Platen wood cutting device for papermaking

A cutting device and pressing plate technology, which is applied in woodworking safety devices, wood processing equipment, manufacturing tools, etc., can solve problems such as random flying, environmental pollution, and cut trees, so as to save production costs, reduce waste, and avoid random flying Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

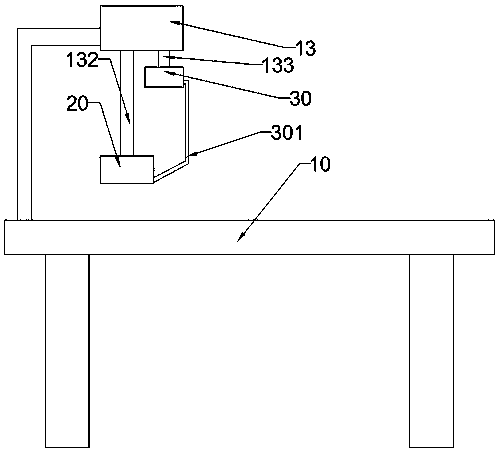

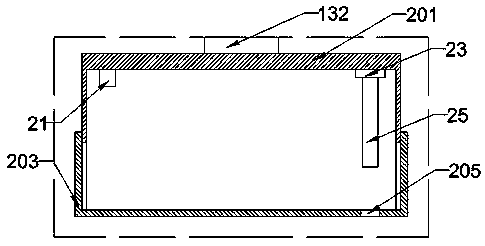

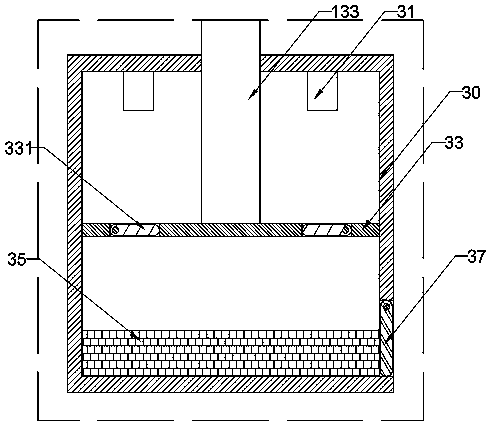

[0023] The reference signs in the drawings of the description include: cutting table 10, cylinder 13, pressing plate 20, piston rod 132, driving rod 133, fixed end 201, sliding end 203, normally closed switch 21, electromagnet 23, cutting knife 25, cutting Groove 205, collection box 30, water outlet pipe 301, bump 31, partition 33, water outlet plate 331, water absorbing part 35, filter screen 37.

[0024] like figure 1 The shown papermaking press plate 20 type wood cutting device includes a cutting table 10 and a cutting mechanism positioned above the cutting table 10. The cutting mechanism includes a cutting knife 25 and a cylinder 13, wherein:

[0025] The lower end of the piston rod 132 of the cylinder 13 is connected with a pressing plate 20, as figure 2 As shown, the cutting knife 25 is connected to the pressing plate 20, and after the pressing plate 20 presses t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com