Full-automatic milling cutter fish-tail cutter

A cutting machine, fully automatic technology, used in electrical components, insulating substrate/layer processing, printed circuit manufacturing, etc. Service life, increased productivity, clean tool surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

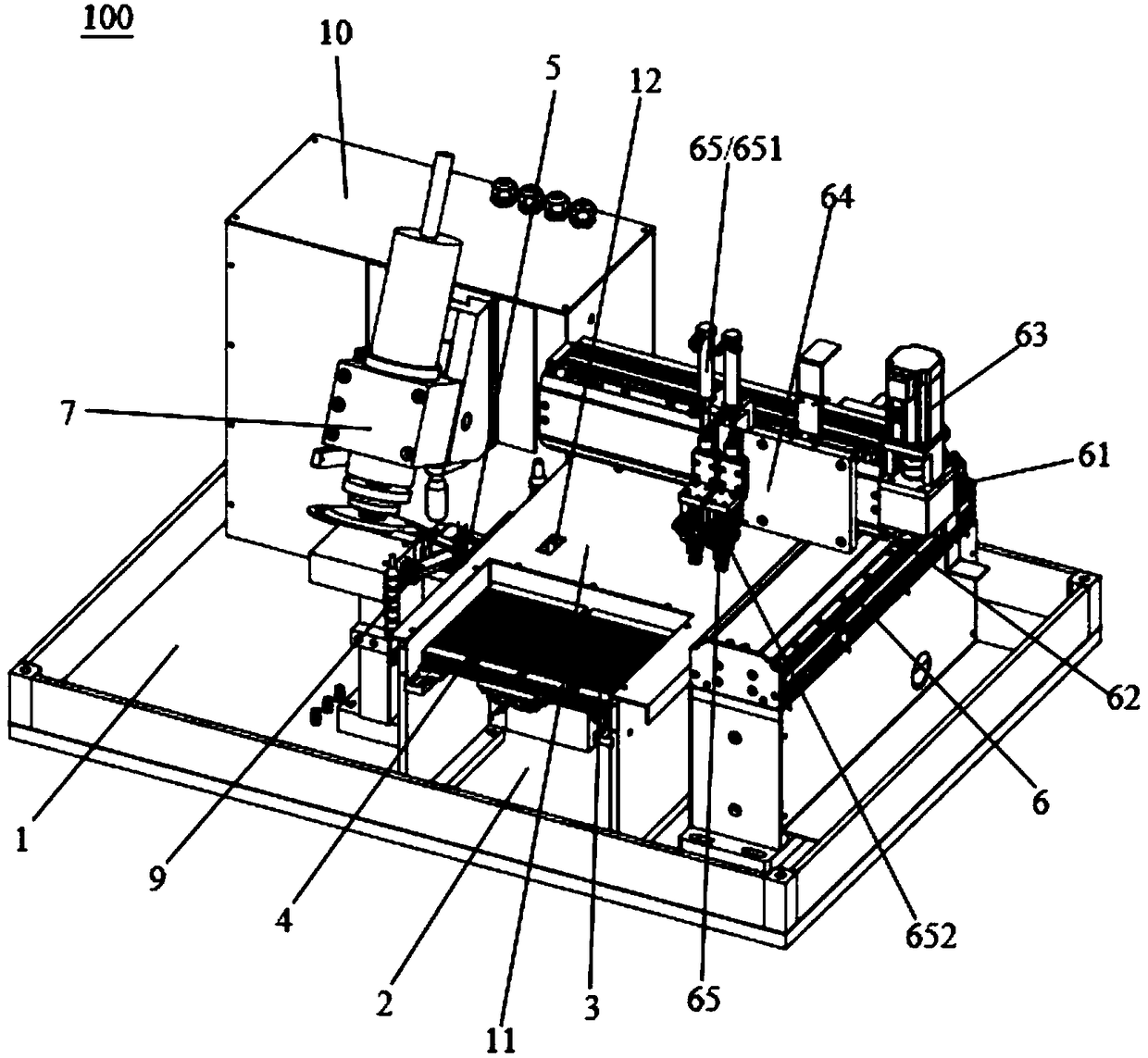

[0025] Please refer to Figure 1-Figure 7 , the present embodiment is a fully automatic milling cutter fishtail cutting machine 100, which includes a cutting area 1, a loading and unloading area 2, and a partition (not marked) that isolates the loading and unloading area and the cutting area, and the loading and unloading area 2 includes side-by-side The set loading tray 3 and receiving tray 4, the tool transfer and rotation unit 5 that drives the tool to move back and forth between the cutting area 1 and the loading and unloading area 2, and the tool grabbing mechanism 6 that realizes automatic loading and unloading of the tool , the cutting zone 1 includes a grinding wheel cutting assembly 7 and a first driving member 8 that drives the grinding wheel cutting assembly 7 to move along the Y axis or along the Z axis.

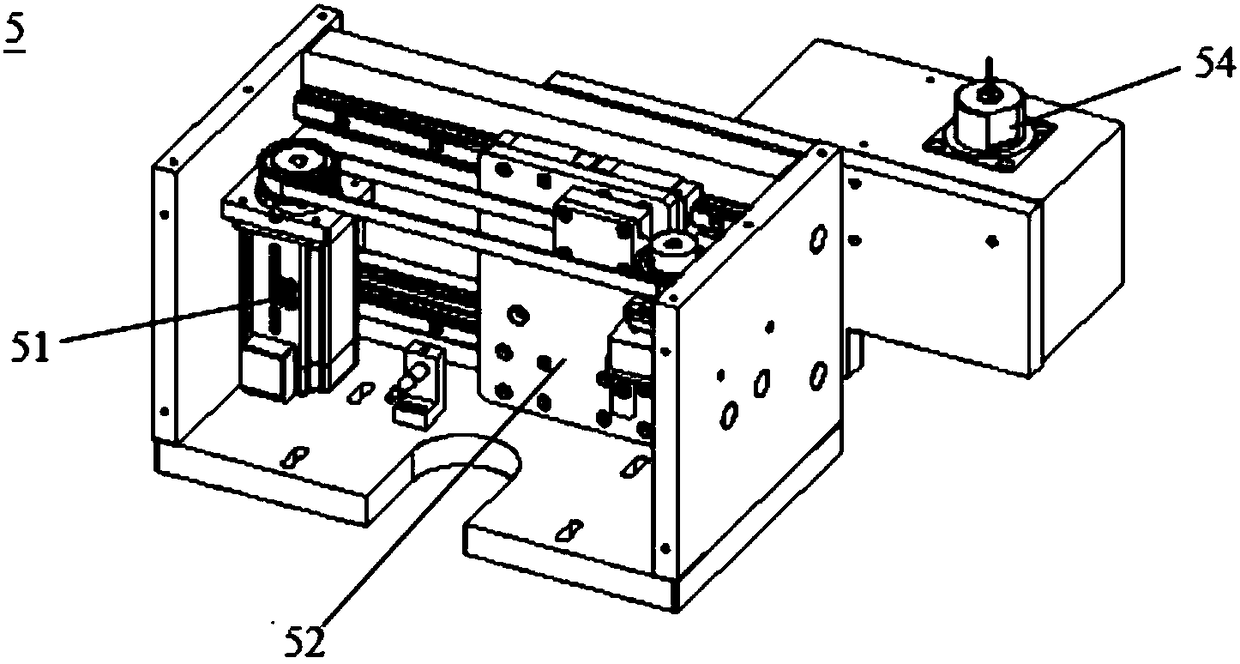

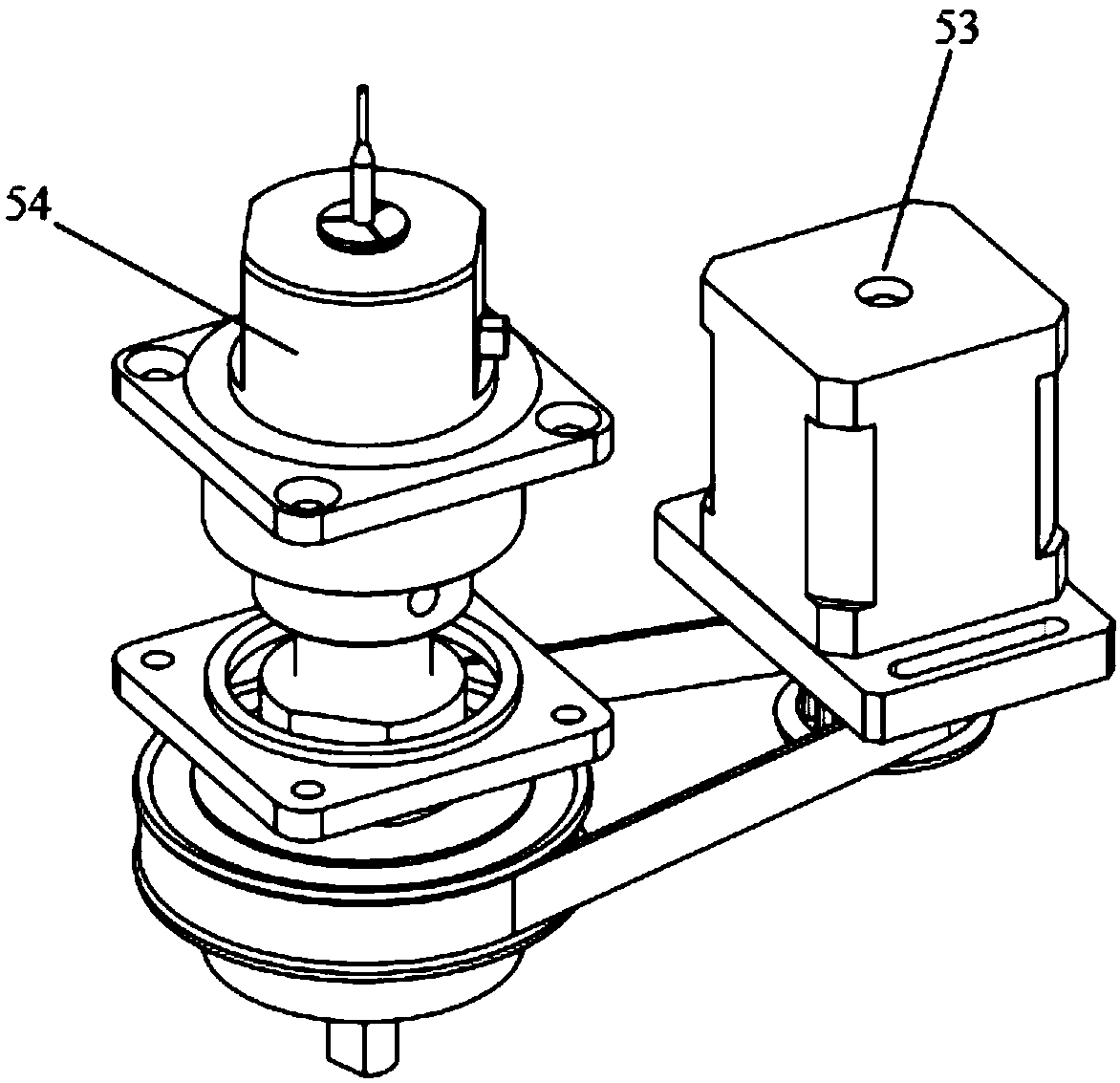

[0026] The tool carrying unit 5 includes a second driving member 51, a first connecting plate 52 driven by the second driving member 51 to move along the Y axis,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com