Patents

Literature

86results about How to "Will not affect processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Equipment and method of correcting and coding for transmission information

InactiveCN101001127AWill not affect processingImprove reliabilityError preventionUser deviceDependability

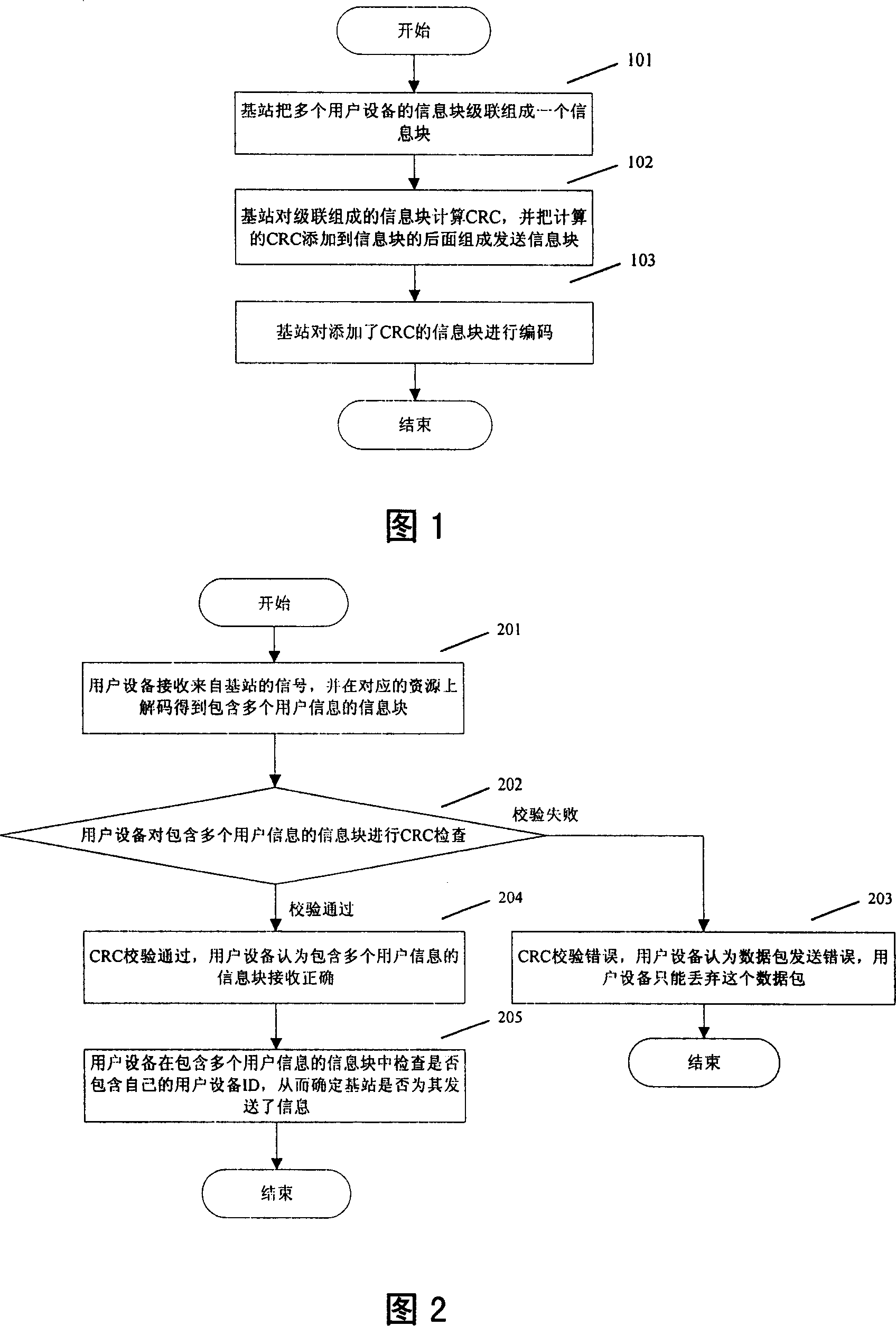

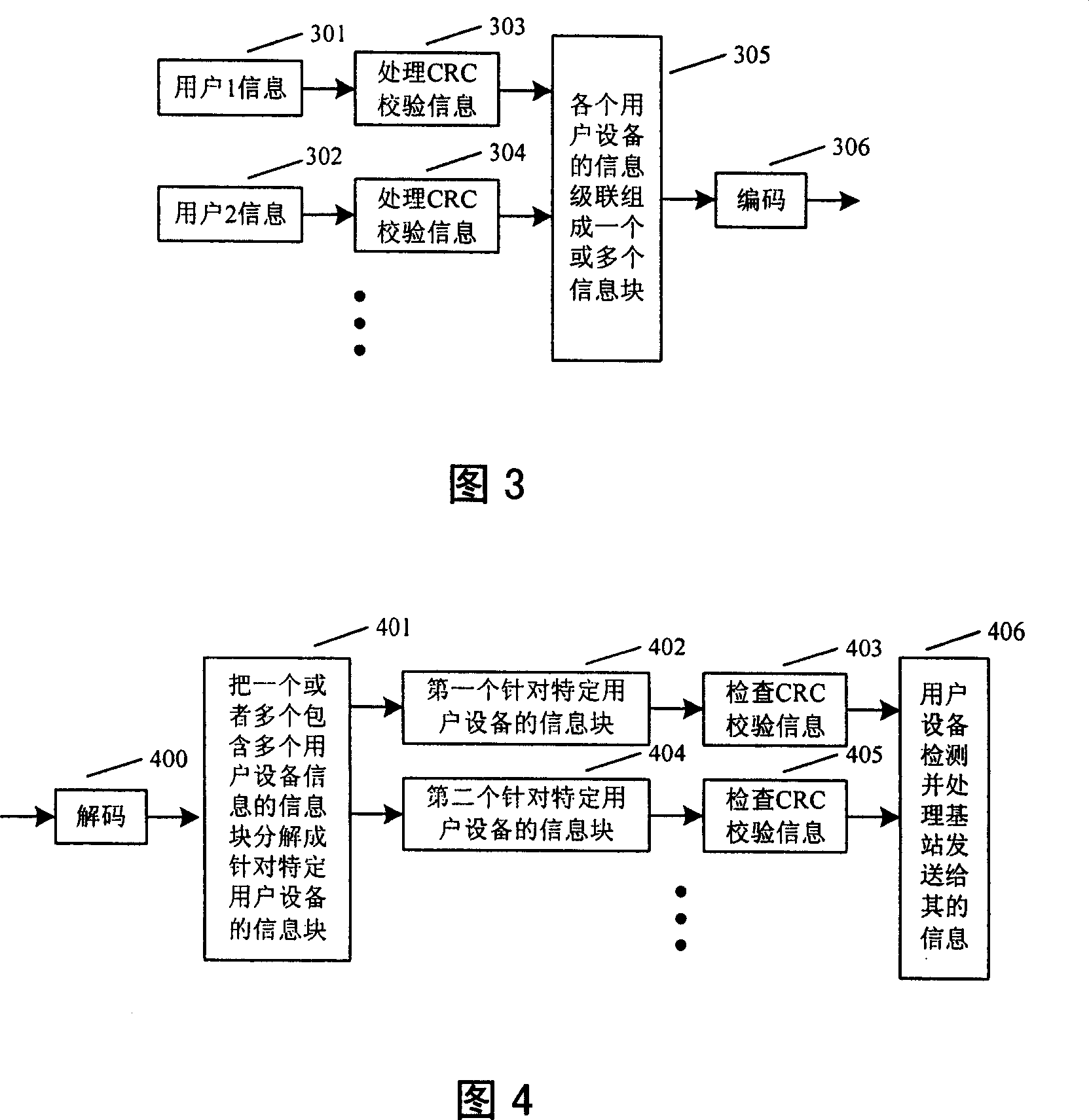

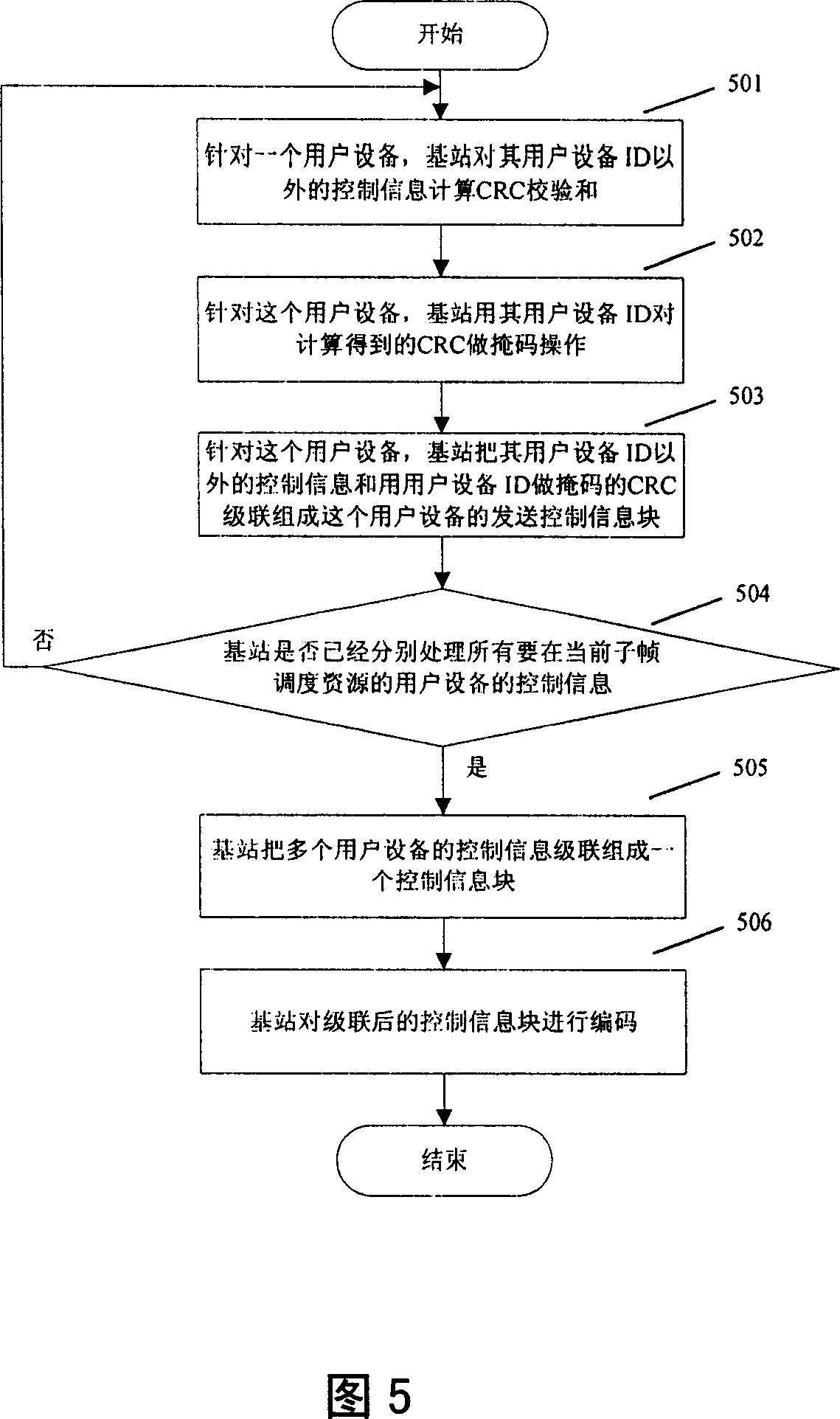

This invention relates to a method for carrying out CRC check and coding process to transmitted information by a base station including: a base station processes CRC check information to the information of each user device and cascades the information blocks got from processing the user devices to form one or multiple information blocks to be coded. When the base station collects information of the multiple user devices in an information block and codes, it adds CRC to the specific information of each device and when the device receives information, it checks CRC to the information block of specific user devices only but not needs to check CRC to the blocks containing multiple user device informarion, if any one in which is faulty, it will not influence the process to specific informationblocks so as to increase the transfer of information.

Owner:BEIJING SAMSUNG TELECOM R&D CENT +1

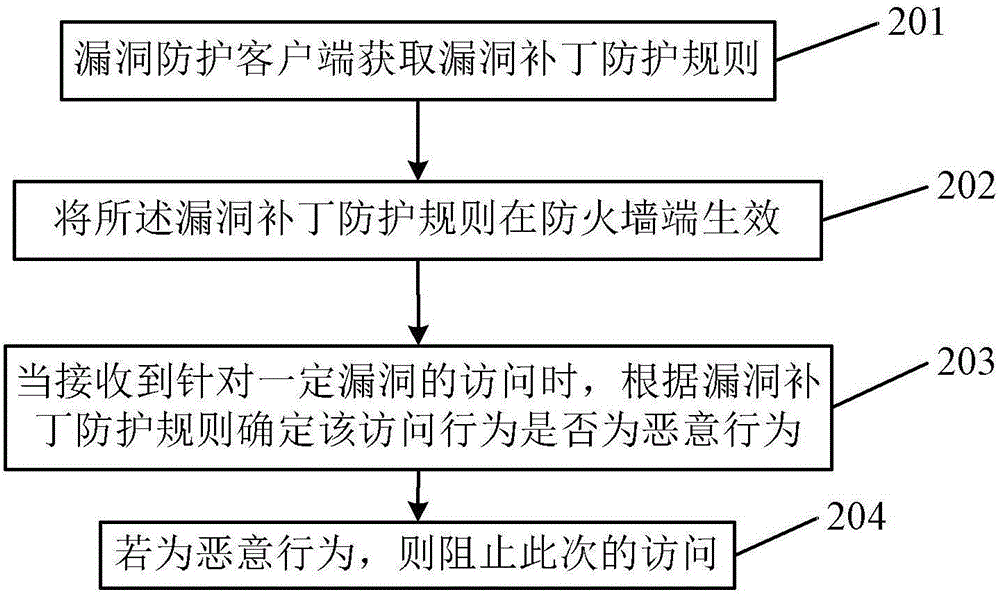

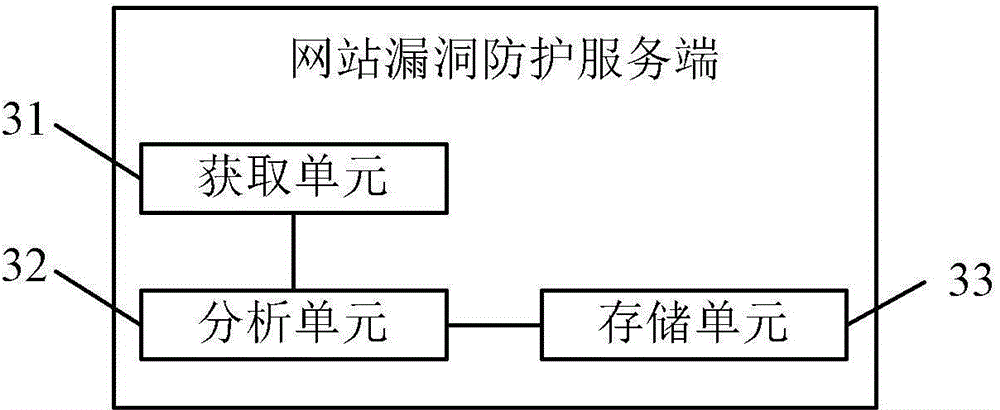

Website bug protection method, device and system

InactiveCN104468563AAchieve protectionWill not affect processingPlatform integrity maintainanceTransmissionSource codeVulnerability

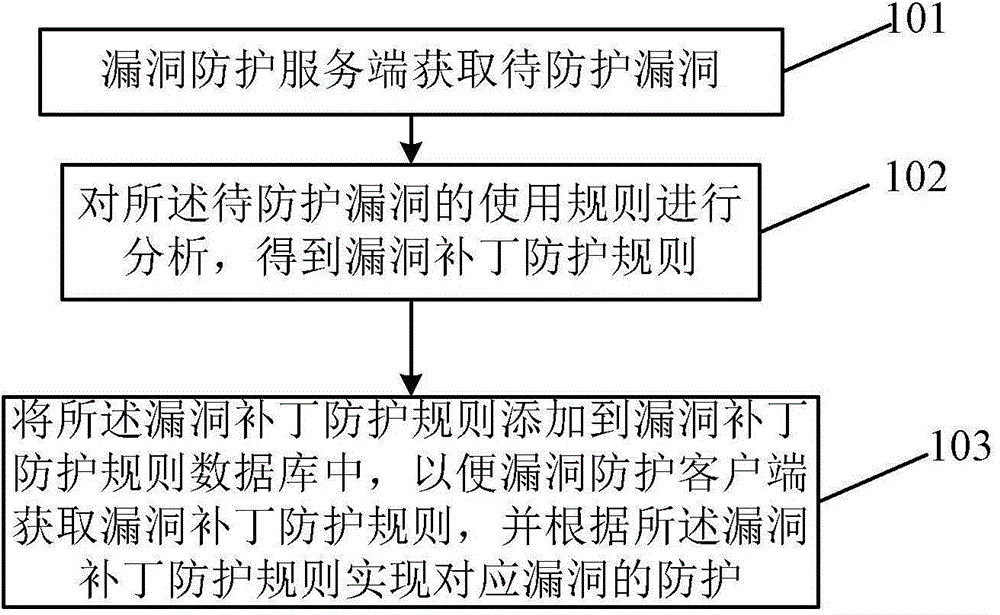

The invention discloses a website bug protection method, device and system, and relates to the technical field of information safety. The main purpose is that a website bug can be protected from being attacked in time on the premise that a program source code is not changed. According to the main technical scheme, a bug protection server end acquires the bug to be protected; the using rule of the bug to be protected is analyzed to obtain a bug patch protection rule; the bug patch protection rule is added into a bug patch protection rule database; a bug protection client end acquires the bug patch protection rule, and the bug patch protection rule is a bug using rule; the bug patch protection rule takes effect at a firewall end; when an access special to certain bugs is received, whether the access behavior is a malicious behavior or not is determined according to the bug patch protection rule; if the access behavior is the malicious behavior, the access is stopped. The website bug protection method, device and system are mainly used in the process of website bug protection.

Owner:BEIJING QIANXIN TECH

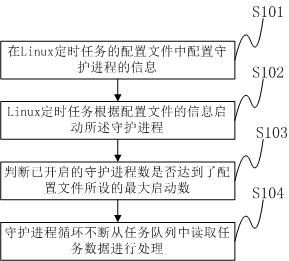

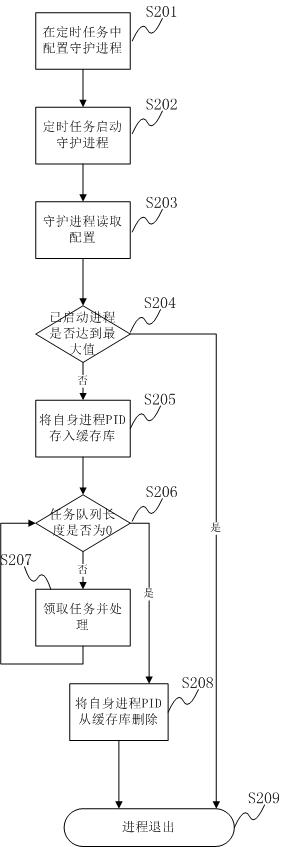

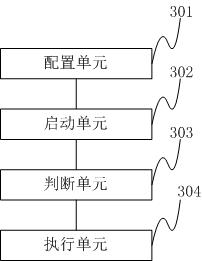

Method and system for realizing daemon process based on Linux timing task

ActiveCN102331950AStrong computing powerIncrease flexibilityMultiprogramming arrangementsGNU/LinuxComputer science

The invention discloses a method for realizing a daemon process based on a Linux timing task. The method comprises the following steps: configuring information of the daemon process in a configuration file of the Linux timing task; starting the daemon process by the Linux timing task according to the information of the configuration file; reading the information of the configuration file and judging if the number of the started daemon process reaches the maximum starting number set by the configuration file; checking the state of a task queue, and if the length of the task queue is more than 0, circularly and continuously reading and processing task data from the task queue by the daemon process. The daemon process provided by the invention dose not reside in the system permanently, dose not occupy system resources all the time and is started by a timing task, and enough processes can be started reasonably according to a task volume to process a to-be-processed task.

Owner:BEIJING ANTIY NETWORK SAFETY TECH CO LTD

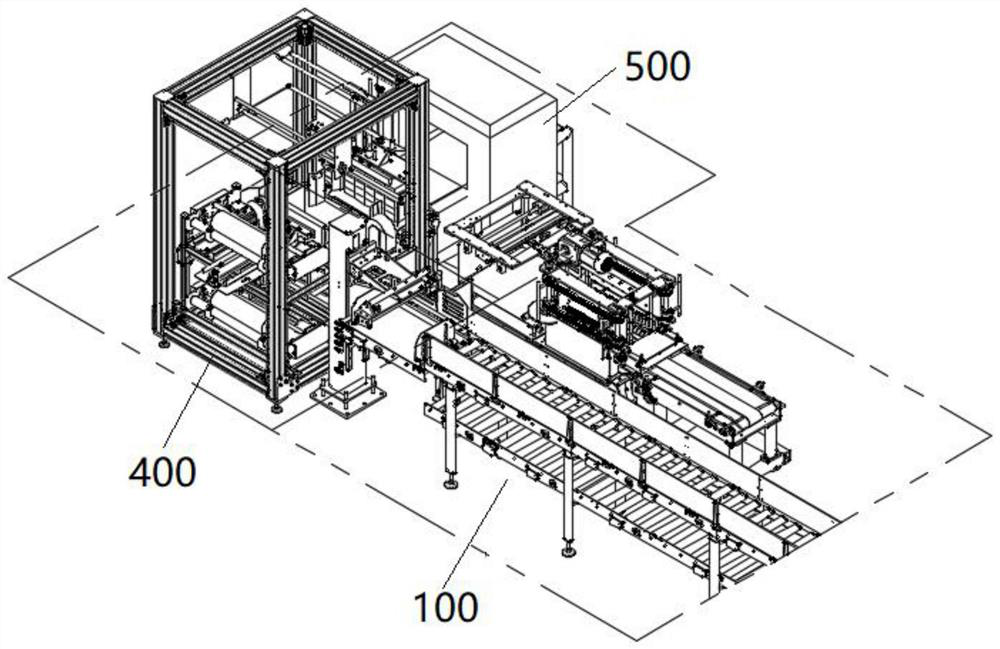

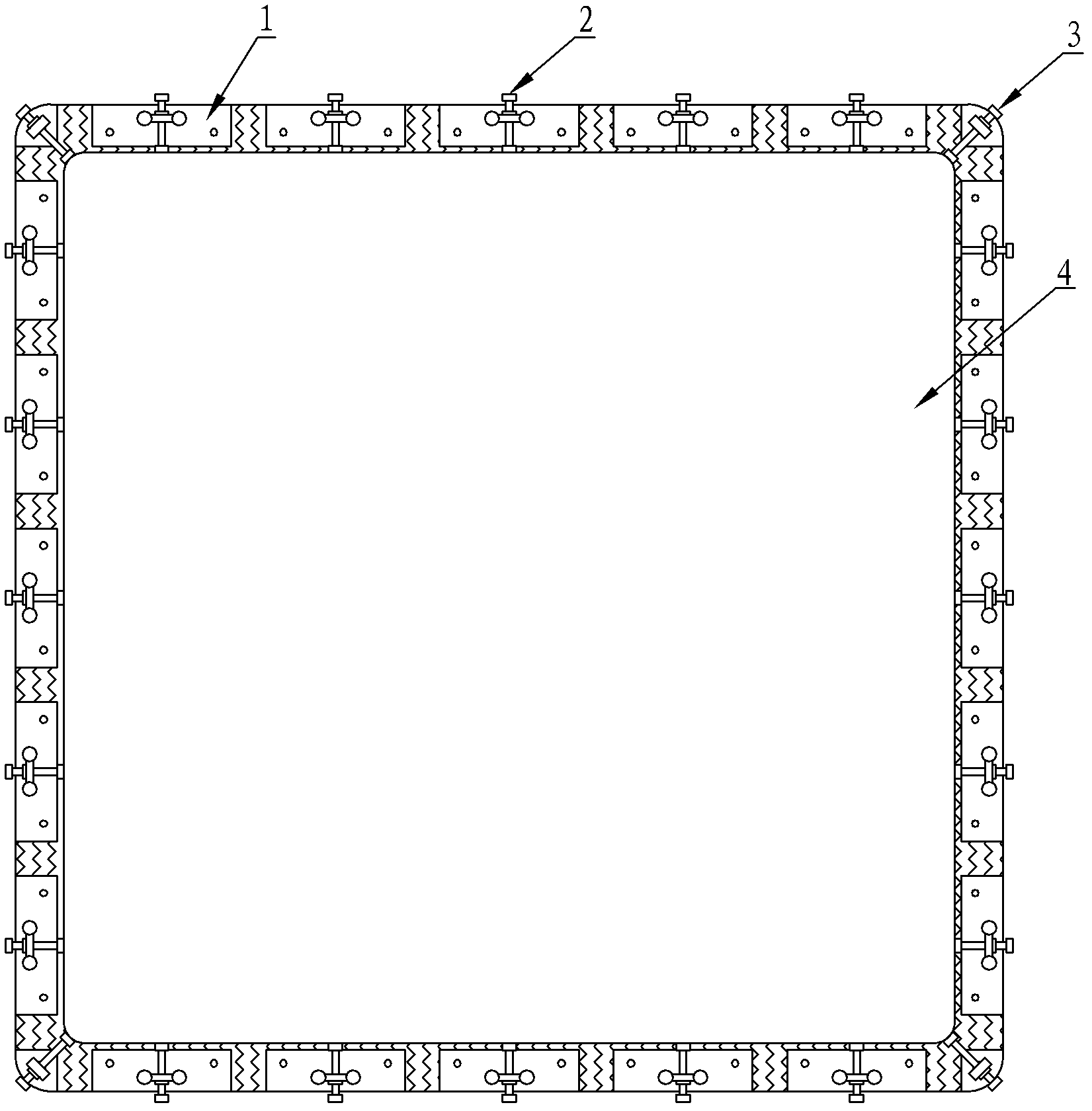

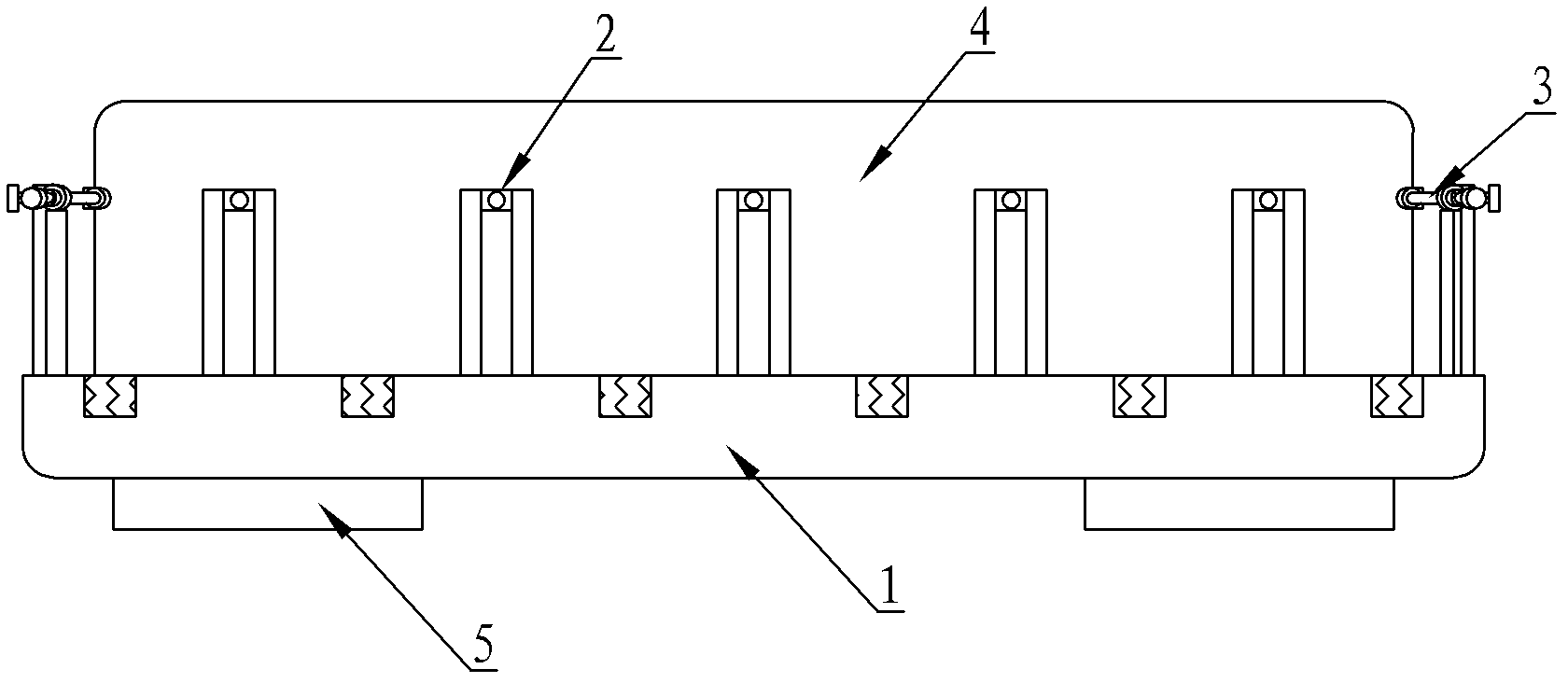

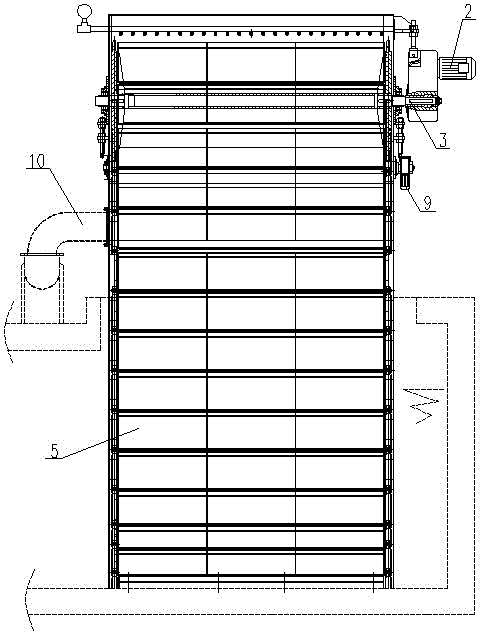

Novel stentering setting machine

InactiveCN102733133AEasy to adjustEnsure the quality of stenter settingStretchingGraphiteMechanical engineering

The invention provides a novel stentering setting machine comprising a guide device, a drawing mechanism, an operation platform and a cropping device, wherein the cropping device is arranged behind the drawing mechanism and the operation platform is placed between the guide device and the drawing mechanism; the drawing mechanism comprises a feeding rail, an oven and a heat exchange device; the feeding rail passes through the oven and the heat exchange device is arranged above the oven; a waste gas outlet pipe of the oven is communicated with a waste gas inlet pipe of the heat exchange device; a hot air outlet pipe of the heat exchange device is communicated with a hot air inlet pipe of the oven; a guide rail adjusting device is additionally arranged between two guide rails, so that the distance between a left guide rail and a right guide rail can be accurately adjusted and each guide rail is respectively adjustable; the novel stentering setting machine is suitable for machining a plurality of types of cloth; meanwhile, cloth tongs slide on graphite and do not generate oil stains; the two connected cloth tongs can be finely adjusted to ensure the stentering setting quality; and an adjustable range of a wrap angle of spreading rolls and a textile is large and the two spreading rolls can be adjusted, so that the spreading effect is good.

Owner:ZHEJIANG RILI INDAL

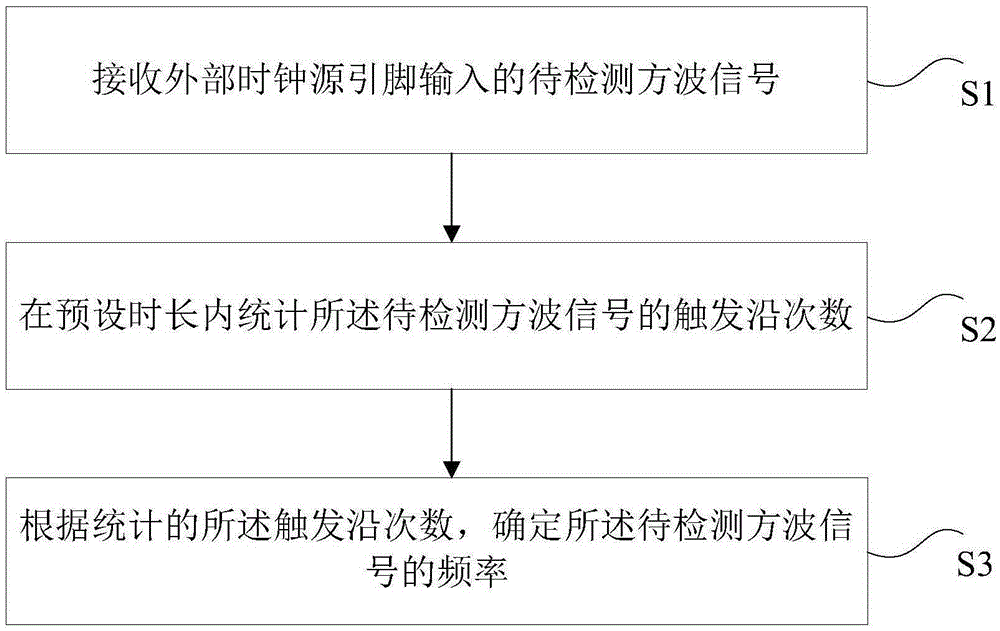

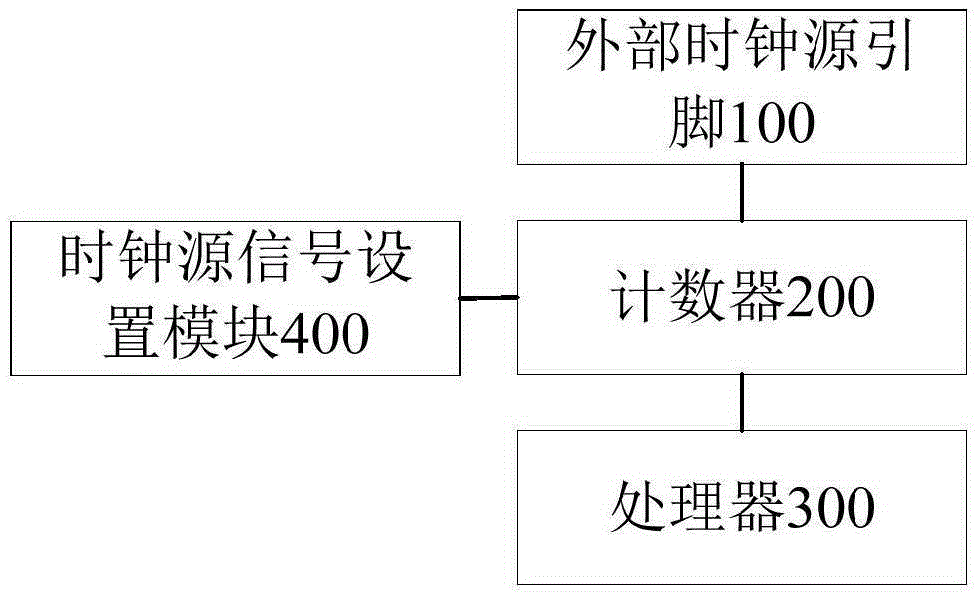

Method and device for detecting signal frequency

ActiveCN105353212AIncrease speedReduce the burden onFrequency to pulse train conversionVIT signalsSquare wave

The invention provides a method and device for detecting signal frequency, and the method comprises the steps: receiving a to-be-detected square wave signal inputted by an external clock source pin; counting the trigger edge number of the to-be-detected square wave signal in a preset time duration; and determining the frequency of the to-be-detected square wave signal according to the trigger edge number. The method and device can detect the frequency of the to-be-detected square wave under the condition of not affecting the operation of other programs.

Owner:GREE ELECTRIC APPLIANCES INC

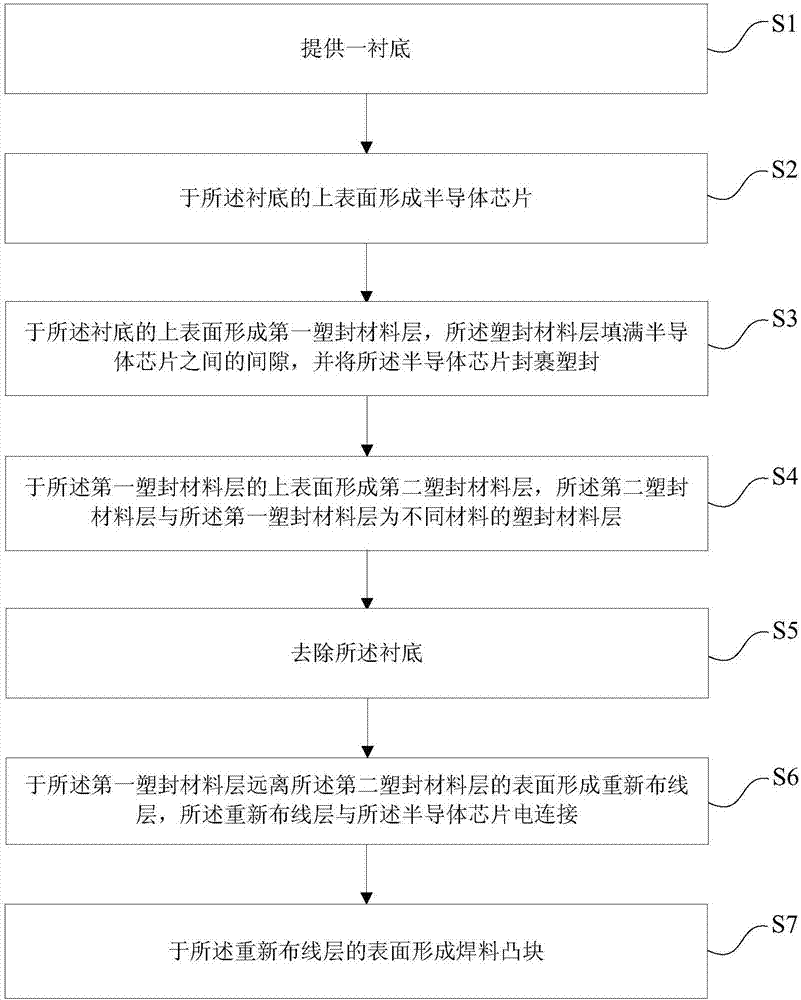

Fan-out package structure and preparation method thereof

InactiveCN107301983AAvoid warpingAvoid breakingSemiconductor/solid-state device detailsSolid-state devicesRedistribution layerEngineering

The invention provides a fan-out packaging structure and a preparation method thereof. The fan-out packaging structure includes: a rewiring layer; a semiconductor chip located on the first surface of the rewiring layer; a first plastic packaging material layer located on the rewiring layer the first surface of the first plastic encapsulation material layer, located on the surface of the first plastic encapsulation material layer away from the rewiring layer; solder bumps, located on the second surface of the rewiring layer. The fan-out packaging structure of the present invention can effectively release the thermal stress caused by thermal expansion or contraction by forming two layers of plastic packaging material layers of different materials, thereby effectively avoiding the warping of the fan-out packaging structure and further avoiding its internal The cracking of the semiconductor chip will not affect the processing of the fan-out packaging structure in the subsequent process.

Owner:SJ SEMICON JIANGYIN CORP

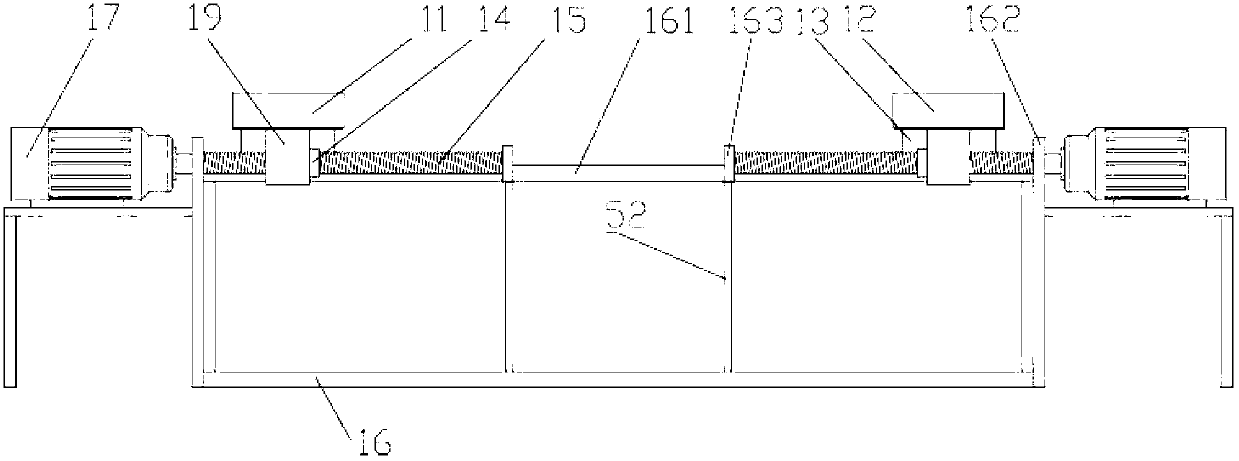

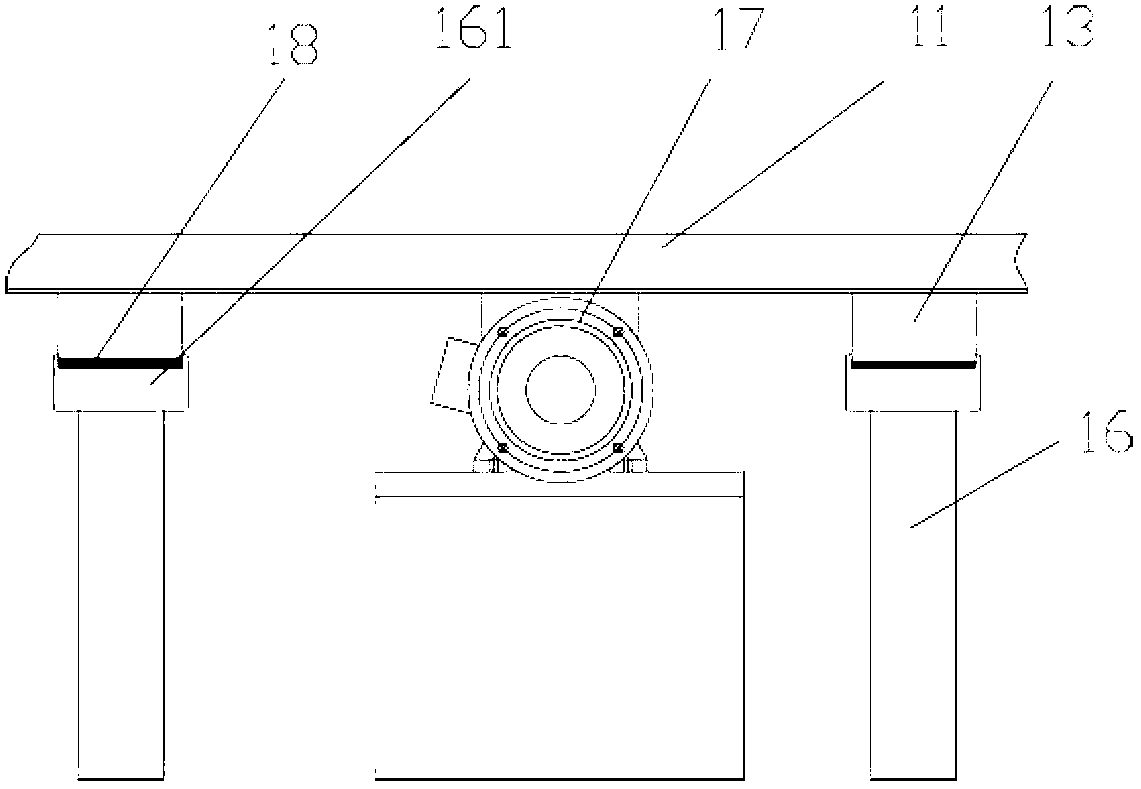

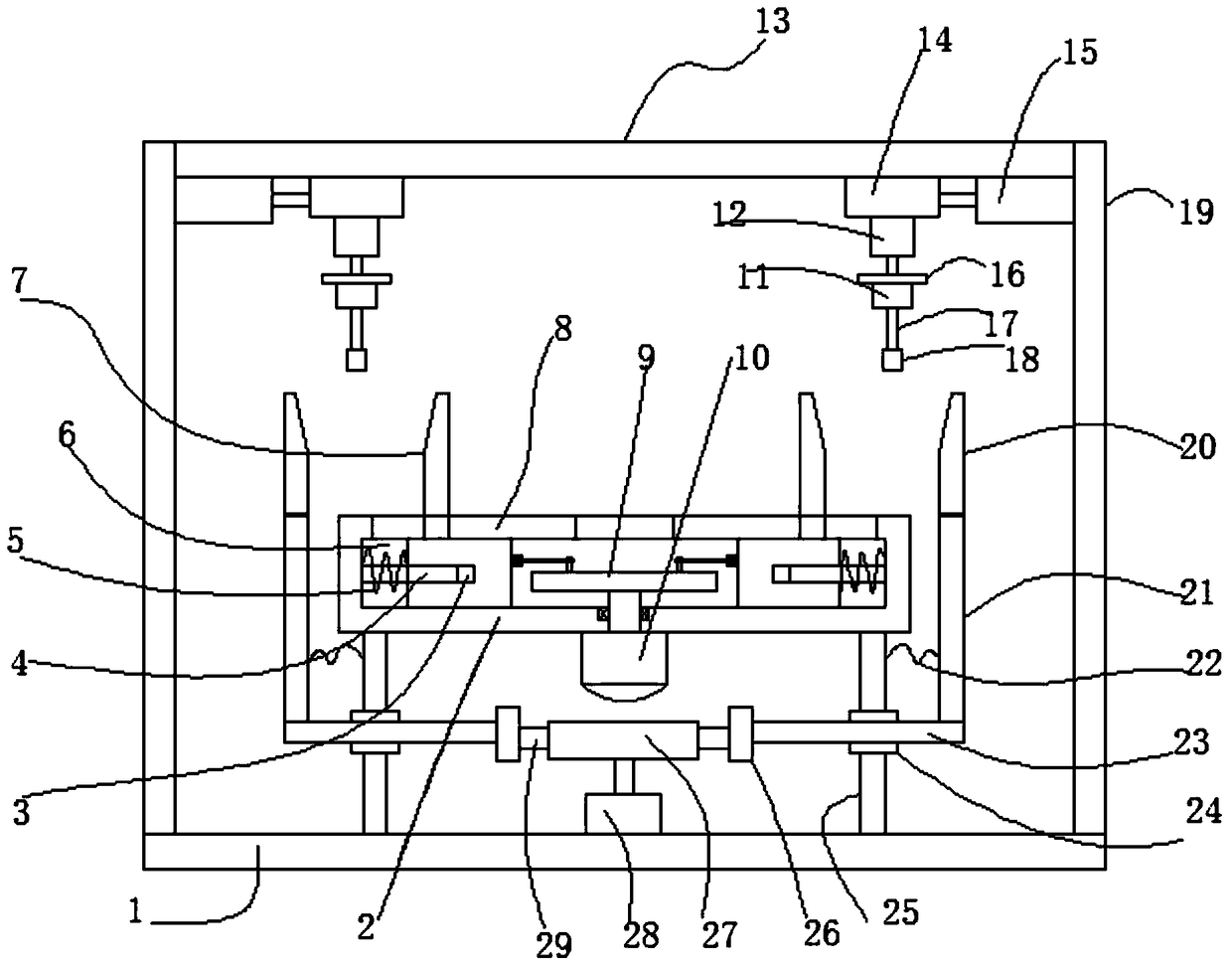

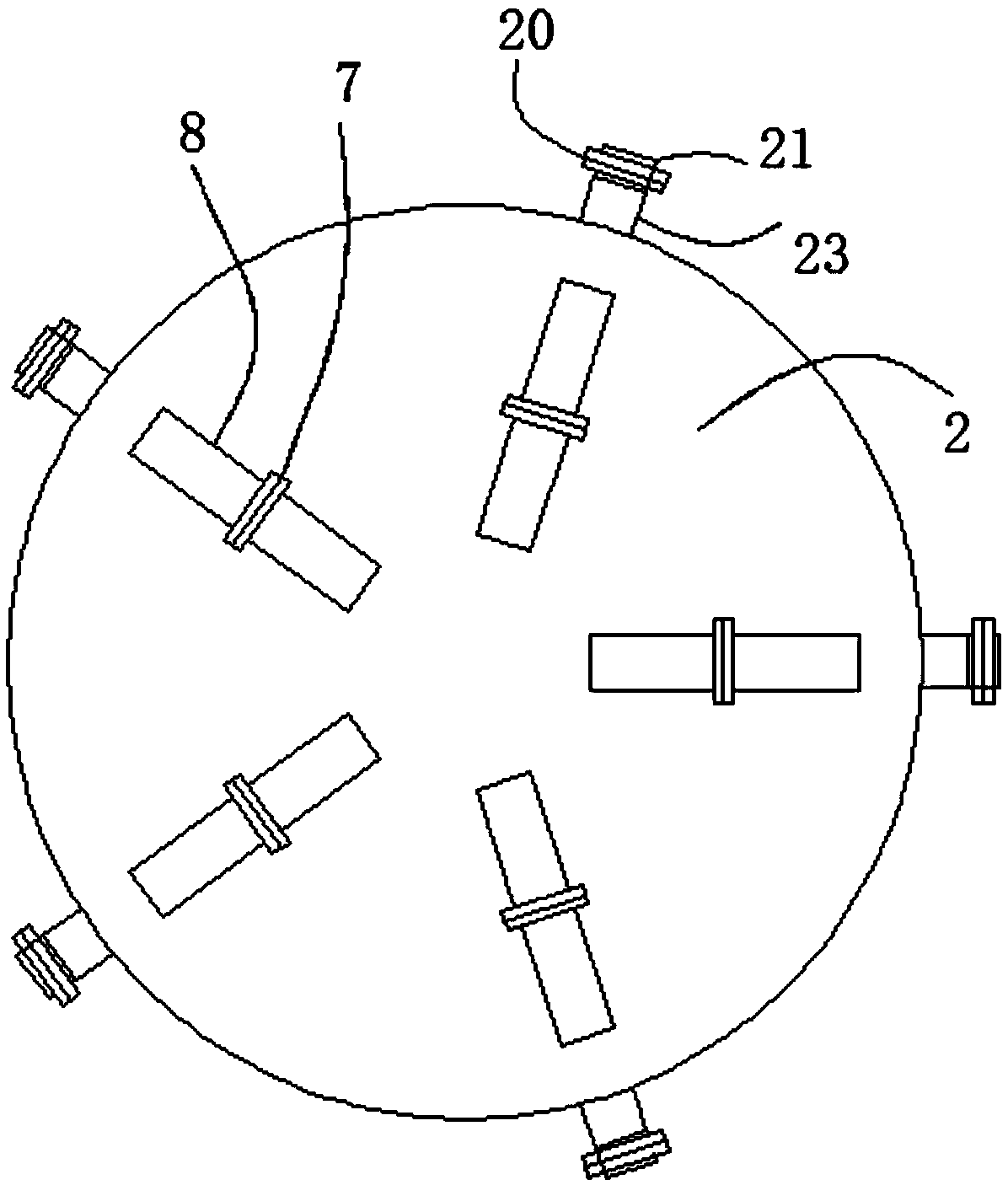

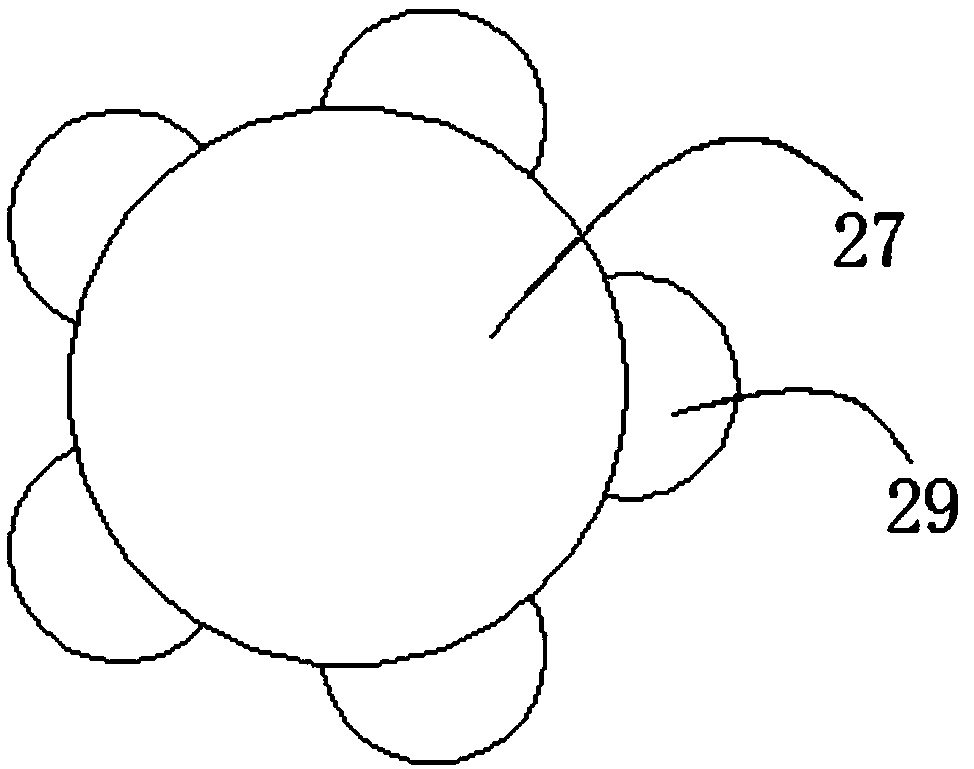

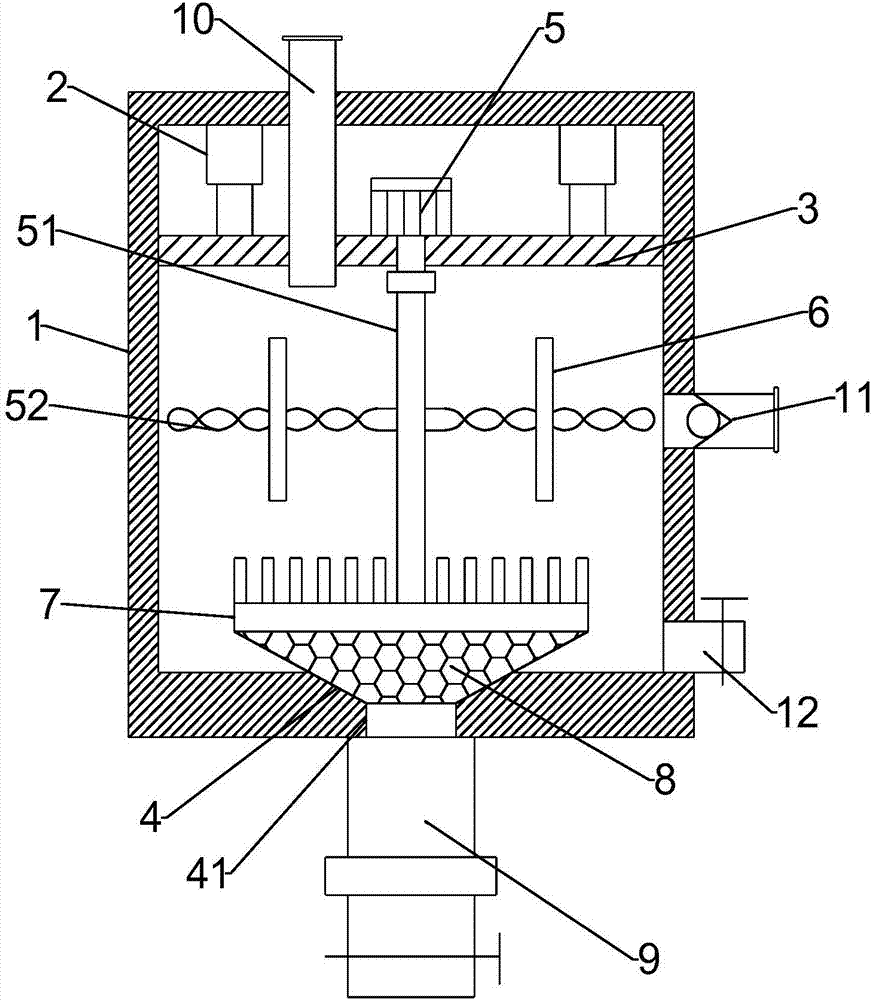

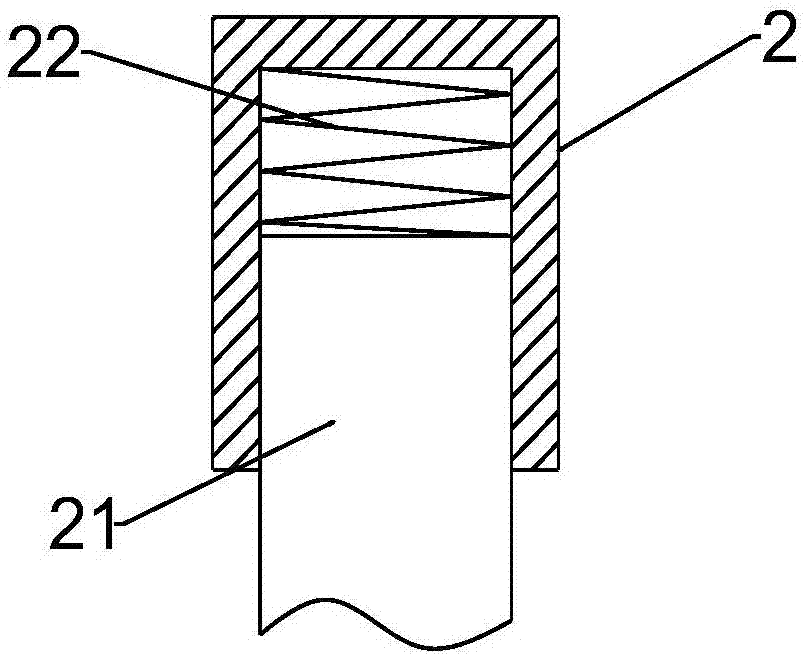

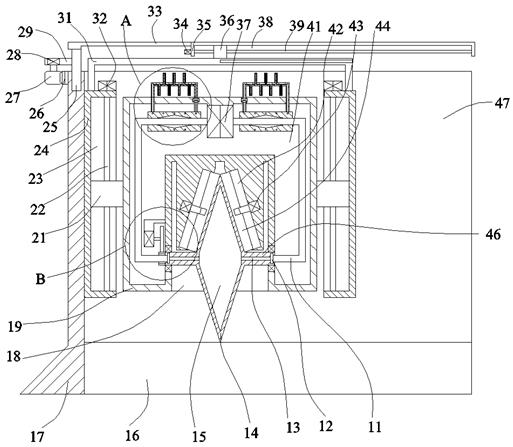

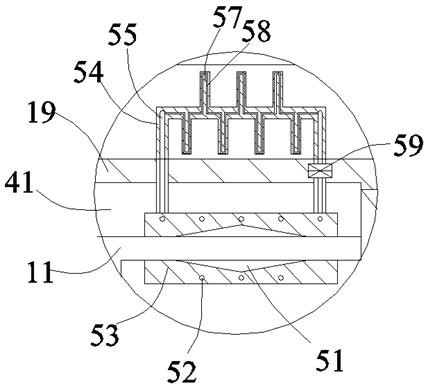

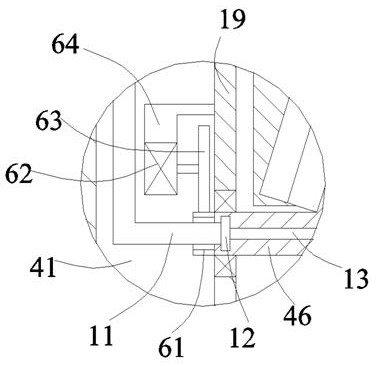

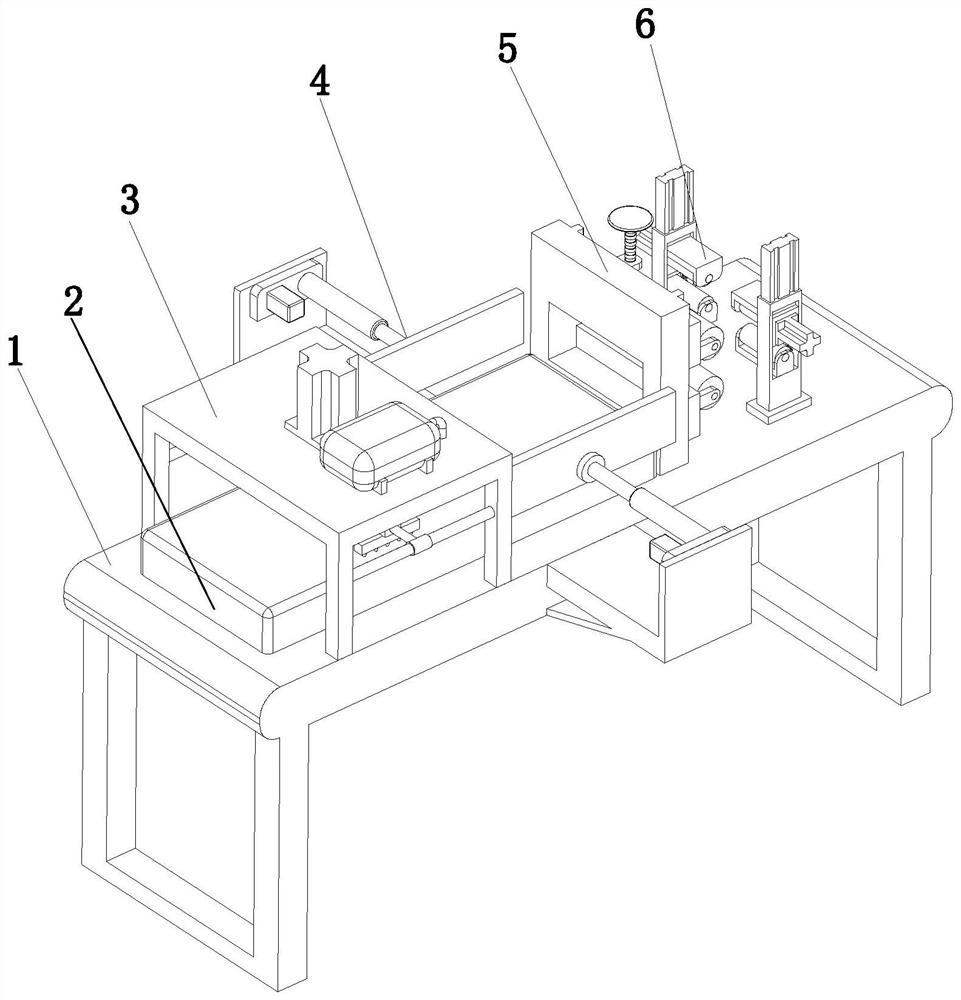

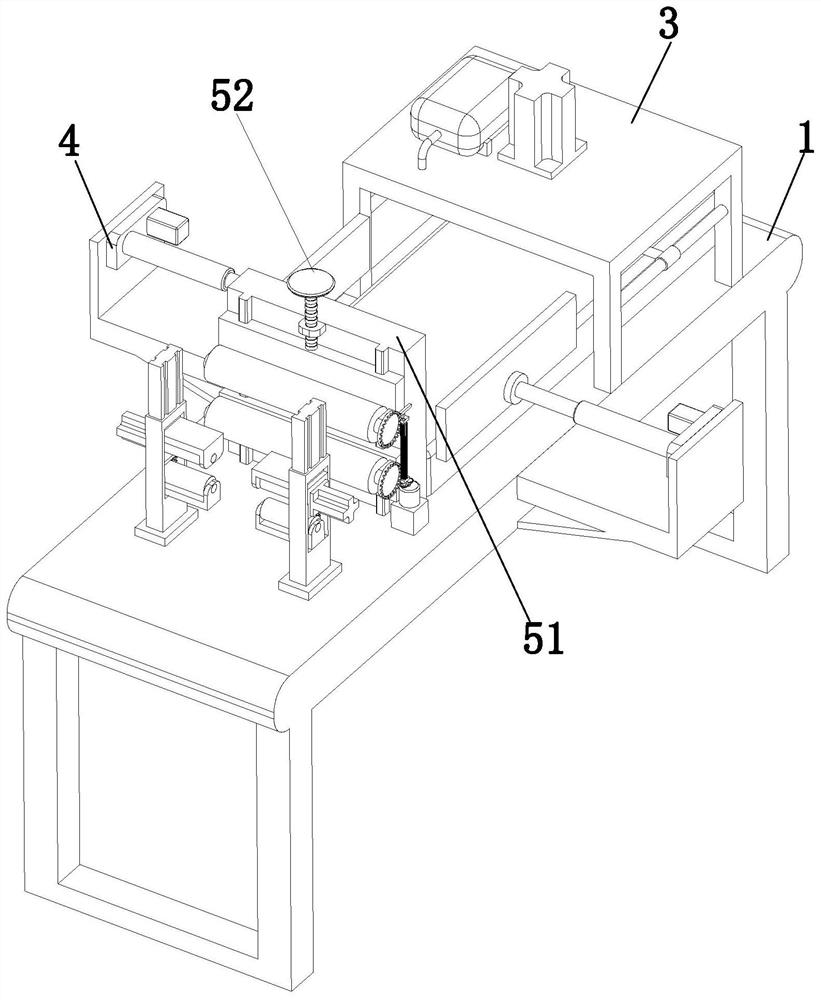

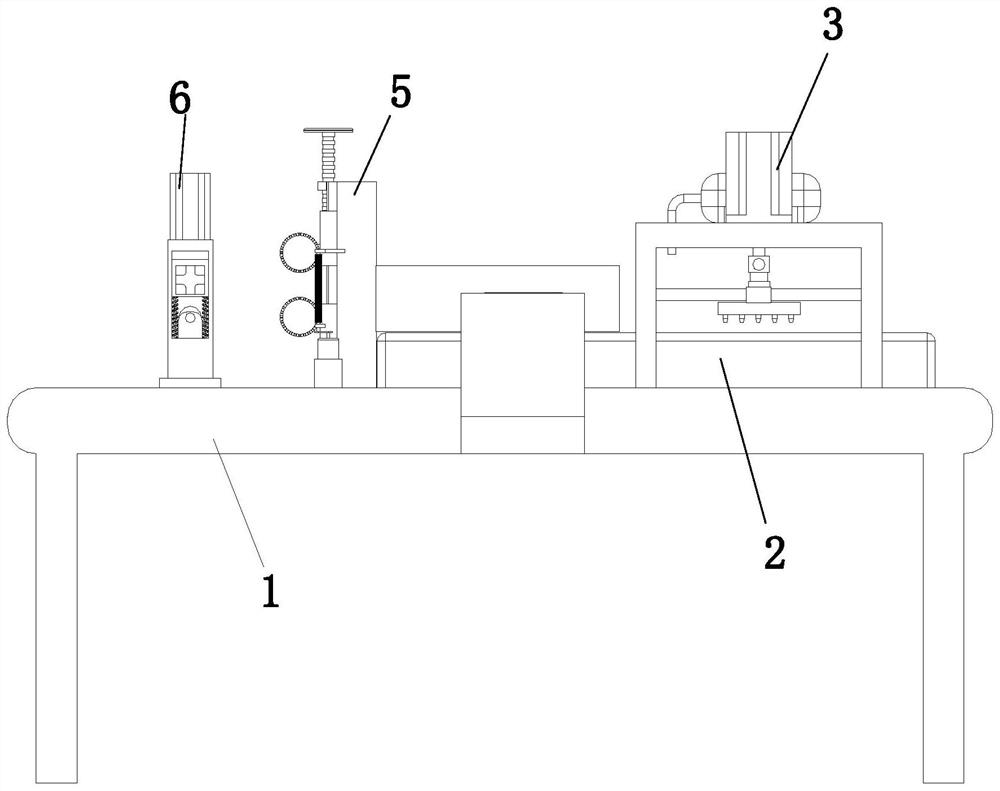

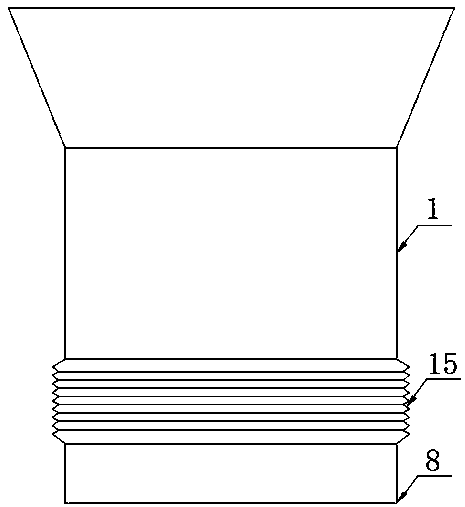

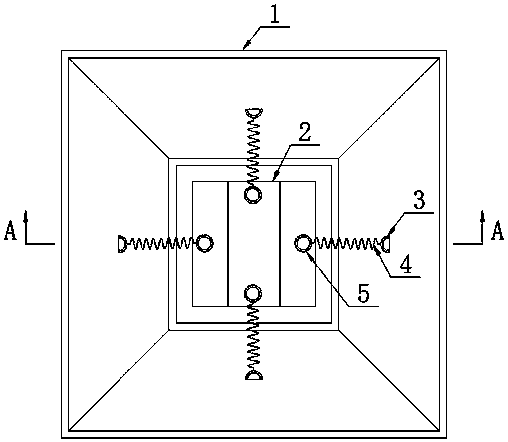

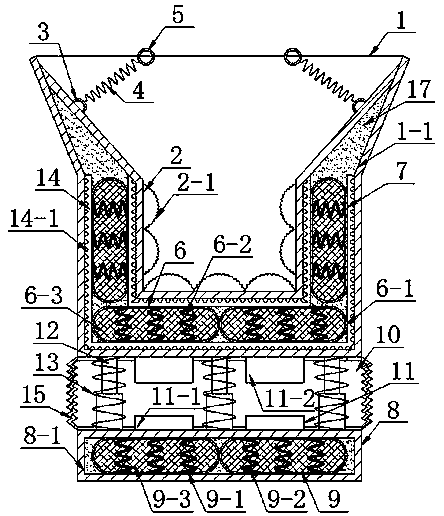

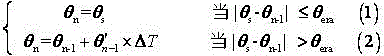

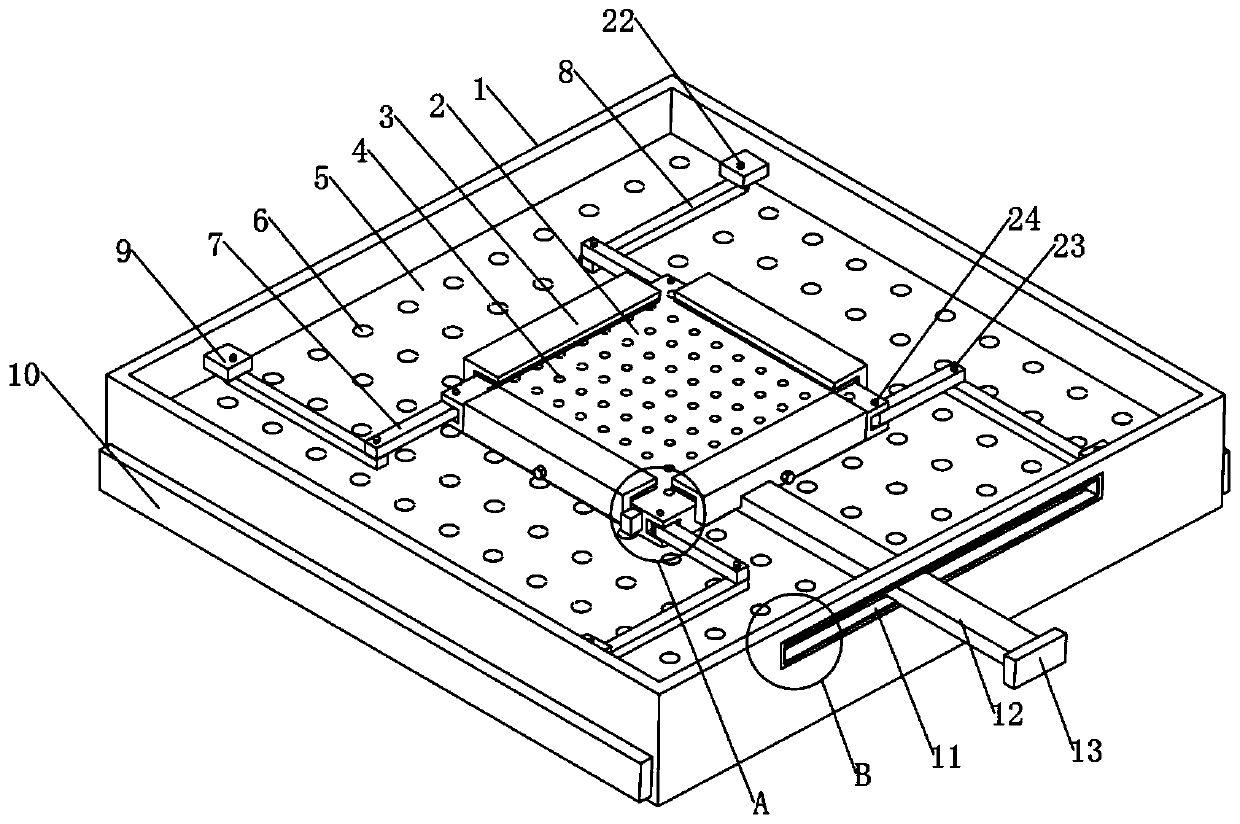

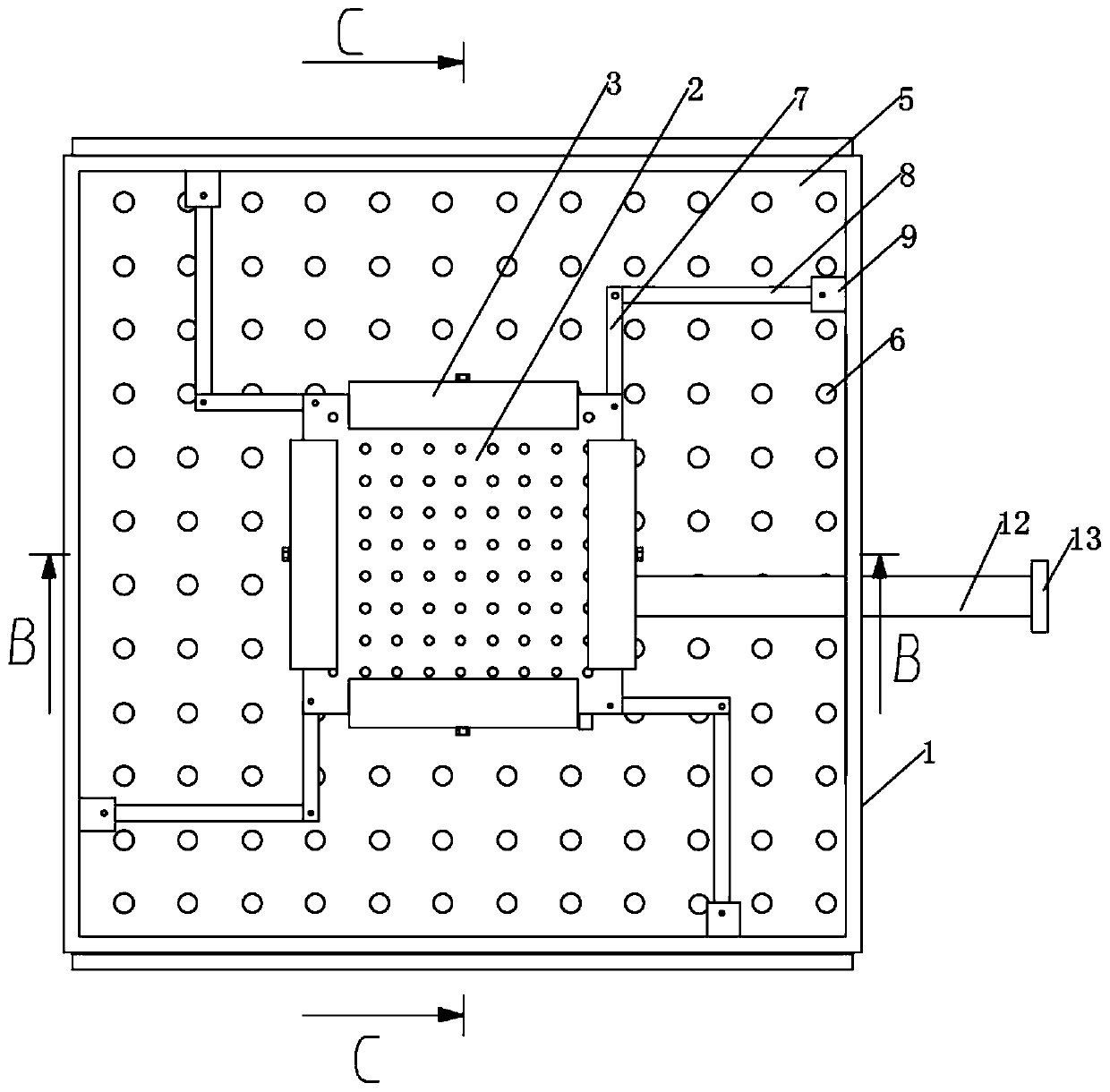

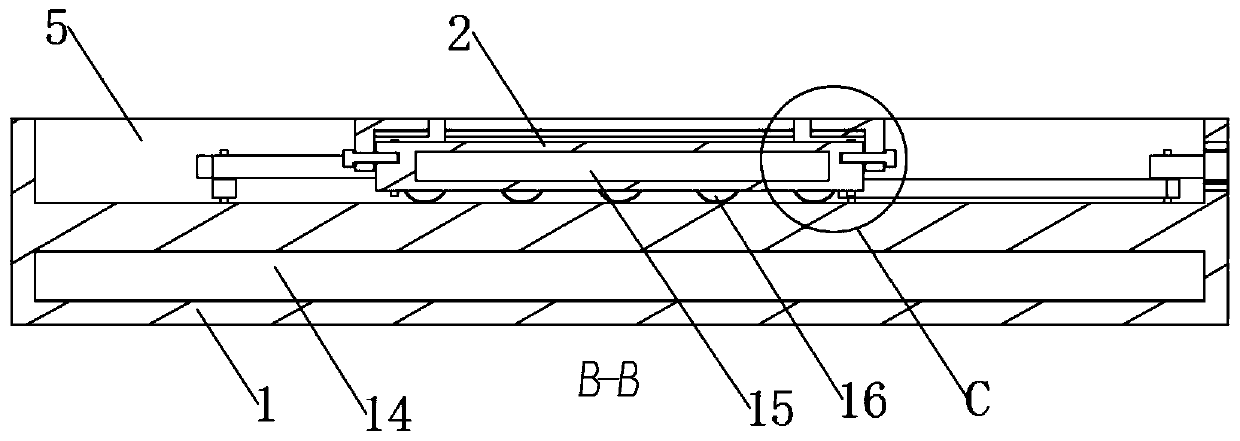

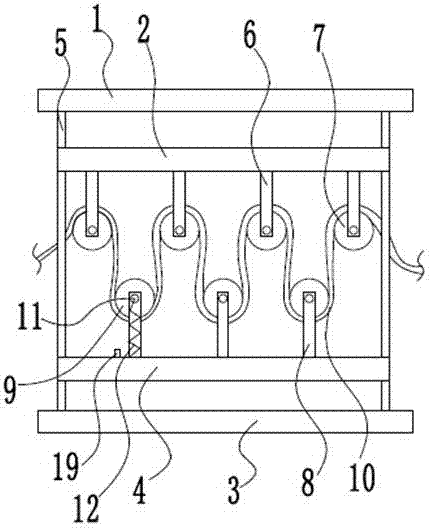

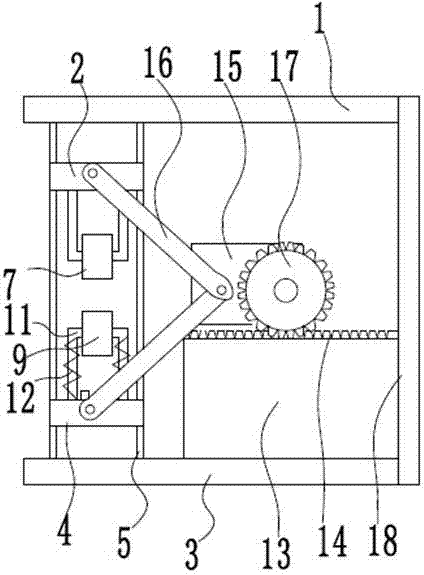

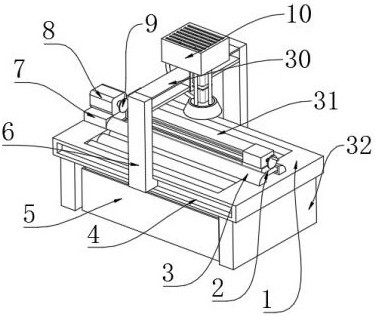

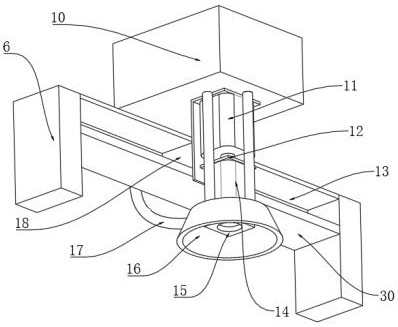

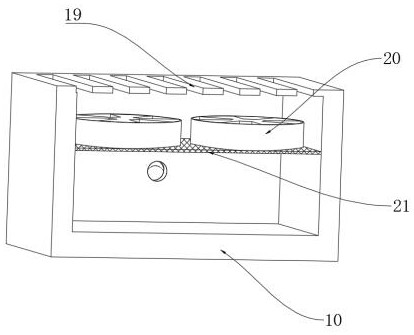

Adjustable bearing processing, fixing and polishing device

ActiveCN109500669AWill not affect processingImprove stabilityRevolution surface grinding machinesGrinding work supportsMechanical engineering

The invention relates to the technical field of bearing processing equipment, in particular to an adjustable bearing processing, fixing and polishing device. The adjustable bearing processing, fixingand polishing device comprises a base and a worktable. A top plate is arranged above the base, the left and right ends of the top plate are connected and fixed to the base through supporting columns,two polishing mechanisms are arranged at the lower end of the top plate, a worktable is arranged above the base, two sides of the lower end of the worktable are connected and fixed to the base throughpositioning barrels, and a clamping mechanism for clamping the inner wall of a bearing outer ring and the outer wall of a bearing inner ring is arranged on the worktable. By improving the defects ofan existing device, the mechanism for clamping the bearing outer ring and the bearing inner ring is designed, and the clamping mode does not affect processing of the bearing outer ring and the bearinginner ring clamping faces, so that the workpiece clamping stability is improved favorably and the processing efficiency is also improved favorably, and the adjustable bearing processing, fixing and polishing device is high in practicality.

Owner:WEST ANHUI UNIV

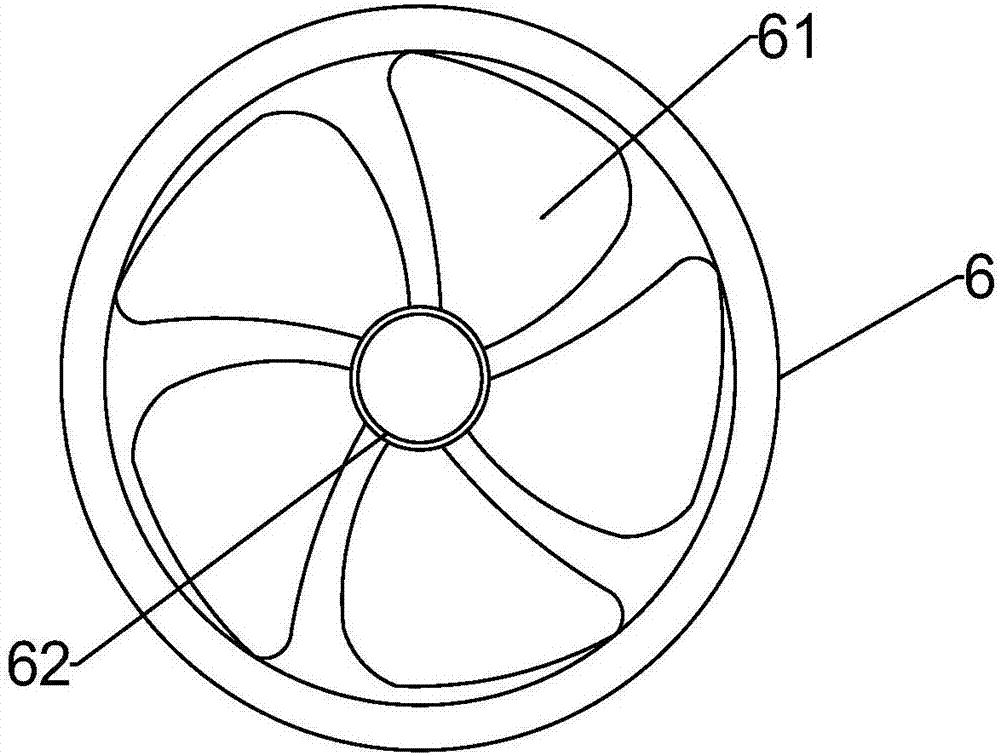

Anti-blocking type continuous water treatment device

InactiveCN107512798ANot easy to stickImprove stirring efficiencyWater/sewage treatment by centrifugal separationSpecific water treatment objectivesWater dischargeUpper joint

The invention discloses an anti-blocking type continuous water treatment device, which comprises a housing, the inner upper wall of the housing is provided with a sliding sleeve, a sliding connecting rod and a compression spring, the lower end of the sliding connecting rod is provided with an upper sliding plate, and the upper sliding plate There are motor, stirring shaft, stirring blade, centrifugal wheel and the first filter screen on the top, the outer frame, blade and inner ring are arranged on the periphery of the stirring blade, and the drainage pipe is arranged in the threaded hole, and the drainage pipe is connected by a double-threaded upper joint. , threaded cover, second filter screen and lower drainage joint, the upper end of the shell is provided with a water inlet pipe, and the right wall of the shell is provided with a filling pipe and a sewage pipe. The present invention can carry out water treatment by stirring, drain water after being filtered by the first filter screen and the second filter screen, improve the water treatment efficiency by setting the outer frame, fan blade and inner ring on the periphery of the stirring fan blade, and set it by the movable upper sliding plate In order to drive the first filter screen to lift when impurities adhere to maintain the continuity of water treatment.

Owner:广州林腾生物科技有限公司

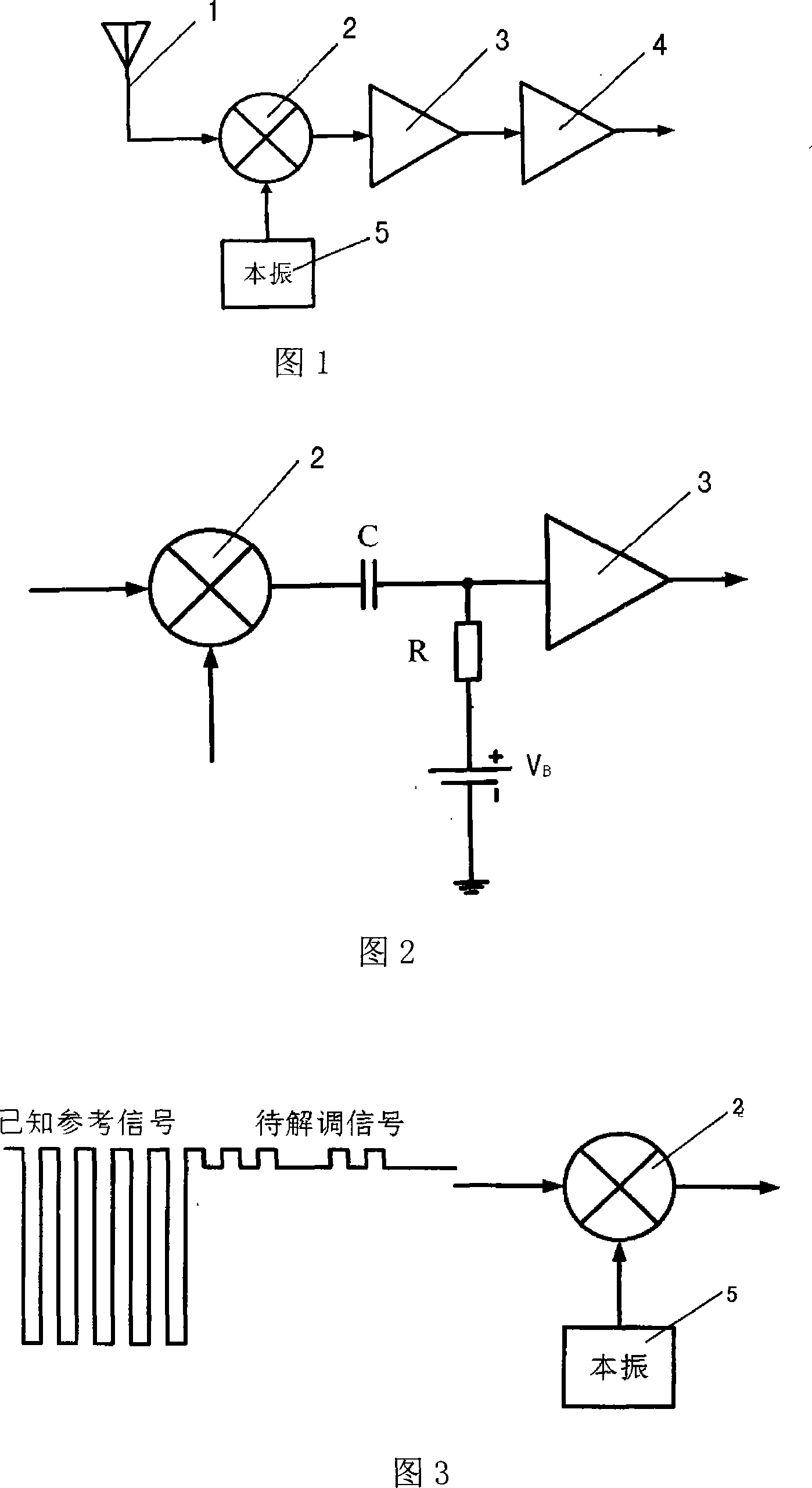

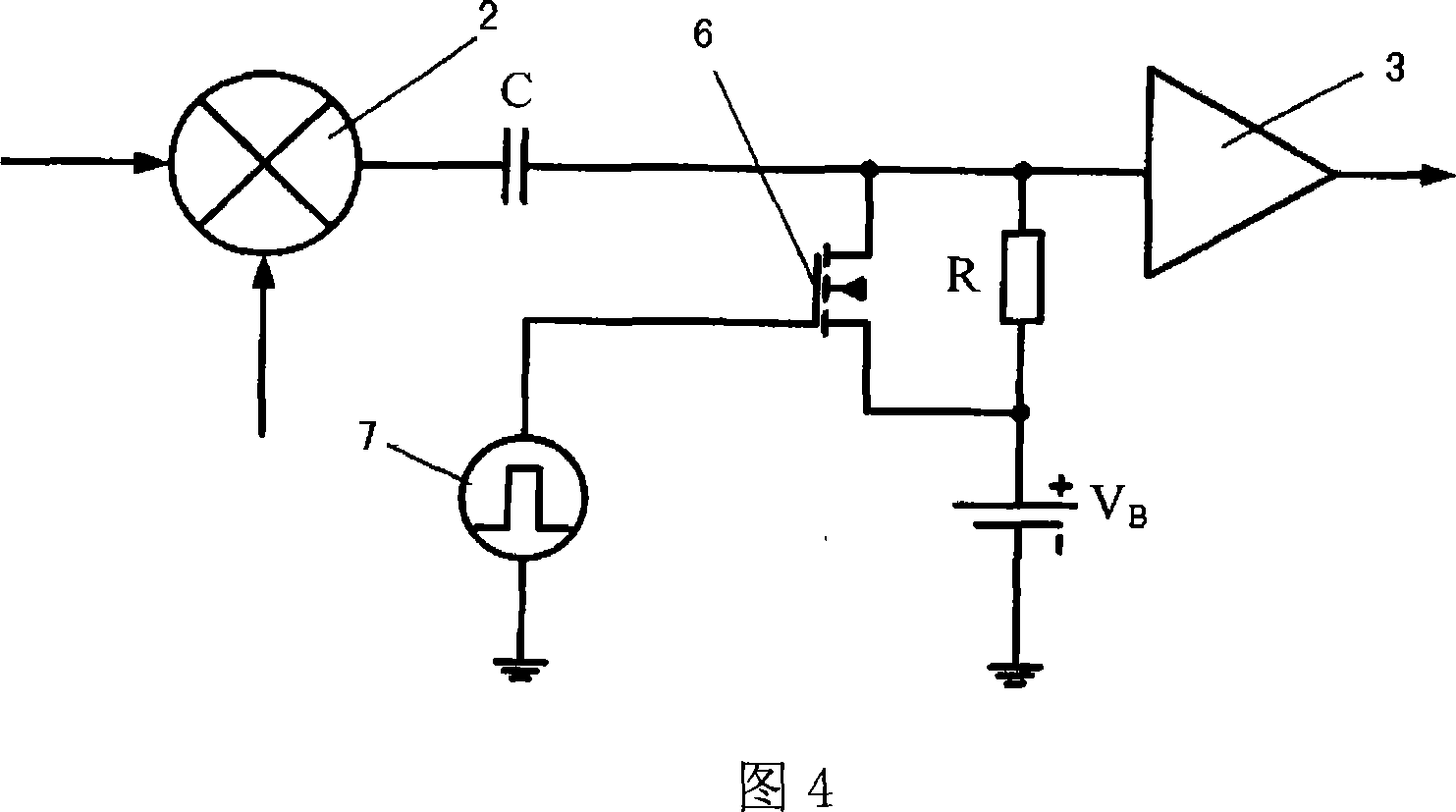

Variable bandwidth filter circuit for RFID read-write equipment

InactiveCN101145207AWill not affect processingHigh speedCo-operative working arrangementsIntermediate frequencyDown conversion mixer

The present invention discloses a variable bandwidth filter circuit, which belongs to the design field of analog integrated circuits, in particular relates to a coupling filter circuit in the radio frequency receiver of a RFID reader, and the present invention can be used in RFID readers. A high-pass filter consisting of a capacitor C and a resistor R is connected between a lower-frequency-conversion mixer which converts frequency directly and an intermediate-frequency amplifier; two ends of the resistor R are connected in parallel with controllable MOS-tube switches to form a high-speed filter circuit with variable bandwidth; used in the RFID reader integrated circuits, the high-pass filter circuit can flit out DC and low frequency components led by directly converting frequency; under specific input signal, the bandwidth of the high-pass filter circuit can change with the signal by connecting in parallel controllable switches on two ends of the resistance in the filter circuit to have quickly respond, thereby improving the speed of the reader.

Owner:ZHEJIANG XINGSHENG IOT TECH

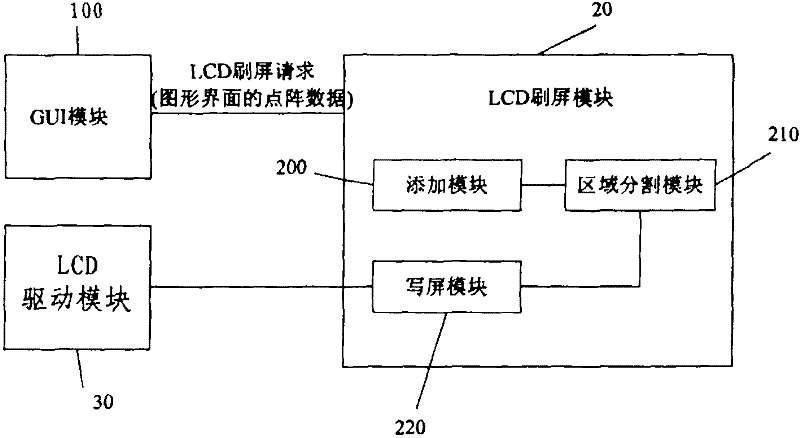

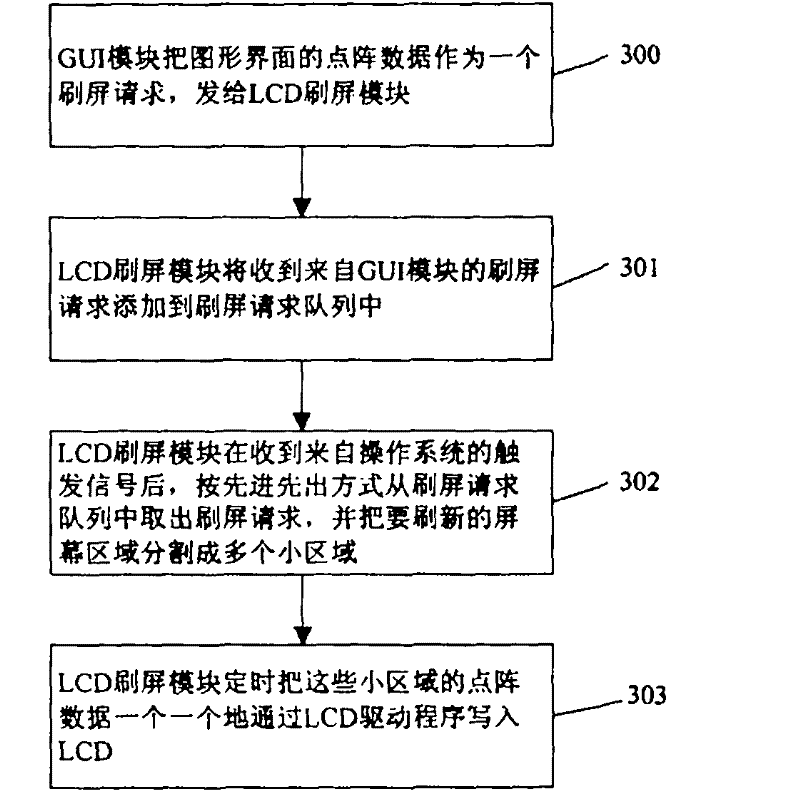

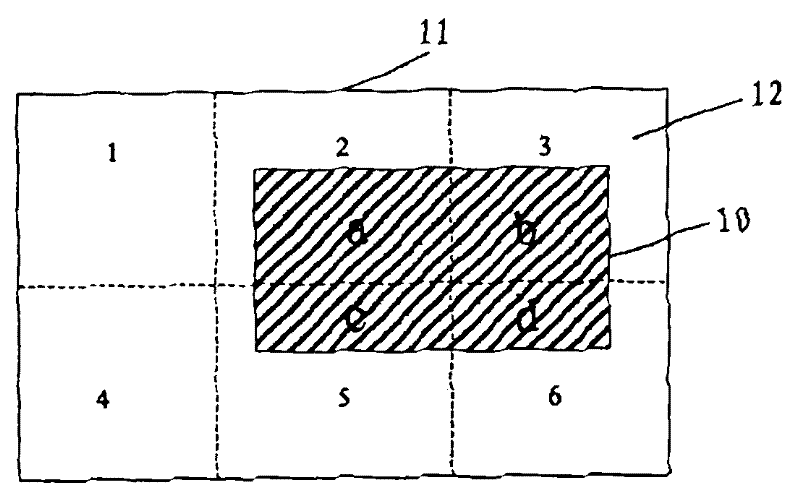

Screen refreshing device and method based on syncretic communication terminal

InactiveCN102184715AWill not affect processingQuick responseStatic indicating devicesSubstation equipmentDot matrixLiquid-crystal display

The invention discloses a screen refreshing device and a method based on a syncretic communication terminal, belonging to the technical field of the structure of the screen refreshing device and the screen refreshing method which are based on the syncretic communication terminal and can improve the procedure response speed in the information or communication technology. The screen refreshing device comprises a GUI (graphic user interface) module, an LCD (liquid crystal display) screen refreshing module and an LCD drive module; through increasing the LCD screen refreshing module, the screen area needing to be refreshed is cut into a plurality of small rectangular areas, and the dot matrix data of the small areas are written into the LCD one by one through the LCD drive module at regular time. Since the screen area needing to be refreshed is cut into a plurality of small rectangular areas, the time for refreshing the small areas cannot influence the processing on other service modules, thus promoting the procedure response speed.

Owner:ZHUHAI JIAMI TECH CO LTD

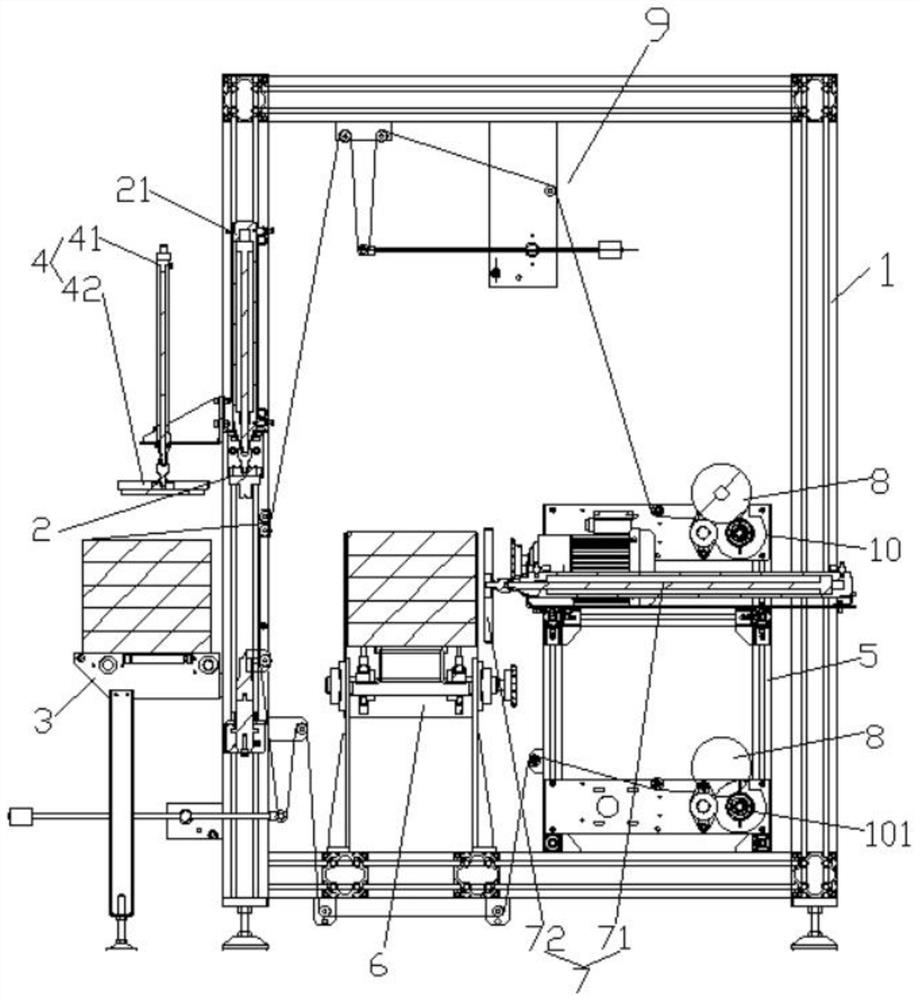

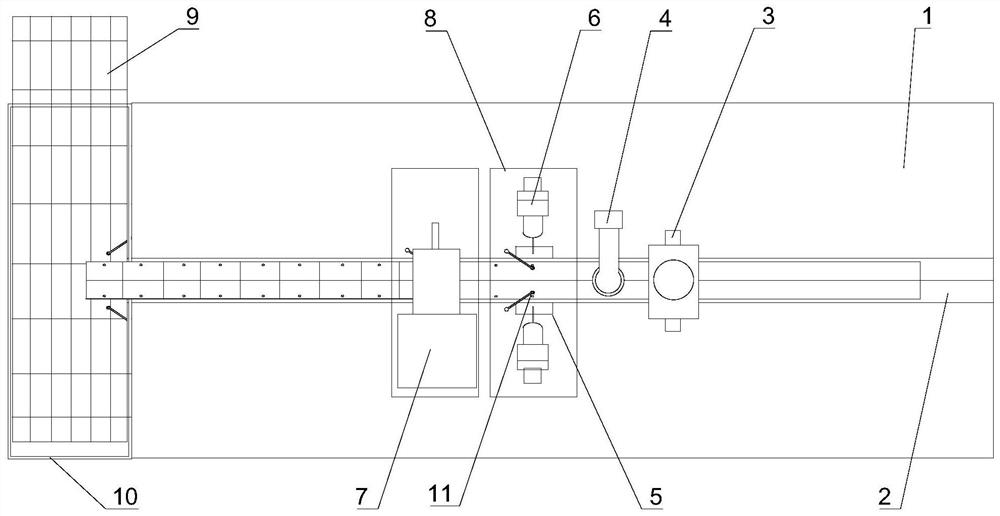

Non-woven fabric film wrapping packaging mechanism and non-woven fabric strip cigarette packaging system

PendingCN111994359ASimple structural designReasonable structural designWrapping material feeding apparatusWrappingNonwoven fabricManufacturing engineering

The invention relates to a non-woven fabric film wrapping packaging mechanism. The non-woven fabric film wrapping packaging mechanism comprises a supporting frame, an ultrasonic sealing and cutting mechanism, a packaging table, a telescopic pressing and positioning device, a support, a material table and a material pushing device. The ultrasonic sealing and cutting mechanism is assembled on the supporting frame and used for welding and cutting two pieces of non-woven fabric which pass through the ultrasonic sealing and cutting mechanism and are distributed up and down. The packaging table is arranged in front of the ultrasonic sealing and cutting mechanism. The telescopic pressing and positioning device is arranged above the packaging table and used for pressing materials on the packagingtable. The support is arranged behind the ultrasonic sealing and cutting mechanism, and two non-woven fabric rolls are arranged on the support in an up-down spaced manner. The material table is arranged between the ultrasonic sealing and cutting mechanism and the support. The material pushing device is assembled on the support and provided with a telescopic end which horizontally stretches and retracts front and back. The material pushing device is used for pushing the materials on the material table to the packaging table through the telescopic end. The non-woven fabric film wrapping packaging mechanism has the beneficial effects that the non-woven fabric film wrapping packaging mechanism is simple and reasonable in structural design, energy-saving, environmental-friendly, economical andconvenient to use, and the production cost is effectively reduced.

Owner:中烟物流技术有限责任公司

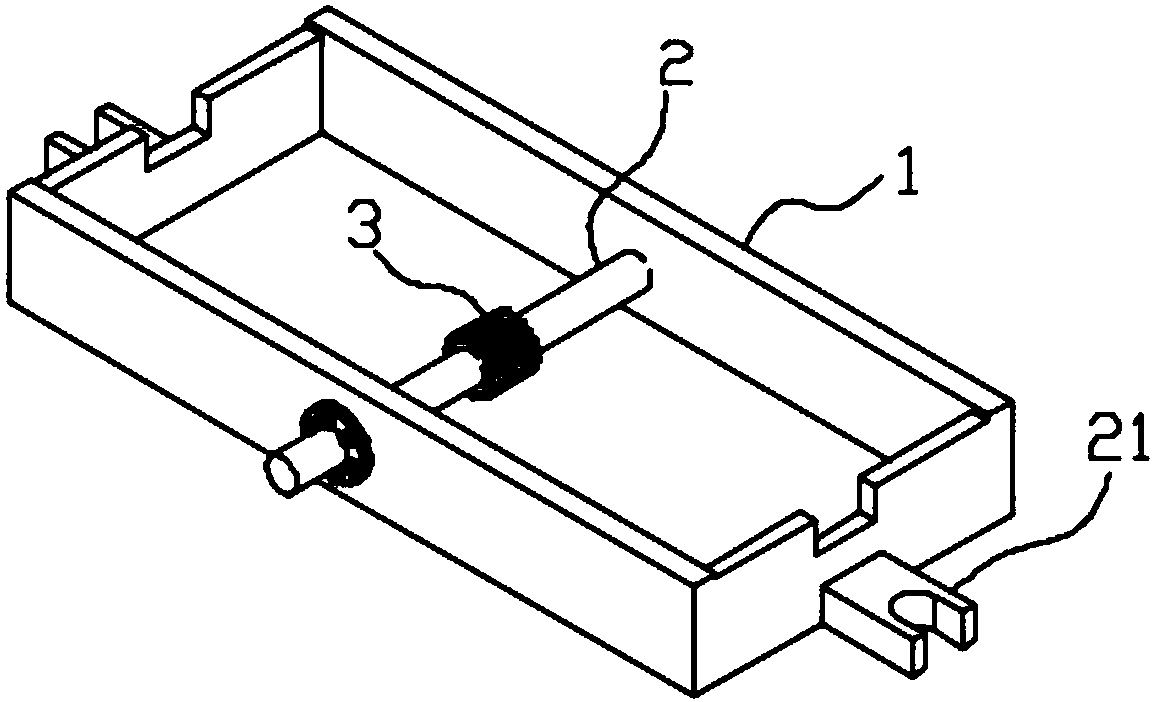

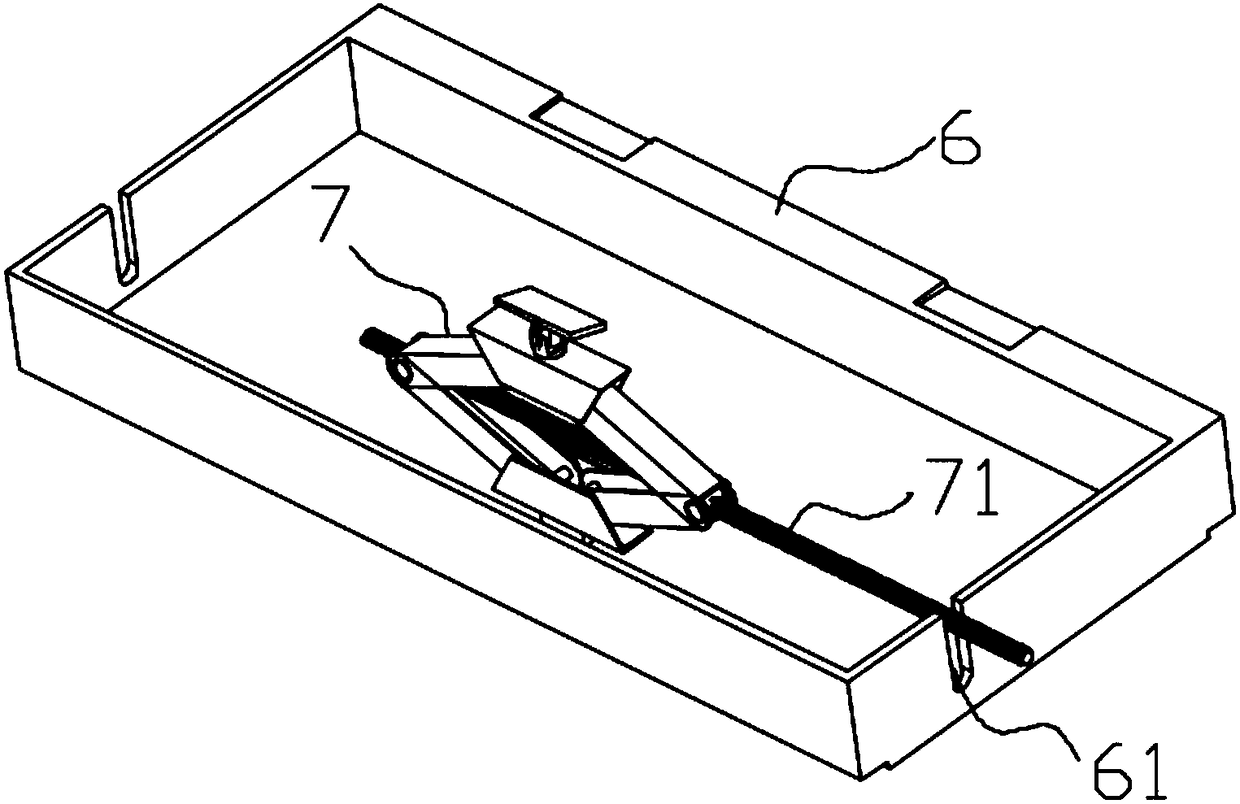

Shot blasting clamp used for thin-wall class parts

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

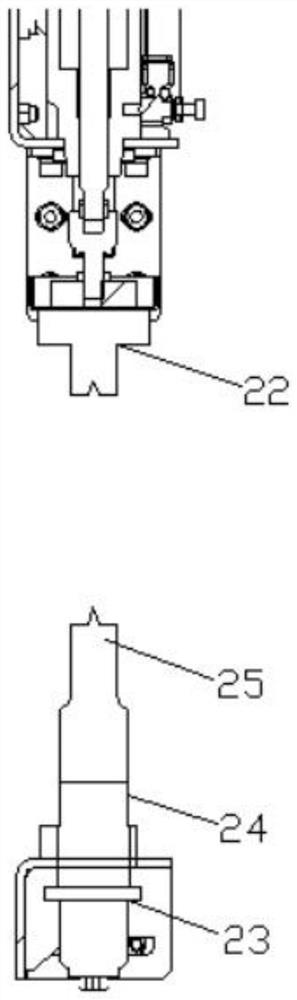

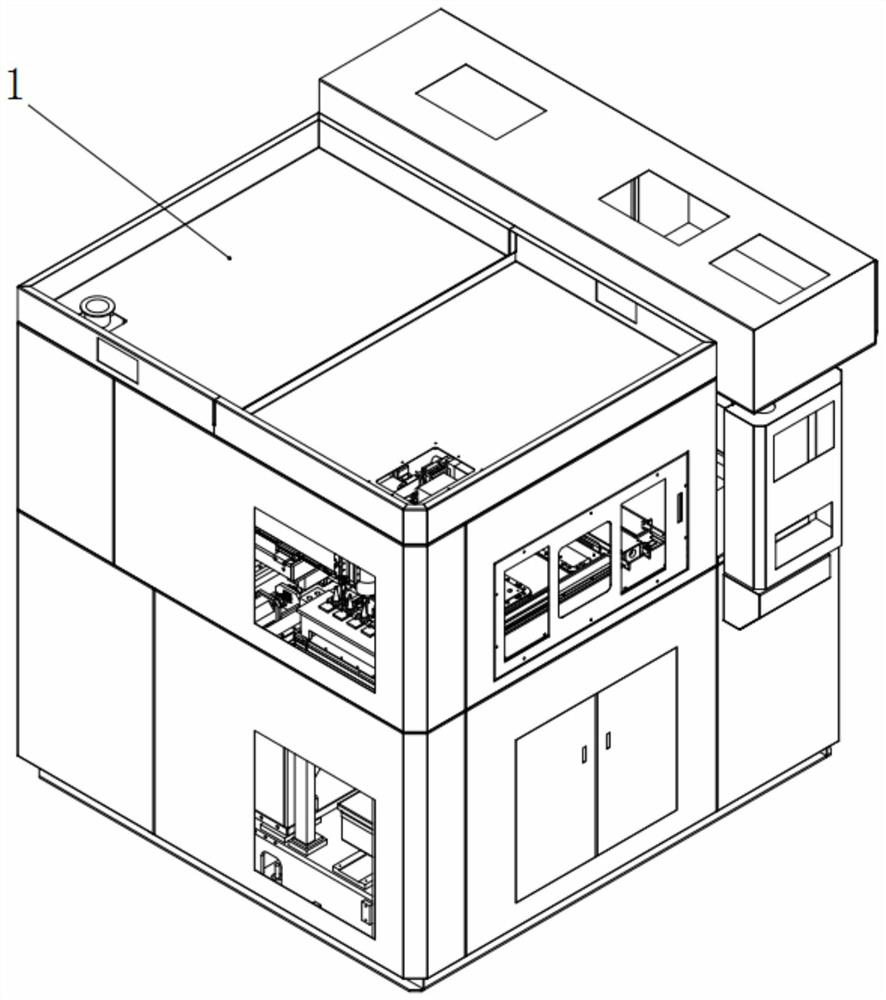

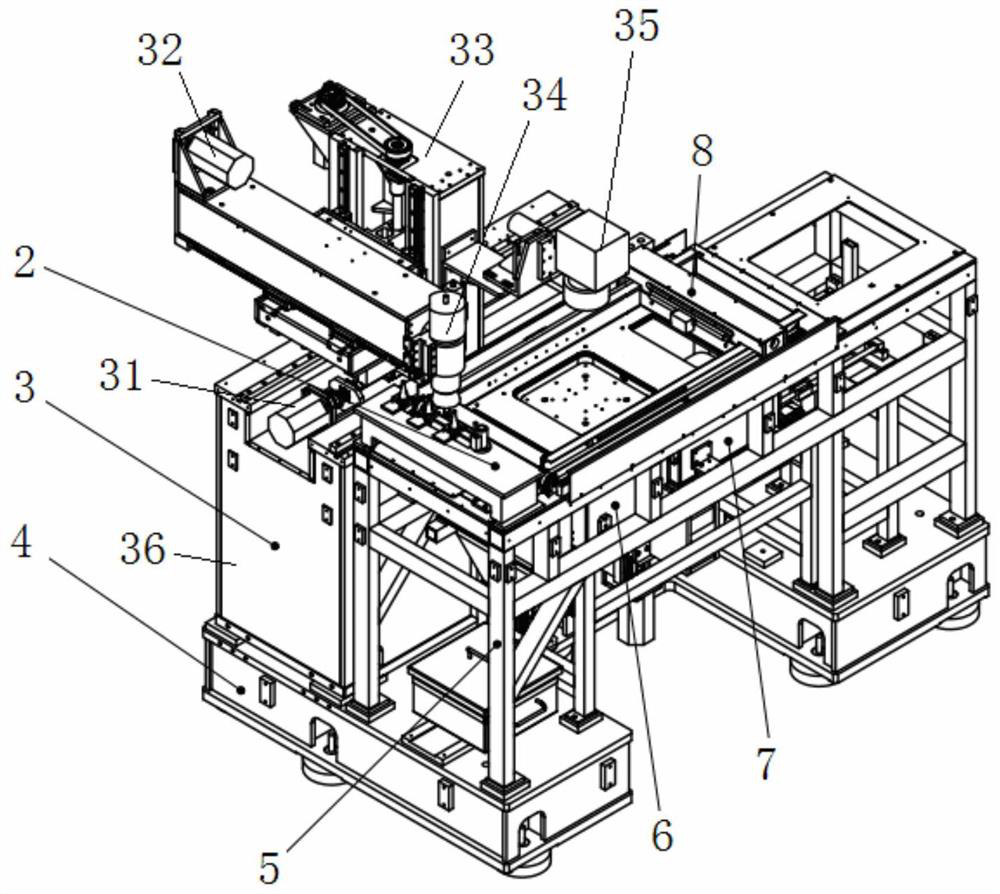

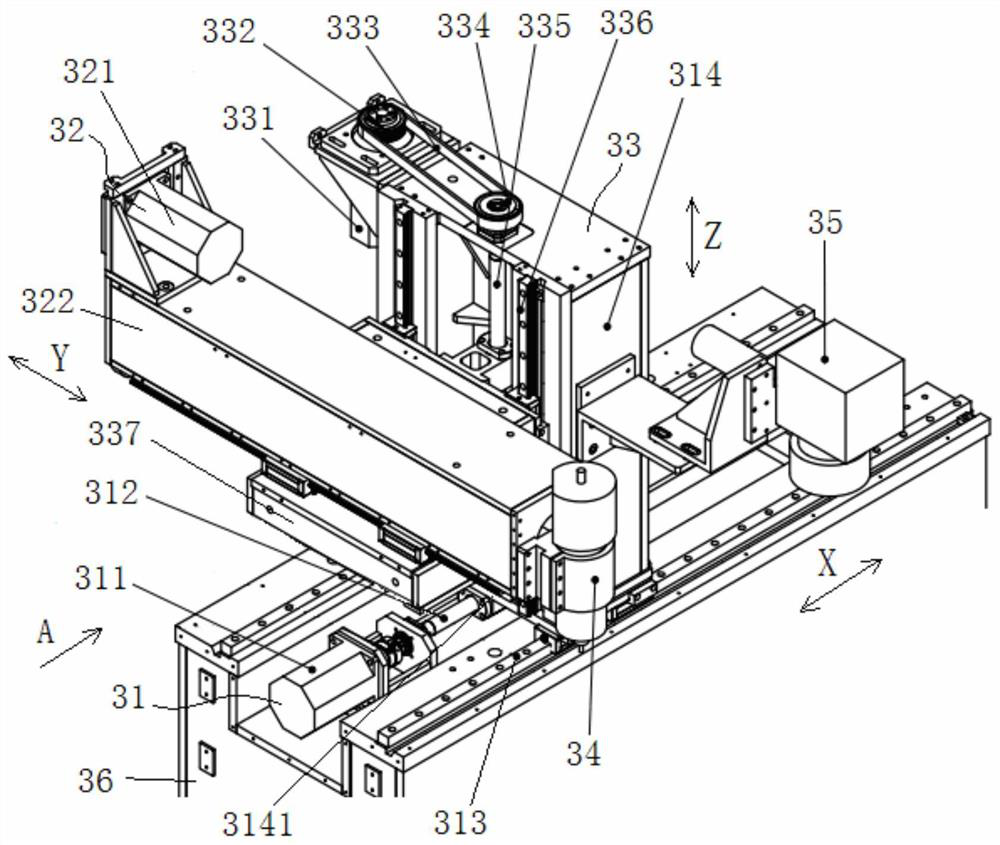

Additive and subtractive composite manufacturing process equipment

ActiveCN112440114AExtended range of movementReduce volumeAdditive manufacturing apparatusOther manufacturing equipments/toolsProcess equipmentMachine building

The invention relates to the technical field of precision machine manufacturing, in particular to additive and subtractive composite manufacturing process equipment which comprises a protective cover,a subtractive device and a support. The subtractive device and the support are arranged in the protective cover, and the subtractive device is provided with an electric spindle with X, Y and Z degrees of freedom and a laser galvanometer with X degrees of freedom. A powder spreading device, a powder supply box and a forming box are arranged on the support, the powder spreading device is provided with a powder spreading panel and a movable scraper, a powder supply port and a forming port are formed in the powder spreading panel, the powder supply box is arranged on the lower side of the powdersupply port, a liftable powder supply piston is arranged in the powder supply box, and the forming box is arranged on the lower side of the forming port. A liftable forming piston is arranged in the forming box, a powder supply moving mechanism is arranged in the support, and the powder supply box is driven by the powder supply moving mechanism to move between the powder supply port and a powder supplementing port. The equipment is reasonable in space layout, good in sealing performance, accurate in powder supply and capable of achieving online detection, the machining quality and precision are guaranteed, and the machining efficiency is improved.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

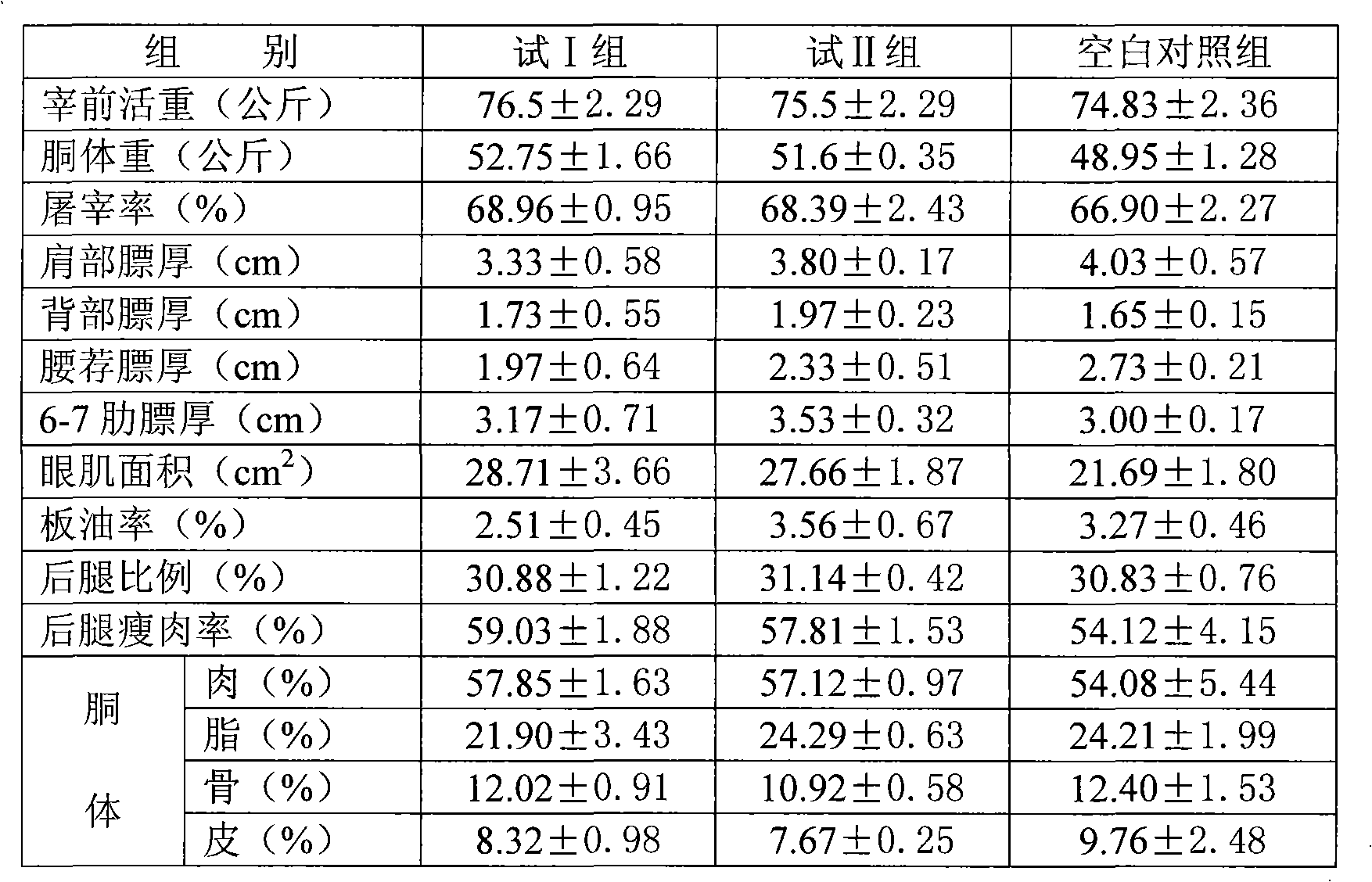

Use of allantoin in preparing feedstuff additive

InactiveCN101347189AImprove the immunityChange the proportional relationshipAnimal feeding stuffLean meatAllantoin

The invention discloses an application of an allantoin for preparing a feed additive, in particular to the application of the allantoin to preparing a feed additive which is used for promoting growth and improving lean meat factor. The feed additive is of a powder, a granule or an oral liquid which consists of the allantoin and edible accessories. The application of the allantoin for preparing the feed additive has the advantages of low cost, convenient use and larger application value.

Owner:刘家鹤

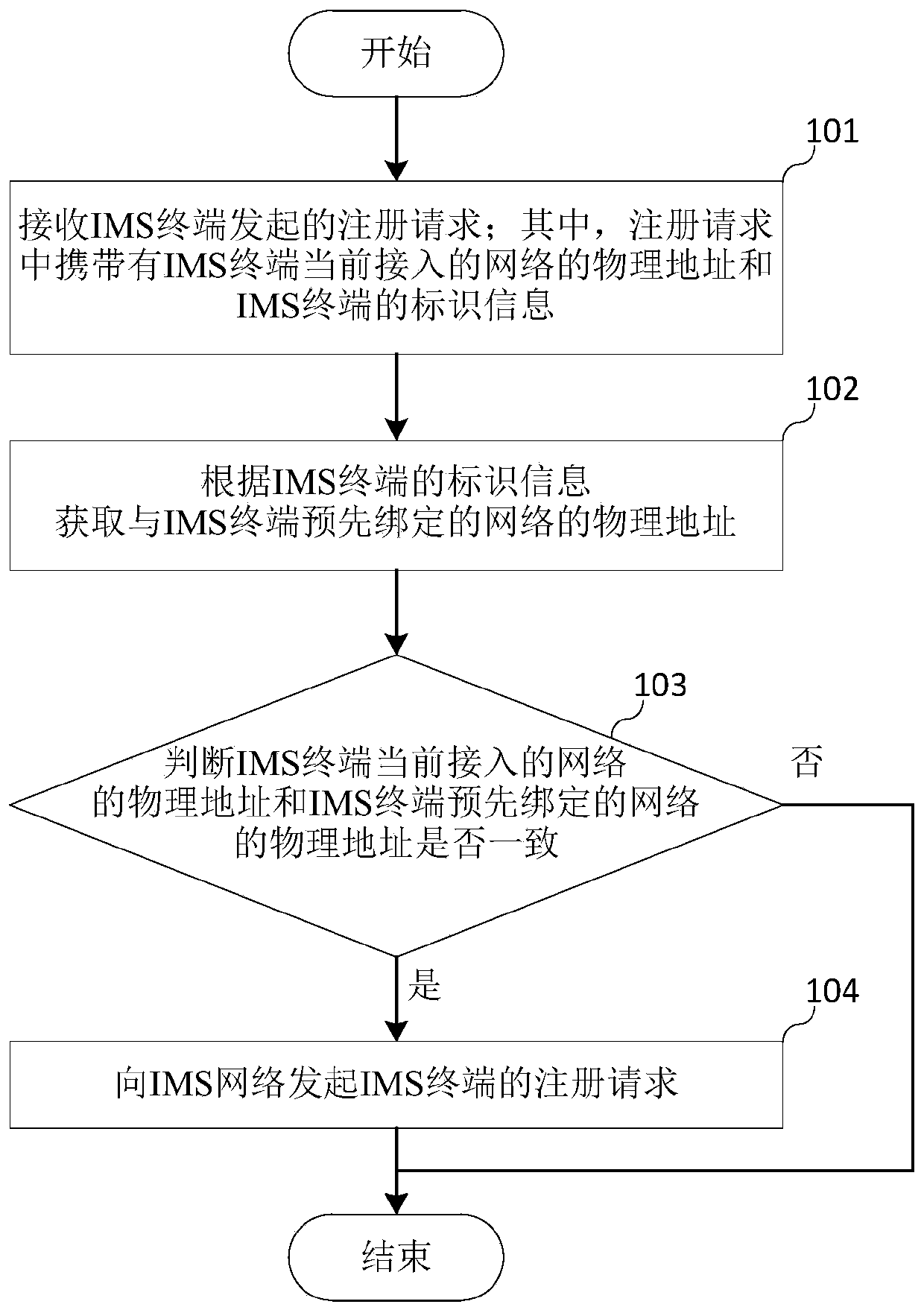

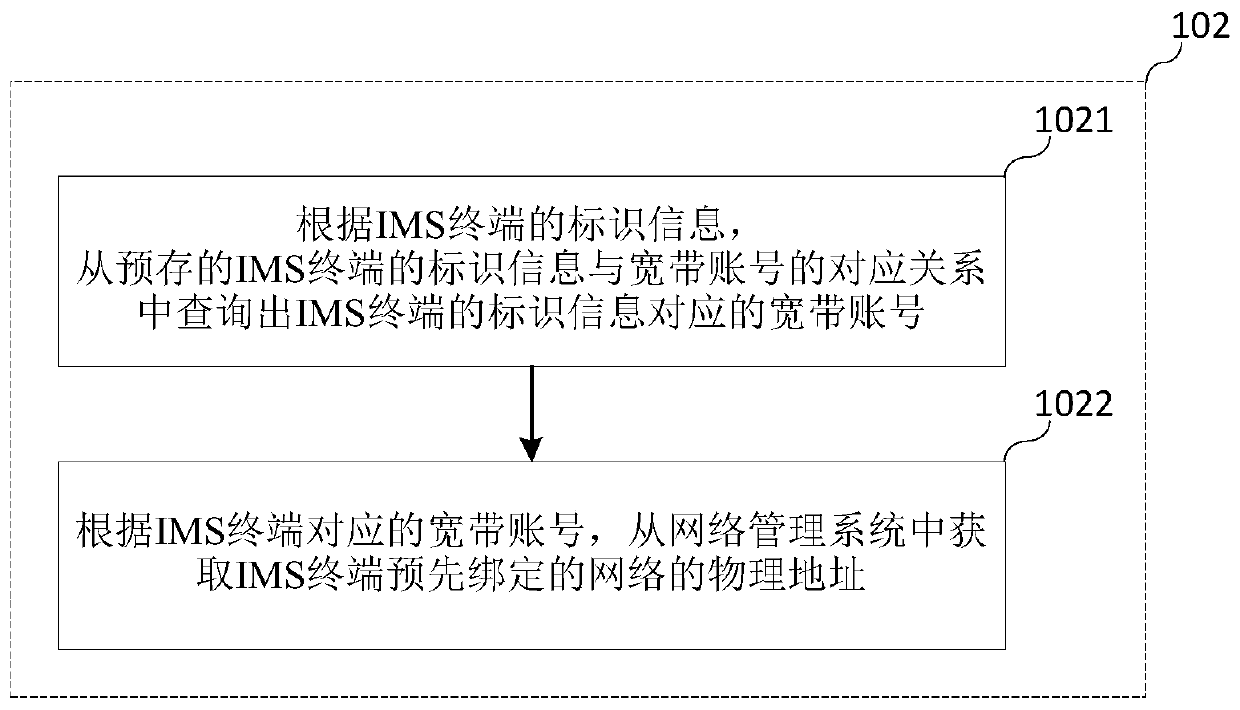

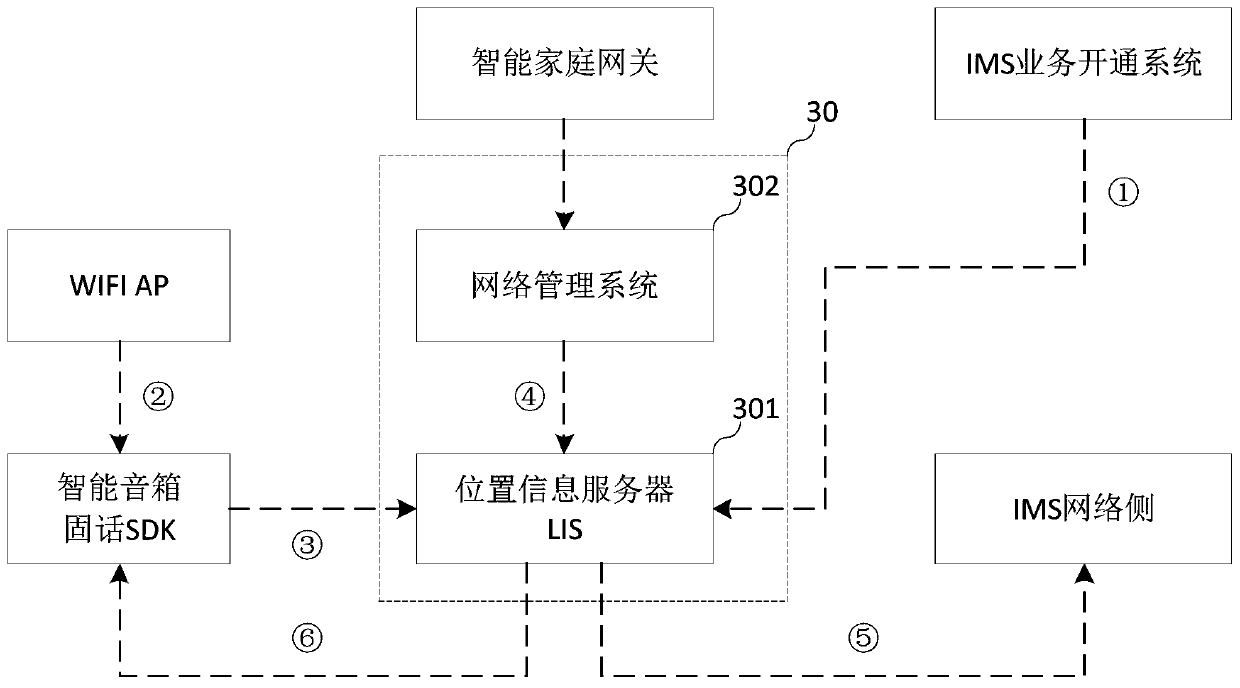

IMS terminal registration method and device, position information server and storage medium

ActiveCN110572820AWill not affect processingIncrease flexibilityConnection managementSecurity arrangementPhysical addressWorkload

The embodiment of the invention relates to the technical field of communication, in particular to an IMS terminal registration method and a device, a position information server and a storage medium.The registration method of the IMS terminal comprises the following steps: receiving a registration request initiated by the IMS terminal, wherein the registration request carries a physical address of a network currently accessed by the IMS terminal and identification information of the IMS terminal; acquiring a physical address of a network pre-bound with the IMS terminal according to the identification information of the IMS terminal; judging whether the physical address of the network currently accessed by the IMS terminal is consistent with the physical address of the network pre-bound bythe IMS terminal; and if yes, initiating registration of the IMS terminal to an IMS network. By adopting the method of the invention, the use of the IMS terminal in the pre-bound network can be limited, and the workload of the IMS network side is effectively reduced.

Owner:CHINA MOBILEHANGZHOUINFORMATION TECH CO LTD +1

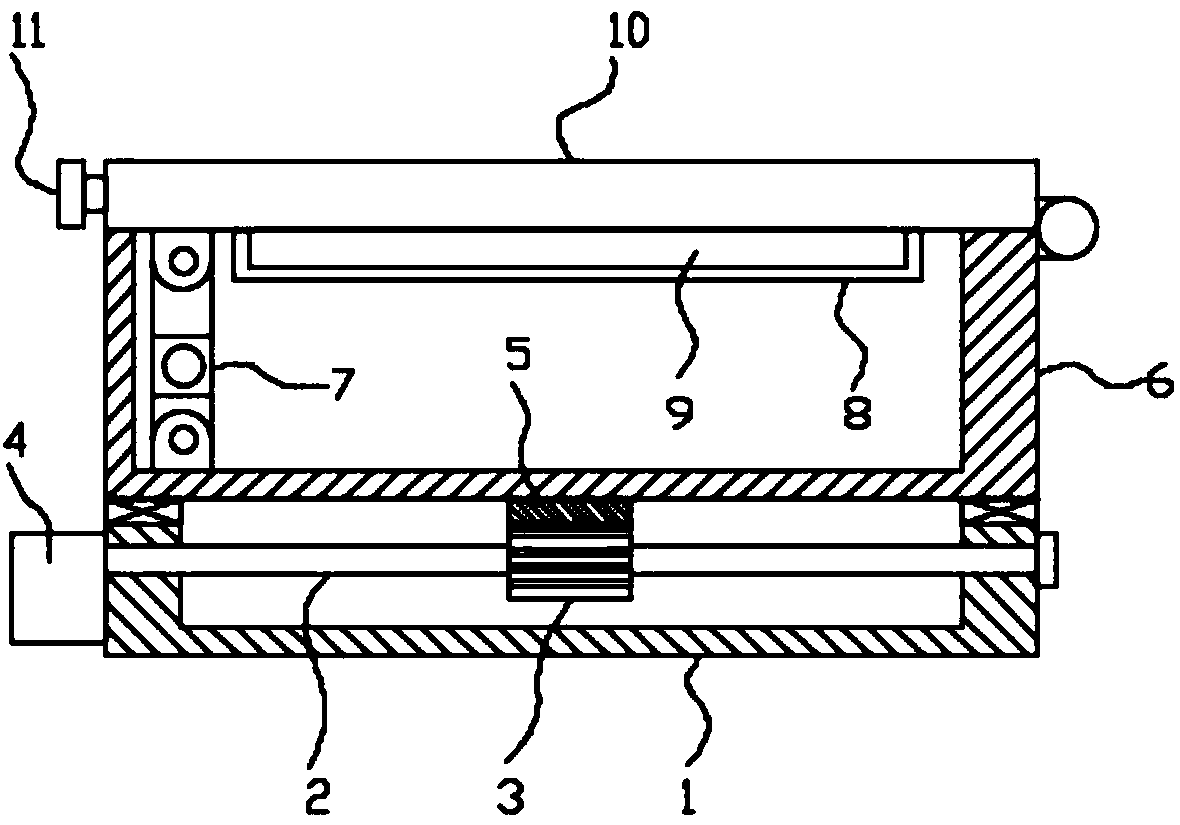

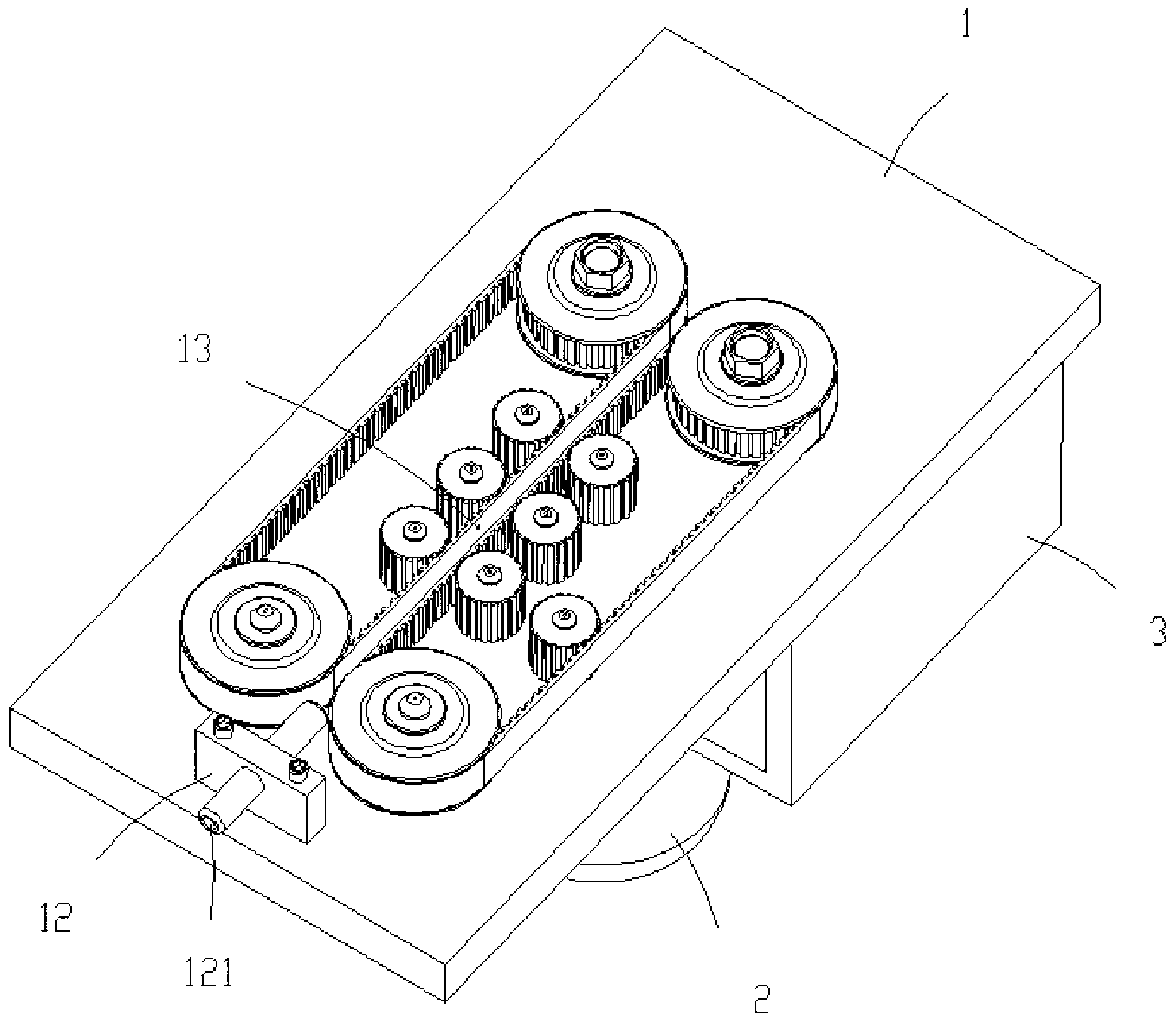

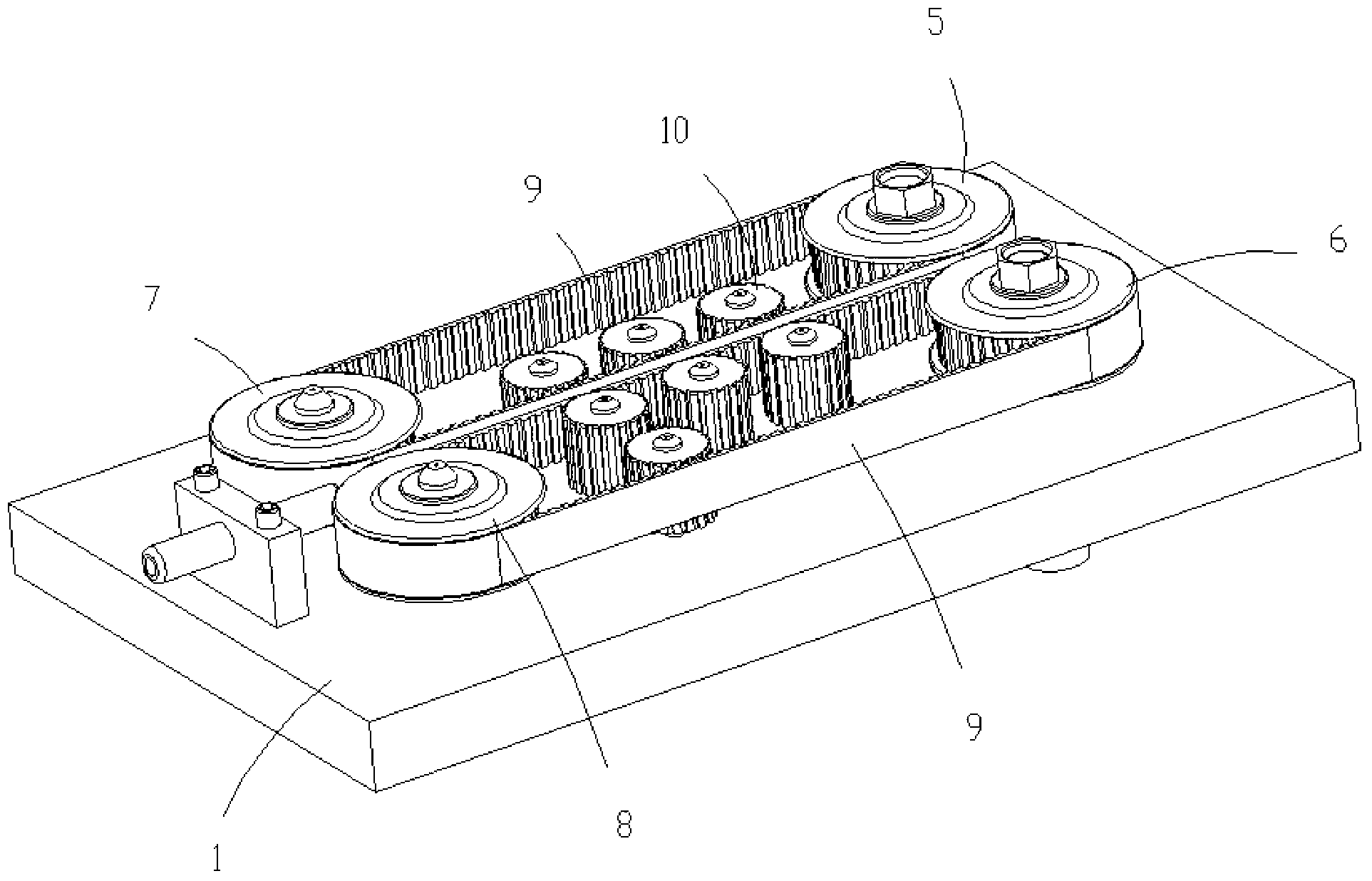

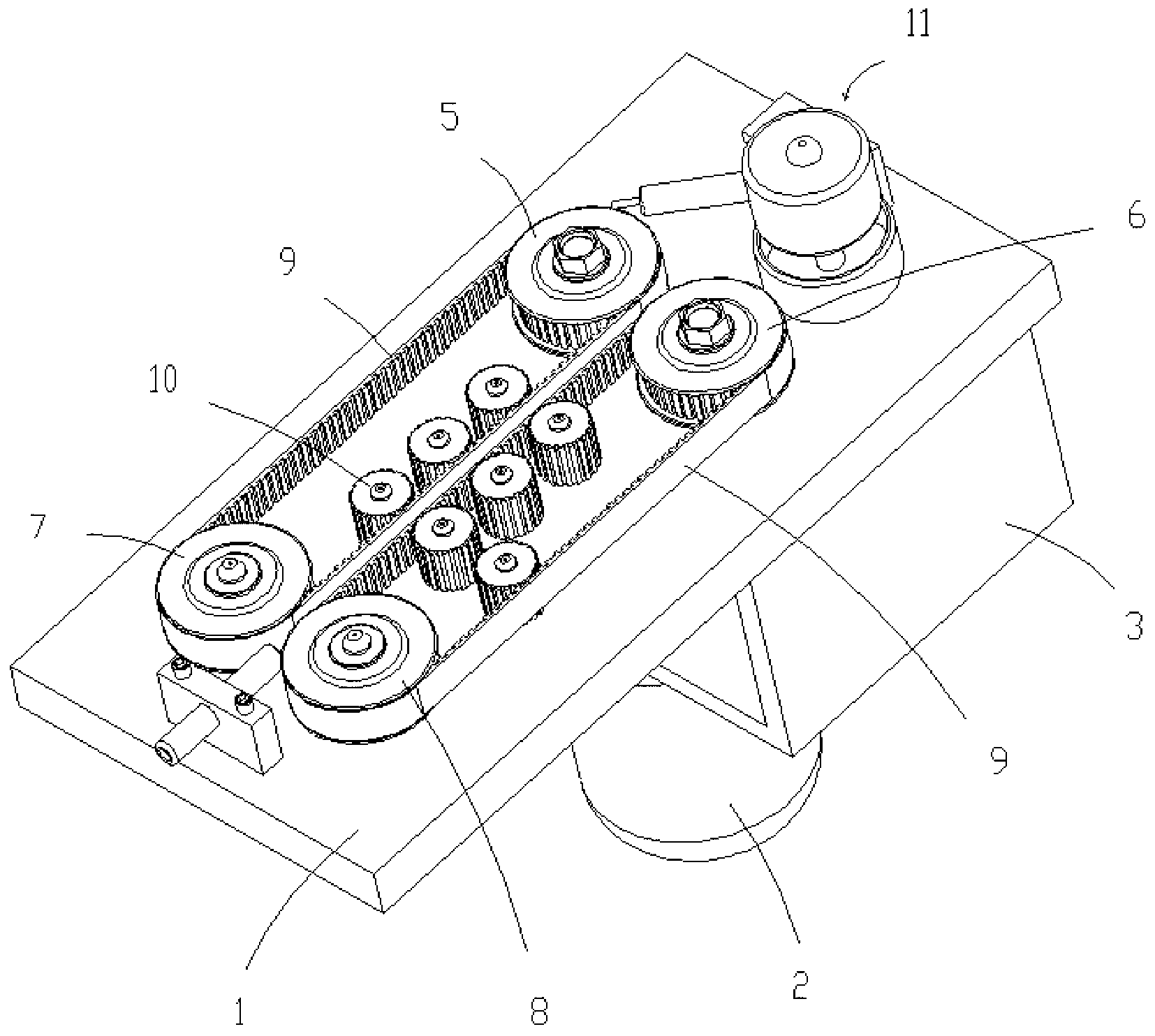

Electric cable synchronous driving device

The invention discloses an electric cable synchronous driving device which comprises a mounting plate (1) and a motor (2). A first belt wheel (5), a second belt wheel (7), a third belt wheel (6) and a fourth belt wheel (8) are hinged on the mounting plate (1), a belt (9) is tensioned on the first belt wheel (5) and the second belt wheel (7), another belt (9) is tensioned on the third belt wheel (6) and the fourth belt wheel (8), a passage (13) allowing electric cables to pass is formed between the two belts (9), and the first belt wheel (2) and the third belt wheel (6) are driven by the motor (2). By the electric cable synchronous driving device, processing of the electric cables are more convenient and processing accuracy can be improved.

Owner:AQ ELECTRIC SUZHOU

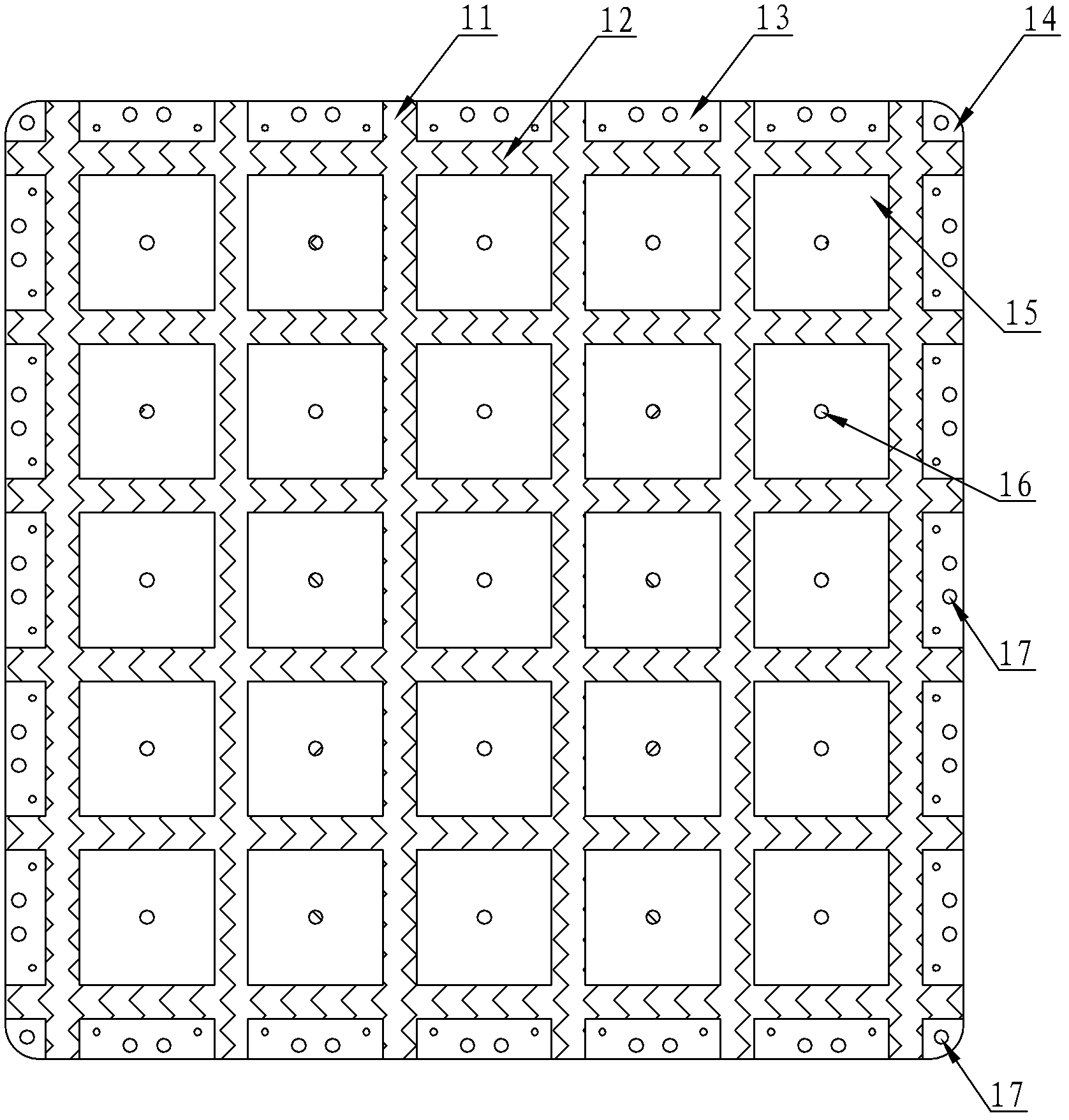

Locating crystal support for cutting polycrystalline silicon ingot

InactiveCN102626961AExtended service lifeStable supportWorking accessoriesFine working devicesIngotEngineering

The invention relates to a locating crystal support for cutting a polycrystalline silicon ingot, which comprises a base plate, a side face locking device, an angle locking device and the polycrystalline silicon ingot, wherein a support seat is arranged on the bottom end of the base plate; an adhesive hole is arranged in a box; two fixed counter bores are arranged in a side face locating module; a fixed counter bore is arranged in the center of an angle locating module; the side face locking device is arranged on the side face locating module; and the angle locking device is arranged on the angle locating module. According to the crystal support, the most effective stability function can be played on the polycrystalline silicon ingot, the location is accurate, the processing of linear cutting cannot be affected, the base plate cannot be abraded easily in a long-time use process, and the service life of the base plate is greatly prolonged.

Owner:JIANGSU ZHAOJING PHOTOELECTRIC TECH DEV

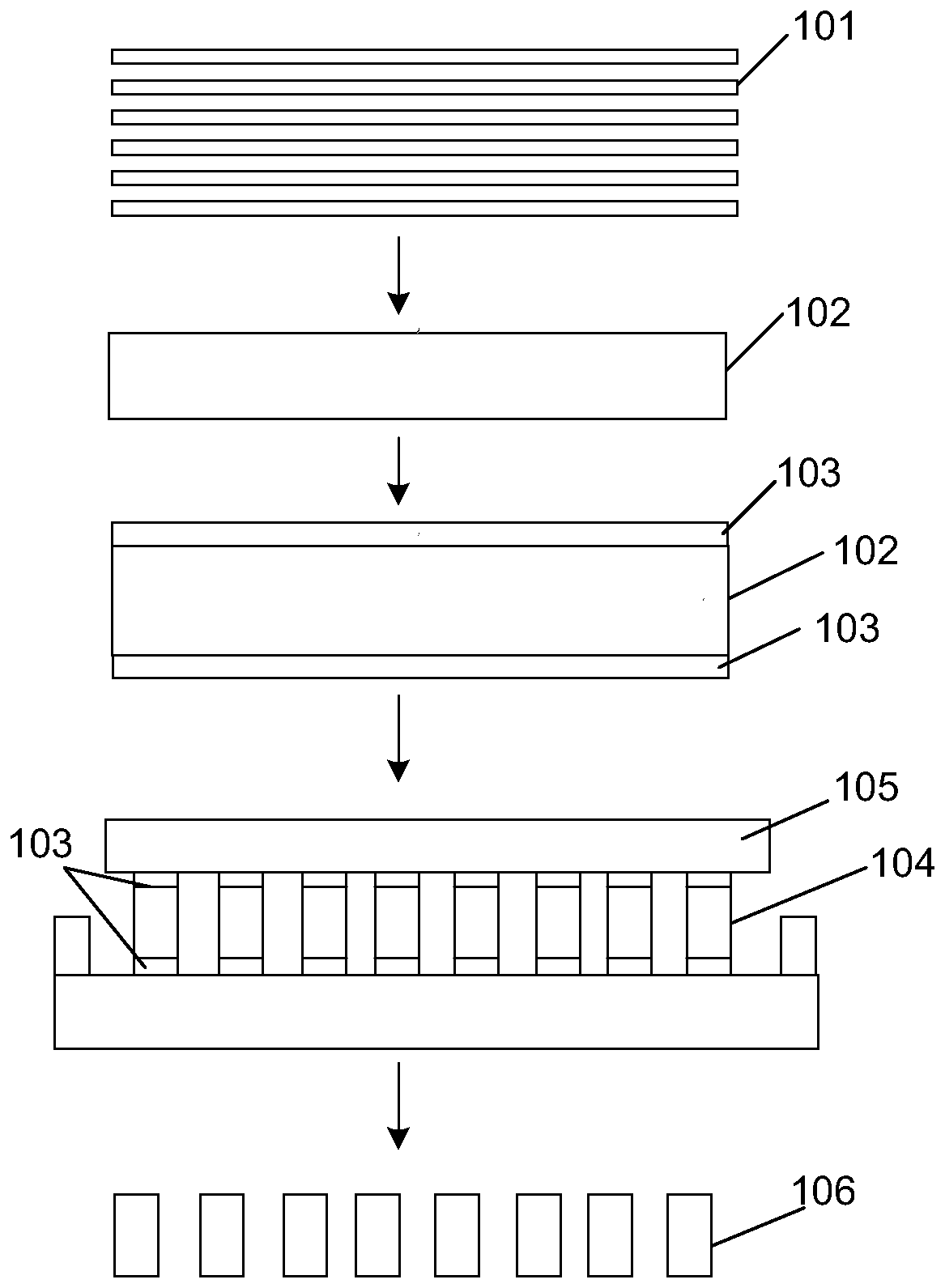

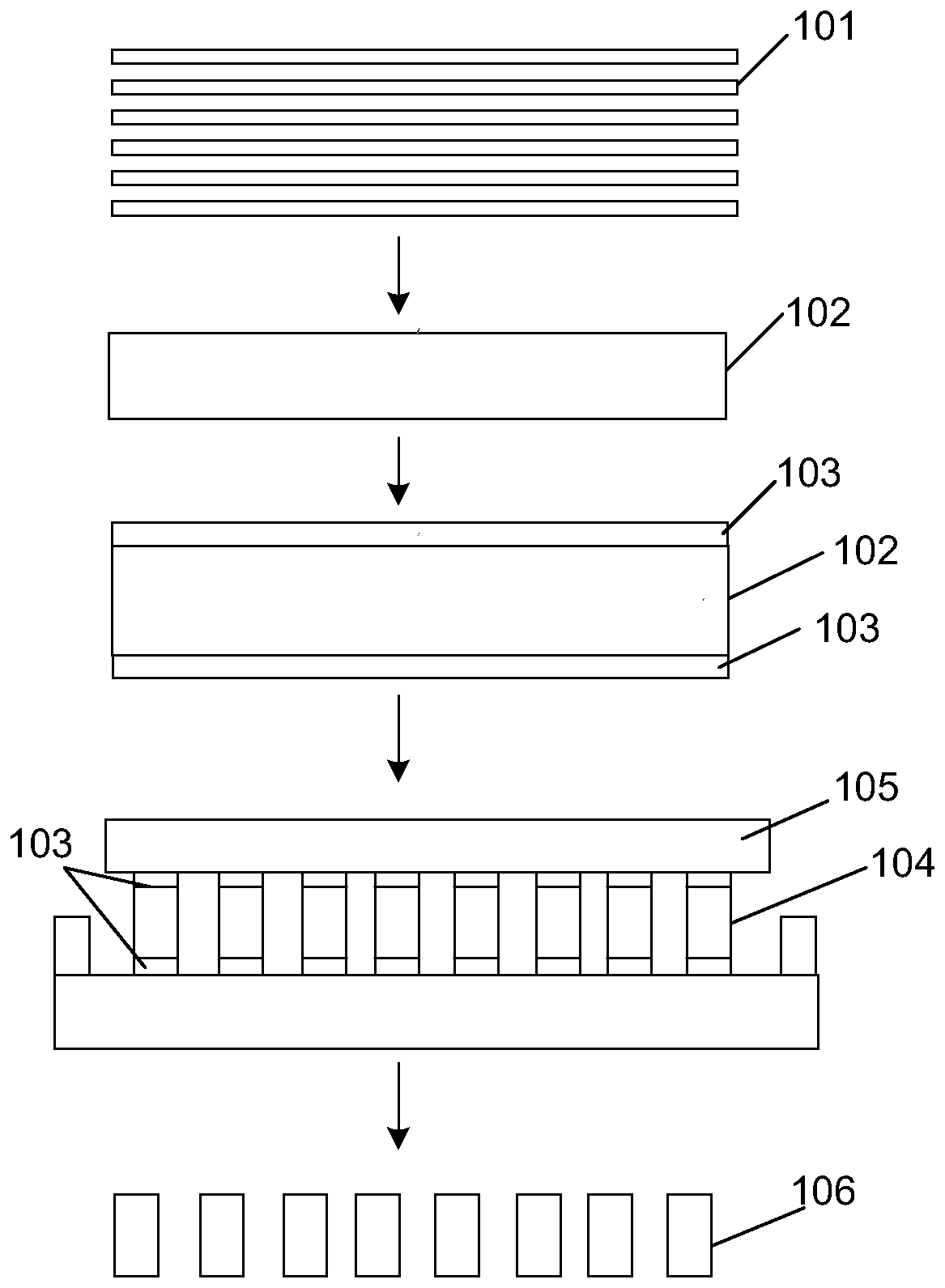

Method for processing laminated chip type electronic component

ActiveCN110012618AProtect the substrate surfaceAvoid cutting damagePrinted circuit secondary treatmentMultilayer circuit manufactureElectrical and Electronics engineeringProduction line

The invention discloses a method for processing a laminated chip type electronic component. The method comprises the steps of (S1) separately stacking at least one layer of carbon-based sacrificial sheet on upper and lower surfaces of a multi-layer substrate, wherein the multi-layer substrate is formed by processing multiple single-layer raw porcelain pieces, and circuits are printed on the surfaces of the single-layer raw porcelain pieces, (S2) performing isostatic pressing on a product formed in step (S1), (S3) cutting the product which is subjected to isostatic pressing in step (S2) into asingle component, and (S4) sintering a product cut in step (S3) to obtain the laminated chip type electronic component after the carbon-based sacrificial sheets are completely decomposed and disappearduring the sintering process. According to the method, the cutting damage can be prevented, the adding of new equipment in a production line is not needed, and the method has the advantages of low cost and high efficiency and is suitable for the mass processing of existing laminated chip type electronic components.

Owner:东莞顺络钽电容电子有限公司

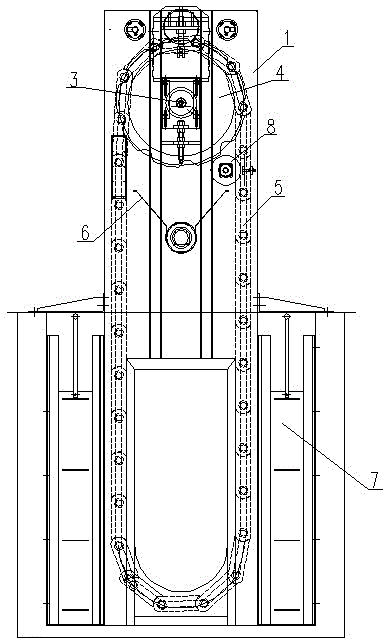

Inward-feeding-type rotary filter screen grille cleaner with cleaning brush

InactiveCN104028028AWill not affect processingSimple structureMoving filtering element filtersSlagWire wheel

The invention relates to an inward-feeding-type rotary filter screen grille cleaner with a cleaning brush. The inward-feeding-type rotary filter screen grille cleaner comprises a cleaner body, a speed reducer, a main shaft, chain wheels and a net chain plate. The speed reducer is fixedly installed a side of the upper end of the cleaner body. The main shaft is connected to the speed reducer. Front and rear two ends of the main shaft are provided respectively with the chain wheels. The net chain plate sleeves the chain wheels. A slag collecting groove is arranged in the net chain plate. The slag collecting groove is located right under the chain wheels. Left and right two sides of the lower end of the net chain plate are provided with water blocking plates. The inward-feeding-type rotary filter screen grille cleaner is characterized in that the cleaning brush is arranged at an included angle position between the lower end of the chain wheel and the net chain plate and the cleaning brush is a steel wire wheel brush and rotates by being driven by a motor installed at a side of the cleaner body. The inward-feeding-type rotary filter screen grille cleaner has a simple structure. Through the cleaning brush arranged at the included angle position between the lower end of the chain wheel and the net chain plate, residual materials on the net chain plate can be cleaned well so that normal device running is guaranteed and follow-up sewage treatment is not influenced.

Owner:JIANGSU TIANYU ENVIRONMENTAL PROTECTION GRP CO LTD

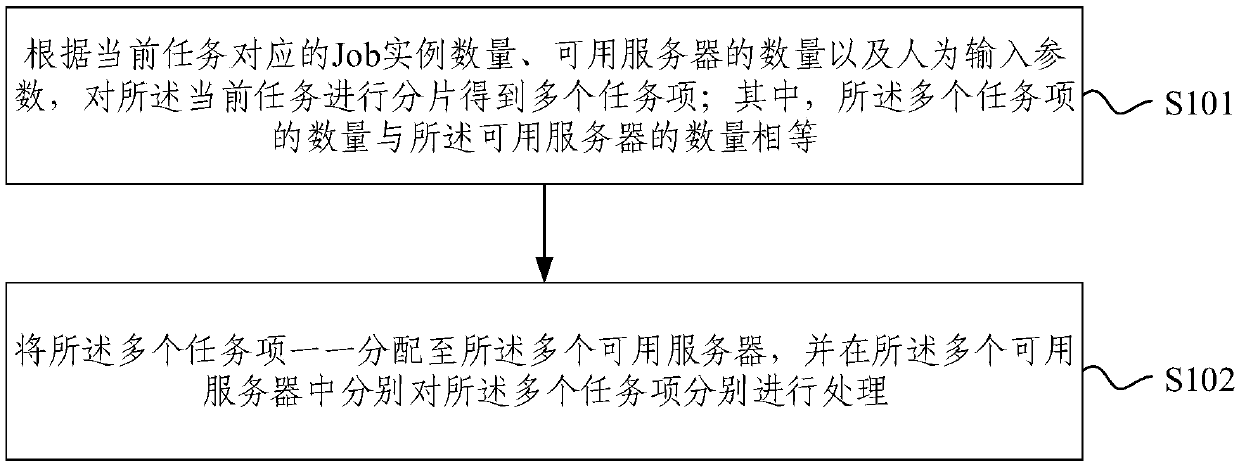

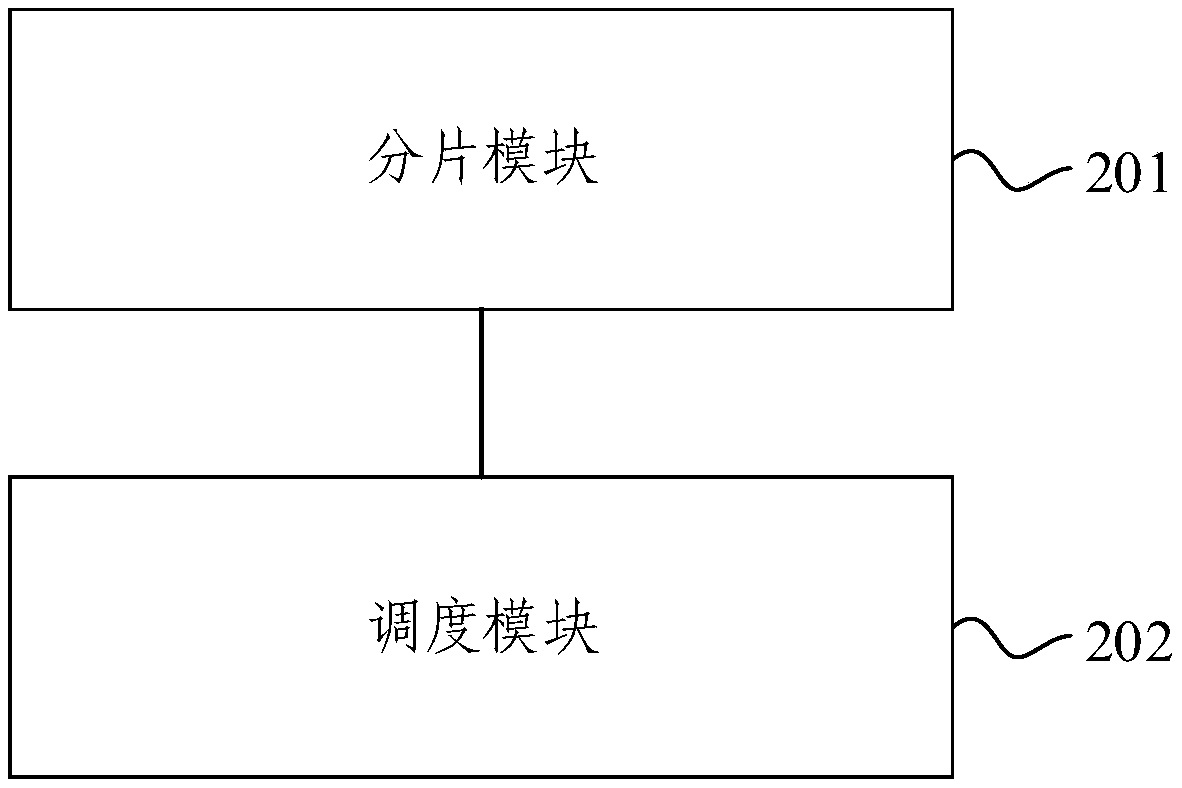

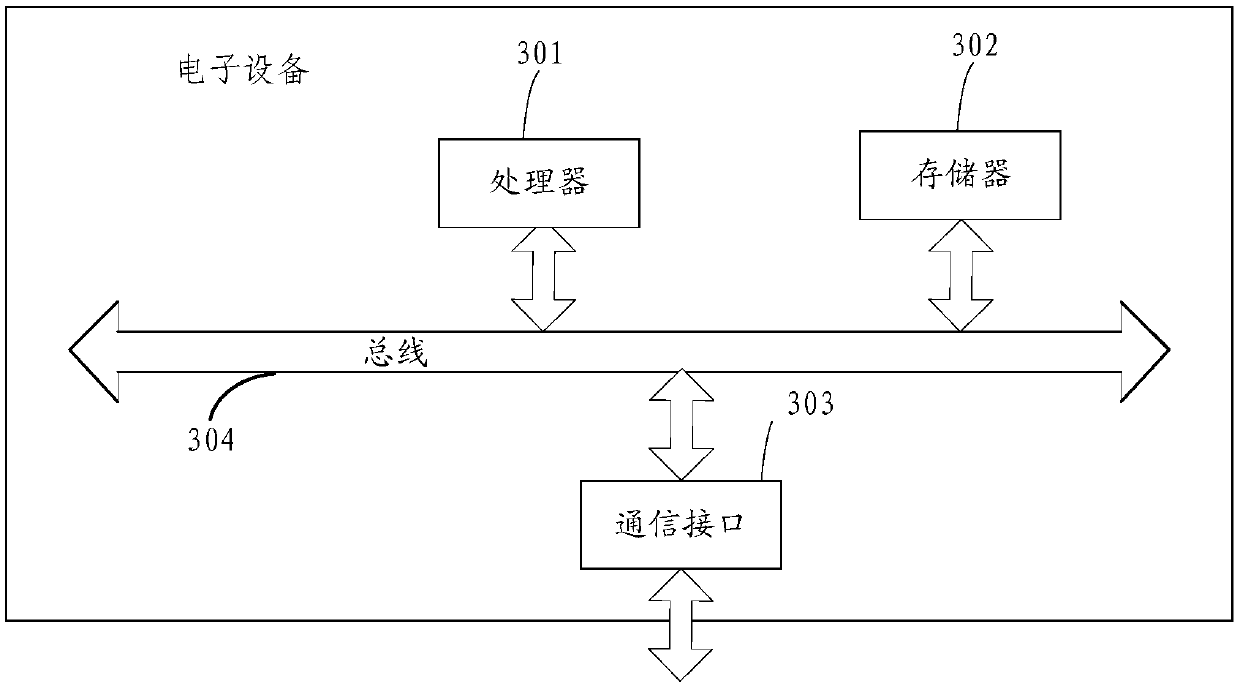

Distributed process scheduling method and system

PendingCN111158896AImprove throughputGreatly improved throughputResource allocationEngineeringParallel processing

The embodiment of the invention provides a distributed process scheduling method and system. The method comprises the steps: carrying out the fragmentation of a current task according to the number ofJob instances corresponding to the current task, the number of available servers and manual input parameters, and obtaining a plurality of task items; wherein the number of the plurality of task items is equal to the number of the available servers; and allocating the plurality of task items to the plurality of available servers one by one, and respectively processing the plurality of task itemsin the plurality of available servers. The method comprises the following steps: fragmenting a current task in a distributed scheduling task environment; compared with an existing stand-alone timing scheduling mode, the method has the advantages that the processing capacity is greatly improved, the processing process of other servers cannot be affected when one server is abnormal, the throughput is large, and the stability is high.

Owner:CHINA MOBILE GROUP SHAIHAI +1

Building material acrylic plate production and manufacturing equipment

InactiveCN111633714APlace stableEfficient cuttingMetal working apparatusConstruction engineeringMachining

The invention relates to building material acrylic plate production and manufacturing equipment. The building material acrylic plate production and manufacturing equipment comprises a supporting frame, a through middle containing cavity with an opening is formed in the supporting frame, and an acrylic plate is arranged in the middle containing cavity; and a sliding cutting-off device capable of ascending, descending, sliding left and right, achieving the cooling process in the process and cutting off the acrylic plate is arranged in the middle containing cavity, and a power connecting device located in the supporting frame and used for driving the sliding cutting-off device to move front and back and left and right is arranged on one side of the sliding cutting-off device. The building material acrylic plate production and manufacturing equipment is simple in structure, the acrylic plate is stably placed by means of the equipment, meanwhile, the structure capable of dissipating heat when the acrylic plate is cut is utilized, the acrylic plate can be efficiently cut by the equipment, and meanwhile the situation that the temperature of the acrylic plate and a cutting knife is too high, and consequently continuous machining of the acrylic plate by the equipment is influenced is avoided; and the acrylic plate can be cut off at multiple angles.

Owner:王涛

Punching, cutting and cleaning device for door frame aluminum profile

InactiveCN112122933AImprove work efficiencyEasy to transportOther manufacturing equipments/toolsMaintainance and safety accessoriesPunchingDust control

The invention provides a punching, cutting and cleaning device for a door frame aluminum profile. The punching, cutting and cleaning device comprises a workbench, a sliding rail for placing the aluminum profile, a translation driving mechanism for driving the aluminum profile to move along the sliding rail, a punching mechanism, a cutting mechanism and a cleaning mechanism, the sliding rail is arranged in the length direction of the workbench, the translation driving mechanism, the punching mechanism and the cutting mechanism are sequentially arranged on the workbench in the moving direction of the aluminum profile, and the cleaning mechanism comprises a first dust removal assembly used for punching dust removal, a second dust removal assembly used for cutting dust removal and a cutting piece cleaning assembly. The aluminum profile punching and cutting device can conduct punching and cutting on the aluminum profile at the same time, the working efficiency is greatly improved, the dustremoval rate is high, the dust removal effect is excellent, and subsequent machining cannot be affected.

Owner:宣城市恒之冉铝材科技有限公司

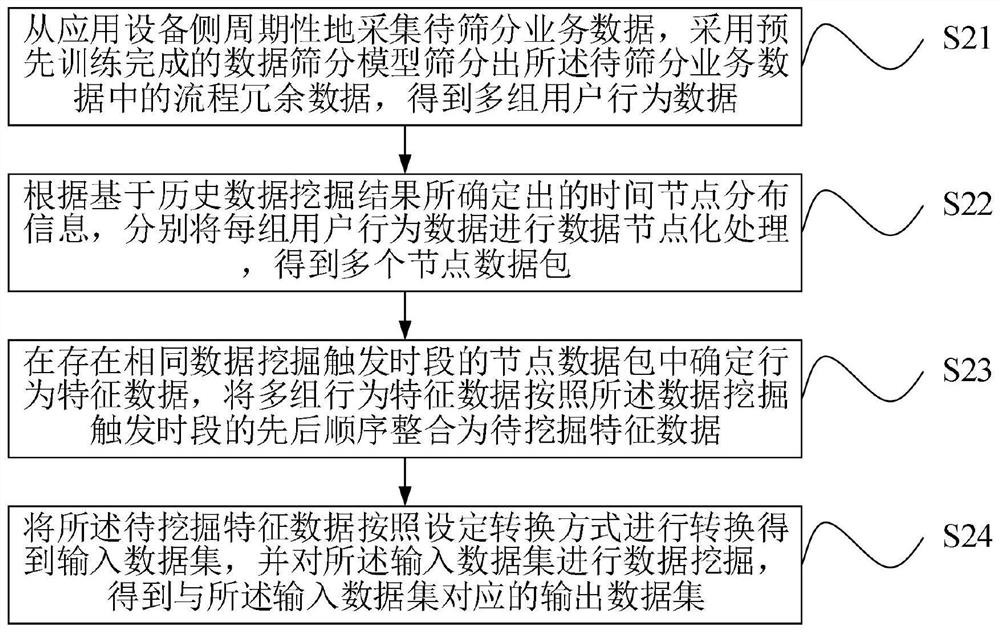

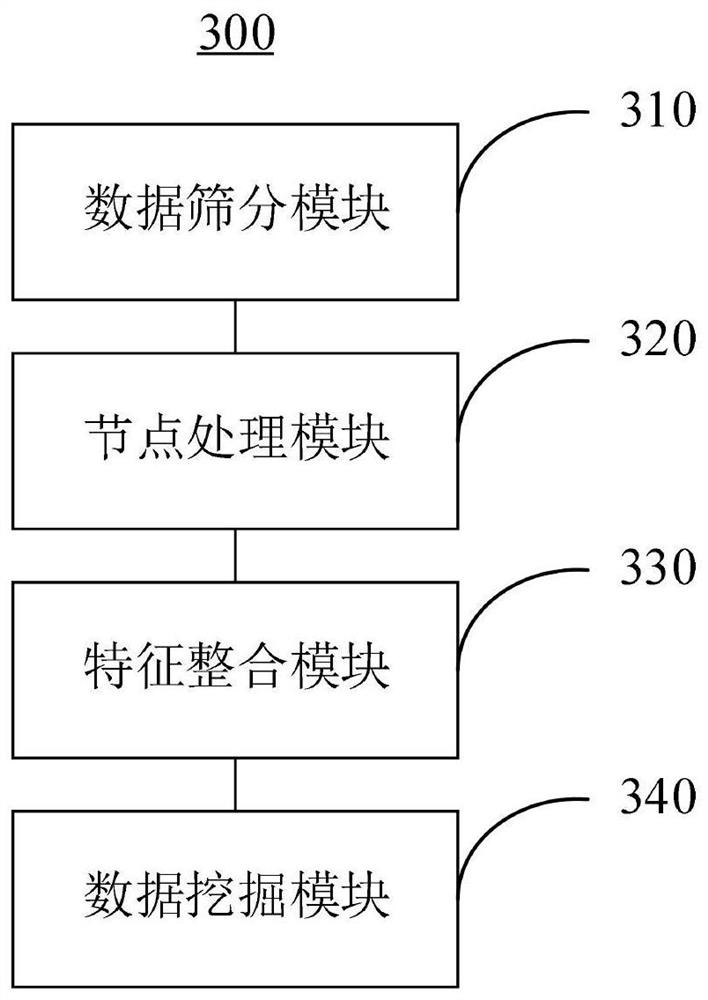

Big data analysis method and artificial intelligence platform applied to cloud computing communication architecture

ActiveCN112199411AReduce data sizeImprove digging efficiencyDatabase management systemsSpecial data processing applicationsData packData set

The invention discloses a big data analysis method and an artificial intelligence platform applied to a cloud computing communication architecture, and the method comprises the following steps: firstly screening out flow redundant data in to-be-screened business data through employing a data screening model, so as to obtain a plurality of groups of user behavior data; secondly, according to time node distribution information determined based on a historical data mining result, performing data nodularization processing on each group of user behavior data to obtain a plurality of node data packets; then determining behavior characteristic data in the node data packets with the same data mining triggering time period, integrating the behavior characteristic data into to-be-mined characteristic data according to the sequence of the data mining triggering time periods, and finally converting the to-be-mined characteristic data according to a set conversion mode to obtain an input data set;and performing data mining on the input data set to obtain an output data set corresponding to the input data set. Therefore, the accuracy of the data mining result can be ensured on the premise of reducing the size of the feature data needing to be mined as much as possible, and the data mining efficiency is improved.

Owner:厦门立马耀网络科技有限公司

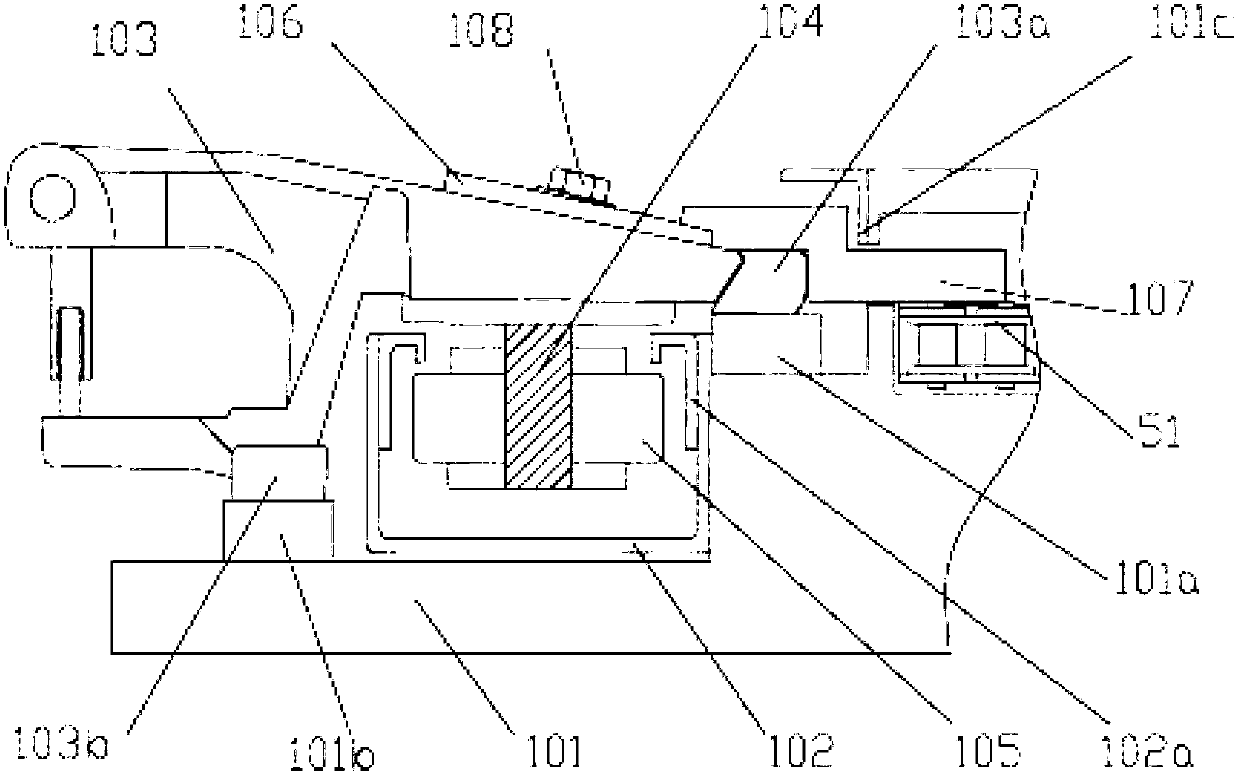

Rolling processing device of transition piece for battery processing

InactiveCN112108562AWill not affect processingEasy to useShaping toolsCleaning using gasesPhysicsEngineering

The invention discloses a rolling processing device of a transition piece for battery processing, and belongs to the technical field of battery processing equipment. The rolling processing device comprises a support frame, a lining moving table, a cleaning device, a limiting device, a rolling device and two side edge pressing devices, wherein the lining moving table is horizontally arranged at thetop of the support frame, and the cleaning device is arranged at the top of the support frame. The limiting device is arranged on the side wall of the support frame, the rolling device comprises a rolling assembly and an adjusting assembly, the rolling assembly is vertically arranged at the top of the support frame, the adjusting assembly is arranged on the rolling assembly, and the two side edgepressing devices are symmetrically arranged on the two sides of the top of the support frame. By rotating a rotating hand disc, the rotating hand disc rotates on an adjusting plate to drive a slidingbase to move on a rolling base, the position of an upper rolling column is moved downwards, the distance between the upper rolling column and a lower rolling column is adjusted according to differentrolling requirements, and different rolling requirements for the transition piece are met.

Owner:惠州市振邦精密五金有限公司

Buffer device for machining and manufacturing

InactiveCN109605116AWill not affect processingImprove buffering effectMaintainance and safety accessoriesAssistive device/technologyEngineering

The invention discloses a buffer device for machining and manufacturing, and relates to the technical field of machining auxiliary equipment. An upper base is arranged at the upper side of a lower base; four side walls and the bottom inside the upper base are fixedly equipped with buffer cushions which are of semi-circular structures, and raised grains are arranged on the outer walls of the buffercushions; hook rings I are fixedly arranged on the inner walls of the four sides of the upper side of the upper base; tension springs are hooked in the hook rings I; the tail ends of the tension springs are hooked in hook rings II; and the hook rings II are arranged inside the upper base, and are fixedly arranged on external processing equipment; a cavity is arranged in a housing of the upper base; a buffer mechanism I is arranged on the bottom of the cavity; buffer mechanisms II are arranged at the four sides of the cavity; an inner cavity is arranged in the lower base; and a multi-buffer damping mechanism is arranged on the bottom, so that buffering and damping effects are improved, and processing of a workpiece is not affected; and sides are equipped with buffer and damping mechanisms,so that multi-direction buffer and damping can be performed, and therefore, the processing equipment is not easily vibrated or impacted, a fault rate is reduced, and the service life is prolonged.

Owner:JIANGSU SECURITY TECH CARRER ACADEMY

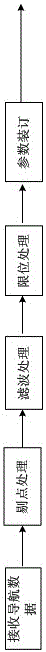

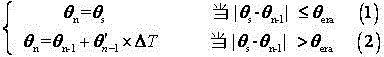

A navigation information filtering method increasing moving alignment precision

PendingCN106403937AAccurate and efficient calculationVersatileNavigation by speed/acceleration measurementsSustainable transportationAngular velocityReal-time computing

A navigation information filtering method increasing moving alignment precision is disclosed. The method includes receiving, by an information interface assembly, navigation data sent by a comprehensive navigation device, subjecting the navigation data to point elimination, limiting and filtering treatment, and outputting an angle, an angular velocity and a ship velocity. The method overcomes a problem of how to obtain smooth and continuous transfer alignment information used for aircrafts through processing high-frequency navigation data in a situation that a shipboard platform is accompanied with vertical and horizontal swing.

Owner:SHANGHAI INST OF ELECTROMECHANICAL ENG

Fabric sewing auxiliary device for automatic textile machinery

ActiveCN110863303AEasy to moveEasy to adjustWork-feeding meansWaste collectionMechanical engineering

The invention relates to the technical field of fabric sewing auxiliary device for automatic textile machinery, in particular to a fabric sewing auxiliary device for automatic textile machinery. The fabric sewing auxiliary device comprises a worktable, the upper surface of the worktable is provided with an operating cavity, a fabric fixing plate is arranged in the operating cavity, balls fitting the bottom surface of the operating cavity are movably inlaid at the bottom edge of the fabric fixing plate, and the fabric fixing plate is movably mounted in the operating cavity through a hinge mechanism. By arrangement of a component for controlling the fabric fixing plate to move in multiple directions, convenience in moving and adjustment of the fabric fixing plate is achieved, and only designof a vertical-lifting fabric sewing mechanism is required, so that production cost is reduced, and structural simplicity is realized. By arrangement of a component for convenience press fitting of fabrics and a component for fabric suction fixation, stable fixation of the fabrics is facilitated, and the fixed fabrics are less prone to deviation. By arrangement of a part for collecting waste in afabric sewing process, convenience in waste collection is achieved, and processing is unaffected.

Owner:临泉县浪鲨克工贸有限公司

Spinning equipment for cotton thread

The invention belongs to the field of textile machinery, and discloses spinning equipment for cotton thread. The spinning equipment comprises a winding part allowing the cotton thread to penetrate through and a power part used for providing power for the winding part; the winding part comprises an upper pressing plate and a lower pressing plate, wherein the upper pressing plate and the lower pressing plate can move relative to each other; connecting rods and guide wheels are arranged on the upper pressing plate and the lower pressing plate, wherein the connecting rods extend inwards, and the guide wheels are connected to the connecting rods in a rotating mode; the guide wheels on the upper pressing plate and the guide wheels on the lower pressing plate are arranged in a staggered mode; the winding part is provided with an inlet allowing the cotton thread to enter the winding part; the second guide wheel, close to the inlet, among all the guide wheels is a trigger wheel; the connecting rod connected to the trigger wheel is a retractable rod with the retractable function; a tension spring used for compressing the retractable rod is connected to the retractable rod; a pressing switch capable of being pressed by the trigger wheel is arranged beside the connecting position of the retractable rod; the power part comprises a movable base which is driven by a motor to move; and pull rods for enabling the upper pressing plate and the lower pressing plate to be in linkage with the movable base are connected between the movable base and the upper pressing plate as well as between the movable base and the lower pressing plate separately.

Owner:ZUNYI TIANYUN TEXTILE CO LTD

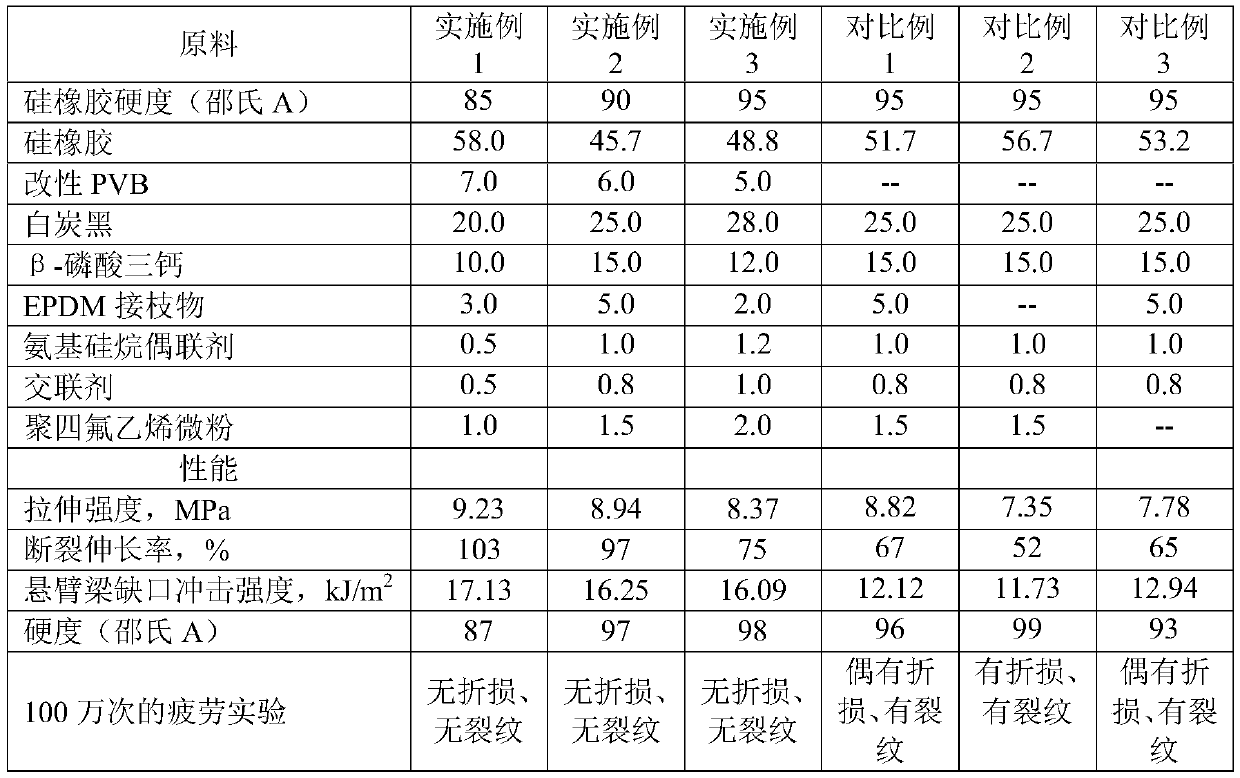

Silicone rubber composite material for fused deposition 3D printing and preparation method thereof

ActiveCN110527297AImprove adhesionImproved resistance to fatigue crackingAdditive manufacturing apparatus3D object support structuresCalcium biphosphatePolymer science

The invention discloses a silicone rubber composite material for fused deposition 3D printing and a preparation method thereof. The invention discloses the silicone rubber composite material which canbe used in a fused deposition 3D printing process, has adjustable hardness, and has a fatigue resistant function, and a preparation method thereof. The composite material comprises the following components in parts by mass: 45.7-58.0 parts of a silicone rubber, 5.0-7.0 parts of a modified PVB, 20.0-28.0 parts of white carbon black, 10.0-15.0 parts of calcium phosphate, 2.0-5.0 parts of a EPDM graft, 0.5-1.2 parts of an amino-silane coupling agent, 0.5-1.0 part of a crosslinking agent, and 1.0-2.0 parts of a lubricant. Through rheological extruder blending and reaction compatibilization, compatibility of the silicone rubber, the bonding resin PVC with the inorganic reinforcing materials is improved, so that the silicone rubber composite material is endowed with good mechanical properties,fatigue resistance and adjustable hardness. The product is particularly suitable for production of fused deposition 3D printed dental medical equipment.

Owner:SOUTH CHINA UNIV OF TECH

Dustproof environment-friendly wood carving machine for wood sculpture

InactiveCN112109154AHigh recovery rateImprove work efficiencyProfiling/shaping machinesBark-zones/chip/dust/waste removalWorkbenchIndustrial engineering

The invention discloses a dustproof environment-friendly wood carving machine for a wood sculpture, and relates to the technical field of wood carving machines. The dustproof environment-friendly woodcarving machine aims to solve the problem of recycling and cleaning waste wood chips of the wood carving machine. The dustproof environment-friendly wood carving machine specifically comprises a workbench; the outer wall of the bottom end of the workbench is fixedly connected with a support through screws; the outer wall of the top end of the workbench is connected with an arc-shaped electric guide rail through bolts; the inner wall of one side of the arc-shaped electric guide rail is slidably connected with a bearing sliding block; the outer wall of the top end of the bearing sliding block is fixedly connected with an adjusting box through the screws; the outer wall of the top end of the workbench is fixedly connected with a bearing block through the screws; a servo motor is connected tothe outer wall of the top end of the bearing block through the bolts; first electric guide rails are machined on the inner walls of the two sides of the workbench; the inner wall of one side of eachfirst electric guide rail is slidably connected with a supporting sliding block; and the outer walls of one sides of the supporting sliding block are fixedly connected with a beam through the screws.According to the dustproof environment-friendly wood carving machine for the wood sculpture, by arranging a chip removing cover, the purpose of comprehensively recycling wood chips generated during wood carving machining is achieved, the recycling rate of the wood chips is increased, and the working efficiency is improved.

Owner:衡阳市无量雕塑艺术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com