Inward-feeding-type rotary filter screen grille cleaner with cleaning brush

A technology for cleaning brushes and decontamination machines, which is applied in the direction of filtration and separation, moving filter element filters, separation methods, etc. It can solve problems affecting the normal operation of the mesh chain plate and the quality of sewage treatment, and achieves a simple structure and guarantees normal operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

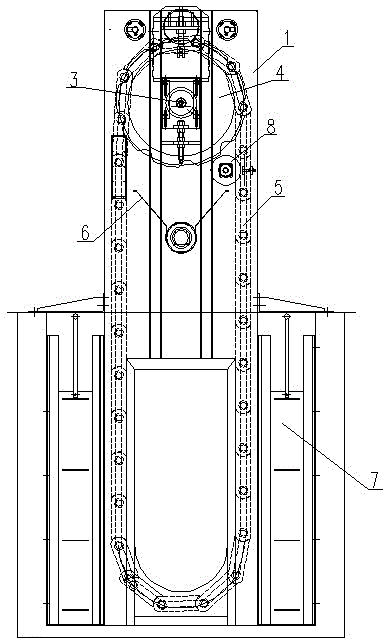

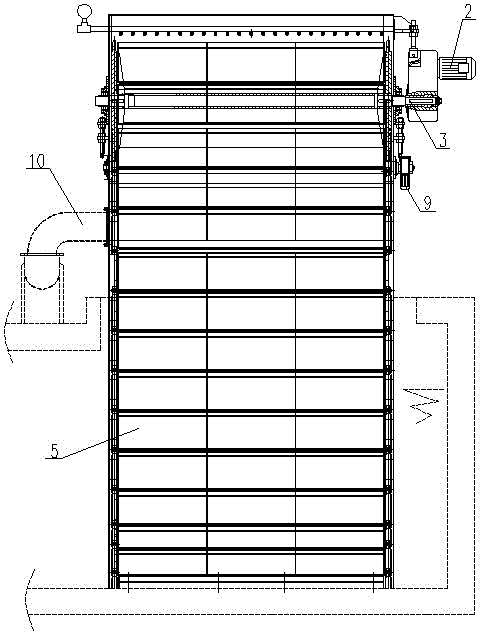

[0009] An internal rotary filter grid decontamination machine with a cleaning brush, including a body 1, a reducer 2, a main shaft 3, a sprocket 4 and a chain plate 5, and the reducer 2 is fixedly installed on the upper end of the body 1 side, the main shaft 3 is connected with the reducer 2, the front and rear ends of the main shaft 3 are respectively equipped with a sprocket 4, the net chain plate 5 is sleeved on the sprocket 4, and the net chain plate 5 is provided with a slag collection groove 6, and the slag collection The groove 6 is located directly below the sprocket 4, and the left and right sides of the lower end of the net chain plate 5 are provided with water retaining plates 7, and the angle between the lower end of the sprocket 4 and the net chain plate 5 is provided with a cleaning brush. It is a wire wheel brush 8 and is driven to rotate by a motor 9 installed on the side of the machine body 1; the slag collection tank 6 has a V-shaped structure, and a slag disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com