Electric cable synchronous driving device

A driving device and cable technology, which is applied in the field of cable synchronous driving device, can solve the problems affecting the processing accuracy, inconvenient processing, cable retraction, etc., and achieve the effect of improving precision and stable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following descriptions are only preferred embodiments embodying the principles of the present invention, and do not therefore limit the protection scope of the present invention

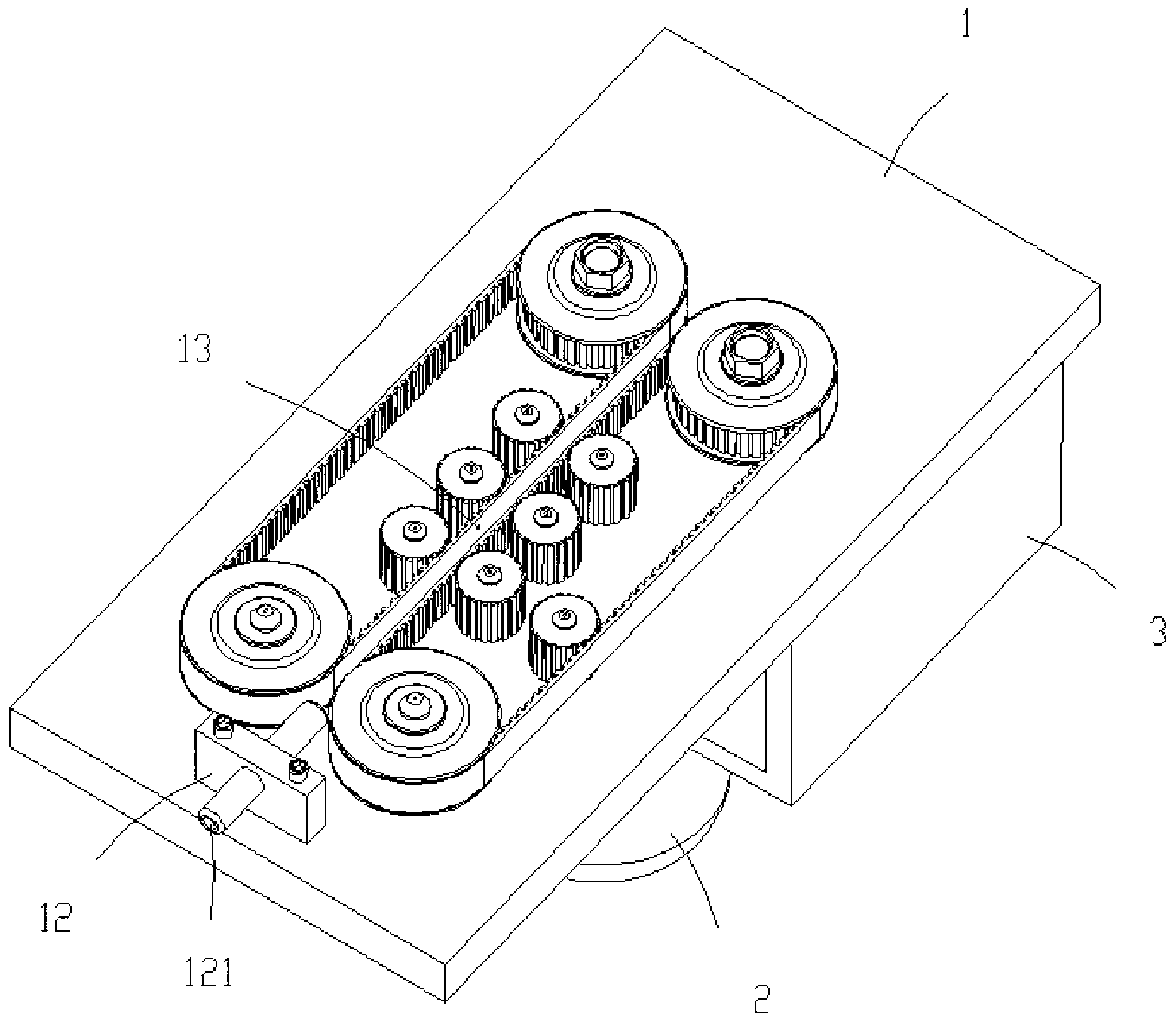

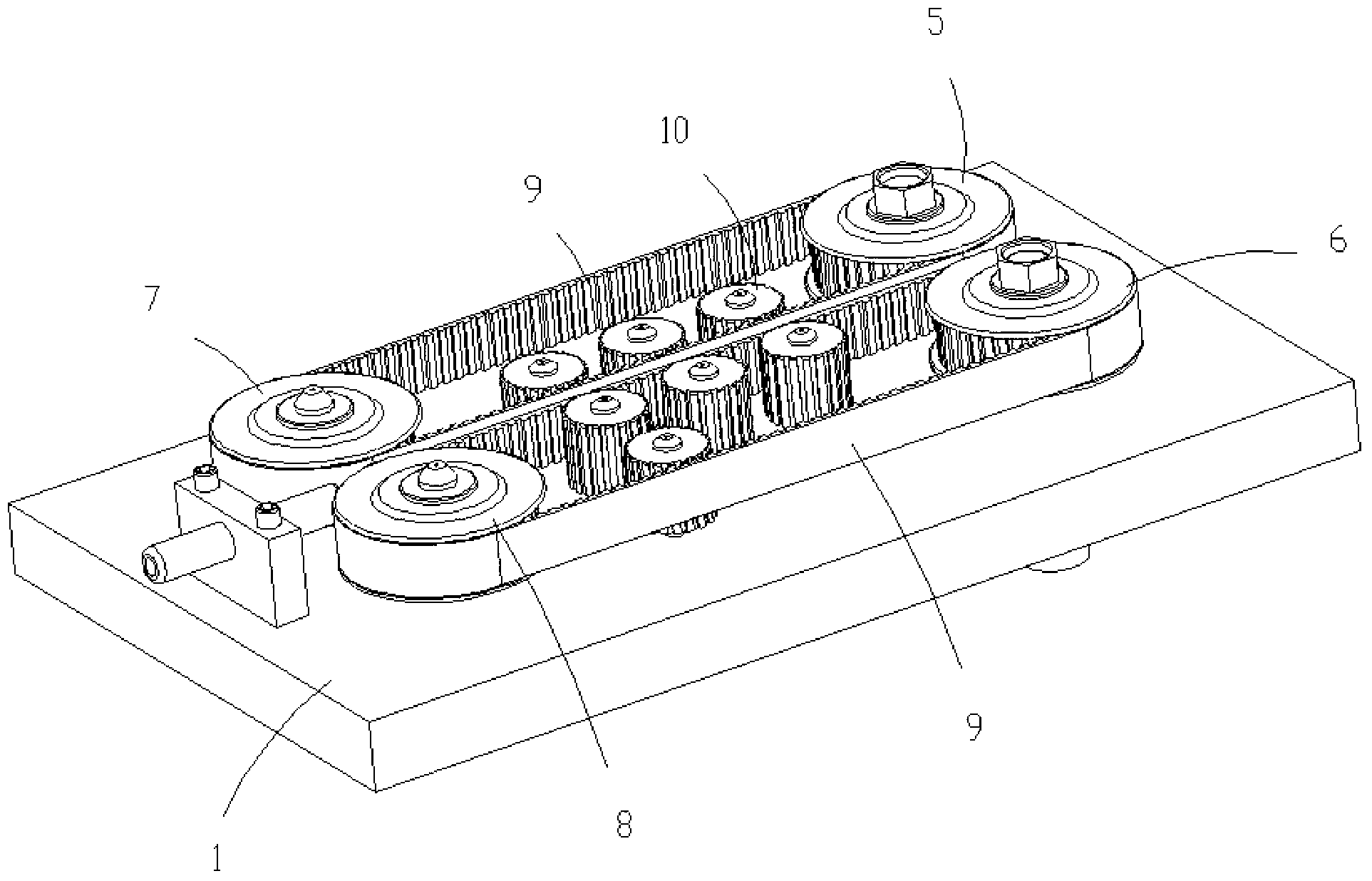

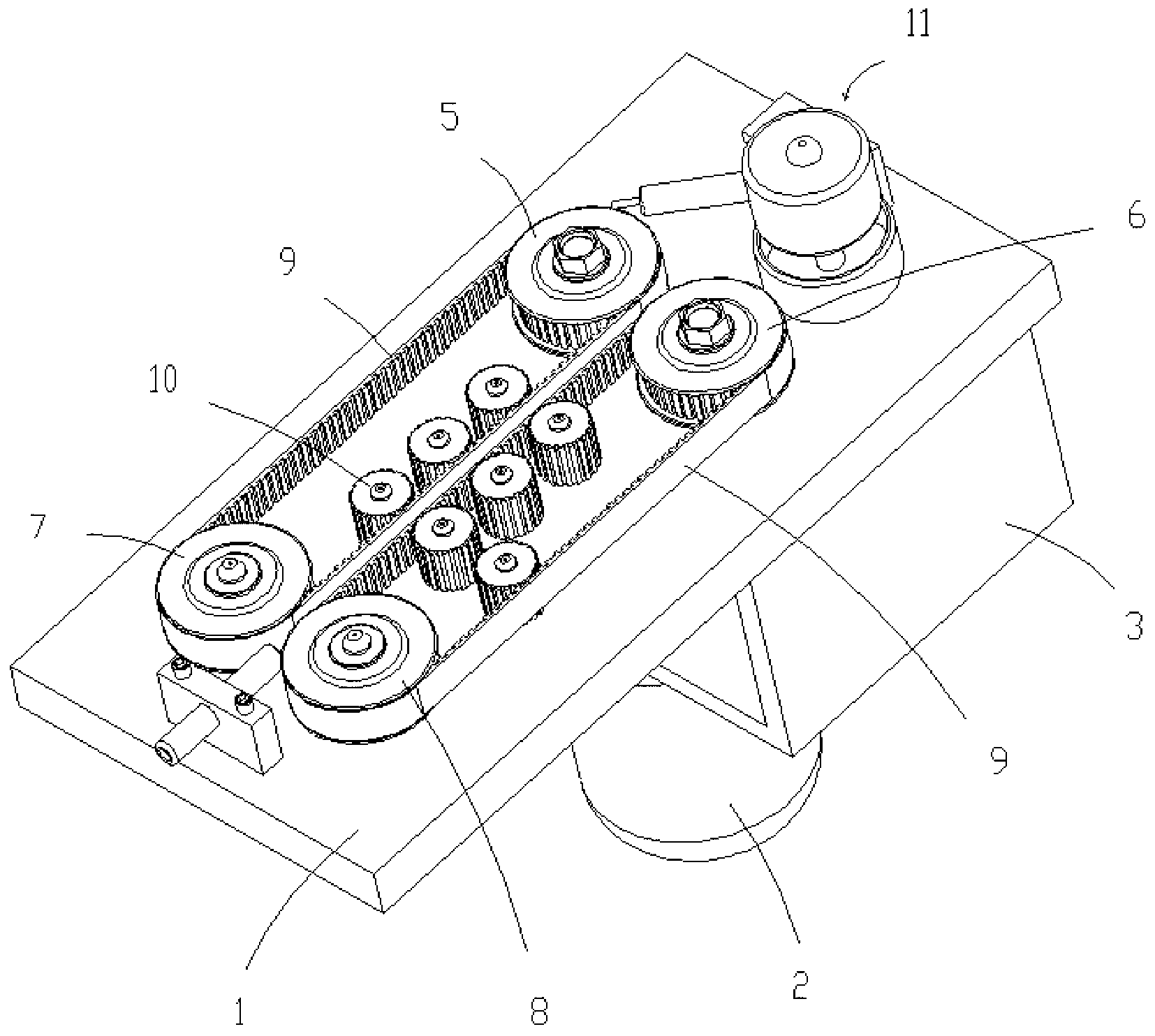

[0020] Such as Figures 1 to 4 Shown is an embodiment of a cable synchronous driving device, which includes a mounting plate 1 and a motor 2, and the mounting plate 1 is hinged with a first pulley 5, a second pulley 7, a third pulley 6 and a fourth pulley 8 , a belt 9 is tensioned on the first pulley 5 and the second pulley 7, another belt 9 is stretched on the third pulley 6 and the fourth pulley 8, and a passing cable is formed between the two belts 9 The aisle 13, the first pulley 2 and the third pulley 6 are driven by the motor 2.

[0021] A belt tensioning pulley 10 is installed on the mounting plate 1, and the belt tensioning pulley 10 presses against the inner side of the belt 9 on the side of the aisle 13. In this embodiment, seven belt tensioning pulleys 10 are arranged in total....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com