Vehicle-mounted snow removal mechanism

A car body and bucket technology, applied in the field of snow removal machinery, can solve the problems of reduced service life and low efficiency, and achieve the effects of prolonging service life, fast operation speed and reducing frequent starts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

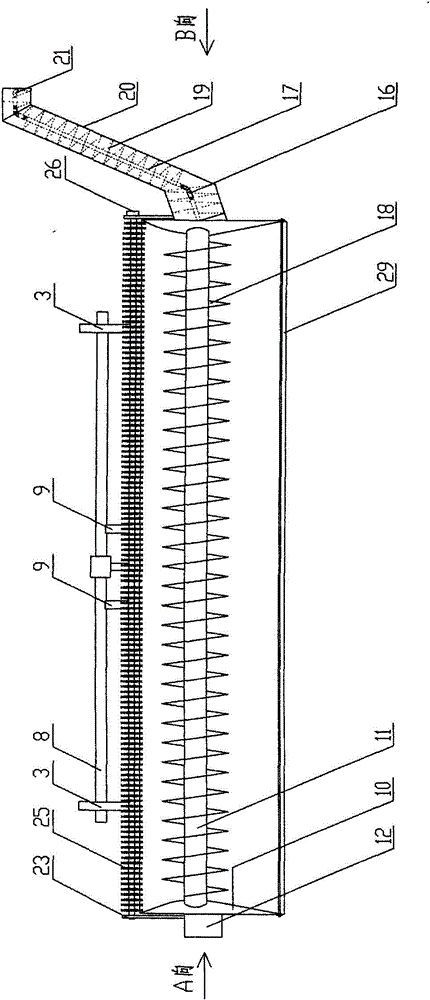

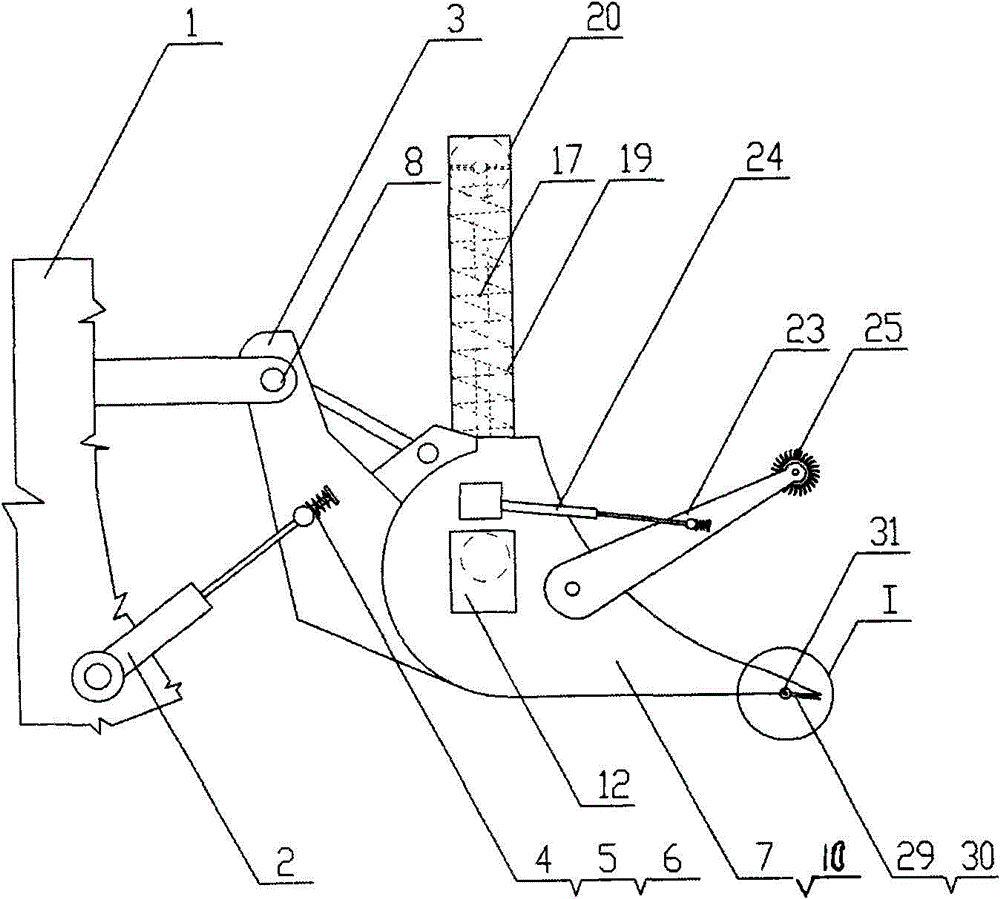

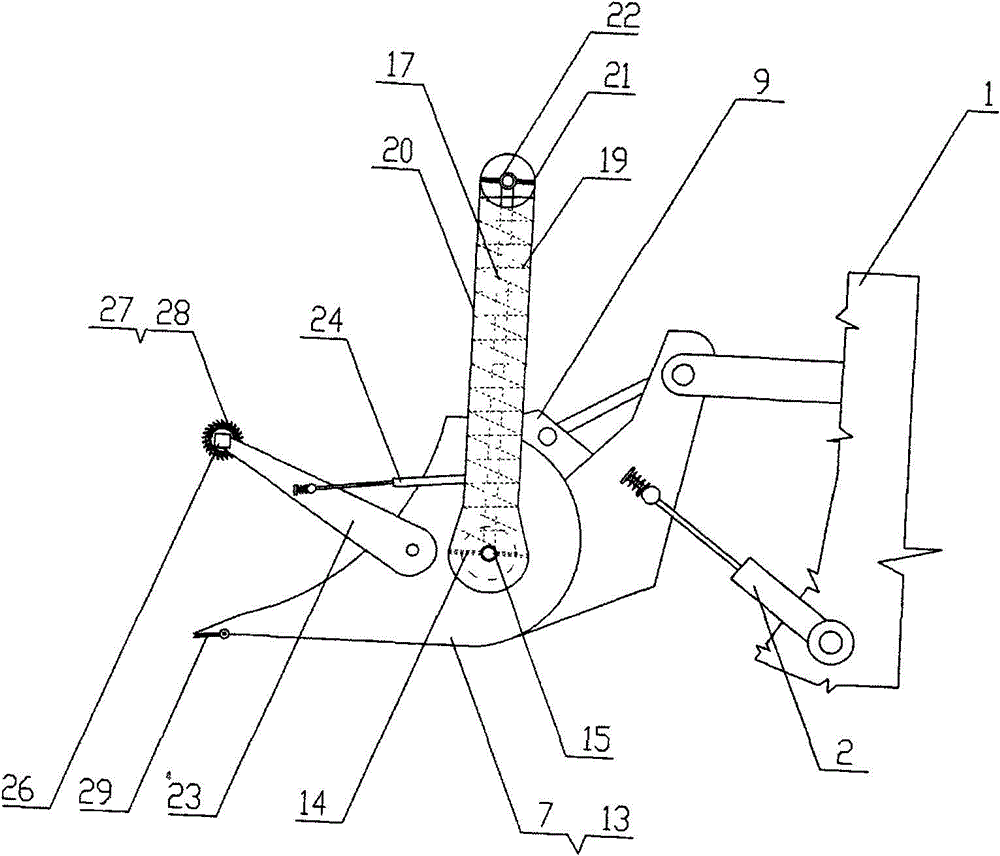

[0015] In the schematic diagram of the vehicle-mounted snow removal mechanism shown in Fig. 1, Fig. 2 and Fig. 3, the car body is a loader with a bucket, and the two hydraulic cylinders 2 on the car body 1 are connected to the end of the piston rod of the shovel. The middle part of the main arm 3 of the bucket support is hinged by a buffer mechanism. The buffer mechanism has a connecting piece 4, which is connected to one end of the short shaft 5, and the short shaft covered with a spring 6 is placed in a slot on the top of the piston rod. There are two main arms of the above-mentioned bucket bracket, the lower part of which is connected with the lower part of the bucket 7, and the upper part is provided with shaft holes, and the bracket shaft 8 arranged in the two shaft holes also passes through the lugs arranged on the car body. The support shaft is also connected to the upper ends of a pair of bucket support auxiliary arms 9, and the lower end of the auxiliary arms is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com