Method for processing laminated chip type electronic component

A technology of electronic components and processing methods, which is applied in the direction of electrical components, multi-layer circuit manufacturing, printed circuits, etc., can solve the problems that affect the appearance reliability of processed and formed devices, the surface defect of the substrate, and the lack of material strength, etc., to achieve low cost, Prevents cutting damage and protects the substrate surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The principles and features of the present invention will be described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not used to limit the scope of the present invention.

[0024] It should be noted that the orientation terms such as left, right, up, down, top, and bottom in this embodiment are only relative concepts, or refer to the normal use status of the product, and should not be regarded as having restrictive.

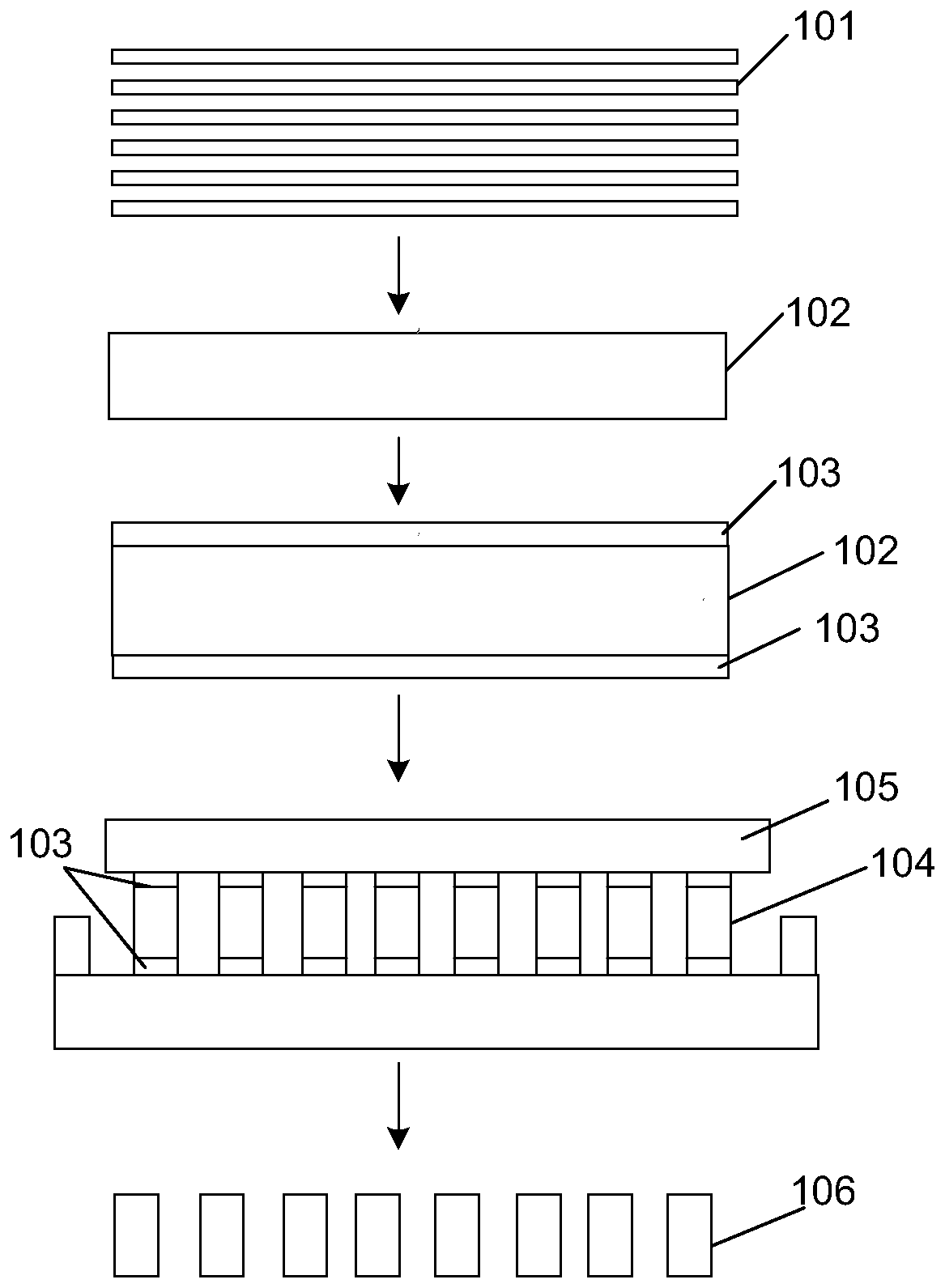

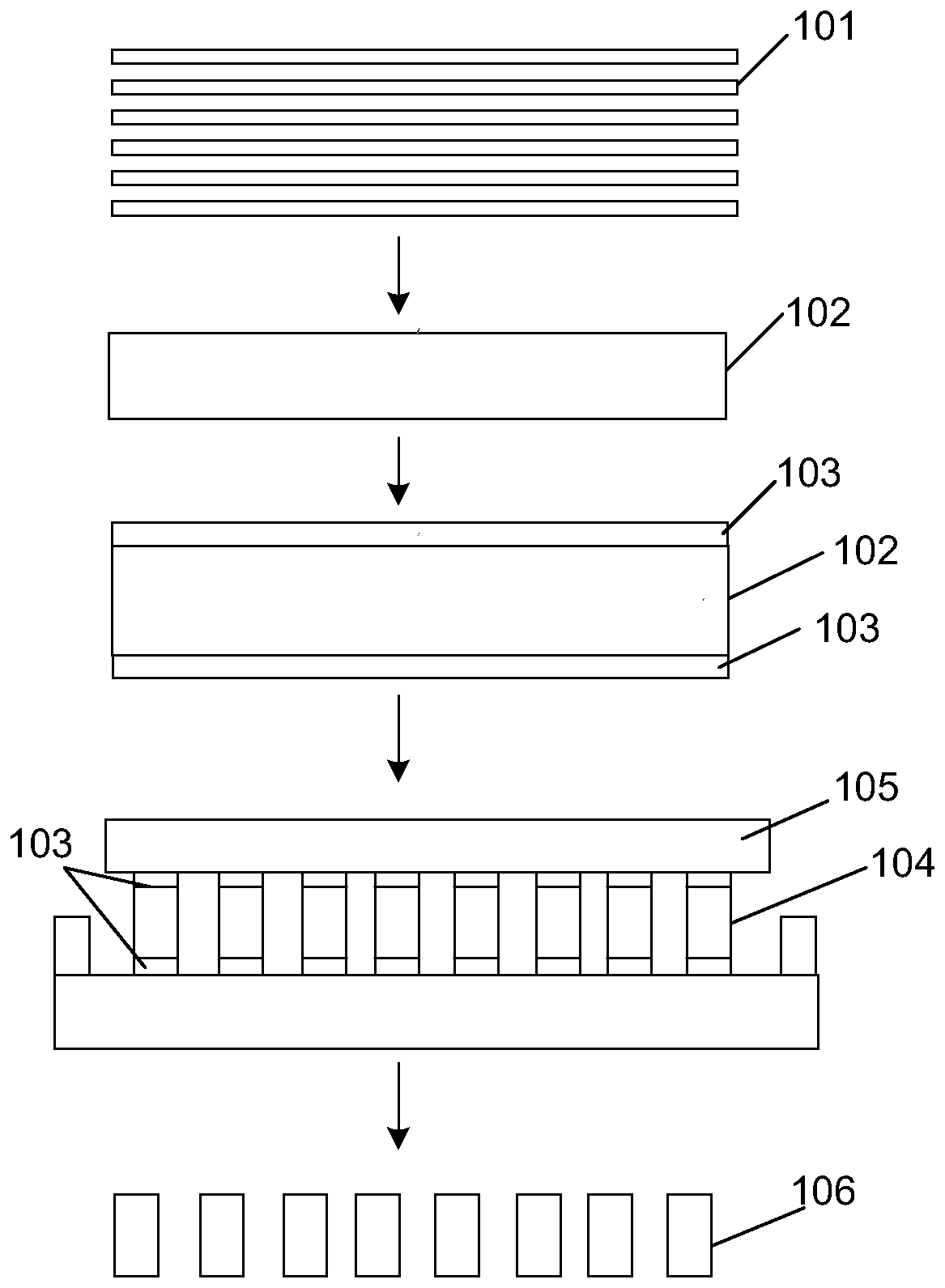

[0025] Such as figure 1 As shown, a processing method of laminated chip electronic components (hereinafter referred to as "components"), in a specific embodiment, the processing method includes the following steps:

[0026] S1. Laminate at least one layer of carbon-based sacrificial sheets on the upper and lower surfaces of the multilayer substrate. The multilayer substrate is processed by a plurality of single-layer green ceramic sheets with circuits printed on the surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com