Wear resistant, heat resistant conveyor chain

A conveyor chain, heat resistance technology, applied in the field of conveyor chains, can solve problems such as uneven wear, increased chain wear and elongation, and damage to chain life, so as to maintain the life of the chain and inhibit chain wear and elongation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

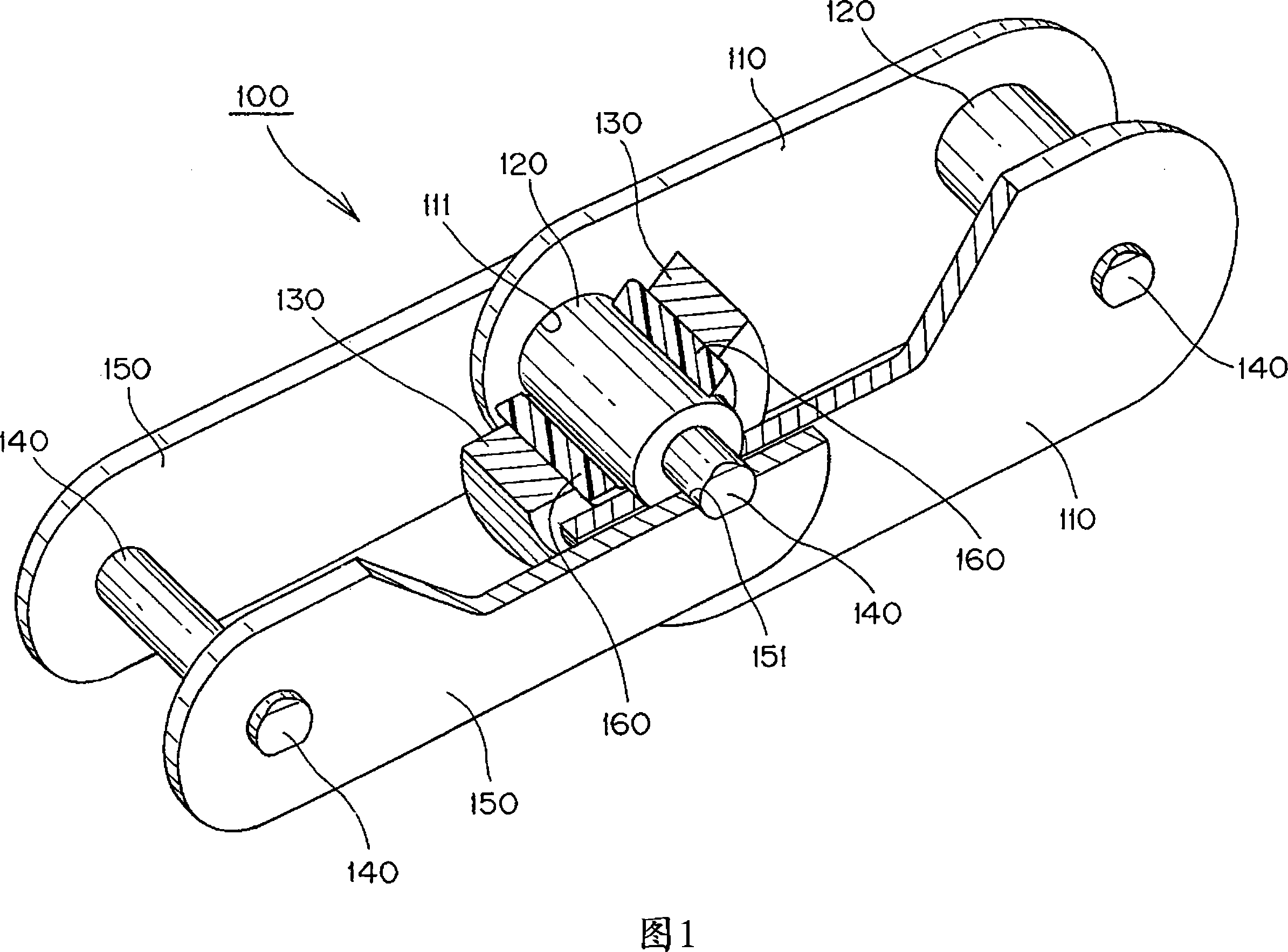

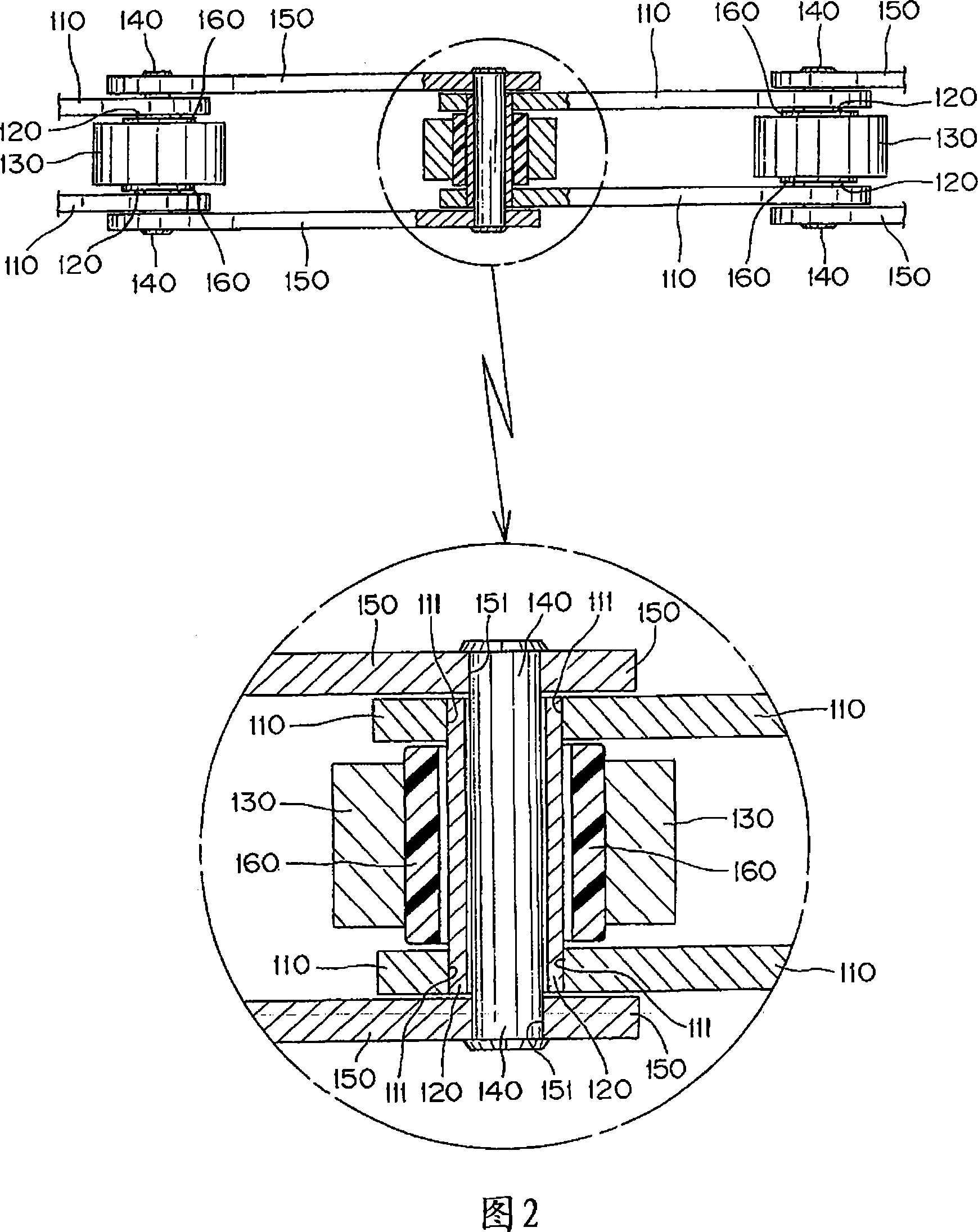

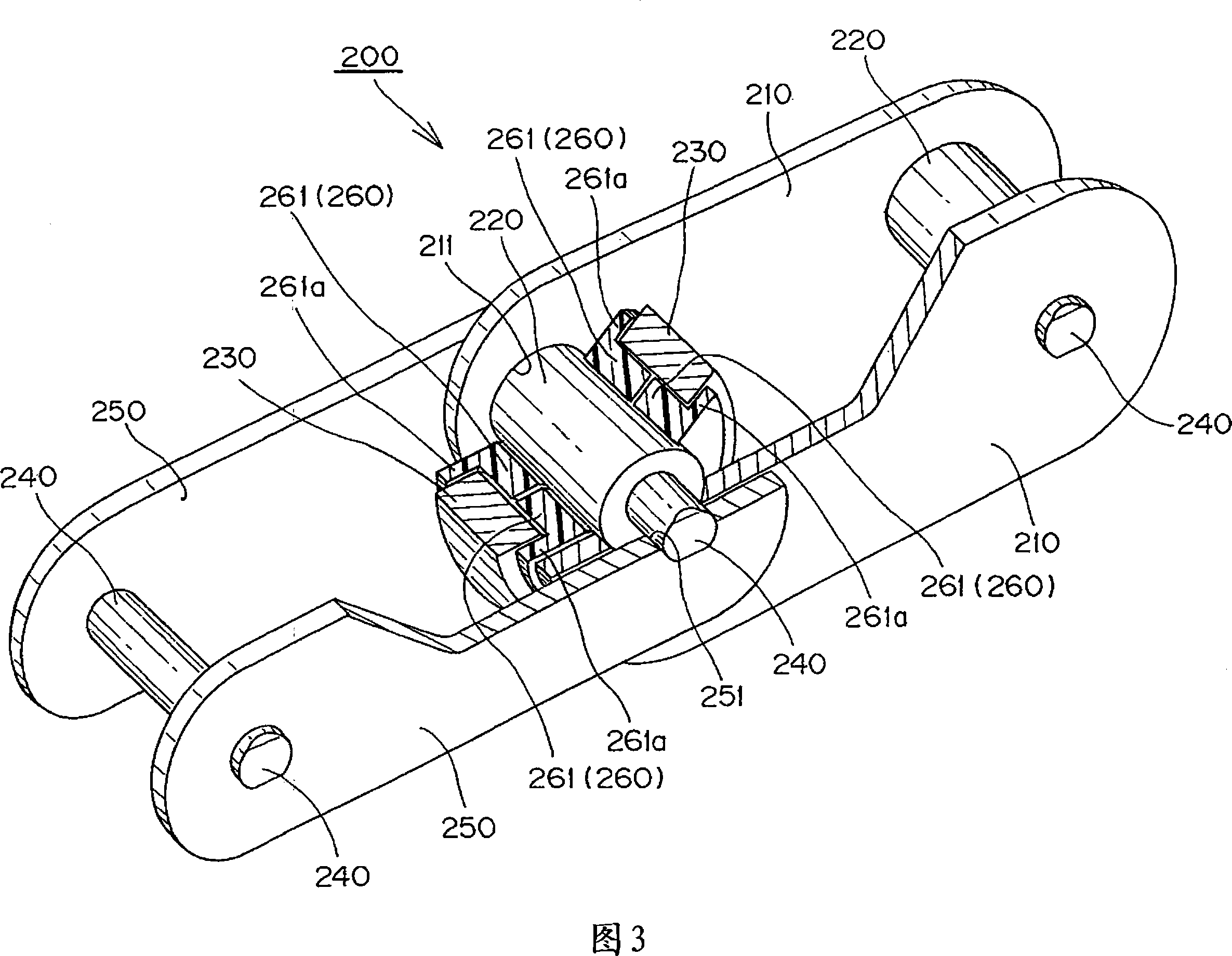

[0024] Hereinafter, the wear-resistant and heat-resistant conveyor chain 100 which is one Example of this invention is demonstrated based on drawing.

[0025] Here, FIG. 1 is a schematic diagram of a wear-resistant and heat-resistant conveyor chain as a first embodiment of the present invention, and FIG. 2 is a partial cross-sectional view of the wear-resistant and heat-resistant conveyor chain shown in FIG. An enlarged view of its important parts, FIG. 3 is a schematic diagram of a wear-resistant and heat-resistant conveyor chain as a second embodiment of the present invention, and FIG. 4 is a wear-resistant and heat-resistant conveyor chain shown in FIG. 3 A section view of a part of a chain and a zoom-in view of its important parts.

[0026]First, as shown in FIGS. 1 and 2 , a wear-resistant and heat-resistant conveyor chain 100 according to a first embodiment of the present invention includes a pair of left and right inner plates 110 spaced apart, press-fitted and fitted i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com