A high-efficiency lifting device for lifting building panels

A technology for lifting devices and building panels, which is applied in the direction of lifting devices, lifting frames, cleaning methods using tools, etc., can solve the problems of panel indentation, low stability, complex lifting and placing procedures of panels, etc., and achieve entry and output The effect of stabilization, efficiency improvement and cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

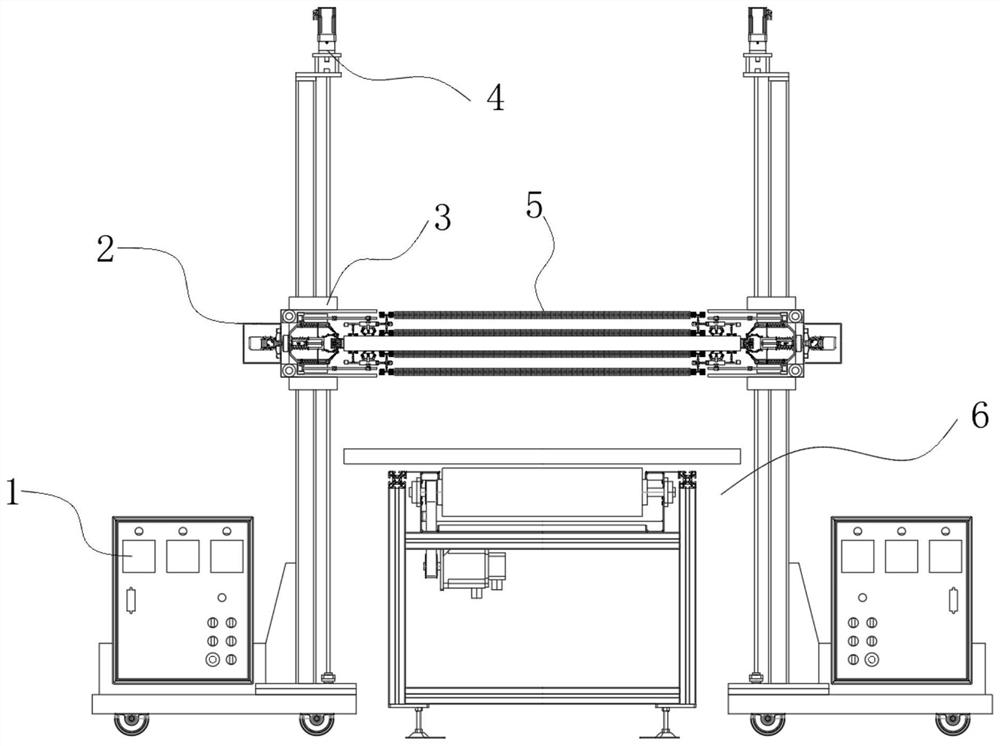

[0031] refer to figure 1 , the present invention provides a technical solution: a high-efficiency lifting device for lifting building boards, which includes a console 1, a lifting device 2, a transmission base 3, a motor 4 and a transmission device 6, the transmission device 6 is left and right A lifting frame is arranged symmetrically on the side, the upper end of the lead screw inside the lifting frame is fixedly connected with the output end of the motor 4, the lifting device 2 is fixed on the transmission base 3, and the motor 4 is controlled by the console 1 to drive the lifting device 2. , downward displacement, the plate is fixed and conveyed in the vertical direction, and a cleaning brush 5 is also connected between the lifting devices 2, which is convenient for cleaning the surface of the plate in real time;

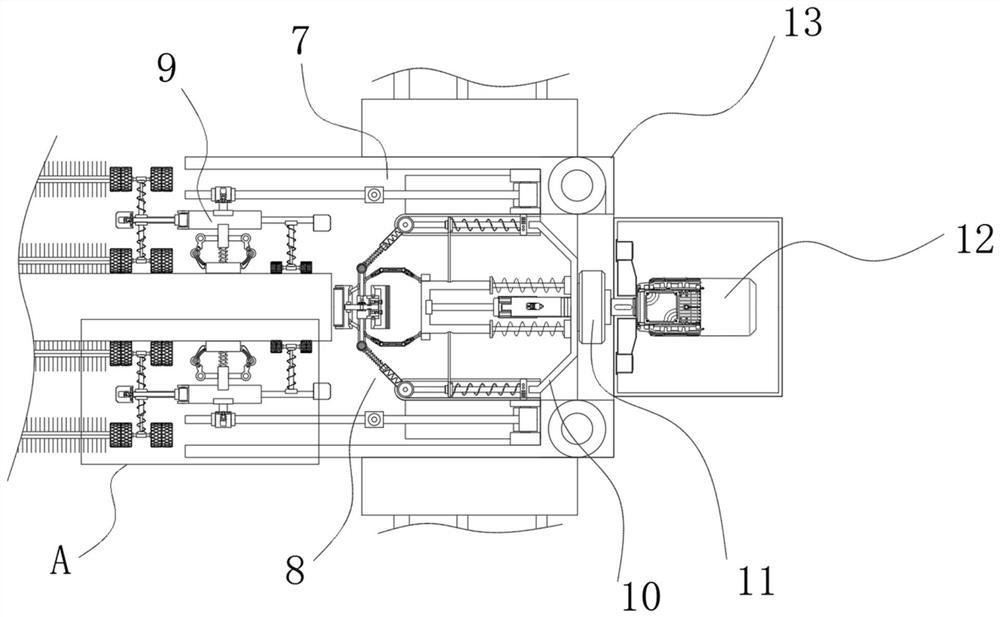

[0032] Among them, the lifting device 2 is arranged on the side of the transmission base 3, which is convenient for the lifting device 2 to rotate. As the best ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com