Antirust oil and preparation method thereof

A technology of anti-rust oil and anti-rust agent, which is applied in the petroleum industry, lubricating composition, etc., can solve the problems of the hard film anti-rust oil's poor heat and humidity resistance, salt spray resistance, insufficient hardness of the coating film, and poor protection. , to achieve good anti-rust effect and fast drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] In one embodiment, the present invention also discloses a preparation method of antirust oil, comprising the following steps:

[0054] Add most of the base oil into the reactor and heat and stir. When the temperature rises to 90-120°C, add rust inhibitor, co-solvent, and antioxidant, stir well to dissolve it completely, and lower the temperature in the reactor to 50-120°C. 80°C, then slowly add the film-forming agent and the rest of the base oil, stir well until the solution is completely dissolved, cool to room temperature, check the output, and complete the preparation;

[0055] Wherein, the mass fraction of each component is: 20-35% of film-forming agent, 5-15% of rust inhibitor, 0.1-5% of co-solvent, 0.1-2% of antioxidant, and 40-75% of base oil;

[0056]Wherein, the film-forming agent is any one or more combinations of tert-butylphenol formaldehyde resin, petroleum resin, lanolin, rosin and maleic anhydride.

[0057] Preferably, the rust inhibitor is any one or a ...

Embodiment 1

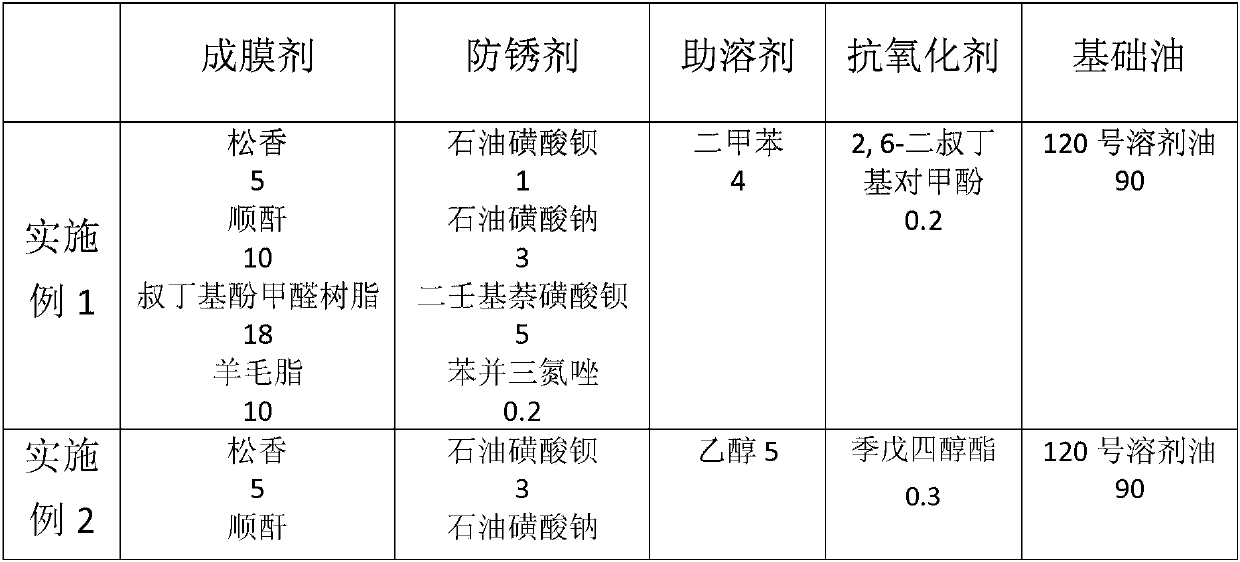

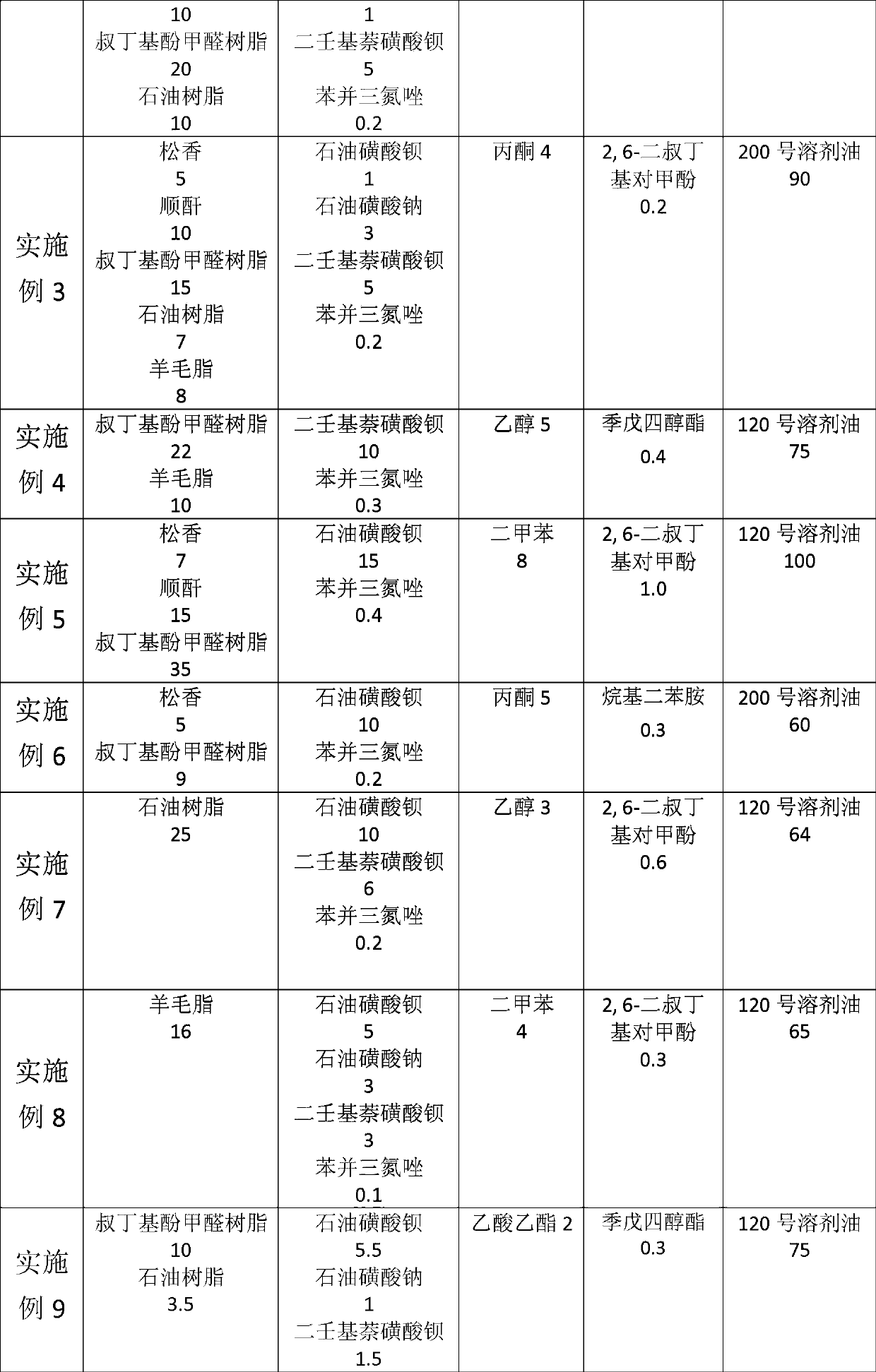

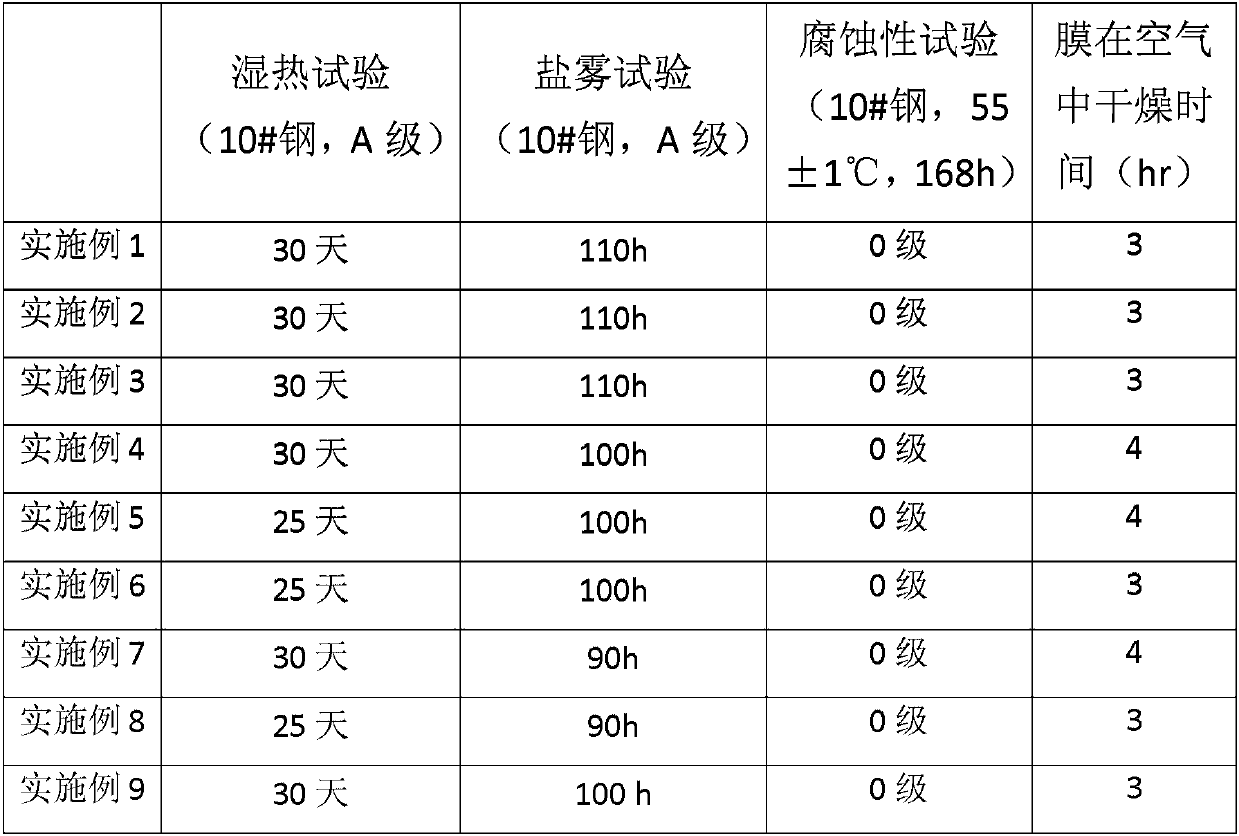

[0071] The present embodiment calculates the raw materials according to the proportioning (percentage by weight) shown in Table 1.

[0072] Step 1: put rosin and maleic anhydride into the reactor, raise the temperature to 90±5°C, stir, add tert-butylphenol formaldehyde resin and lanolin in sequence, raise the temperature to 140±10°C, and keep it for 1 hour.

[0073] Step 2: When the temperature drops to 80-90°C, add part of the base oil into the reaction kettle and stir to prepare a film-forming resin, and keep it for later use.

[0074] Step 3: Add the rest of the base oil into an empty reactor and stir, add rust inhibitor, co-solvent, and antioxidant, raise the temperature to 60-70°C, and fully stir to dissolve it completely.

[0075] Step 4: The internal temperature of the reactor is lowered to 50-60°C, and then slowly add the film-forming resin obtained in Step 2, stir well, cool to room temperature, take a sample for inspection, and filter after passing the test to comple...

Embodiment 2-3

[0080] The experimental procedure is the same as in Example 1, the only difference being that the ratio of raw materials shown in Table 1 is different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com