Device for treating flue gas produced during waste incineration for power generation

A technology for flue gas treatment and waste incineration, which is applied in the direction of gas treatment, separation methods, and separation of dispersed particles, etc. It can solve the problems of heat loss in the flue, difficulty in removing fly ash, and accumulation of fly ash, so as to improve efficiency and avoid cutting Effects of destroying and slowing down the flow velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

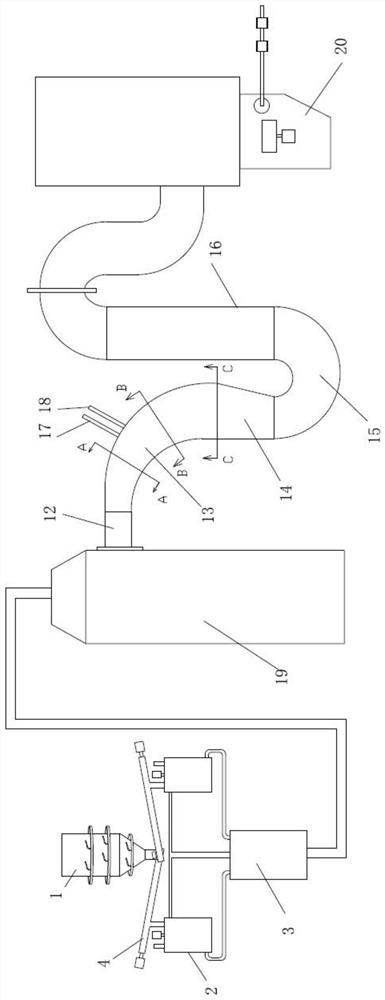

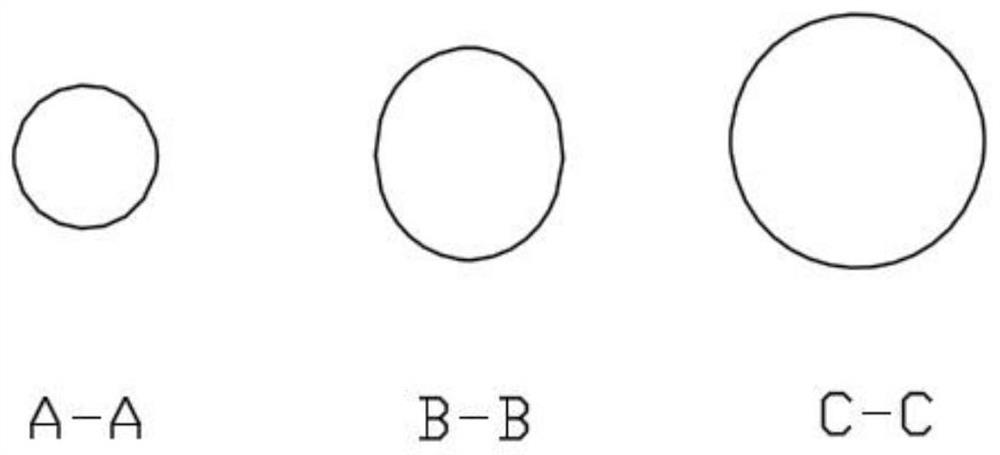

[0031] like figure 1 As shown, a waste incineration power generation flue gas treatment device of the present invention includes a flue gas semi-dry treatment device, a dry treatment device, a bag filter and an ash unloading device installed below it. The flue gas semi-dry processing device, dry processing device, and bag filter are connected in sequence.

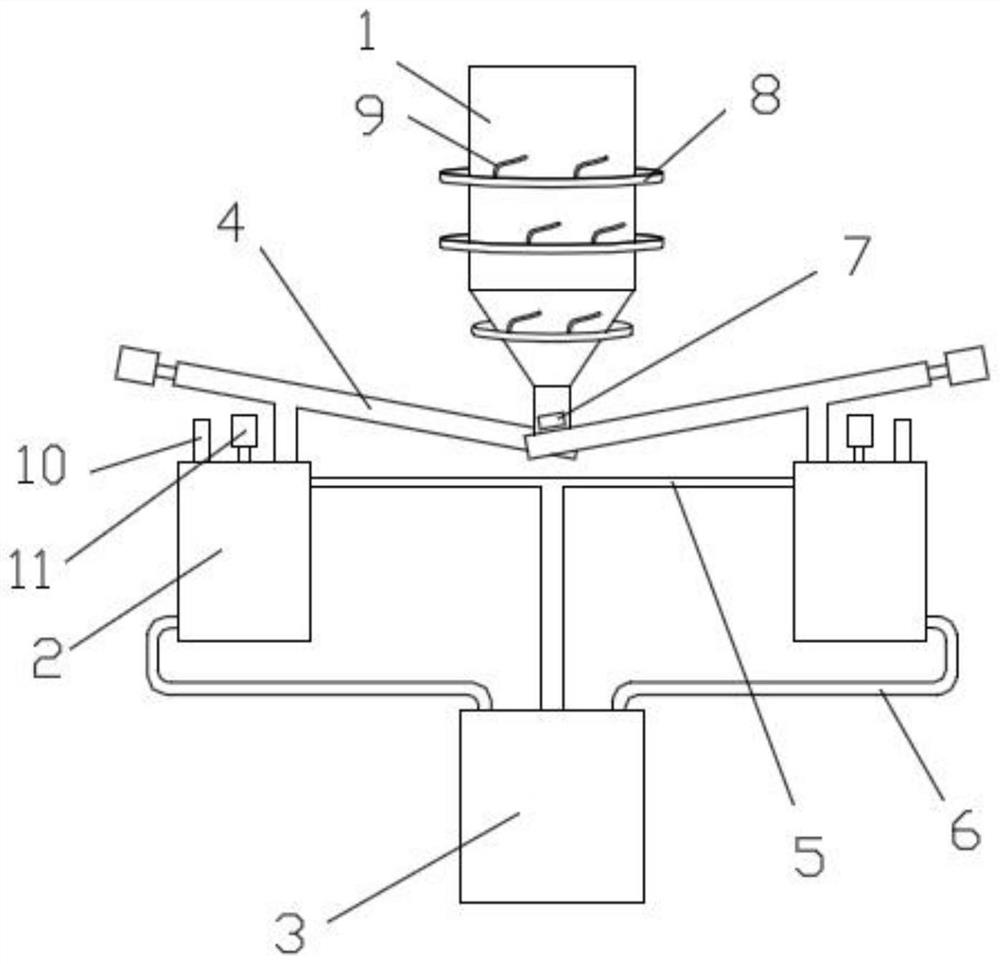

[0032] combine figure 1 , 3 As shown, the present invention is a flue gas semi-dry treatment device in a waste incineration power generation flue gas treatment device, including a slurry preparation device. The slurry preparation device includes a lime silo 1 , a lime slurry preparation tank 2 and a lime slurry storage tank 3 . A screw quantitative feeder 4 is provided at the lower part of the lime silo 1 to connect the discharge port of the lime silo and the feed inlet on the top of the lime slurry preparation tank respectively. There are multiple lime slurry preparation tanks, and correspondingly there are multiple scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com