Adjustable bearing processing, fixing and polishing device

A bearing processing and adjustable technology, applied in metal processing equipment, grinding machines, manufacturing tools, etc., can solve problems such as low processing efficiency, unstable equipment operation, complex structure, etc., to improve processing efficiency, practicability, and stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

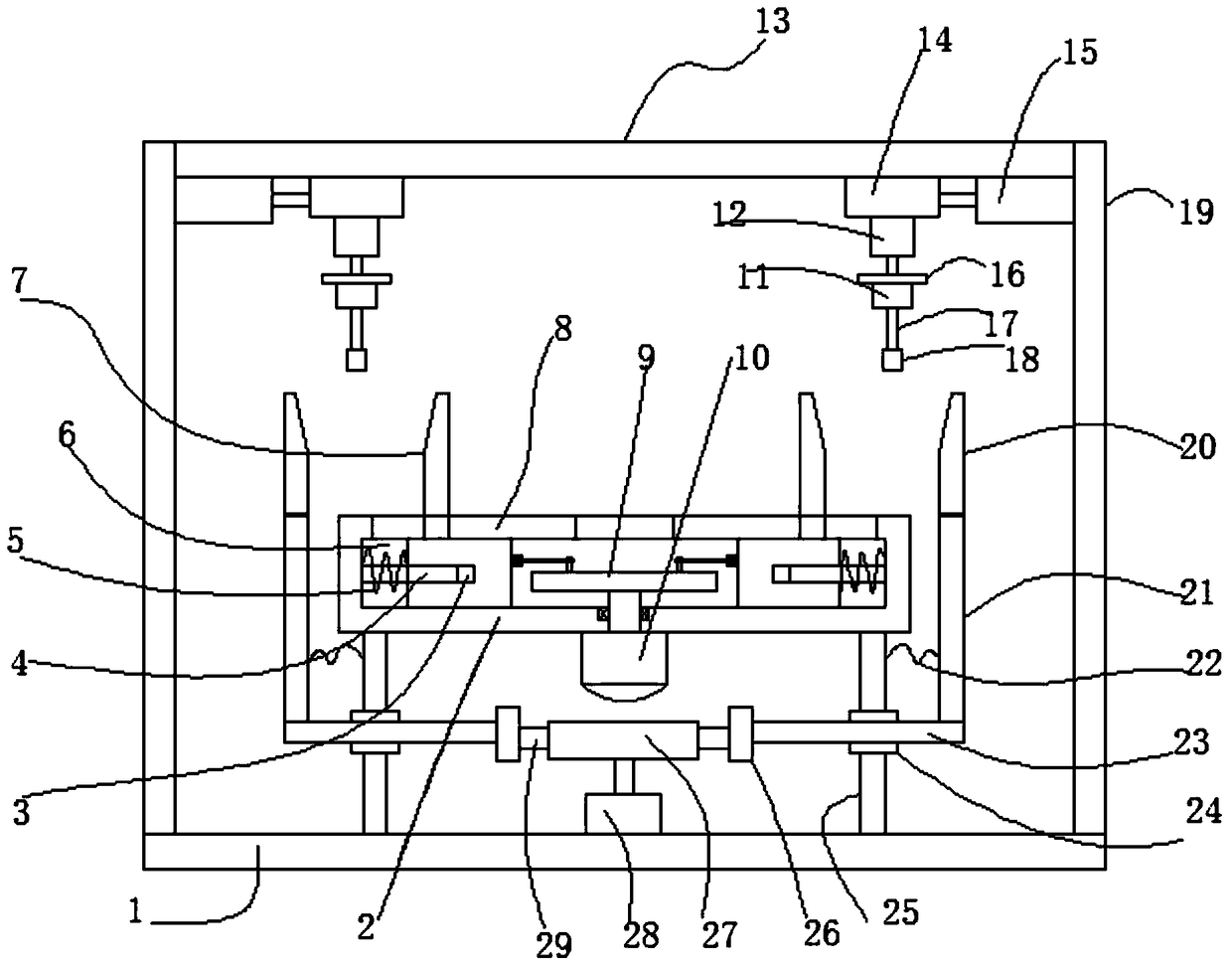

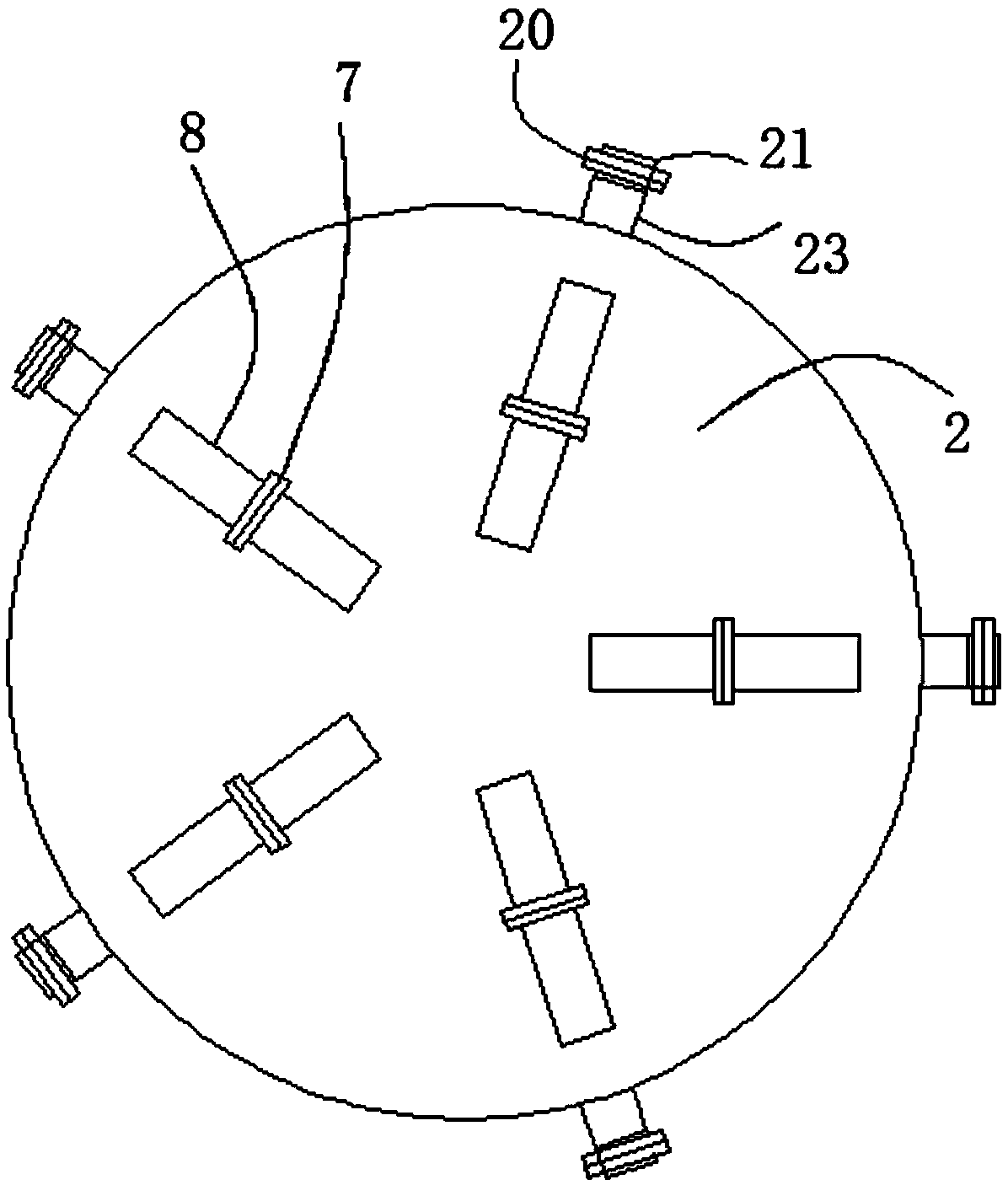

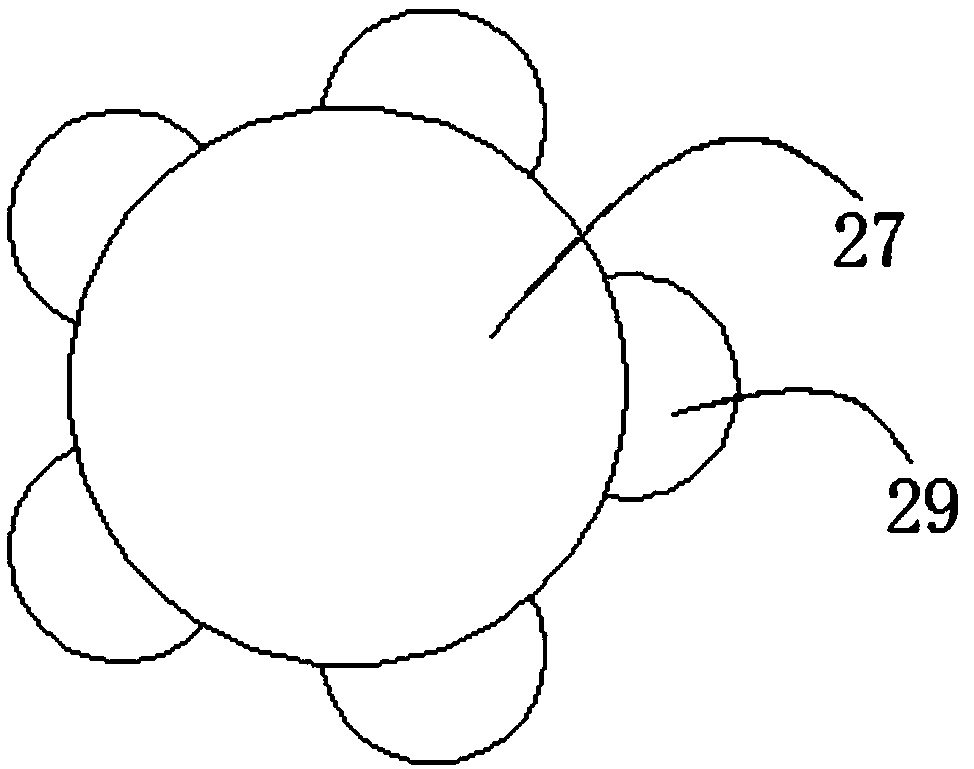

[0023] see Figure 1-4 , in an embodiment of the present invention, an adjustable fixed grinding device for bearing processing includes a base 1 and a workbench 2, a top plate 13 is provided above the base 1, and the left and right ends of the top plate 13 are connected to the base 1 through support columns 19 Fixed, the lower end of the top plate 13 is provided with two grinding mechanisms, the grinding mechanism includes the No. 2 telescopic cylinder 15 arranged on the lower end of the top plate 13, the output end of the No. 2 telescopic cylinder 15 is provided with a horizontal sliding seat 14, and the lower end surface of the horizontal sliding seat 14 No. 1 telescopic cylinder 12 is installed, and the output end of described No. 1 telescopic cylinder 12 is connected with fixed plate 16, and described fixed plate 16 lower end is equipped with grinding motor 11, and the output end of described grinding motor 11 is provided with grinding shaft 17, grinds The output end of th...

Embodiment 2

[0029] The difference from Embodiment 1 is that the outer ring splint 20 and the inner ring splint 7 are detachably connected, which facilitates the later fixing of different bearings, because the clearances between the outer ring and the inner ring of different bearings are different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com