Brazing furnace hot wall

A furnace wall and brazing technology, applied in welding equipment, electric heating devices, auxiliary devices, etc., can solve problems such as affecting the brazing process, stubborn grease, etc., and achieve the effect of adapting to long-term use, preventing deformation, and saving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

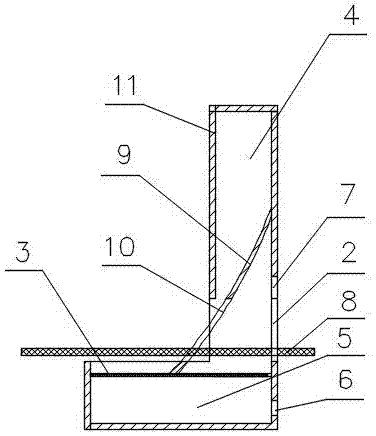

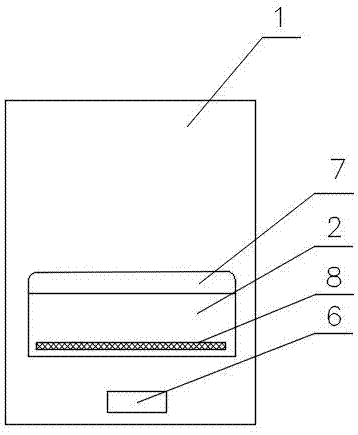

[0013] Below in conjunction with accompanying drawing, the present invention will be further described, but not as limitation of the present invention: a kind of brazing furnace fire wall, comprises sealing wall 1 and charging port 2, and described sealing wall 1 is provided with charging port 2; It is characterized in that: a firewall 3 is arranged inside the sealing wall 1, a reinforcing rib 9 is arranged between the sealing wall 1 and the firewall, and the sealing wall 1 includes a long-end sealing wall 4 and a short-end sealing wall 5; The right wall of the short-end sealing wall 5 is provided with a fan interface 6, the right wall of the long-end sealing wall 5 is provided with a feed port 2, and the upper part of the feed port 2 is provided There is an insulating door 7; a fire wall 3 is arranged inside the short-end sealing wall 5, and the fan interface 6 is arranged directly below the fire wall 3; a grid-like feeding structure 8 is arranged inside the feed inlet 2, The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com