Disk-type conveyer with multiple feeding and discharging points

A technology for unloading trays and conveyors, which is applied in the direction of conveyor objects, transportation and packaging, etc. It can solve the problems of high maintenance costs, large application limitations, and large dust, and achieves a high degree of automation, flexible layout and use, and ensures safe operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

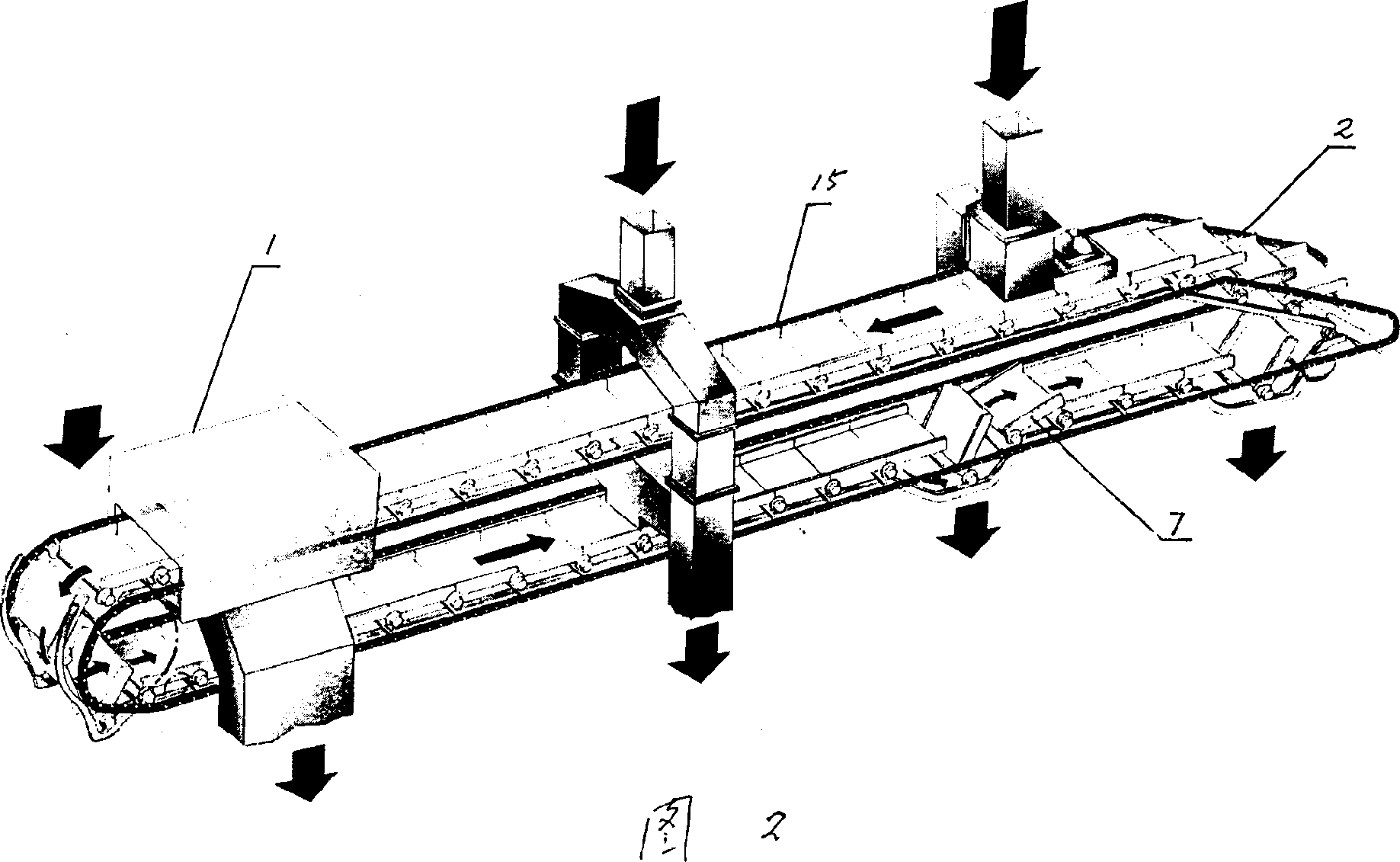

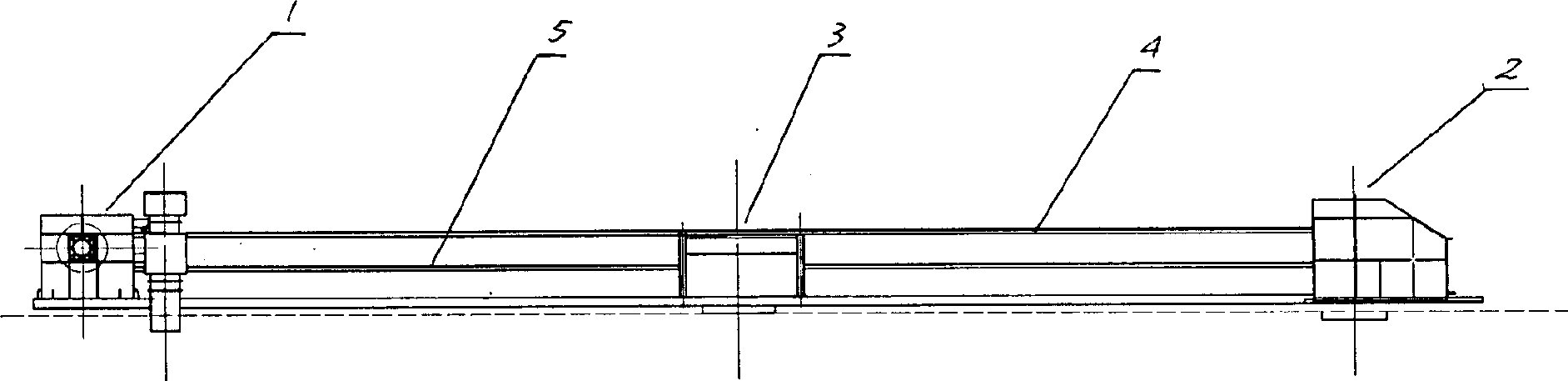

[0008] The multi-point feeding and multi-point unloading pan conveyor is composed of the head device 1, the tail device 2, the intermediate connection and supporting intermediate device composed of rails and brackets, and the multi-point set according to actual needs. The feeding and discharging device is composed of a running and conveying device composed of a tray and a chain; the head device 1 includes a driving mechanism composed of a motor 8 and a reducer 9; The large sprocket assembly 11 on the shaft 10 (hereinafter referred to as the transmission shaft), the chain 15 mounted on the large sprockets 12 at both ends of the assembly, and the head transmission mechanism composed of the upper and lower track systems configured; the tail device includes There is a tail slewing mechanism composed of a driven sprocket set, a roller set, a track system and a tensioning mechanism packaged in a box; the feeding and discharging device is composed of a track system, an automatic contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com