Locating crystal support for cutting polycrystalline silicon ingot

A technology of polycrystalline silicon ingot and crystal support, which is applied in the field of positioning crystal support for cutting polycrystalline silicon ingot, can solve the problems of broken first screw, wear of threaded hole, short service life, etc., and achieves the effect of accurate positioning and increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

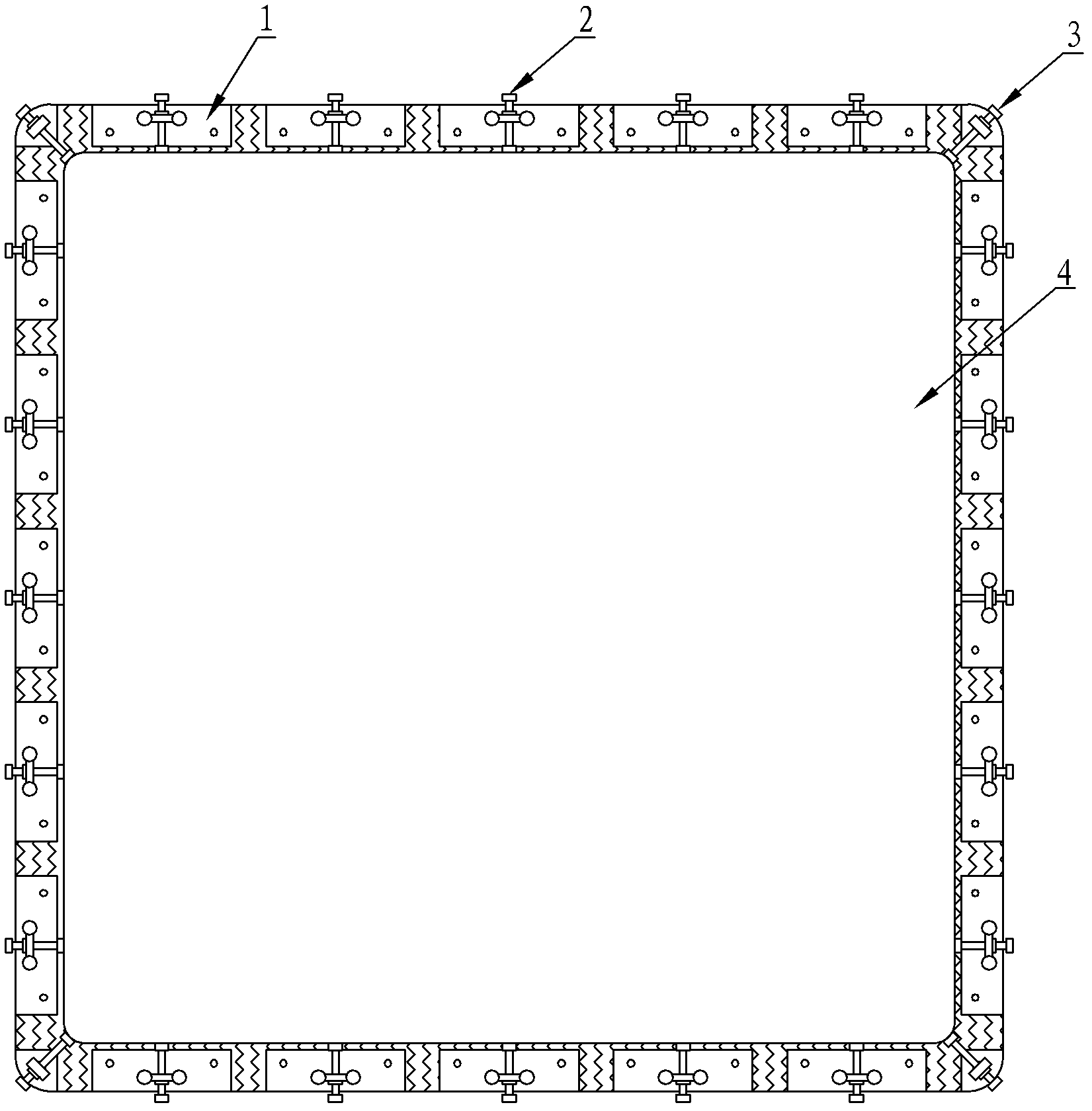

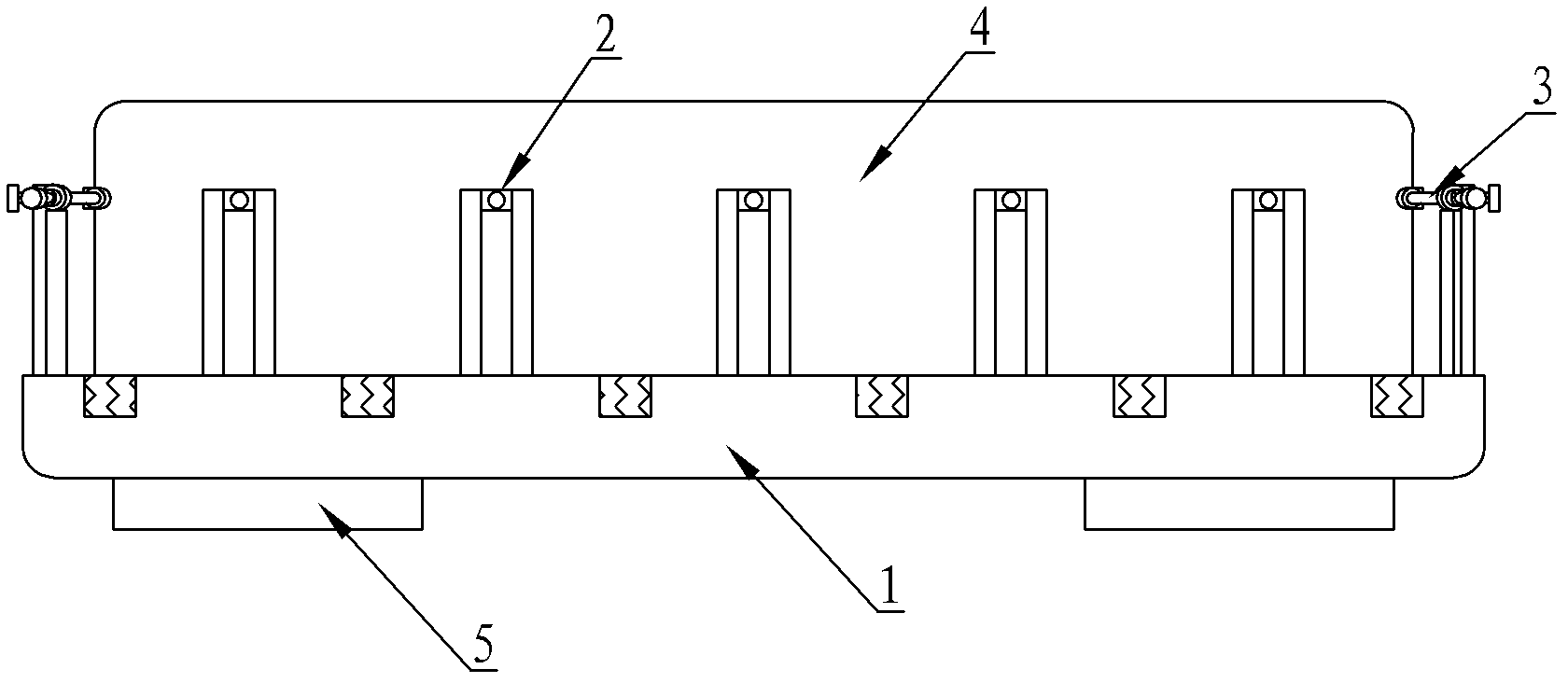

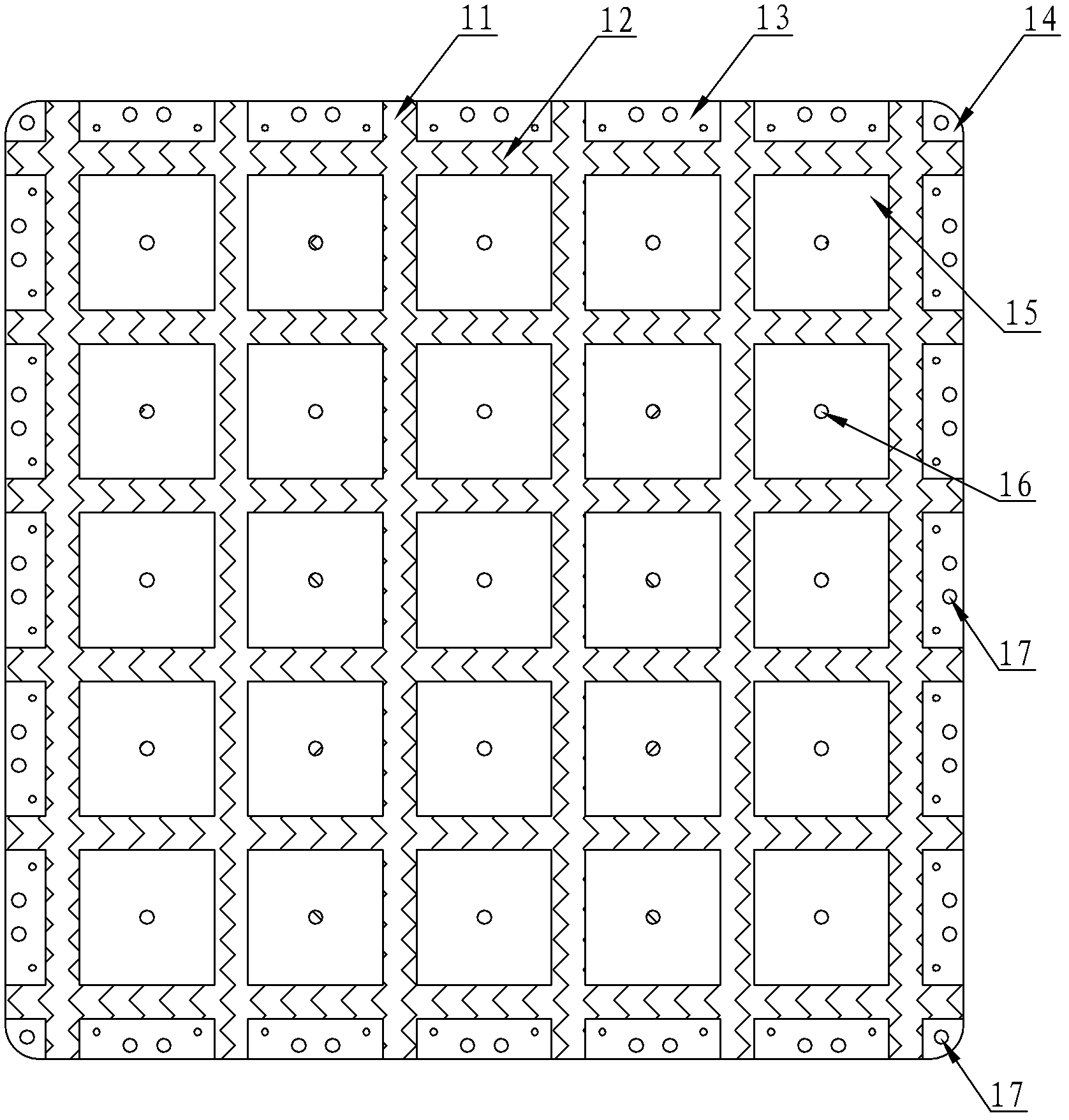

[0023] A positioning crystal holder for polycrystalline silicon ingot cutting, such as figure 1 , figure 2 with image 3 The bottom plate 1, the side locking device 2, the corner locking device 3 and the polysilicon ingot 4 are shown as shown in the figure. The upper end surface of the bottom plate 1 is provided with longitudinal cutting grooves 11 and transverse cutting grooves 12, forming equidistant distribution around the bottom plate 1. Side positioning module 13, corner positioning module 14 is formed at the four corners, 25 square grids 15 divided by longitudinal cutting grooves 11 and transverse cutting grooves 12, bonding holes 16 are provided in each square grid 15, and positioning on the side The module 13 is provided with two fixed counterbores 17, and the center of the corner positioning module 14 is provided with a fixed counterbore ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com