Punching, cutting and cleaning device for door frame aluminum profile

A cleaning device, door frame aluminum technology, applied to other manufacturing equipment/tools, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problems of affecting processing accuracy, slow processing efficiency, unfavorable processing of metal waste, etc., to improve High working efficiency, high dust removal rate, and excellent dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

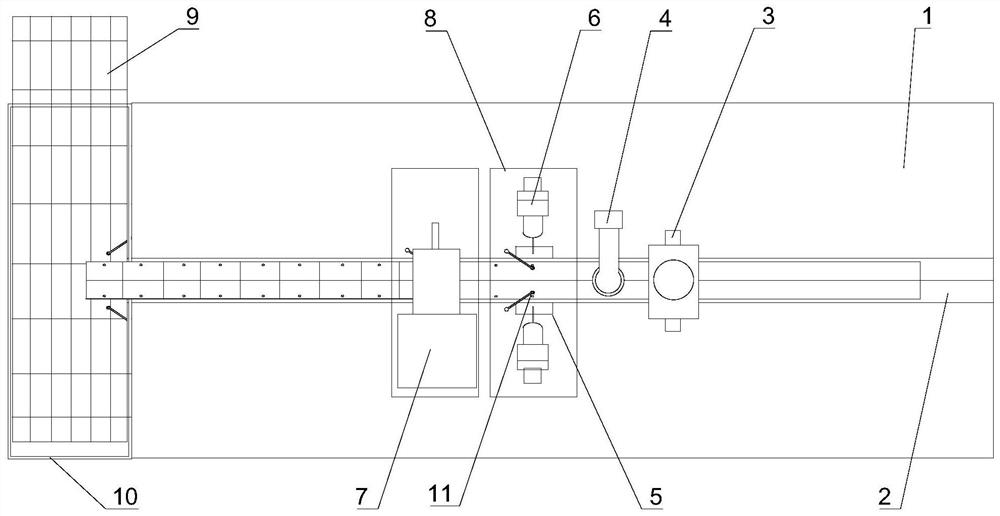

[0022] refer to figure 1 , a punching, cutting and cleaning device for door frame aluminum profiles proposed by the present invention, comprising: a workbench 1, a slide rail 2 for placing aluminum profiles, a translational drive mechanism for driving the aluminum profiles to move along the slide rails 2, Punching mechanism 6, cutting mechanism 7 and cleaning mechanism;

[0023] The slide rail 2 is arranged along the length direction of the workbench 1, and the translation drive mechanism, the punching mechanism 6 and the cutting mechanism 7 are sequentially arranged on the workbench 1 along the moving direction of the aluminum profile;

[0024] The cleaning mechanism includes a first dust removal assembly for punching dust removal, a second dust removal assembly for cutting dust removal, a cutting piece cleaning assembly, a dust collection box and a negative pressure generator;

[0025] The first dust removal assembly includes a first dust collection cover 8, a first cleanin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com