Spinning equipment for cotton thread

A cotton thread and equipment technology, which is used in the transportation of filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of repairing broken threads during shutdown, and the twisting machine cannot automatically detect broken threads, so as to avoid shutdown and save processing. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below by means of specific embodiments:

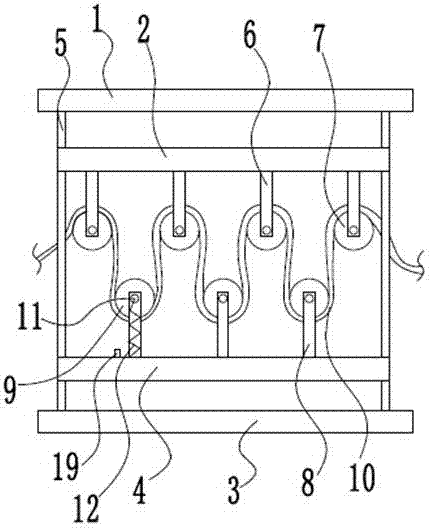

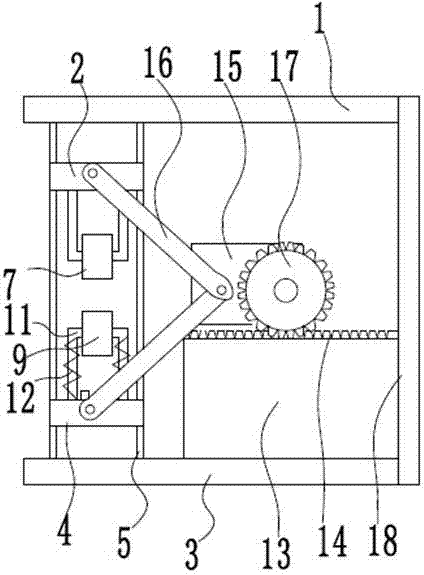

[0030] The reference signs in the drawings of the description include: top plate 1, upper platen 2, bottom plate 3, lower platen 4, guide column 5, upper connecting rod 6, upper guide wheel 7, lower link 8, lower guide wheel 9, cotton thread 10 , rotating shaft 11, extension spring 12, workbench 13, rack 14, movable seat 15, pull bar 16, gear 17, baffle plate 18, push switch 19.

[0031] Such as figure 1 and figure 2 As shown, the spinning equipment for cotton thread 10 includes a top plate 1 and a bottom plate 3 and four guide posts 5 connected between the top plate 1 and the bottom plate 3 . Between the top plate 1 and the bottom plate 3 are connected a winding part through which the cotton thread 10 passes and a power part for providing power for the winding part. The winding part includes an upper pressing plate 2 and a lower pressing plate 4 that can move relativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com