Antirust bolt

A bolt and thread technology, applied in the field of bolt maintenance, can solve problems such as small area, unsatisfactory loosening effect of loosening agent, difficulty in quickly loosening bolts, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings.

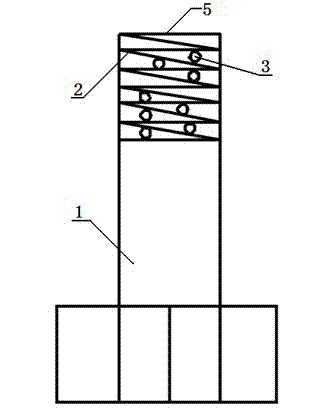

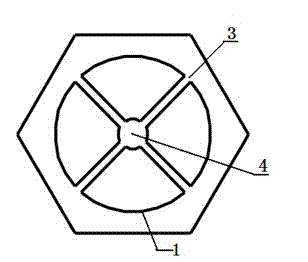

[0010] see figure 1 , 2 , a kind of anti-rust bolt, comprising a bolt body 1, one end of the bolt body 1 is provided with a connecting thread 2, at least one oil outlet hole 3 is arranged in the groove of the connecting thread 2, and the oil outlet hole 3 is connected with the bolt body 1 The inner and axially arranged oil injection holes 4 communicate with each other, and the oil inlet of the oil injection hole 4 is arranged at the top end 5 of the bolt.

[0011] The working principle of the present invention is:

[0012] When in use, inject the bolt loosening agent or lubricating oil into the oil filling hole 4 along the oil inlet under a certain pressure, and make the bolt loosening agent or lubricating oil enter the connecting thread 2 along the oil filling hole 4 through the oil outlet hole 3, and the connecting thread 2. Derust and loosen the fasteni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com