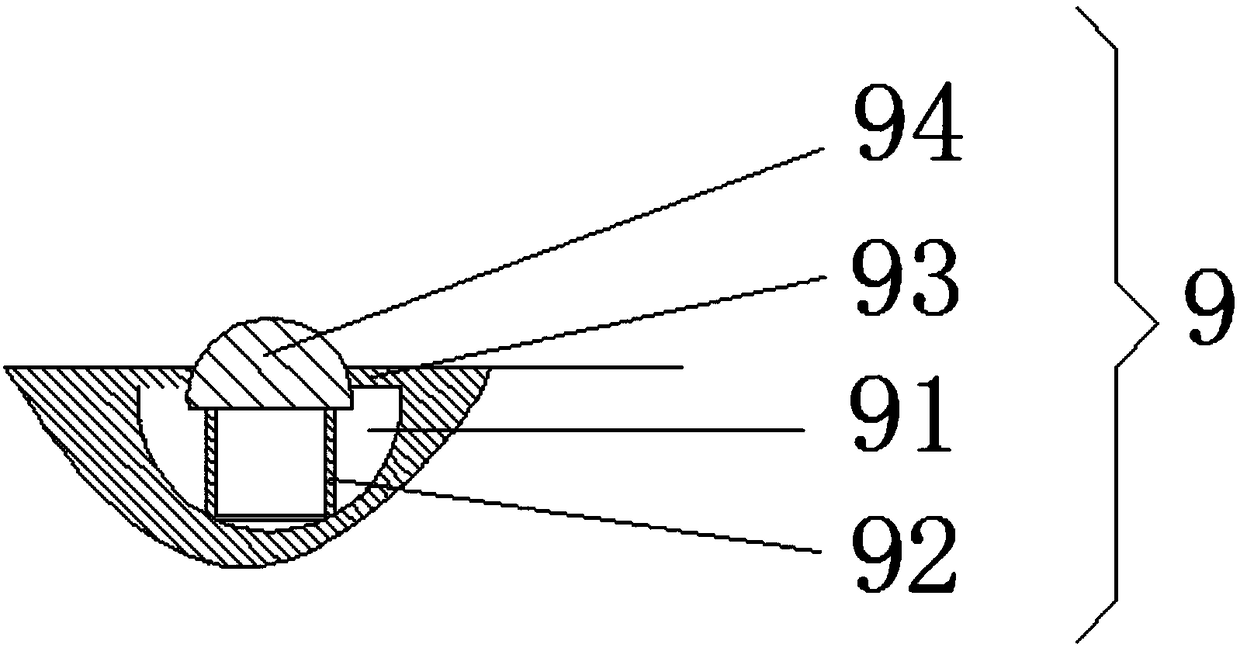

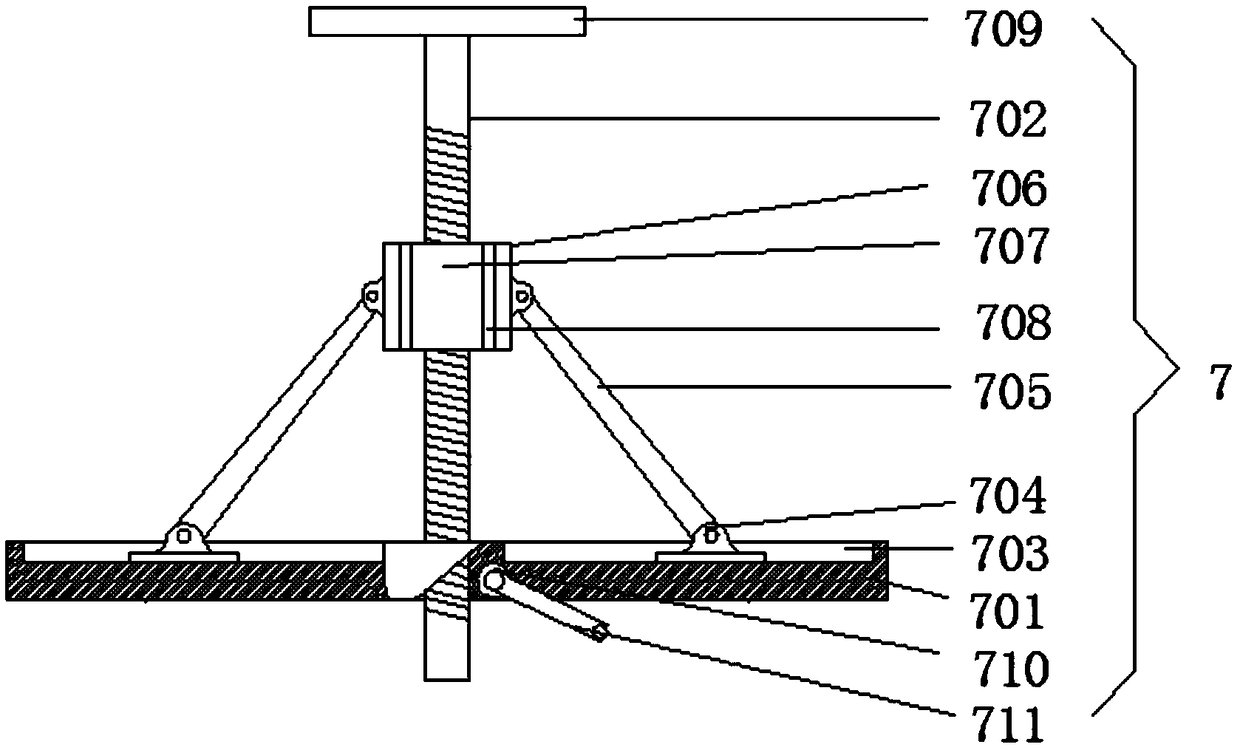

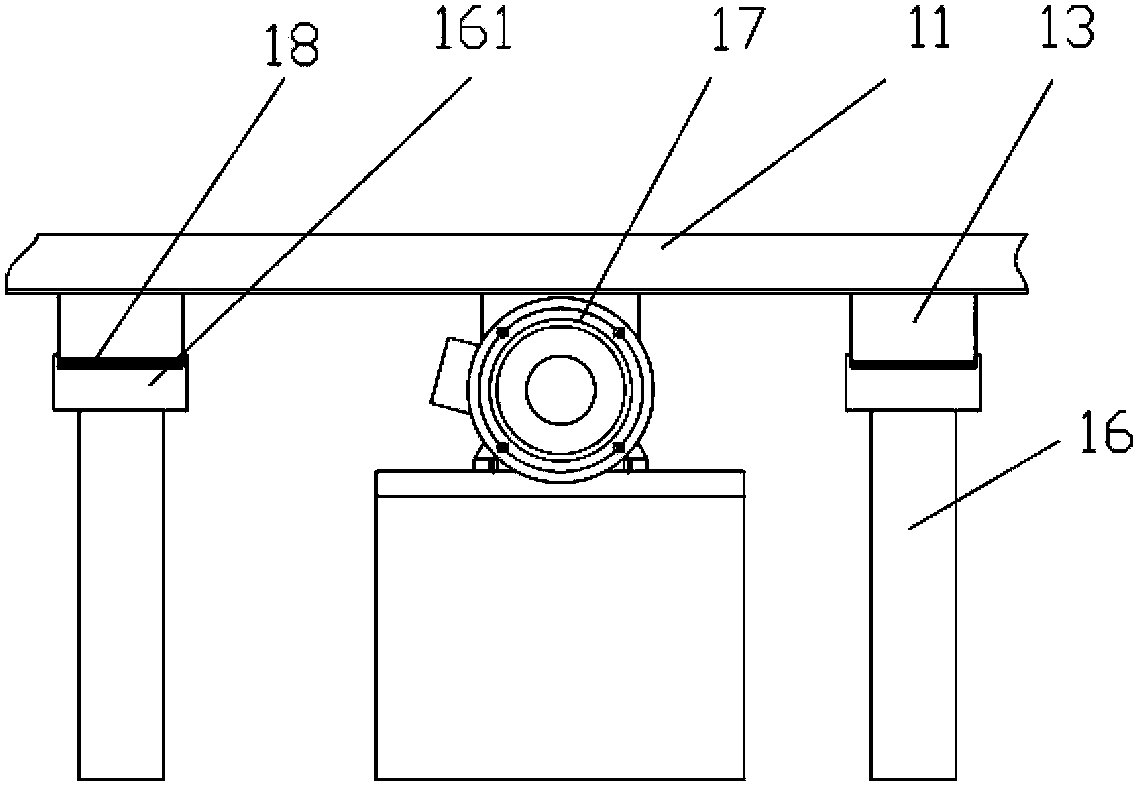

Lifter device with high safety

InactiveCN108689354AImprove securityImprove adaptabilitySafety devices for lifting equipmentsEngineering

The invention discloses a lifter device with high safety and relates to the field of lifter equipment. The lifter device comprises a lifter bottom supporting table. A lifting frame is arranged in themiddle of the top of the lifter bottom supporting table. A lifting device is arranged in the middle of the side, close to the lifter bottom supporting table, of a cross supporting beam. A plurality ofbayonet ball devices are arranged on the side, away from the lifting frame, of a lifter top supporting table. The position, located above a straight toothed plate, of an operating plate base is rotationally connected with a rotating gear through a rotary shaft. A folding ladder is arranged on the left side of the operating plate base. By means of the lifter device with the high safety, the problems that a currentlAy-used lifter mostly adopts cooperation between a hydraulic lifting column and an oil pump, the number of mechanical faults is large, a great amount of oil dirt is prone to being generated after long-time use meanwhile, the maintenance cost is also high, in addition, a workbench cannot be moved, and working staff fail to reach the ground quickly under faulty conditions are solved.

Owner:湖州吴兴久虹机械有限公司

Preparation method of non-degumming poly urethane (PU) driving wheel

The invention provides a preparation method of a non-degumming poly urethane (PU) driving wheel. The preparation method of the non-degumming PU driving wheel comprises the procedures of blasting treatment, solvent cleaning, coating adhesive, heating and vulcanizing molding with PU injected. Ultrasonic cleaning, rinsing, rustproof treatment and drying treatment are carried out on an iron core machined by a lathe before the blasting treatment. The ultrasonic cleaning and the rustproof treatment and the like are carried out on the iron core before the blasting treatment on the iron core, and therefore greasy dirt in deep micropores of the iron core is clean-removed. Besides the rustproof treatment is carried out on the surface of the iron core, PU sizing materials are enabled to be bond with the iron core together without a membrane, and therefore bonding effect is enhanced, degumming is prevented well, and product quality is improved.

Owner:CHUZHOU YULIN POLYURETHANE

Long-acting antirust oil and preparation method thereof

The invention discloses long-acting antirust oil and a preparation method thereof. The long-acting antirust oil comprises the following components in parts by weight: 60-70 parts of base oil, 3-8 parts of petroleum barium sulfonate, 0.5-1 part of dodecenylsuccinic acid, 0.2-1 part of sorbitan monooleate, 2-6 parts of wool fat, 0.2-0.8 part of tert-butyl p-cresol, 0.5-1 part of benzotriazole, 0.5-1 part of stearic acid and 0.5-1 part of industrial lecithin. The preparation method comprises the steps of adding the base oil into a container, heating and then adding the petroleum barium sulfonate and the benzotriazole into the container; continuously heating and stirring to enable machine oil to be completely dehydrated; cooling and then adding the dodecenylsuccinic acid and the wool fat; stirring, dissolving and then continuously cooling; adding the rest components, and evenly stirring and mixing; filtering impurities to obtain the long-acting antirust oil. After a metal plate is treated by the long-acting antirust oil, a performance test is carried out on the metal plate, and the result proves that the long-acting antirust oil disclosed by the invention has the protection function for a long time.

Owner:吴江市宝鑫机械有限公司

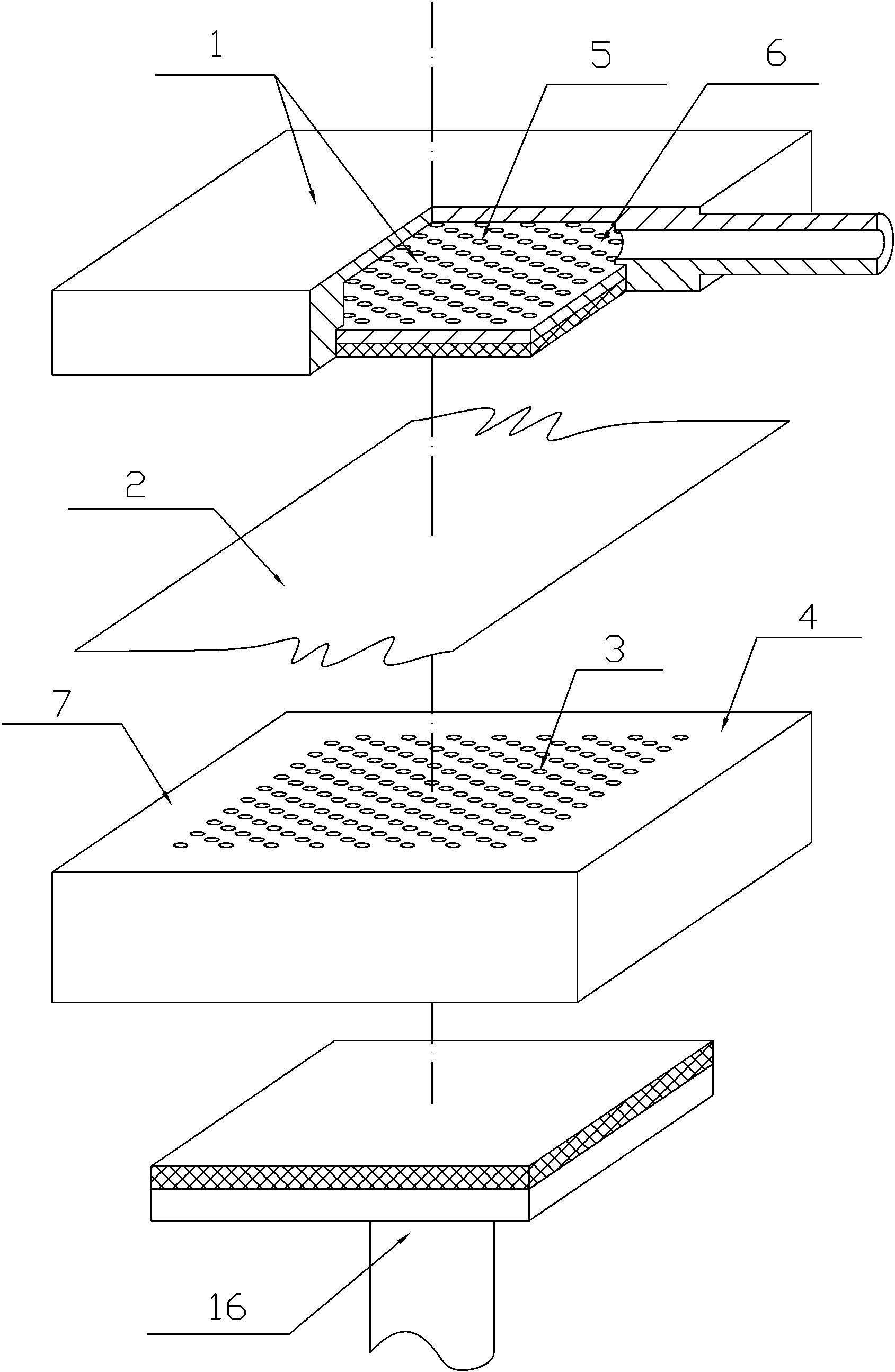

Film pneumatic punching method and corresponding equipment

The invention relates to a film pneumatic punching method and equipment, which is particularly suitable for punching on metal foils. In the traditional mechanical punching method, damages are easy to cause and notches are rough, and in a metal hole-corrosion method, a process is complex, has high cost and is easy to generate electrolyte pollution. Thus, the blasting film punching method provided by the invention comprises the following steps of: 1, tightly pressing films on a bottom die provided with a plurality of gas cavity holes by using a top die; 2, then introducing high-pressure gas into an intake cavity of the top die to break through the films at all gas cavity holes to enter the gas cavity holes so as to realize punching; 3, cutting off a high-pressure gas source; and 4, finally, moving away a movable sealing piece to exhaust the high-pressure gas and punchings. The invention also relates to corresponding film punching equipment. The blasting film punching method and the corresponding equipment have the advantages of no oil stain, low cost, even notch without burrs and smooth punchings exhausting and are suitable for punching on various films, particularly metal foils.

Owner:ZHEJIANG CHANGYUDA PHOTOELECTRIC COMM

Processing process of washable cowhide garment leather

InactiveCN109913594AWashableNo smellTanning treatmentPre-tanning chemical treatmentPulp and paper industryMoisture

The invention belongs to the technical field of garment fabric processing, and provides a processing process of washable cowhide garment leather. The processing process comprises the following steps that the cowhide is sequentially subjected to pretreating, soaking, deashing, pickling, tanning, retanning, rinsing, dyeing, fatliquoring, drying, moisture regaining, softening and finishing. The cowhide garment leather prepared by the processing process of the washable cowhide garment leather has the advantages of water washing resistance, odorless, oil stain-free and high mechanical strength; thetanning process is environmentally friendly and pollution-free; and the cost of the production flow is low and the process is simple.

Owner:淮安市联发制衣有限公司

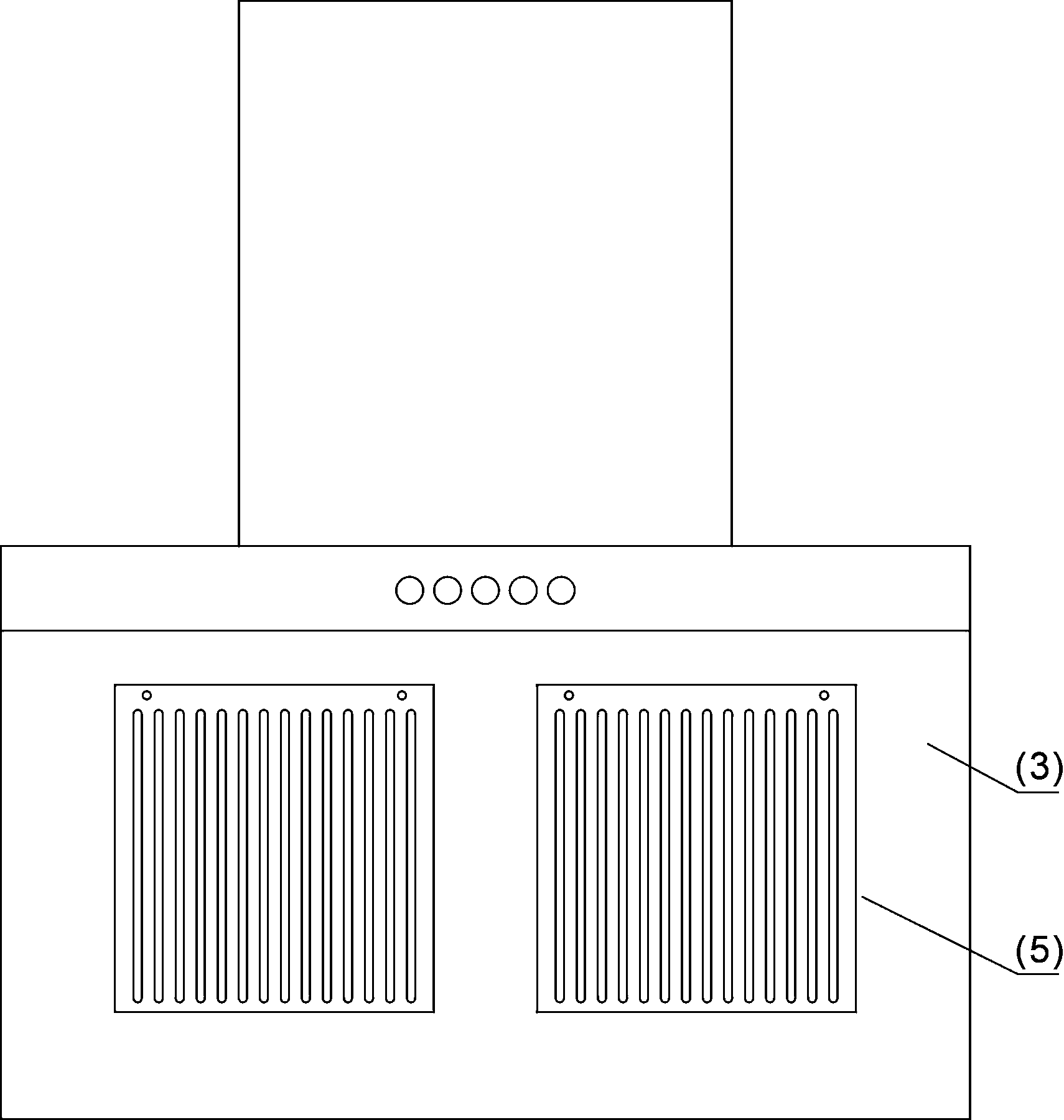

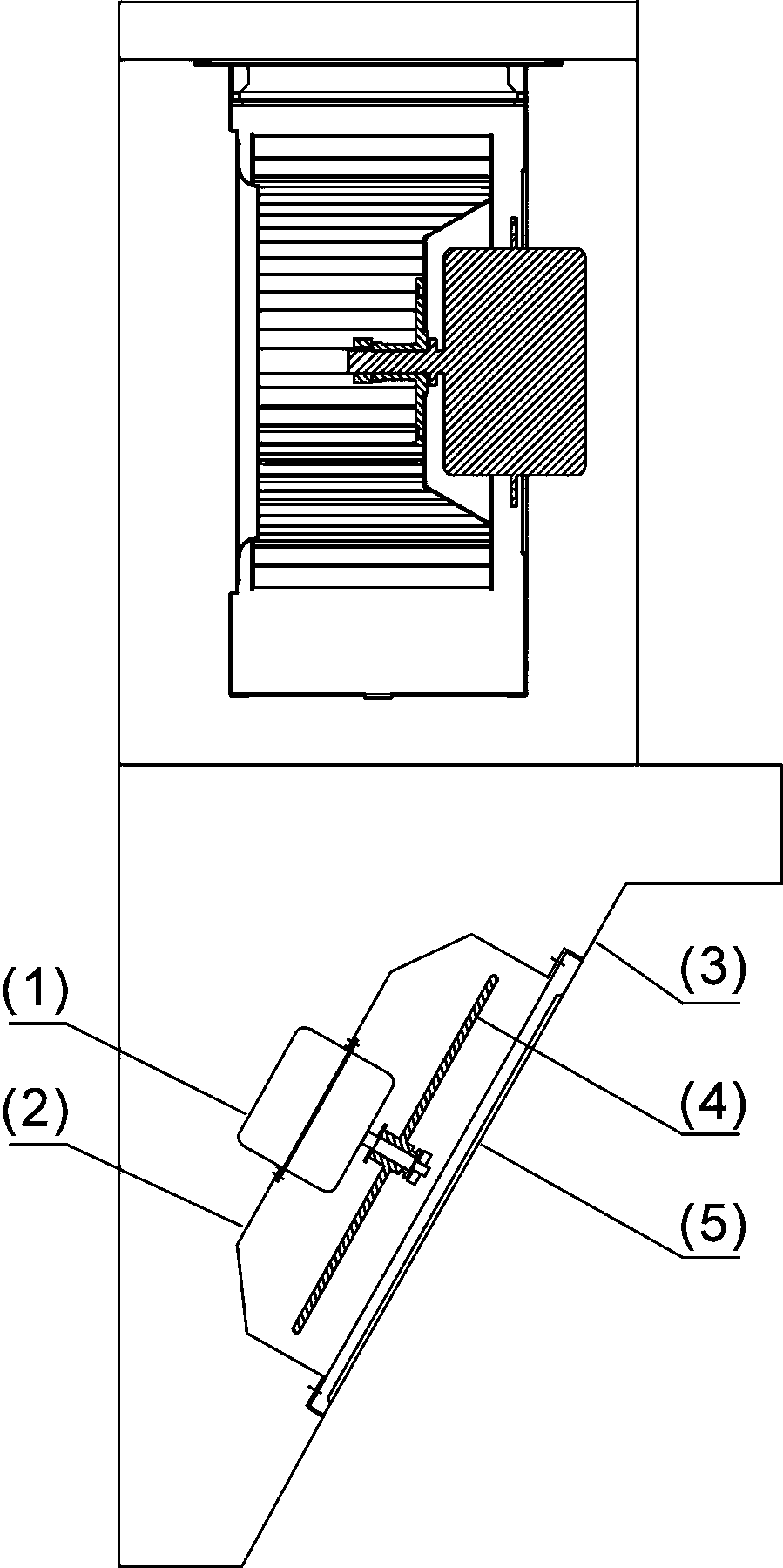

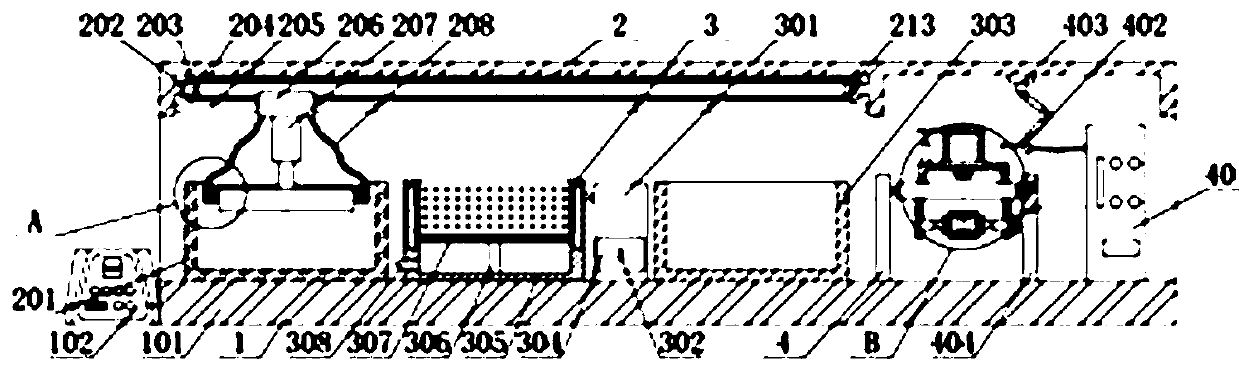

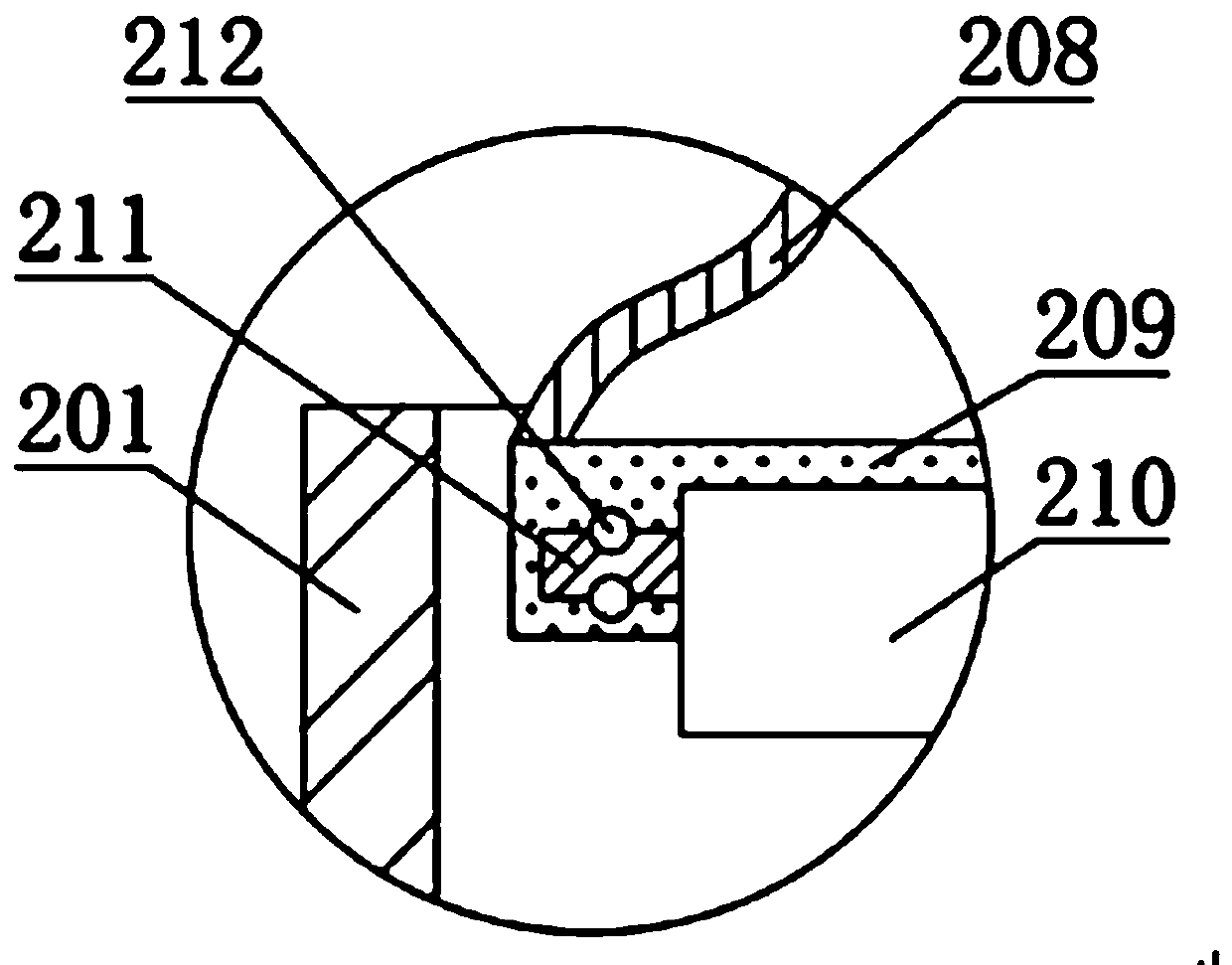

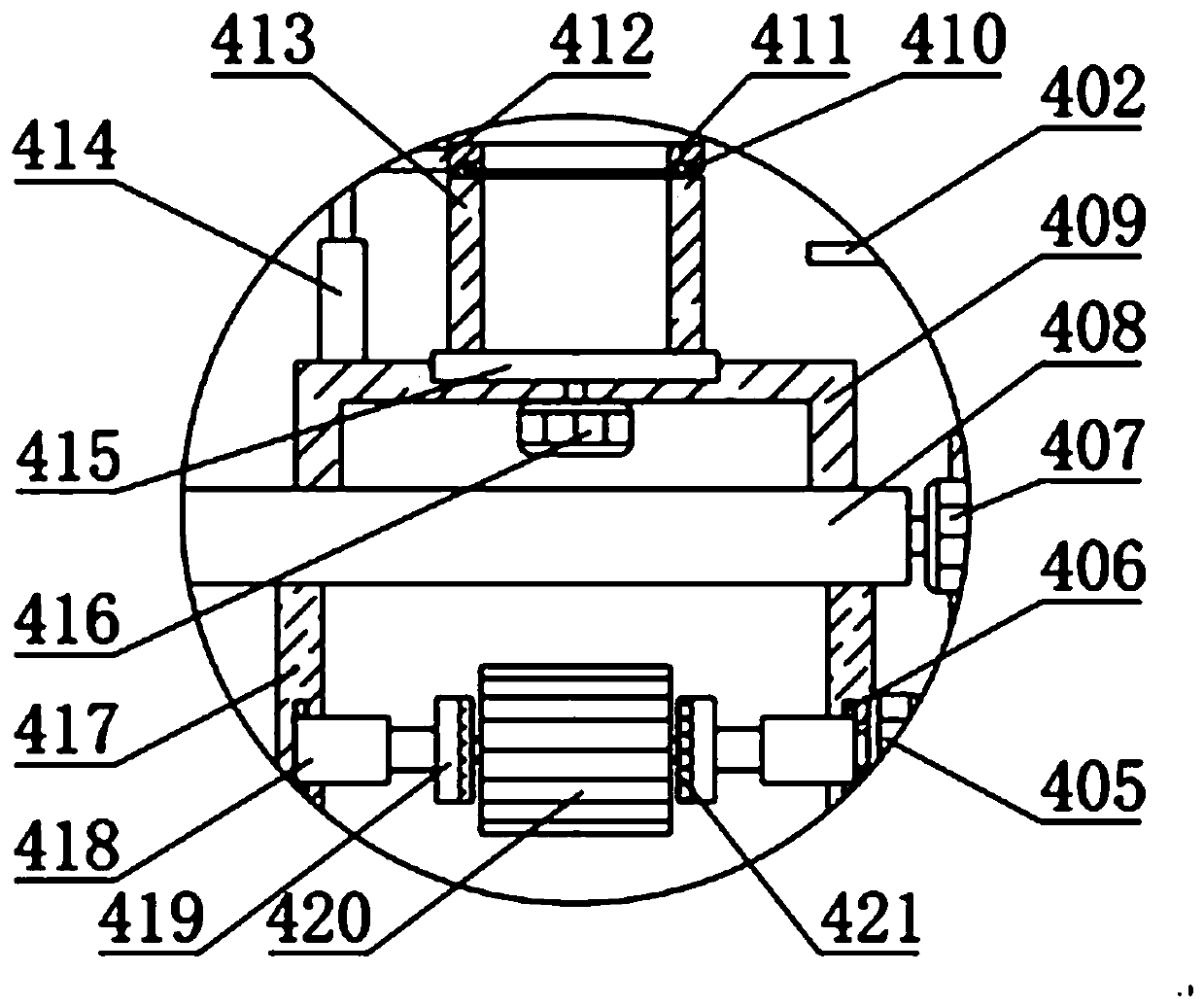

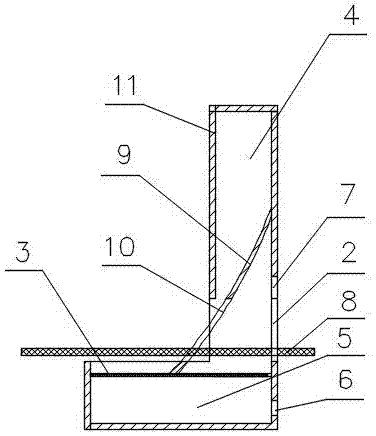

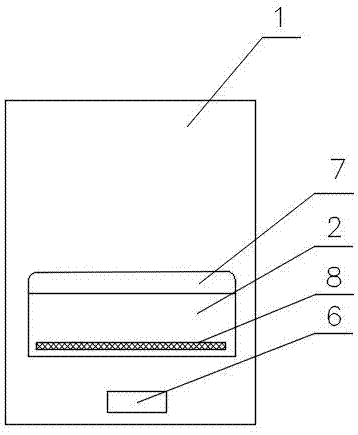

Electric rotating purification filter screen type range hood

InactiveCN104141976AEasy to separateNo oil stainsDomestic stoves or rangesLighting and heating apparatusAtmospheric airPulp and paper industry

An electric rotating purification filter screen type range hood is characterized in that a high speed rotating purification filter screen is arranged at the smoke suction hole of an air collecting plate behind a screen grid of a range hood. Primary fat separation is formed when oil smoke goes through the screen grid, and secondary fat separation is formed due to centrifugal action when the oil smoke goes through the high speed rotating purification filter screen, so thorough separation is realized before the oil smoke enters a volute fan, thereby the fat separation effect of the range hood is effectively improved, and atmospheric environment is protected. The electric rotating purification filter screen type range hood is technically characterized in that a motor support is arranged at the inner side of the smoke suction hole of the air collecting plate, the motor support is provided with a small motor, and a circular purification filter screen is fixed on the small motor.

Owner:钱福生

Fabrics having soil resistance and no oil stains after wiping and manufacturing method thereof

ActiveUS20080220677A1Eliminate disadvantagesPrevent penetrationLiquid surface applicatorsFibre treatmentTectorial membraneEngineering

The present invention provides a fabric having soil resistance and no oil stains after wiping and a manufacturing method thereof. The fabric of the present invention comprises an underlayer and a soil-resistant protection film, which can effectively prevent oil corrosion, penetration, and permeation of the surface of the fabric, thus resulting in no oil stains after wiping. The manufacturing method of the present invention comprises the steps of dyeing, setting, performing an underlayer surface treatment to form an underlayer on a surface of the fabric, and performing a soil resistance processing treatment to form a soil-resistant protection film on the surface of the underlayer.

Owner:FORMOSA TAFFETA CO LTD

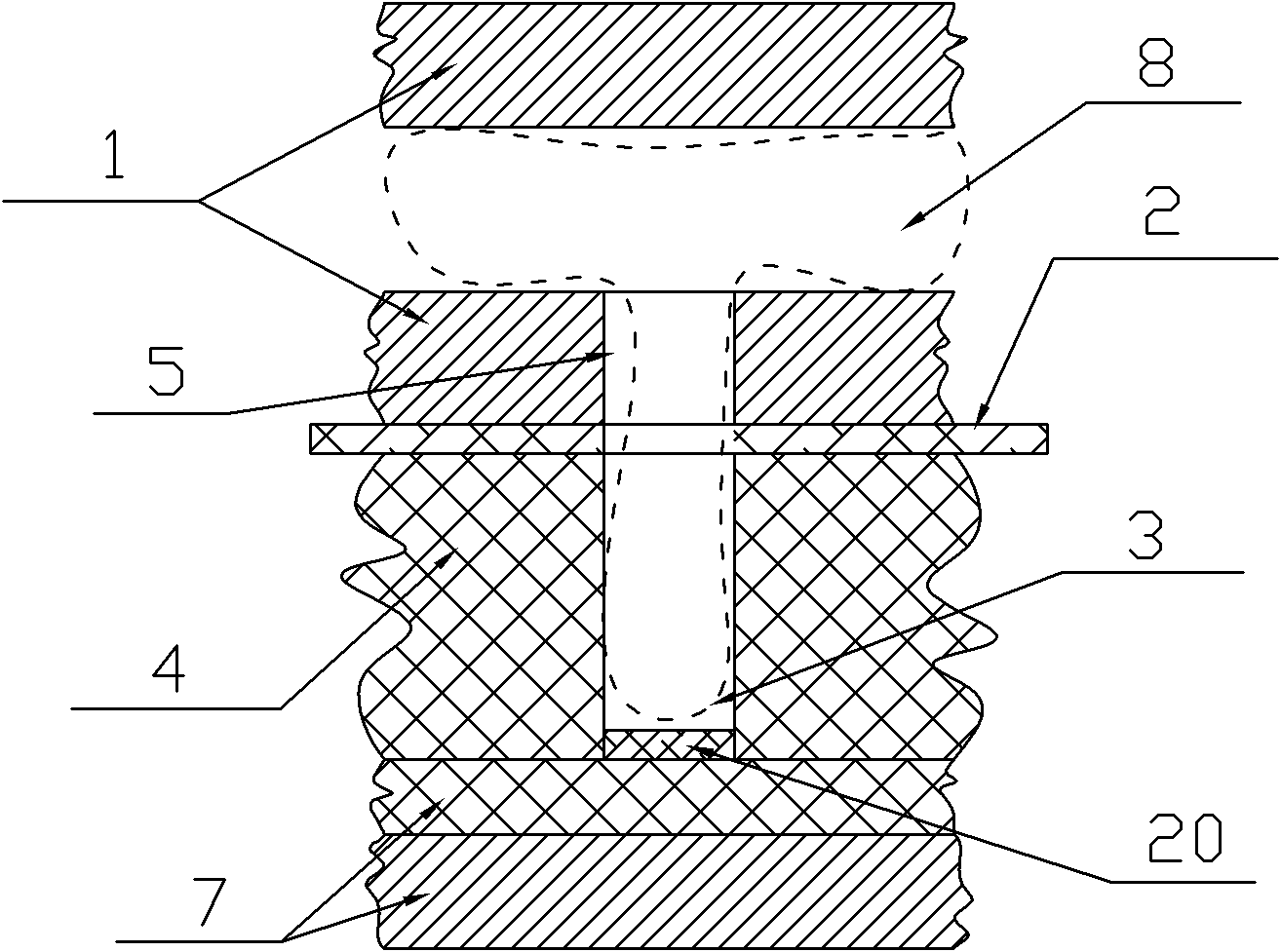

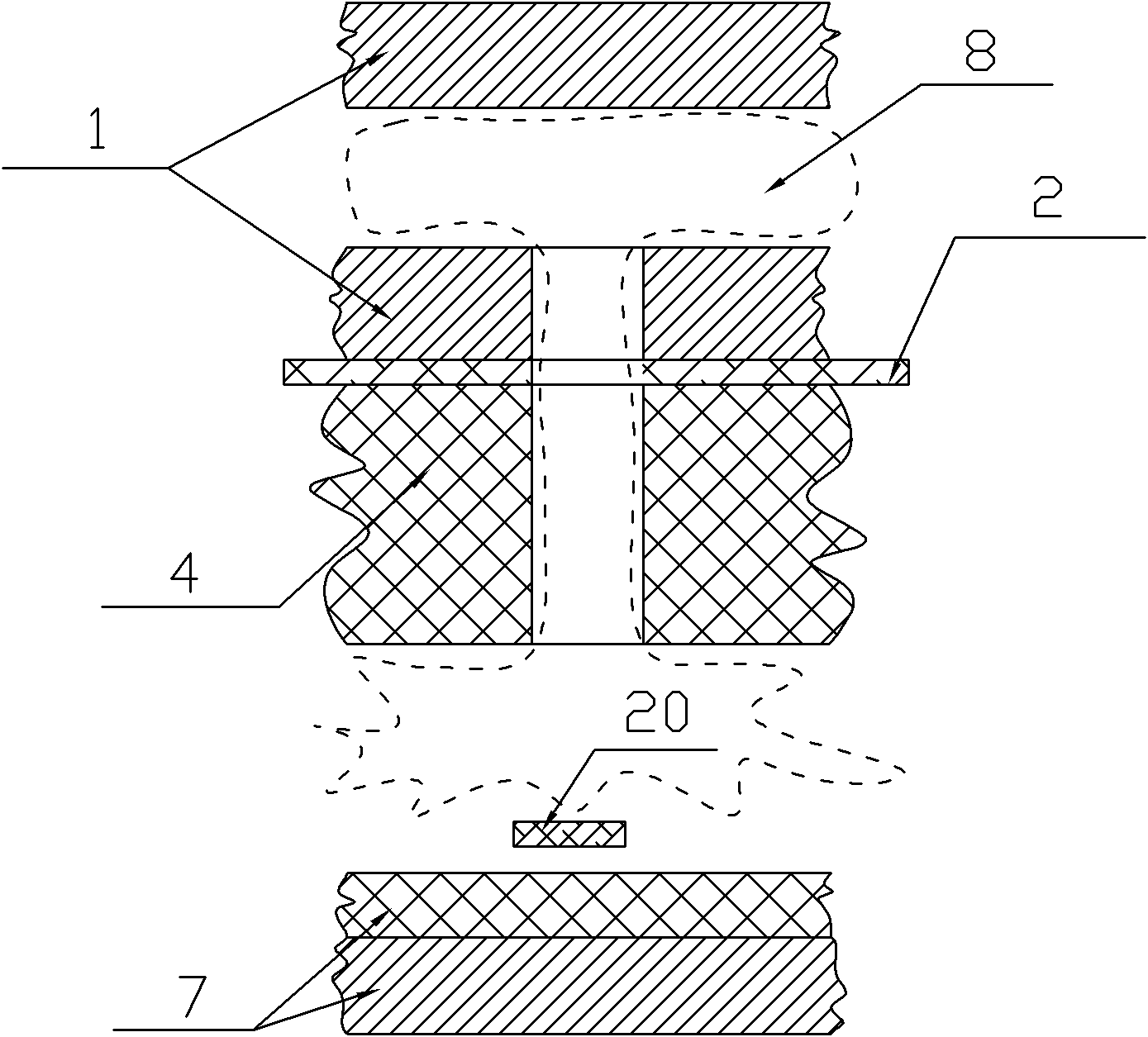

Preforming process of rubber sheet for vulcanization of shock insulation support

PendingCN114536701APreforming Process OptimizationSimple production processPolymer scienceVulcanization

The invention relates to a preforming process of a rubber sheet for vulcanization of a shock insulation rubber support, which comprises the following steps: extruding a rubber compound through a cold feed extruder, controlling the temperature at 90 + / -5 DEG C, feeding the extruded rubber compound into a multi-roller calender through an automatic continuous rubber supply conveyor belt for calendering, cooling the extruded rubber sheet, controlling the temperature of the cooled rubber sheet at 30 + / -10 DEG C, and carrying out preforming; and then slicing by means of an intelligent digital vibration cutting system, or selecting a 0.1-0.5 mm PTFE soft plate to isolate the rolled and cooled rubber sheet and storing the whole roll of rubber sheet, and finally weighing the rubber sheet and collecting the rubber sheet according to the rubber feeding weight of each shock insulation rubber support. By the adoption of the process, preforming production equipment for inner-layer rubber and outer-coating rubber of different shapes and specifications is unified, the slicing size can be flexibly adjusted according to fluctuation of the rolling thickness, the rubber sheet preforming time of the shock insulation rubber support can be shortened to the maximum extent, and the production benefit is improved.

Owner:ZHEJIANG TIANTIE IND

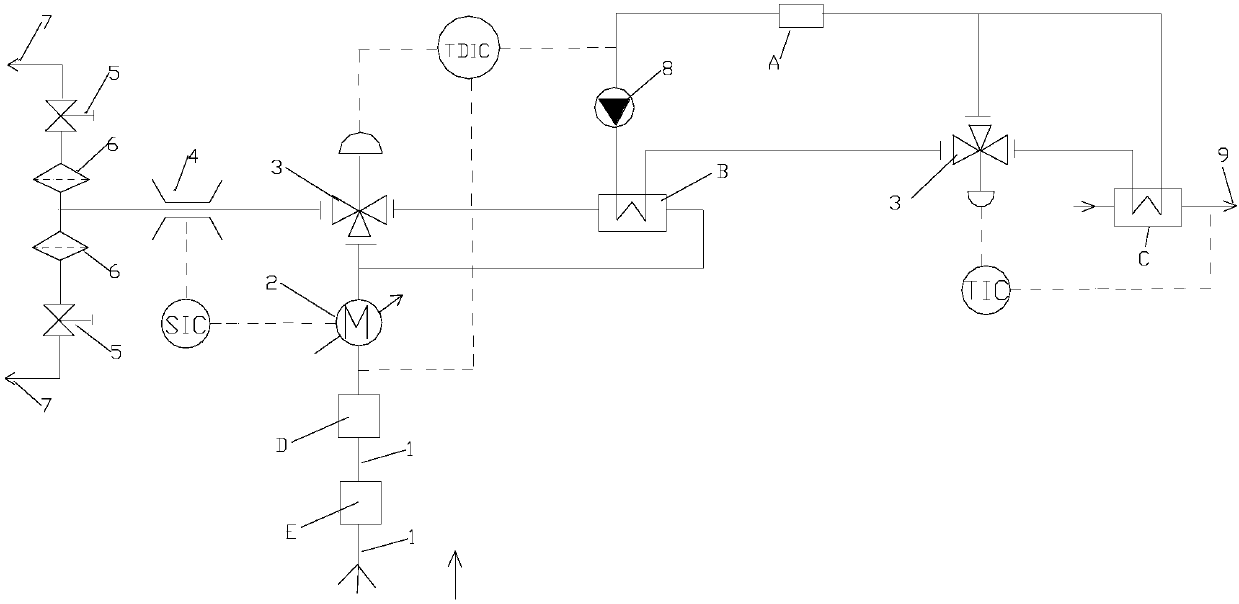

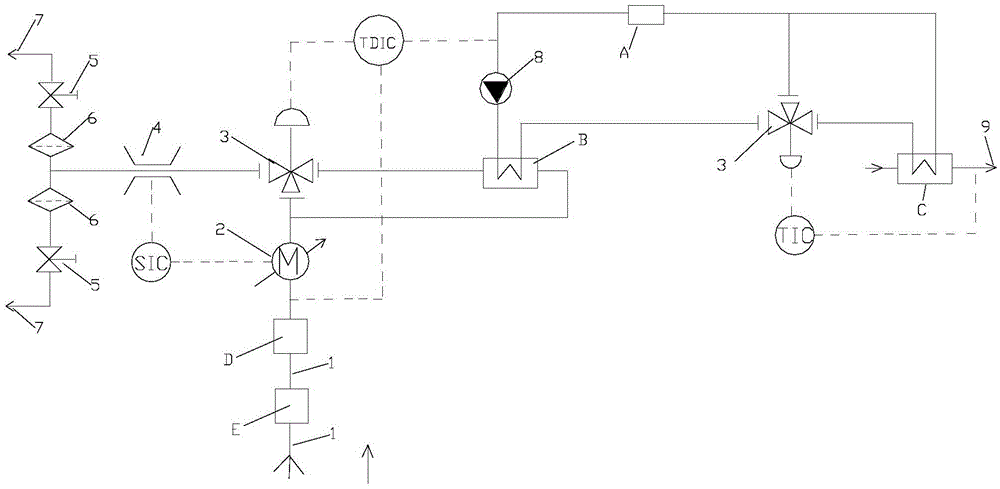

Aging treatment heat recovery device

ActiveCN105627772BImprove cleanlinessNo oil stainsWaste heat treatmentWaste heat recovery unitTemperature control

The invention discloses a novel aging treatment heat energy recycling device. The novel aging treatment heat energy recycling device comprises a heat collecting module, a motor, a pipeline, a heat pump, an electric three-way regulating valve, a manual regulating valve, an environment filter, a temperature difference control module, a flow control module, a temperature control module and a speed control module, wherein the heat collecting module comprises a heat energy recycling module and a heat energy absorption exchange module, the heat energy absorption exchange module comprises a heat energy absorption exchange module B and a heat energy absorption exchange module C, and the heat energy recycling module comprises a heat energy recycling module A and a heat energy recycling module E. The novel aging treatment heat energy recycling device collects and utilizes clean heat energy directly emitted into atmospheric environment when large-power auxiliary equipment specific to BOPP factories normally run, and carries out recycling, combined distribution, circular treatment and utilization as well as intelligent regulation control so as to realize clean, environment-friendly and efficient heat energy recycling and utilization. The requirements of special high-value-added products on production technologies are met, and the energy utilizing efficiency is improved.

Owner:贵州金田新材料科技有限公司

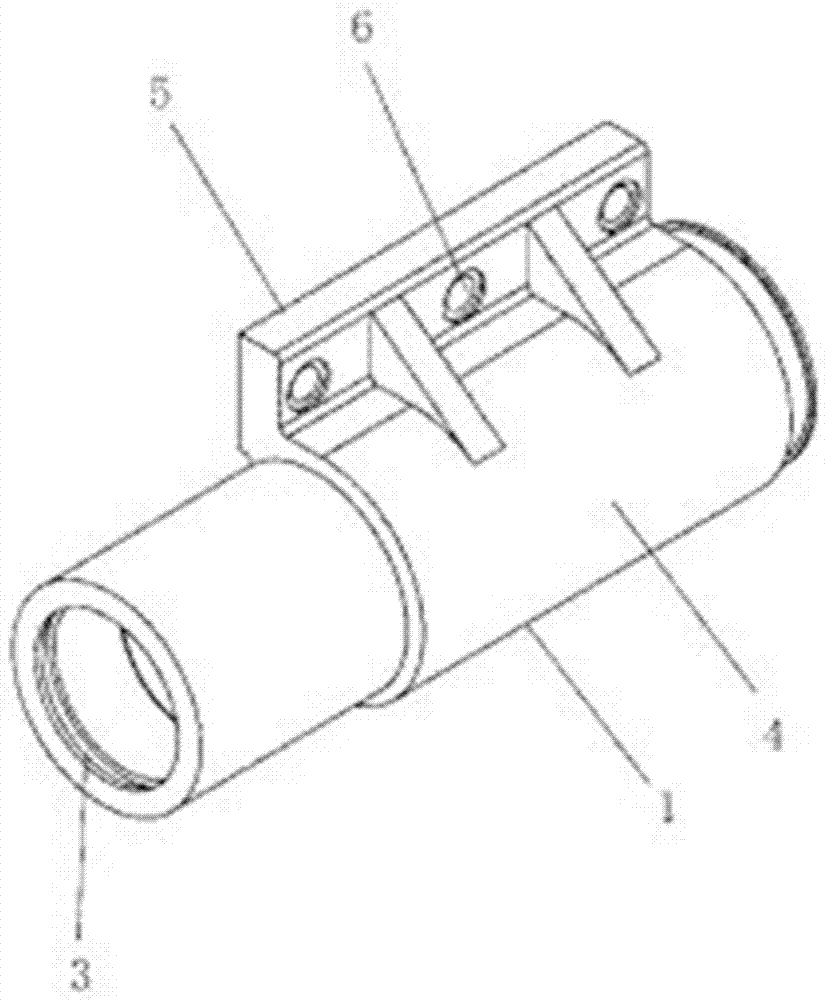

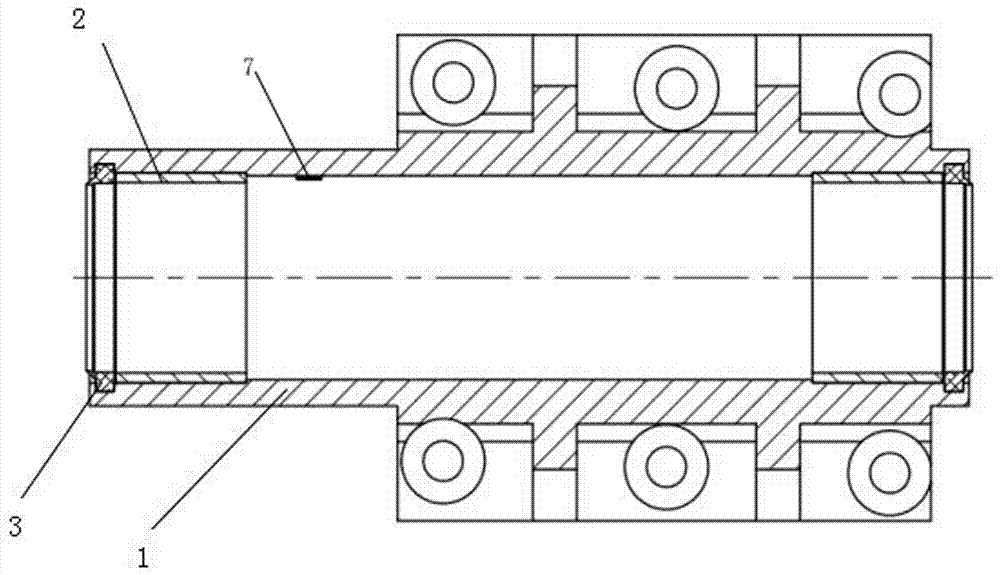

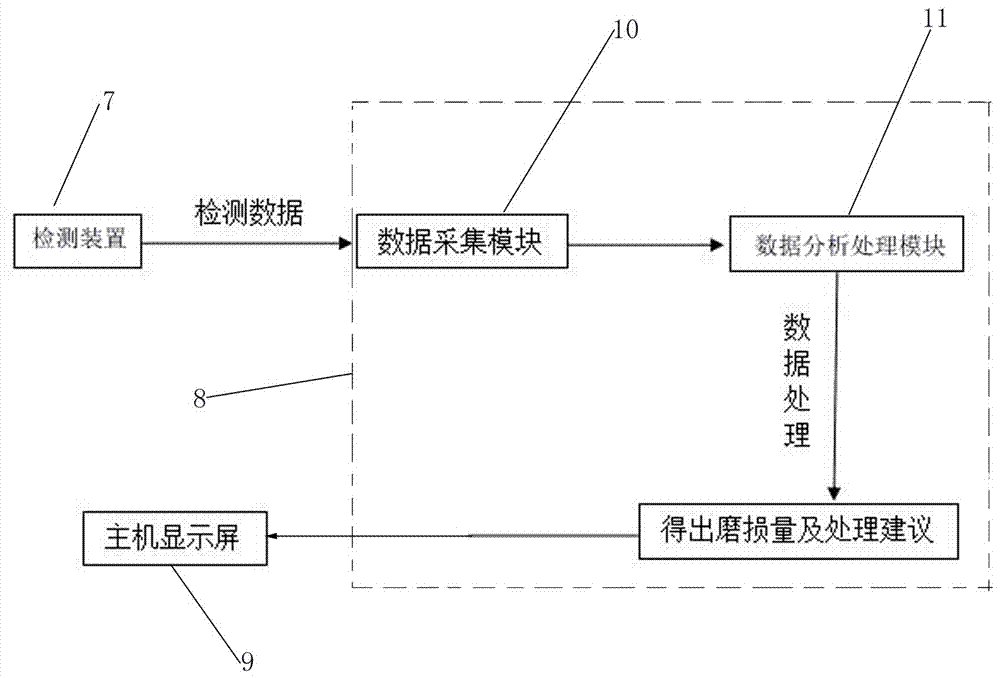

Dustproof guide sleeve

InactiveCN106868966ANo oil stainsImprove the environmentRailway track constructionEngineeringData processing

The invention relates to a dust-proof guide sleeve, comprising a guide sleeve body, a detection device is arranged inside the guide sleeve, the detection device is connected to a data processing host through a wired connection or a wireless connection, and the detection device is used for Detect the relative gap between the guide sleeve and the guide column so as to obtain the wear status information of the guide sleeve and transmit it to the data processing host, and the data processing host will transmit the processed data to the host display screen, and the host display screen will The data and reference suggestions processed by the data processing host are displayed on the display screen of the host. Since the guide sleeve of the present invention has a built-in detection device, it is used to detect the relative vibration of the guide column and the guide sleeve in the working state, measure and calculate the relative gap, thereby obtain the wear state of the guide sleeve, and give reference suggestions.

Owner:RUVER GENERAL EQUIP CO LTD CHINA HENAN

Novel aging treatment heat energy recycling device

ActiveCN105627772AImprove cleanlinessNo oil stainsWaste heat treatmentTemperature controlTemperature difference

The invention discloses a novel aging treatment heat energy recycling device. The novel aging treatment heat energy recycling device comprises a heat collecting module, a motor, a pipeline, a heat pump, an electric three-way regulating valve, a manual regulating valve, an environment filter, a temperature difference control module, a flow control module, a temperature control module and a speed control module, wherein the heat collecting module comprises a heat energy recycling module and a heat energy absorption exchange module, the heat energy absorption exchange module comprises a heat energy absorption exchange module B and a heat energy absorption exchange module C, and the heat energy recycling module comprises a heat energy recycling module A and a heat energy recycling module E. The novel aging treatment heat energy recycling device collects and utilizes clean heat energy directly emitted into atmospheric environment when large-power auxiliary equipment specific to BOPP factories normally run, and carries out recycling, combined distribution, circular treatment and utilization as well as intelligent regulation control so as to realize clean, environment-friendly and efficient heat energy recycling and utilization. The requirements of special high-value-added products on production technologies are met, and the energy utilizing efficiency is improved.

Owner:贵州金田新材料科技有限公司

Zanthoxylum schinifolium processed peanuts and preparation method thereof

The invention discloses zanthoxylum schinifolium processed peanuts and a preparation method thereof. The zanthoxylum schinifolium processed peanuts are prepared as follows: dry-fried peanut kernels are stir-fried in vegetable oil and ingredients and then are braised with dried shallots. Specifically, the zanthoxylum schinifolium processed peanuts are prepared from components of raw materials in parts by mass as follows: 6-10 parts of vegetable oil, 60-85 parts of peanuts, 0.5-2 parts of ginger slices, 3-8 parts of zanthoxylum schinifolium, 3-6 parts of shredded chili, 0.5-2 parts of garlic, 0.2-0.8 parts of sugar, 0.5-1.5 parts of salt and 0.3-1.2 parts of the dried shallots. Dry-frying, frying and braising of the peanuts are combined, moisture can be rapidly drained during dry-frying, theoriginal flavor of the peanuts is kept, the peanuts are fried with the ingredients at the high temperature to be spicy and tasty; dry-frying and frying are combined, the oil consumption can be reduced, the frying time can be shortened, and the peanuts taste crisp; during braising, the dried shallots are added to increase the aroma, so that the peanuts are better flavored, are spicy, aromatic andtangy, have little irritation and are tasty, healthy and functional snack food.

Owner:西安哈牙食品有限公司

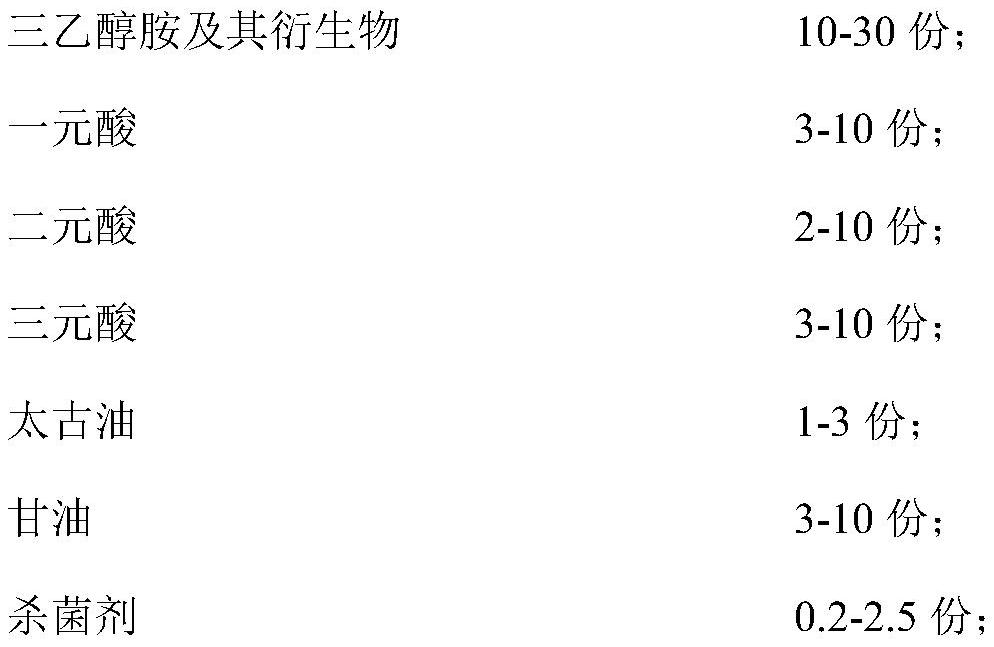

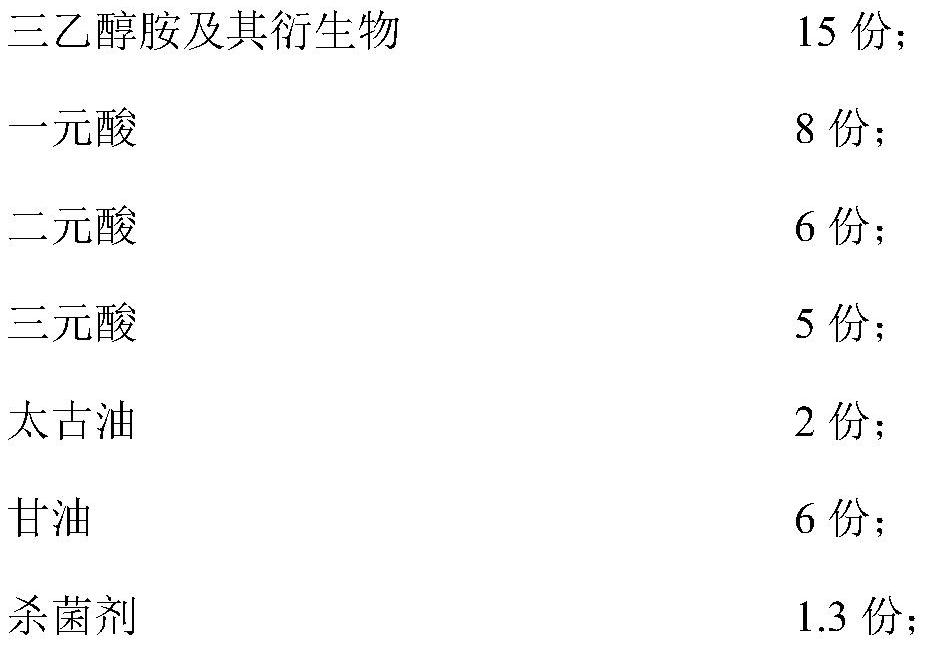

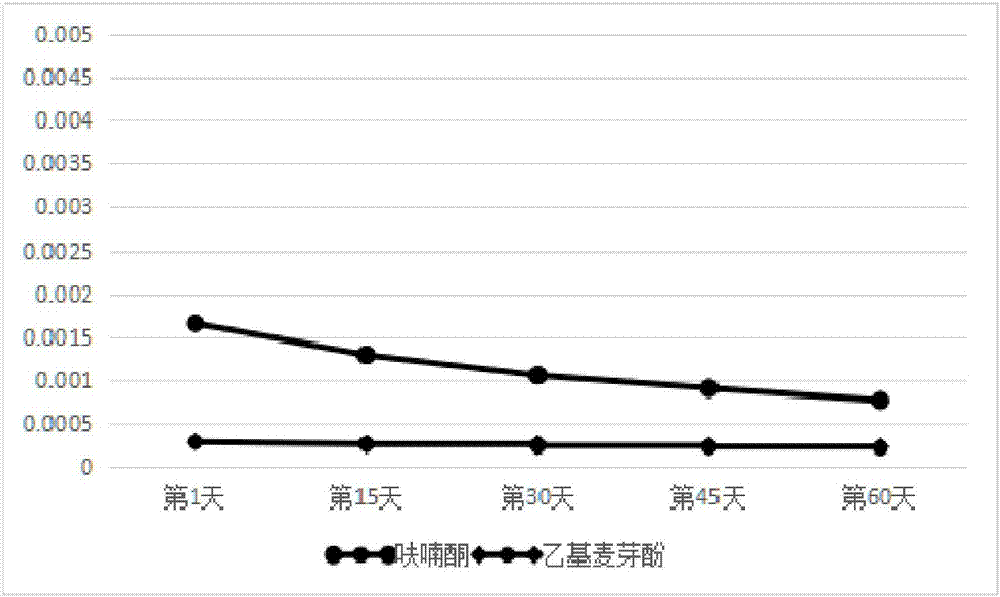

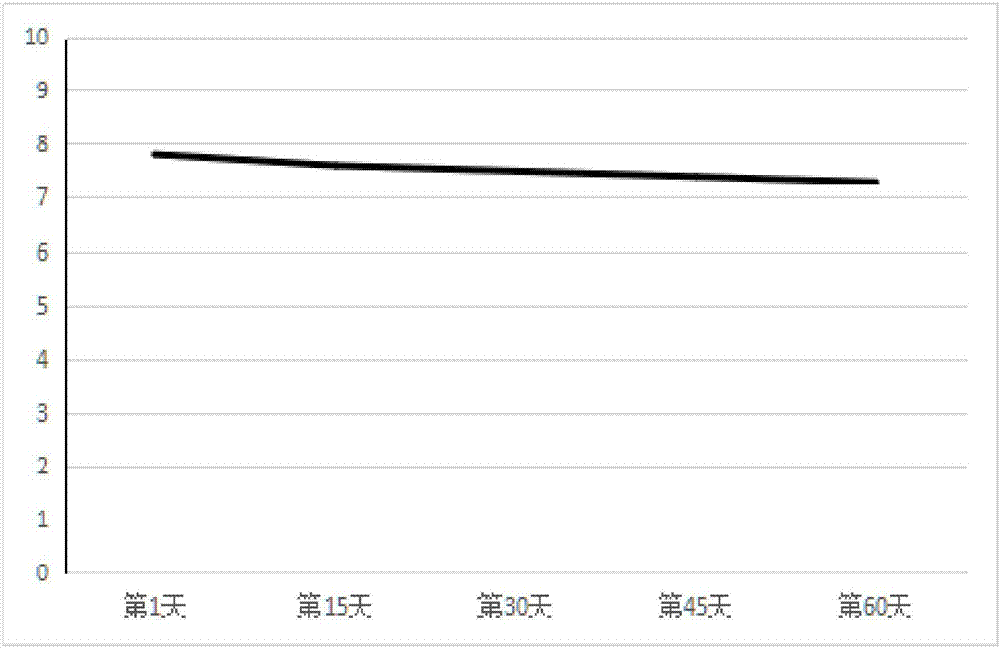

Preparation process of a fully synthetic cutting fluid with high lubricity and high temperature resistance

The present invention provides a high-lubricity, high-temperature-resistant fully synthetic cutting fluid preparation process. The preparation method is as follows: S01, add the raw material triethanolamine and its derivatives into water, start stirring and heating, stir evenly, and heat; S02 Add raw materials monobasic acid and dibasic acid in sequence, and stir until completely dissolved; S03, add raw material sage oil and tribasic acid in sequence, and stir until completely dissolved; S04, add raw material glycerin and fungicide, and stir until uniform and transparent; S05 Properly cool to After room temperature, the material can be discharged.

Owner:宇龙精机科技(浙江)有限公司

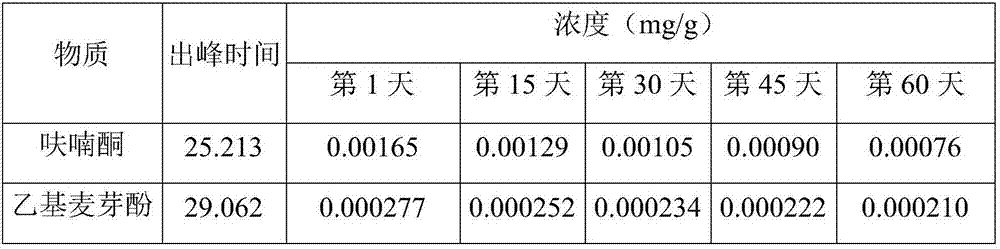

Perfuming method for cigarette case paper

InactiveCN107034733APleasant aromaNo water stainsPaper/cardboardPulp material addition processesEngineeringRaw material

The invention discloses a perfuming method for cigarette case paper. The perfuming method for cigarette case paper is characterized by comprising the following steps: preparing an essence capsule solution by using essence and hydroxypropyl-beta-cyclodextrin as raw materials; and then dispersing the essence capsule solution into gloss oil, and uniformly coating the cigarette case paper with the gloss oil to finish perfuming of the cigarette case paper. The cigarette case paper perfumed by the method has pleasant perfume, and perfume holding time is long.

Owner:CHINA TOBACCO ANHUI IND CO LTD +1

Manufacture process for inner layer rubber calendaring sheet of shock-insulation rubber supporting base

Owner:YUNNAN QUAKESAFE SEISMIC ISOLATION TECH

Filtering device and filtering method

PendingCN112791471AReduce pollutionNo oil stainsStationary filtering element filtersProcess engineeringMechanical engineering

The invention discloses a filtering device and a filtering method.The filtering device comprises a filter screen assembly, a cleaning assembly and a pushing assembly, the filter screen assembly comprises a filter screen, the cleaning assembly comprises a spray-washing part, and a water spraying opening of the spray-washing part faces the filter screen; the pushing assembly comprises a guide rail and an air cylinder arranged on the guide rail, the guide rail is arranged on the filter screen, the air cylinder is arranged on the spray-washing part, and the air cylinder moves along the guide rail to drive the spray-washing part to move on the surface of the filter screen. According to the technical scheme, use of oil stains can be reduced in the cleaning process, and water pollution is reduced.

Owner:云南翰能环保科技有限公司

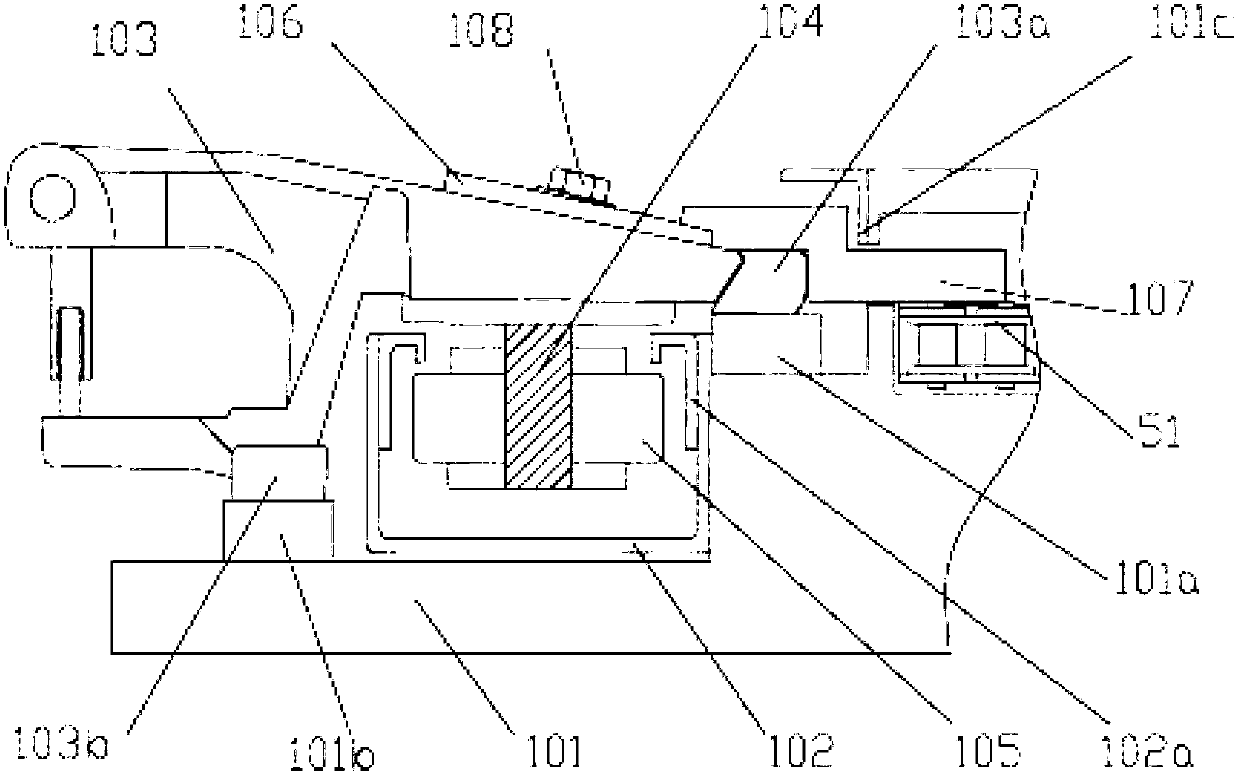

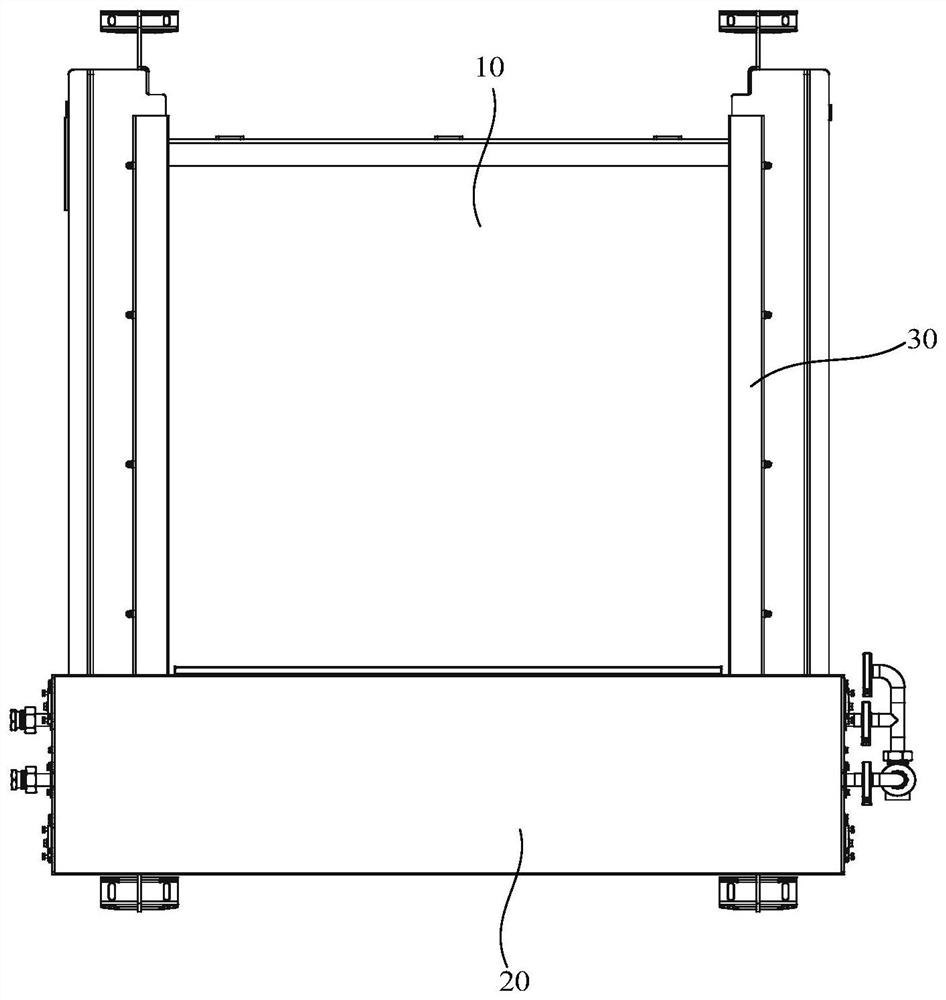

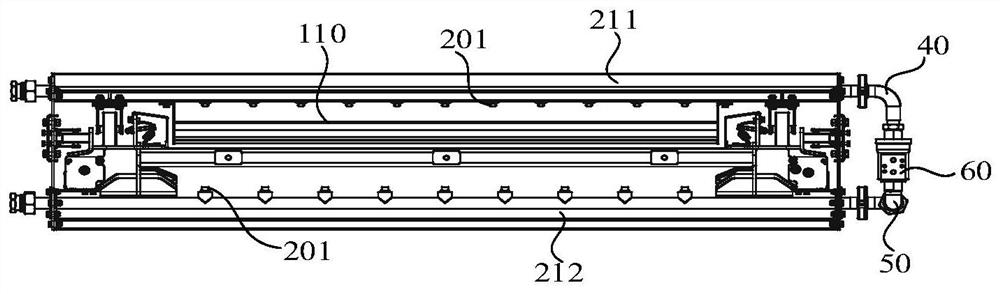

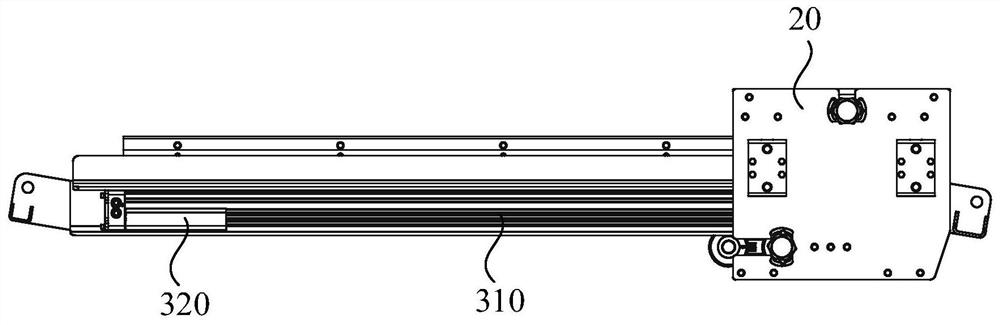

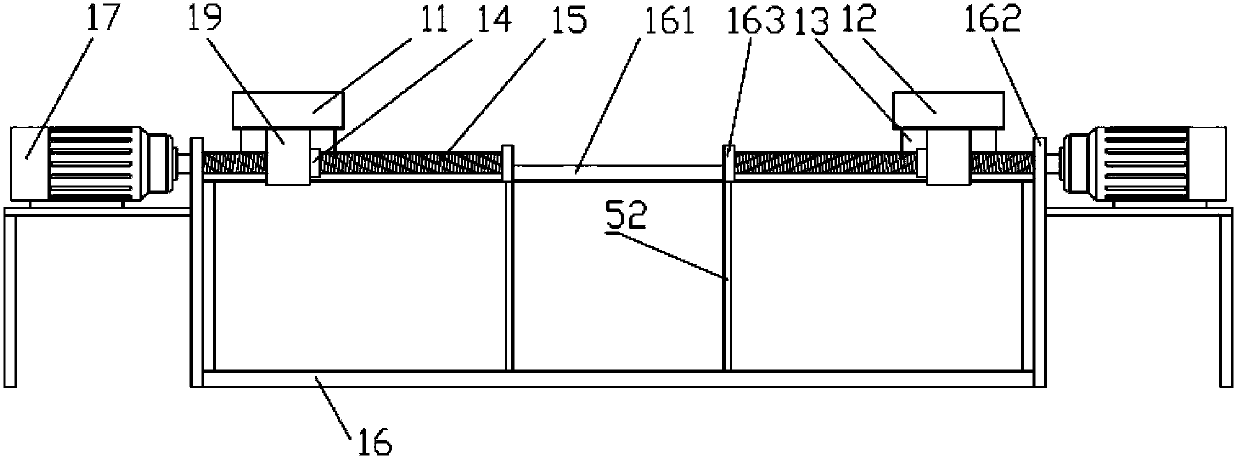

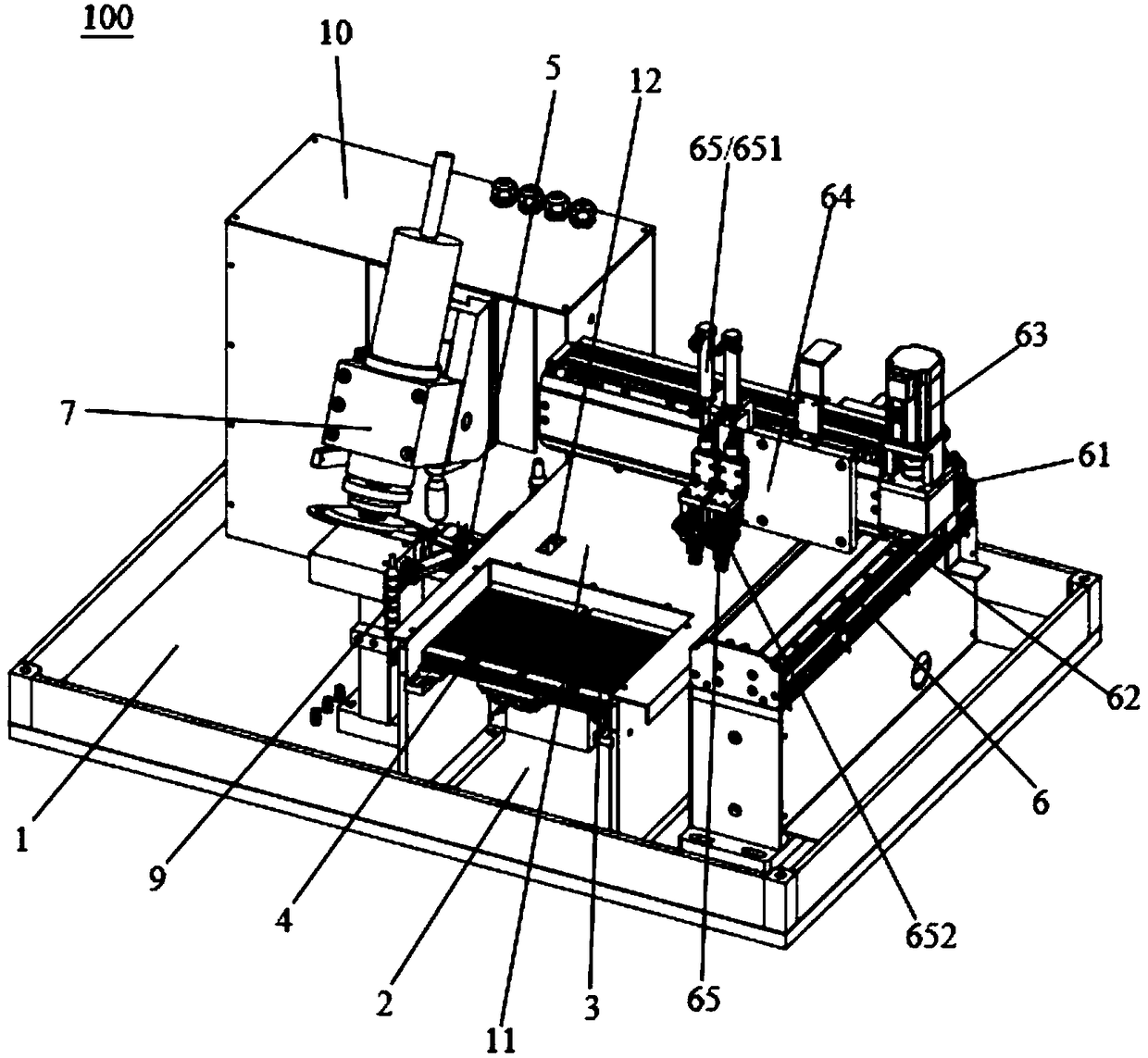

Continuous fiber impregnation system

The invention discloses a continuous fiber impregnation system. The continuous fiber impregnation system is characterized by comprising a glue storing tank, a gradient draft tube, an impregnation tank, a recovery tank, a vacuum pump and a fiber spreading impregnation transmission system, wherein the lower part of the glue storing tank is communicated with the impregnation tank through the gradient draft tube, the recovery tank is arranged below the impregnation tank, the fiber spreading impregnation transmission system passes through the impregnation tank and arranged above the recovery tank, the bottom of the recovery tank is communicated with the glue storing tank through a return pipe, the glue storing tank is communicated with the vacuum pump through a vacuum tube, the glue storing tank, the gradient draft tube and the tank wall of the impregnation tank are all of a double-layer structure, and multiple segments of resistance wires are arranged in the middle part of the double-layer structure. According to the invention, a glue storage zone and an impregnation zone are separated and are connected through pipelines with temperature gradient, and a fiber positioning device, a spreading device, a glue controlling device and a tension force adjusting device are arranged; a redundant glue solution can be recycled. With the system provided by the invention, fibers can be fully impregnated, and the glue solution does not gel in advance.

Owner:TAISHAN SPORTS IND GRP +1

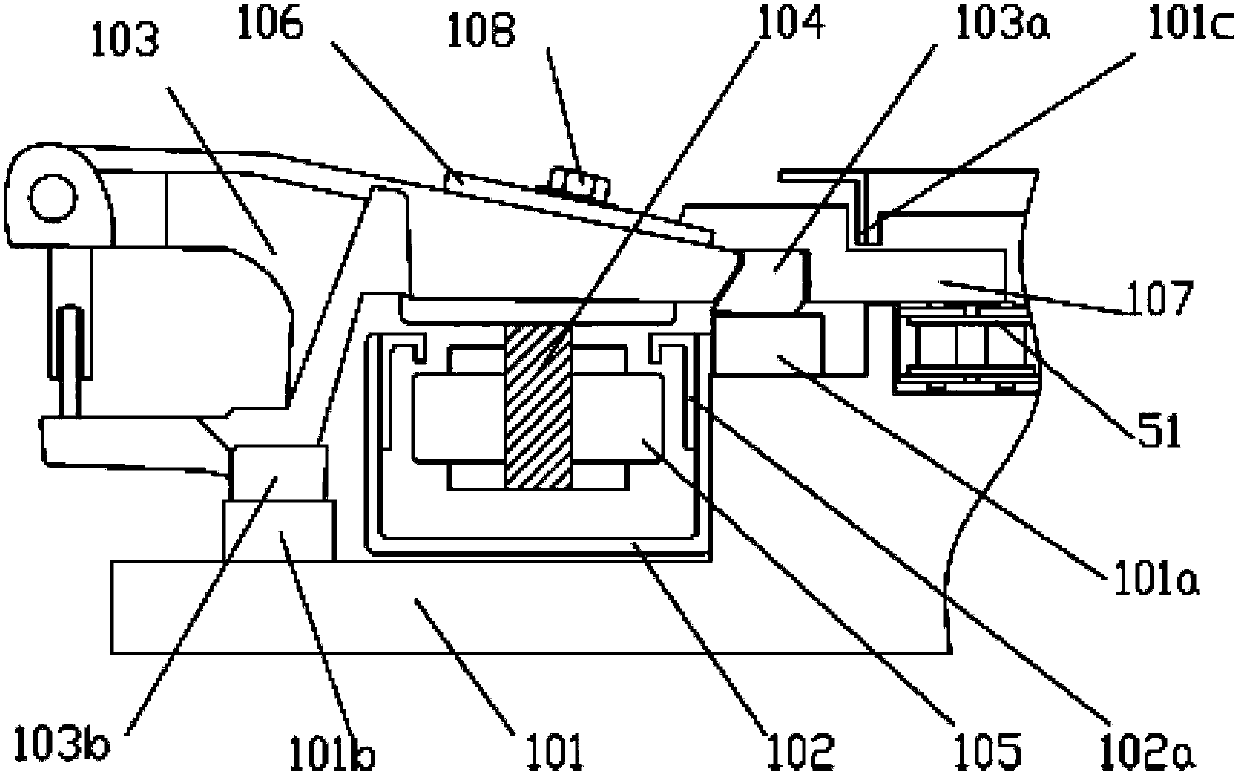

Novel stentering setting machine

InactiveCN102733133BEasy to adjustEnsure the quality of stenter settingStretchingEngineeringGraphite

The invention provides a novel stentering setting machine comprising a guide device, a drawing mechanism, an operation platform and a cropping device, wherein the cropping device is arranged behind the drawing mechanism and the operation platform is placed between the guide device and the drawing mechanism; the drawing mechanism comprises a feeding rail, an oven and a heat exchange device; the feeding rail passes through the oven and the heat exchange device is arranged above the oven; a waste gas outlet pipe of the oven is communicated with a waste gas inlet pipe of the heat exchange device; a hot air outlet pipe of the heat exchange device is communicated with a hot air inlet pipe of the oven; a guide rail adjusting device is additionally arranged between two guide rails, so that the distance between a left guide rail and a right guide rail can be accurately adjusted and each guide rail is respectively adjustable; the novel stentering setting machine is suitable for machining a plurality of types of cloth; meanwhile, cloth tongs slide on graphite and do not generate oil stains; the two connected cloth tongs can be finely adjusted to ensure the stentering setting quality; and an adjustable range of a wrap angle of spreading rolls and a textile is large and the two spreading rolls can be adjusted, so that the spreading effect is good.

Owner:ZHEJIANG RILI INDAL

Flotation machine stator and rotor production device

ActiveCN111570163ARealize automatic cleaningEasy to moveDrying gas arrangementsPretreated surfacesEngineeringMechanical engineering

The invention relates to the technical field of flotation machine stator and rotor production, in particular to a flotation machine stator and rotor production device. The flotation machine stator androtor production device comprises a main device, a cleaning device, a drying device and a spraying device, wherein one end of the main device is fixedly connected with the cleaning device; the dryingdevice is arranged on the right side of the cleaning device; the drying device is fixedly connected with the main device; the spraying device is arranged on the right side of the drying device; and the spraying device is fixedly connected with the main device. In the flotation machine stator and rotor production device, a drying box and the like are arranged, and a rotor and a stator which are cleaned can be dried rapidly through the drying box, so that spraying on the surfaces of the rotor and the stator is facilitated. Through the arrangement of a swivel, limiting rings, compression rings and the like, when nickel-based tungsten carbide powder needs to be sprayed on the surface and the inner wall of the stator, the stator is placed between compression plates, then the stator is driven to rotate by the swivel, and meanwhile a spray head is driven to perform rapid spraying on the surface and the inner wall of the stator by a mechanical arm.

Owner:迁安信润和机械设备有限公司

Brazing furnace hot wall

PendingCN107344259ANo oil stainsAvoid deformationHeating appliancesSoldering auxillary devicesEngineeringMechanical engineering

A brazing furnace hot wall comprises a sealing wall and a feeding inlet. The feeding inlet is formed in the sealing wall. The brazing furnace hot wall is characterized in that a hot wall body is arranged in the sealing wall; the sealing wall comprises a long end sealing wall body and a short end sealing wall body; a fan connector is arranged on the right side of the short end sealing wall body; the feeding inlet is formed in the right side of the long end sealing wall body; a heat insulating door is arranged above the feeding inlet; the hot wall body is arranged in the short end sealing wall body; the fan connector is arranged under the hot wall body; a grid-shaped feeding structure is arranged in the feeding inlet; reinforcing bars are arranged between the sealing wall and the hot wall body; and a material passing port is formed in the reinforcing bars. The brazing furnace hot wall can effectively remove oil stains on the surface of a workpiece and help the workpiece to be preheated, the cost is reduced, and the production efficiency is improved.

Owner:托普工业(江苏)有限公司

Fabrics having soil resistance and no oil stains after wiping and manufacturing method thereof

ActiveUS8349748B2Eliminate disadvantagesPrevent penetrationFibre treatmentSynthetic resin layered productsEngineeringSoil resistance

The present invention provides a fabric having soil resistance and no oil stains after wiping and a manufacturing method thereof. The fabric of the present invention comprises an underlayer and a soil-resistant protection film, which can effectively prevent oil corrosion, penetration, and permeation of the surface of the fabric, thus resulting in no oil stains after wiping. The manufacturing method of the present invention comprises the steps of dyeing, setting, performing an underlayer surface treatment to form an underlayer on a surface of the fabric, and performing a soil resistance processing treatment to form a soil-resistant protection film on the surface of the underlayer.

Owner:FORMOSA TAFFETA CO LTD

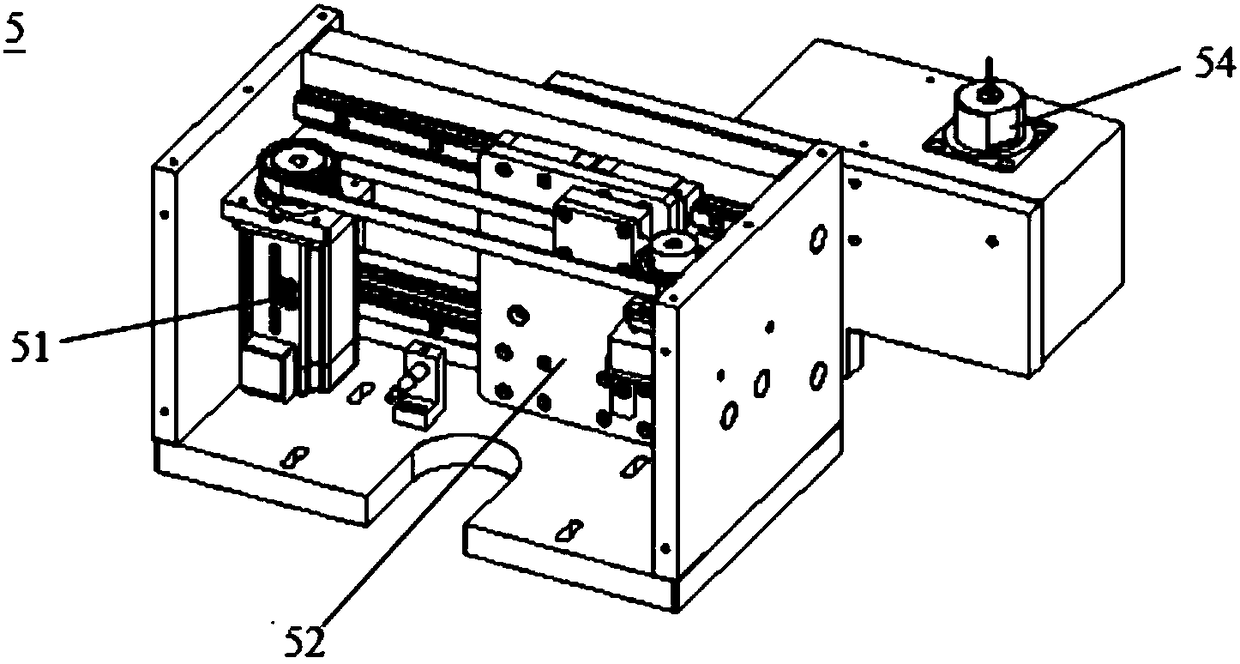

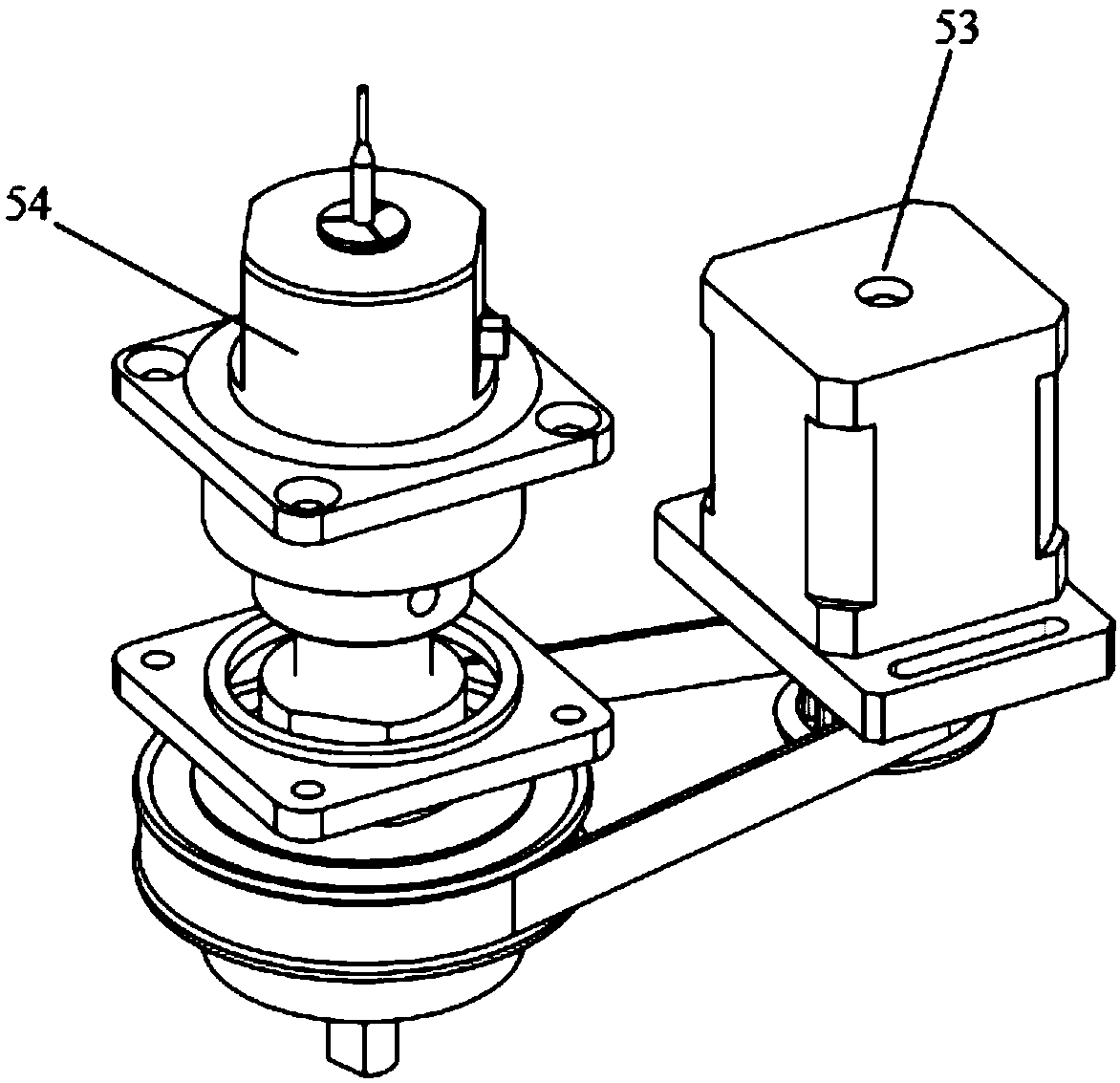

Full-automatic milling cutter fish-tail cutter

PendingCN108377613AIncrease productivityImprove versatilityInsulating layers/substrates workingEngineeringMilling cutter

The invention discloses a full-automatic milling cutter fish-tail cutter which comprises a cutting region, a loading and unloading region and a partition plate used for isolating the loading and unloading region and the cutting region; the loading and unloading region comprises a loading disc and a receiving disc which are arranged in parallel, a cutter transfer rotation unit used for driving a cutter to move back and forth between the cutting region and the loading and unloading region and a cutter grabbing mechanism used for realizing automatic loading and automatic unloading of the cutter;and the cutting region comprises a sand wheel cutting component and a first drive piece used for driving the sand wheel cutting component to move along an Y axis or a Z axis. The full-automatic milling cutter fish-tail cutter provided by the invention can realize automatic loading, automatic cutting and automatic unloading and optimizes the processing environment as the cutting blade cutting region is separated from the loading and unloading region.

Owner:KUNSHAN YISHITENG ALLOY TOOL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com