Patents

Literature

61results about How to "Uninterrupted work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

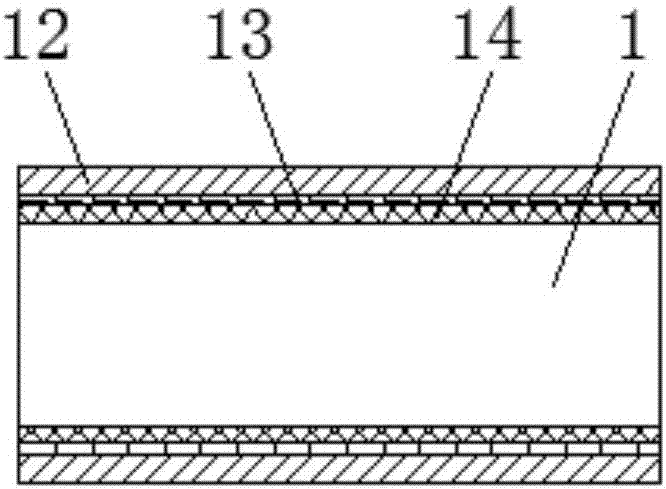

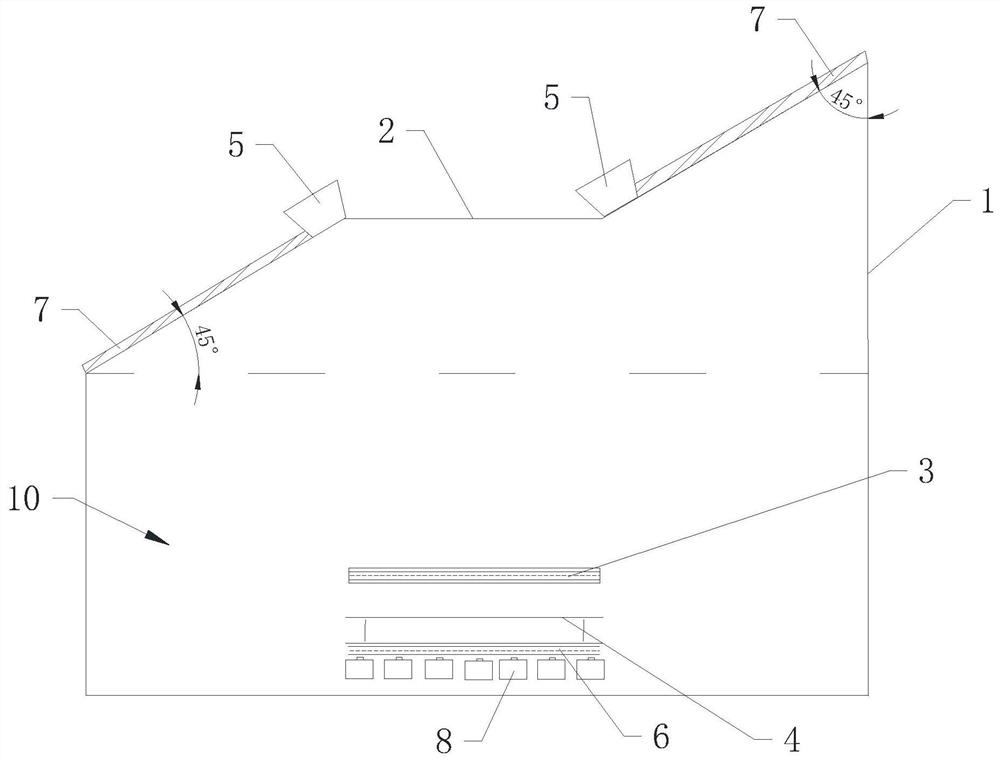

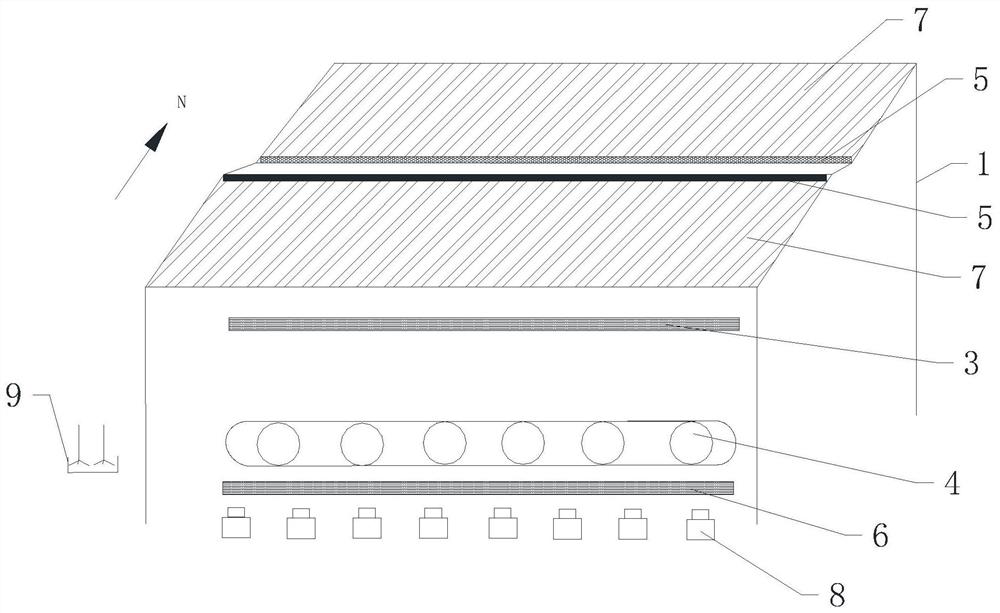

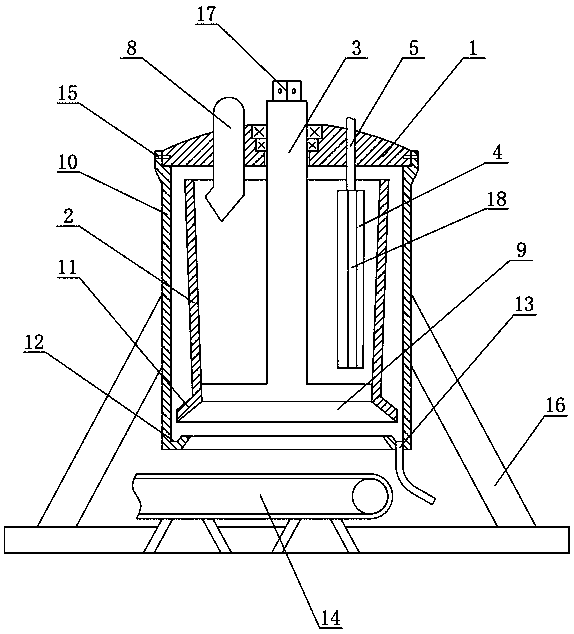

Self-made heat conductor and heating equipment into which insulating heat conduction material is embedded and implementation method of self-made heat conductor and heating equipment

PendingCN108366442AHeating evenlyLow costOverhead installationHeating element shapesElectrical conductorEngineering

Owner:SICHUAN UNIV +1

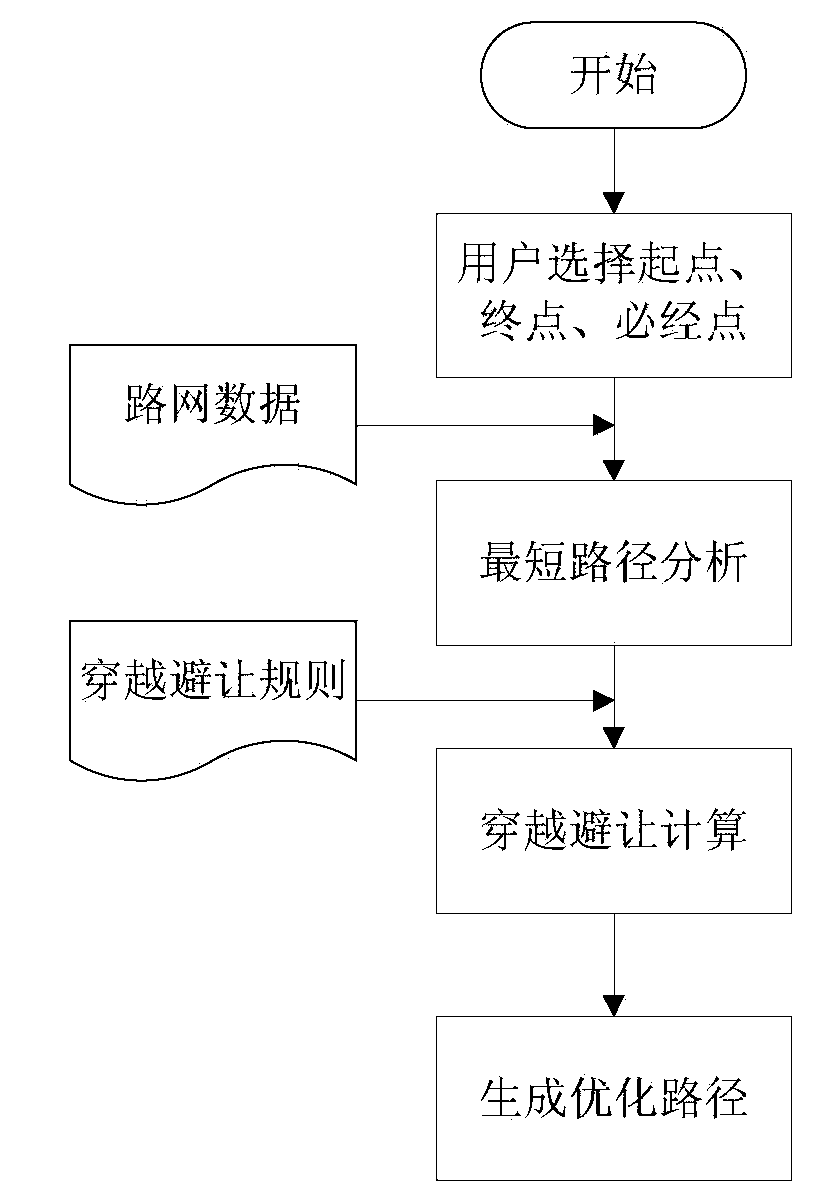

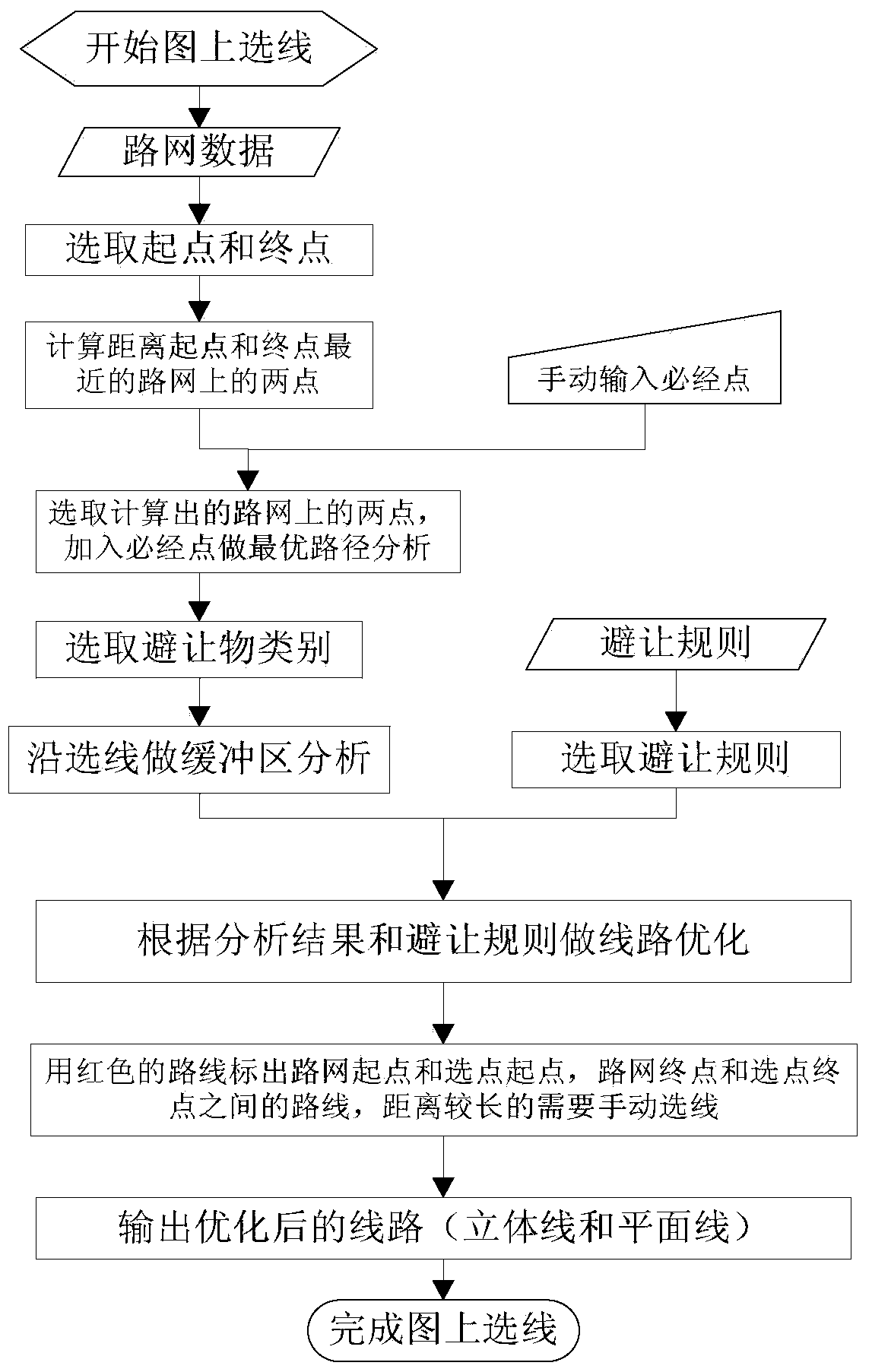

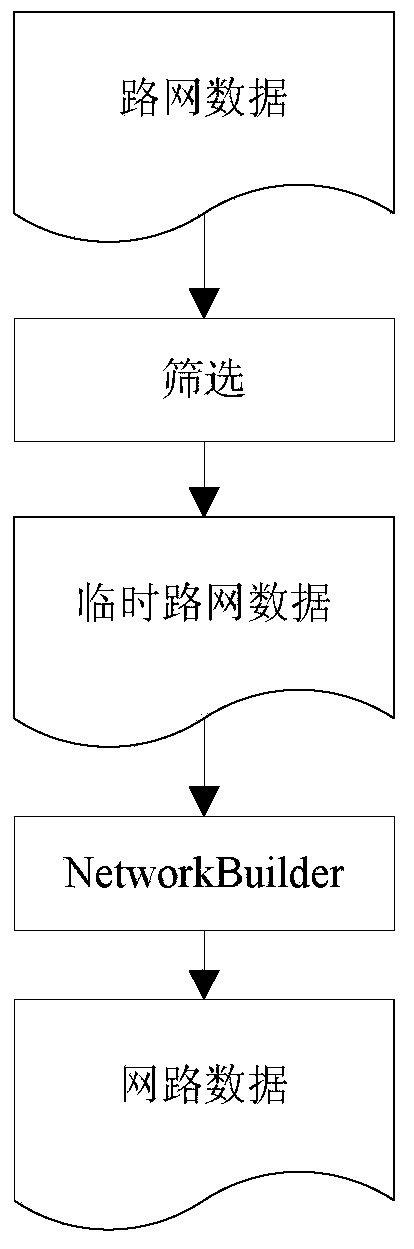

Method for selecting and laying movable oil conveying pipeline based on Beidou satellite

ActiveCN103711987ARealize auxiliary decision-makingReduce weightPipe laying and repairDesign optimisation/simulationPower stationNavigation system

The invention discloses a method for selecting and laying a movable oil conveying pipeline based on a Beidou satellite. The method comprises the following steps that S1, according to collected satellite remote sensing images and GIS data in a database, a crossing and spanning avoidance model is guided in, and a primary selection line of an oil pipeline is generated on a map; S2, real topography data are collected through a Beidou second-generation navigation system, the primary selection line is corrected, and a final line is determined; S3, a process scheme including pipefitting calculation, hydraulic power station distribution, a valve model and a line emptying model is generated according to the final line. The whole set of investigation and line selection and the automatic solution scheme of process design are achieved, the process and equipment of the movable oil conveying pipeline are intelligently designed fast and efficiently, and therefore the work efficiency of selecting and laying the movable oil conveying pipeline is improved.

Owner:军事科学院系统工程研究院军事新能源技术研究所

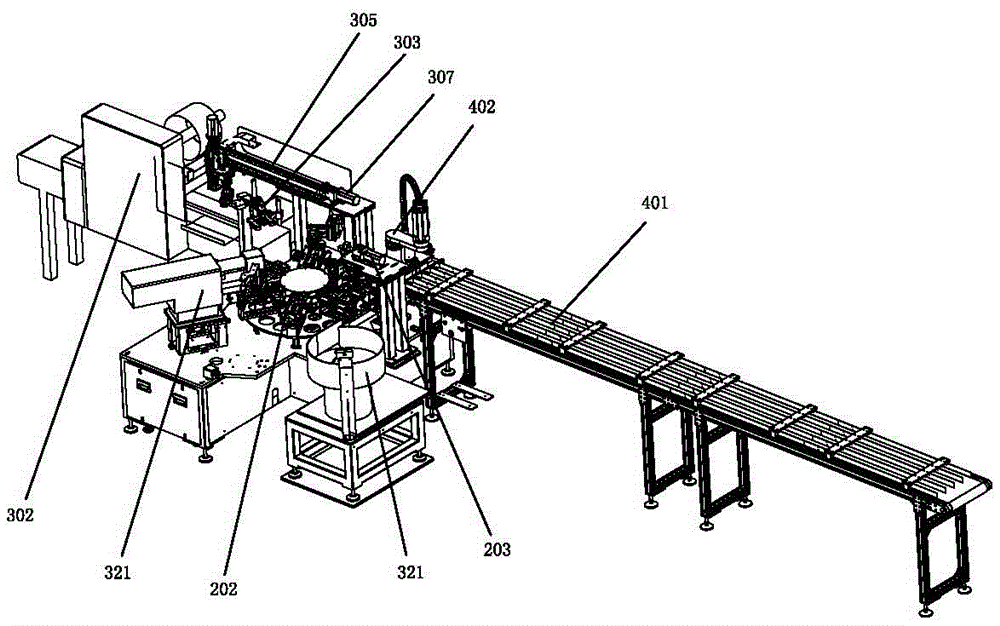

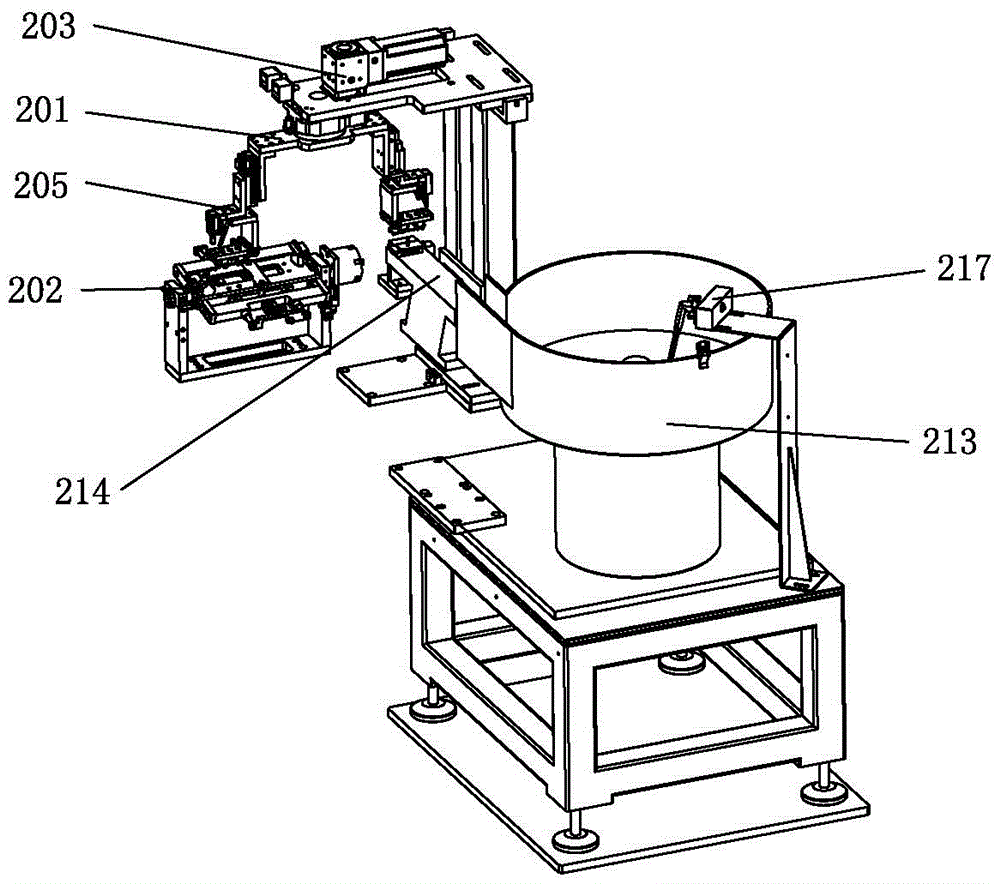

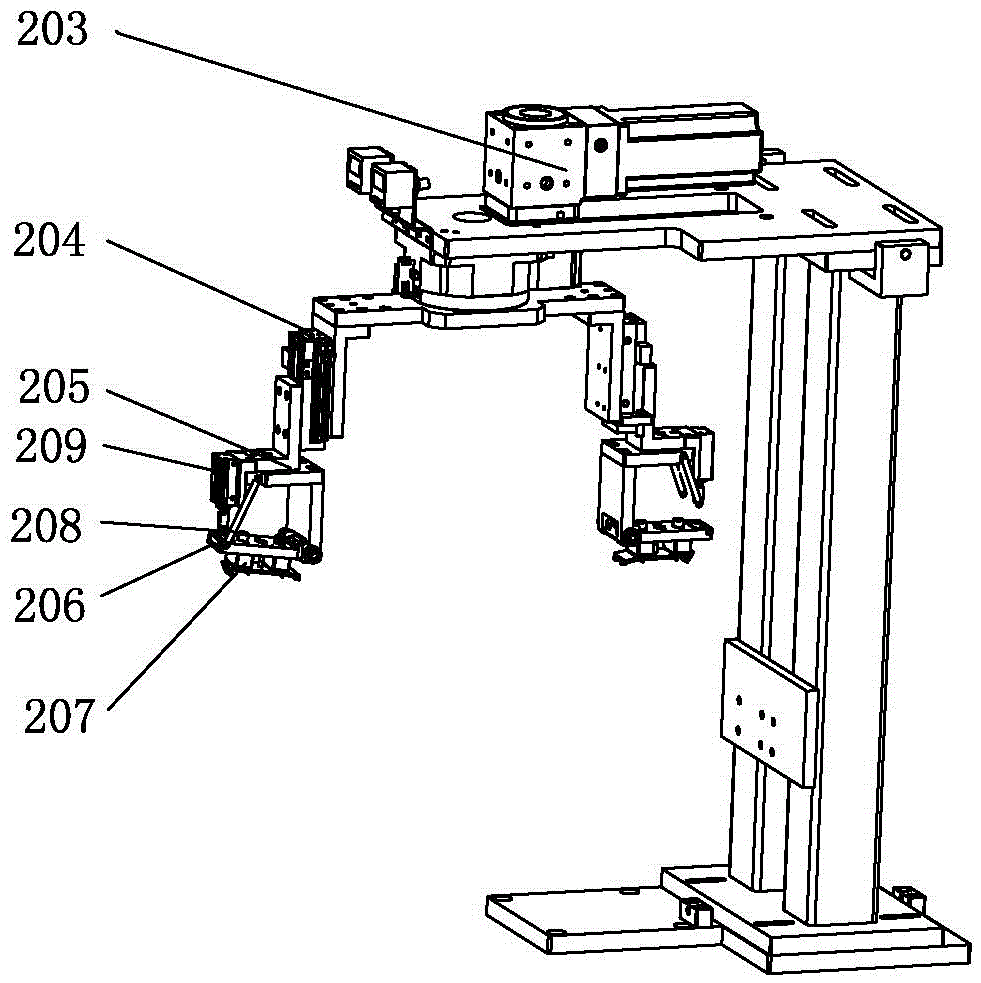

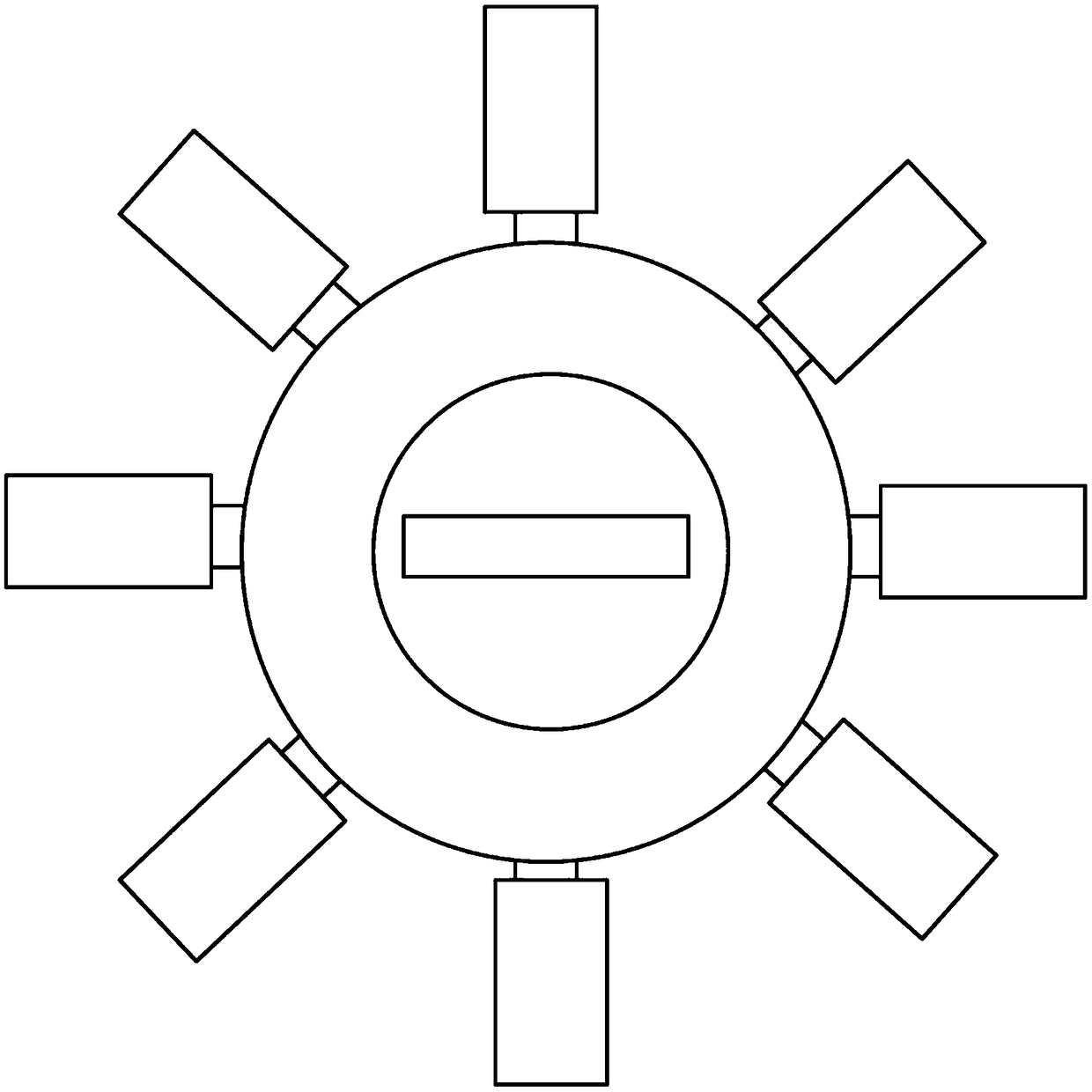

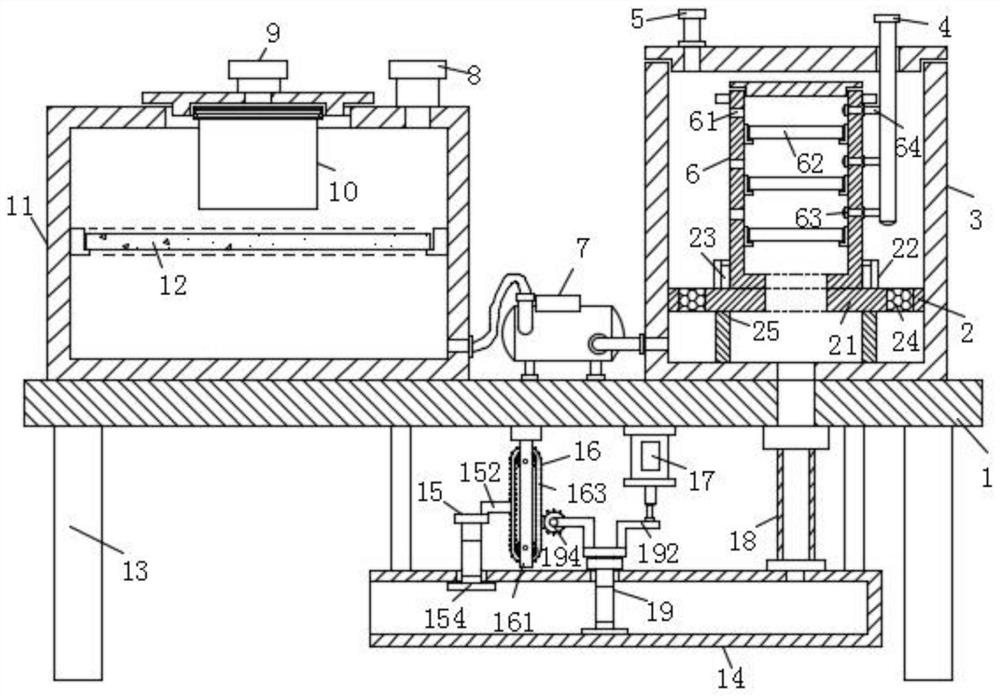

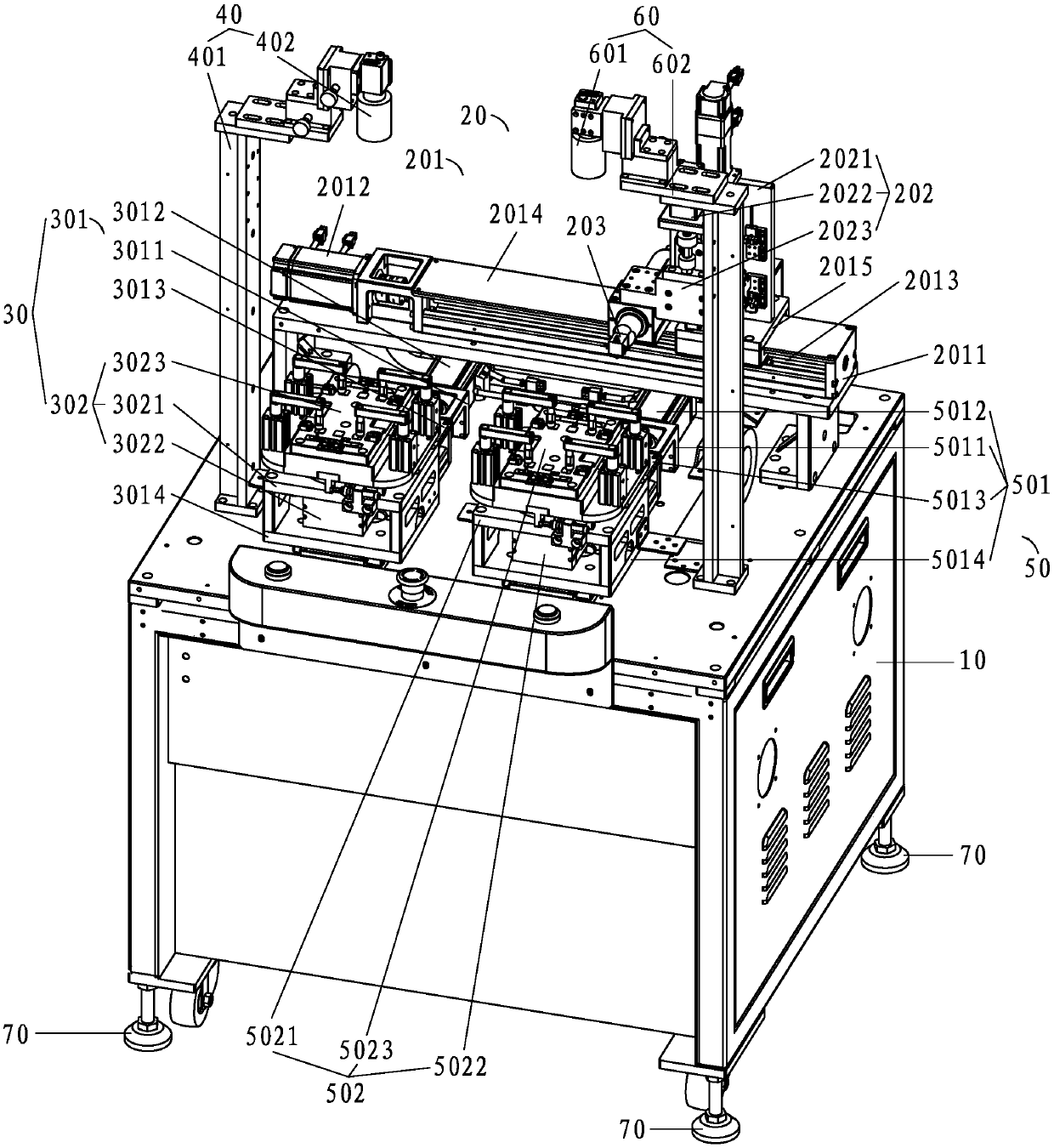

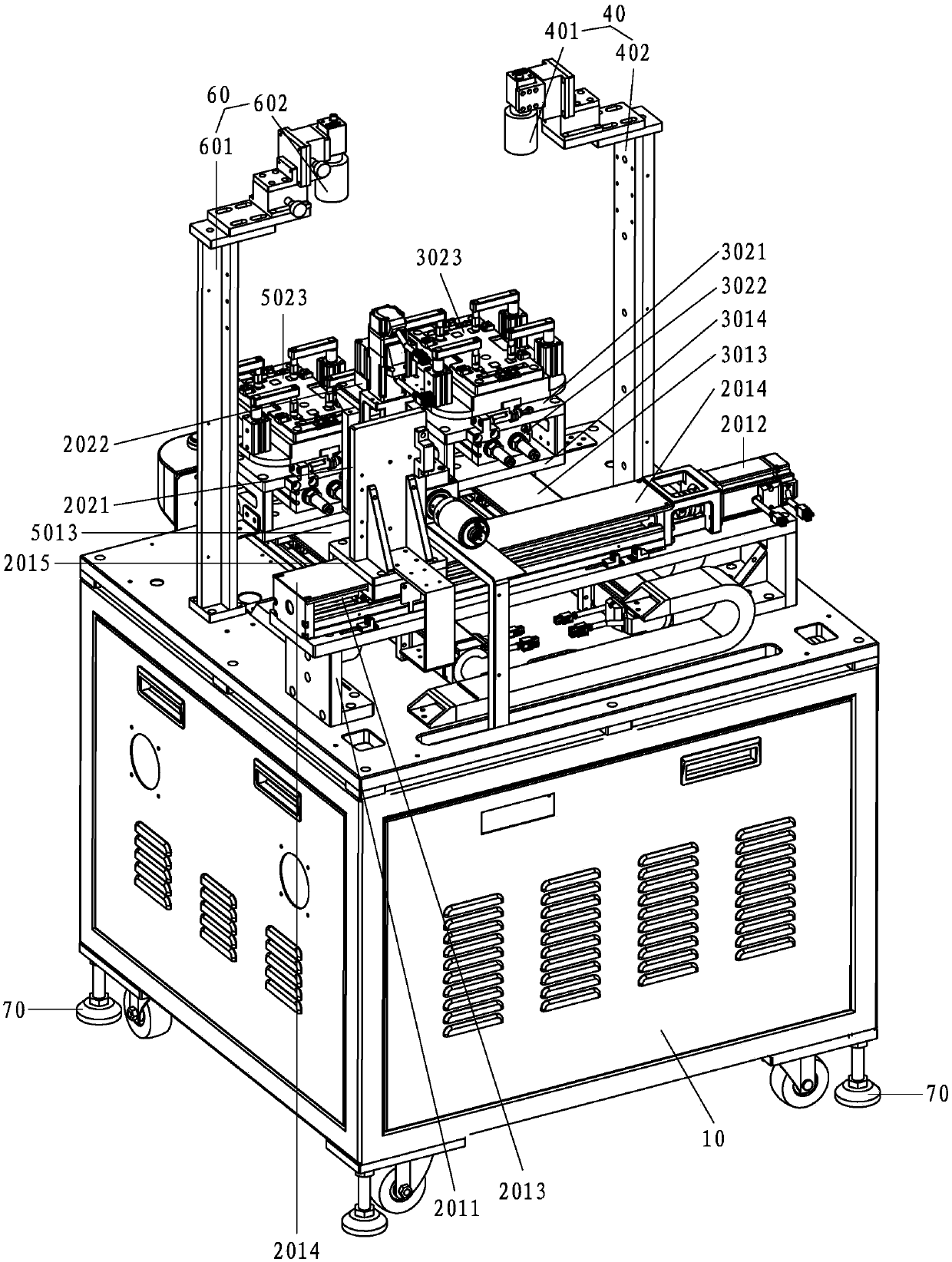

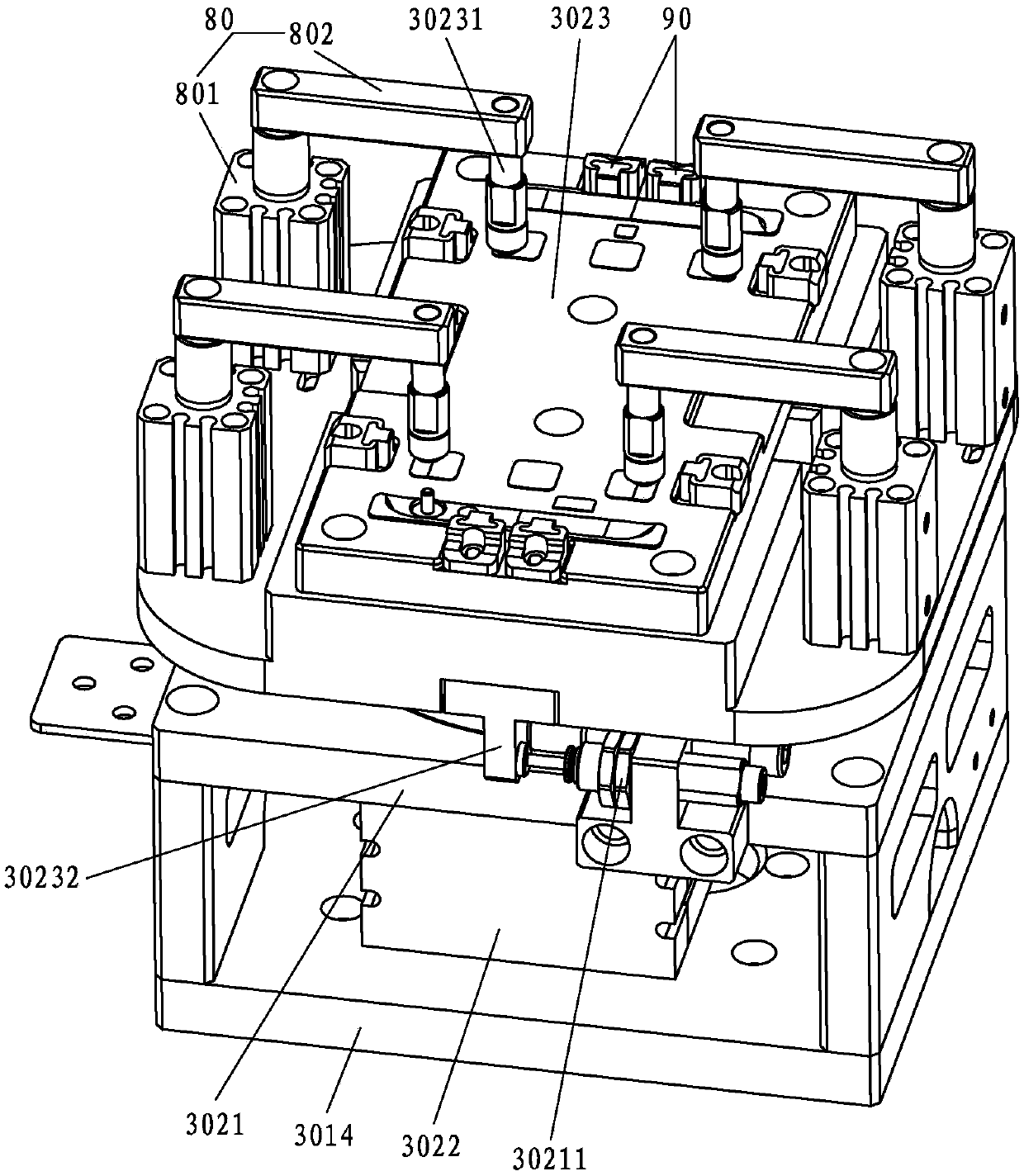

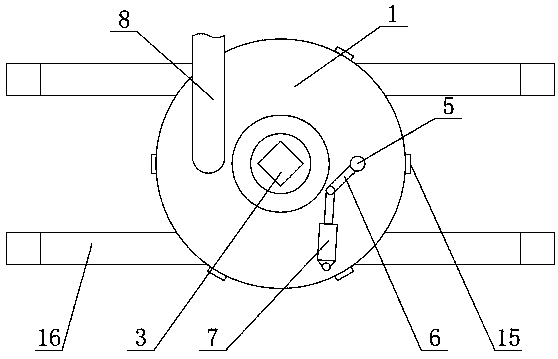

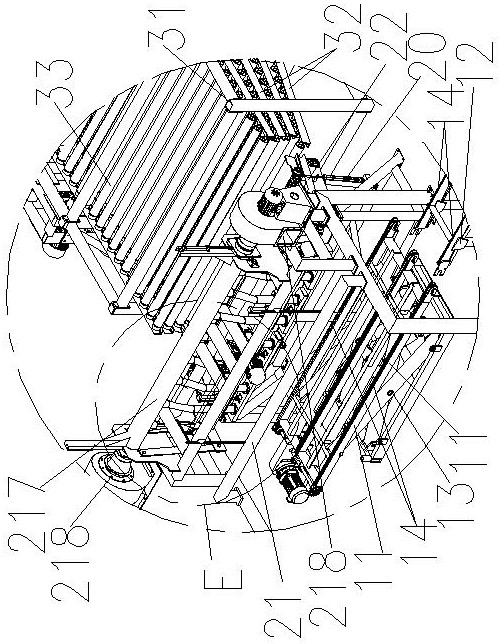

Remote control unit battery rear cover automatic assembly machine

ActiveCN106736376AHigh degree of automationImprove assembly efficiencyMetal working apparatusRemote controlEngineering

The invention relates to the technical field of remote control unit processing, in particular to a remote control unit battery rear cover automatic assembly machine. The remote control unit battery rear cover automatic assembly machine comprises a rotary disc, a plurality of automatic turnover jigs, a disc motor, an incoming material adding mechanism and a rear cover automatic assembly device. The automatic turnover jigs are arranged on the rotary disc in an annular array manner and used for bearing the remote control units to be separated. The disc motor is used for driving the rotary disc to rotate. The incoming material adding mechanism is used for placing the remote control units on the automatic turnover jigs. The rear cover automatic assembly device is arranged on the rotary disc and comprises a rotary support, the automatic turnover jigs and a rotary mechanism. The automatic turnover jigs are used for storing the remote control units to be assembled, and the rotary mechanism is used for driving the rotary support to rotate. Assembly mechanisms are fixed to the two sides of the rotary support correspondingly. The remote control unit battery rear cover automatic assembly machine can automatically completely the assembly work of remote control unit battery rear covers, and is high in production efficiency.

Owner:东莞市五鑫自动化科技有限公司

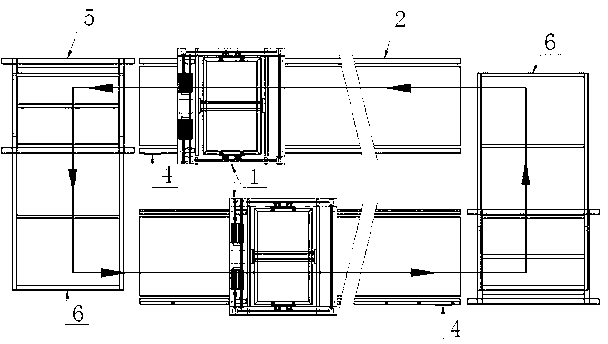

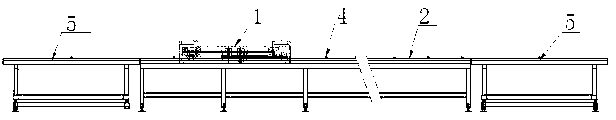

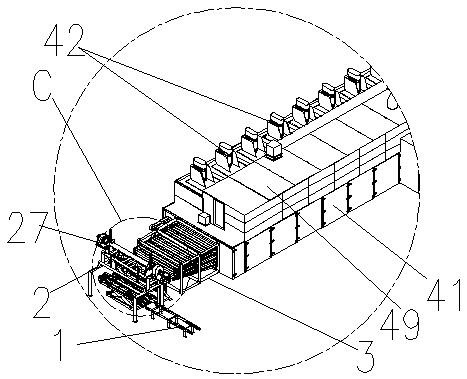

Full-automatic embossing machine

InactiveCN103158340AImprove efficiencyReduce the number of plate changesScreen printersPrinting press partsEngineeringUltimate tensile strength

The invention discloses a full-automatic machine which comprises an embossing machine body and a plurality of clamps used for locating the embossing machine body. The embossing machine body is arranged on table boards, an operating rail of the embossing machine body is arranged on the table boards, the number of the table boards is plural, and the table boards are arranged side by side and connected through turning systems, a shifting car and turning rails of the shifting car are arranged on the turning systems, the shifting car is used for shifting the embossing machine body, a signal emission device is arranged on the shifting car, the turning rails are rectilinear rails and perpendicular to the plane of the table boards, and included angles of 90 degrees are formed between the turning rails and the table boards. The full-automatic machine has the advantages of being high in automation degree and capable of enlarging product category, improving efficiency for dozens of times, improving product quality, reducing labor intensity and reducing production cost and complexity of labor.

Owner:山东宏美数码科技股份有限公司

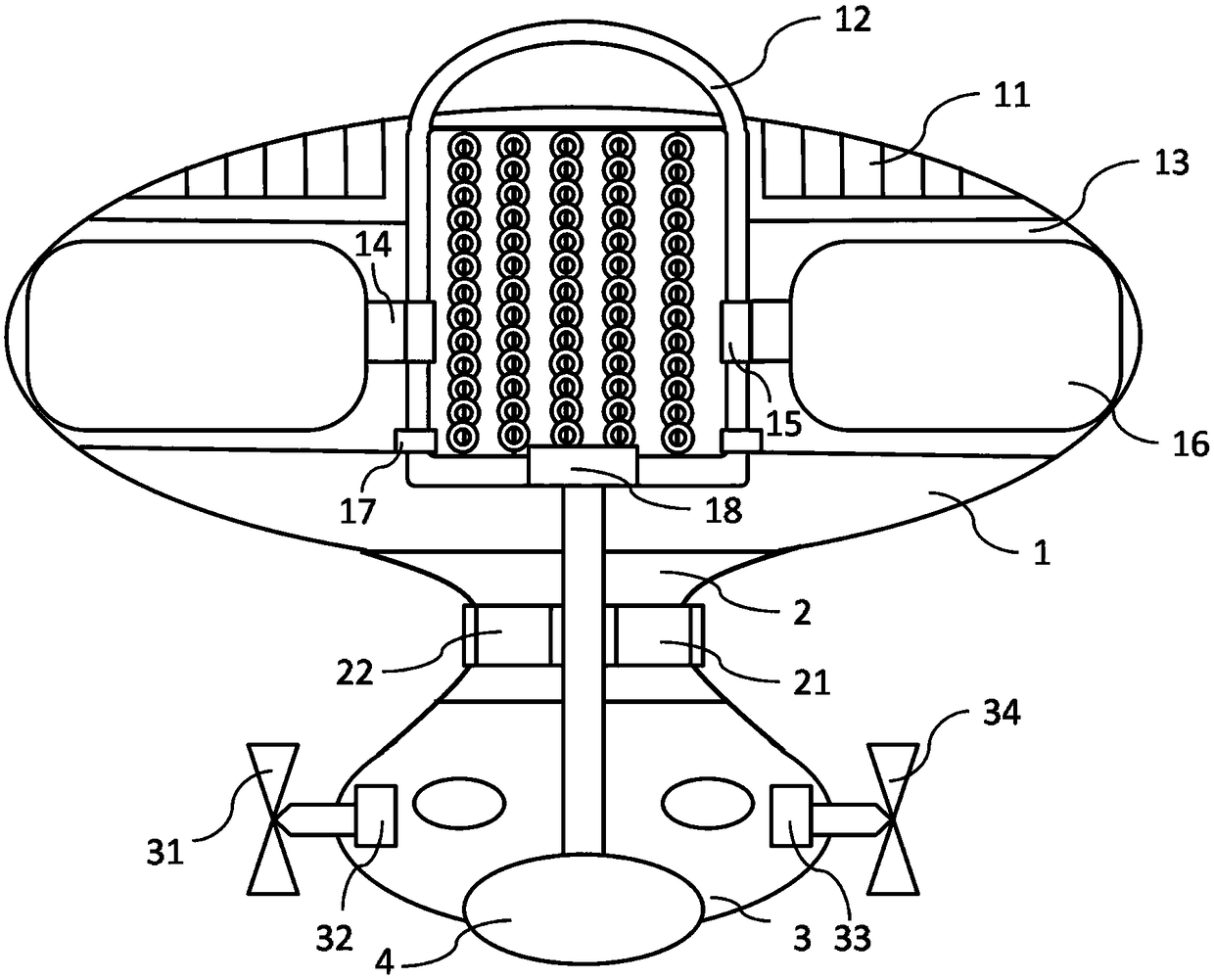

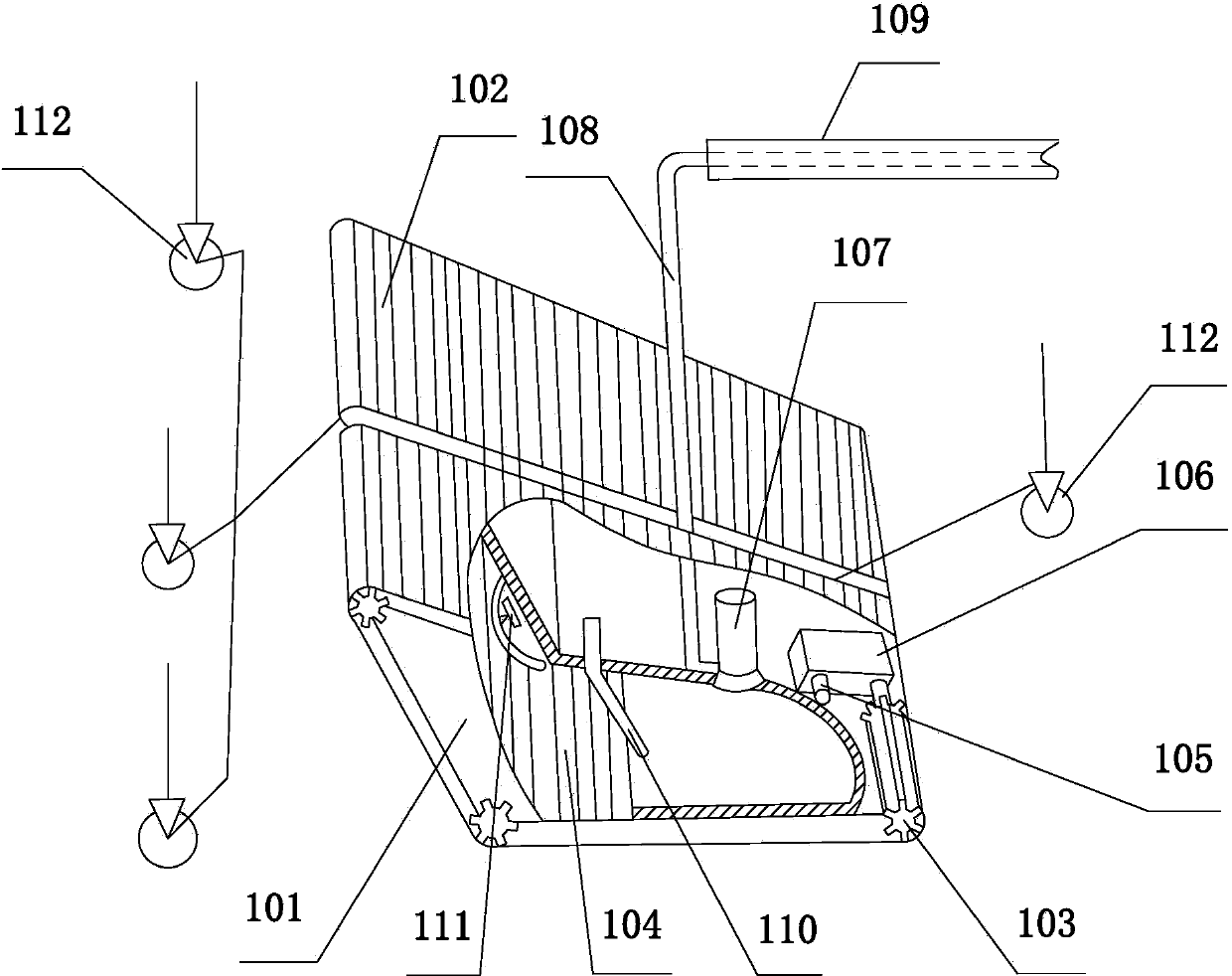

Intelligent petroleum machine for petroleum removal at sea

ActiveCN108867592AAutomation noTake advantage ofWater cleaningGeneral water supply conservationMaterial resourcesPetroleum

The invention provides an intelligent petroleum machine for petroleum removal at sea. Specifically, the intelligent petroleum machine comprises a petroleum removal machine body; the intelligent petroleum machine can achieve automatic and uninterrupted operation, is equipped with a solar storage battery and can fully utilize the characteristic of sufficient light at sea to reduce energy consumptionand make full use of environmental resources; a bioreactor can be periodically replaced and adjusted, the two modes of physical petroleum removal and biological petroleum removal are integrated, thepetroleum removal efficiency is high, and the thickness of a petroleum layer is not limited; the intelligent petroleum machine can replace a traditional petroleum containment treatment mode, the position of petroleum stains is judged through an optical sensor, the intelligent petroleum machine moves to the position of the petroleum stains, and the manpower and material resources are saved.

Owner:YANCHENG DEZHENG MACHINERY CO LTD

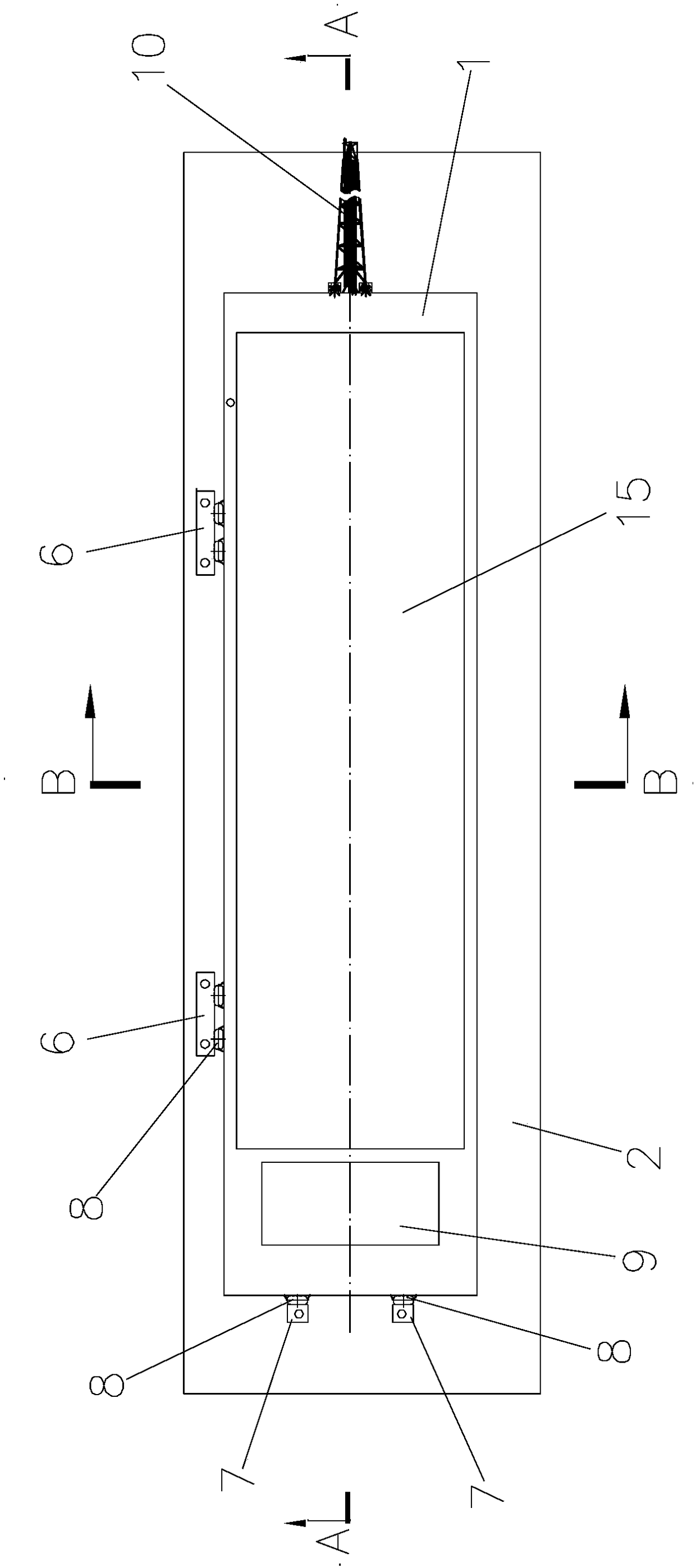

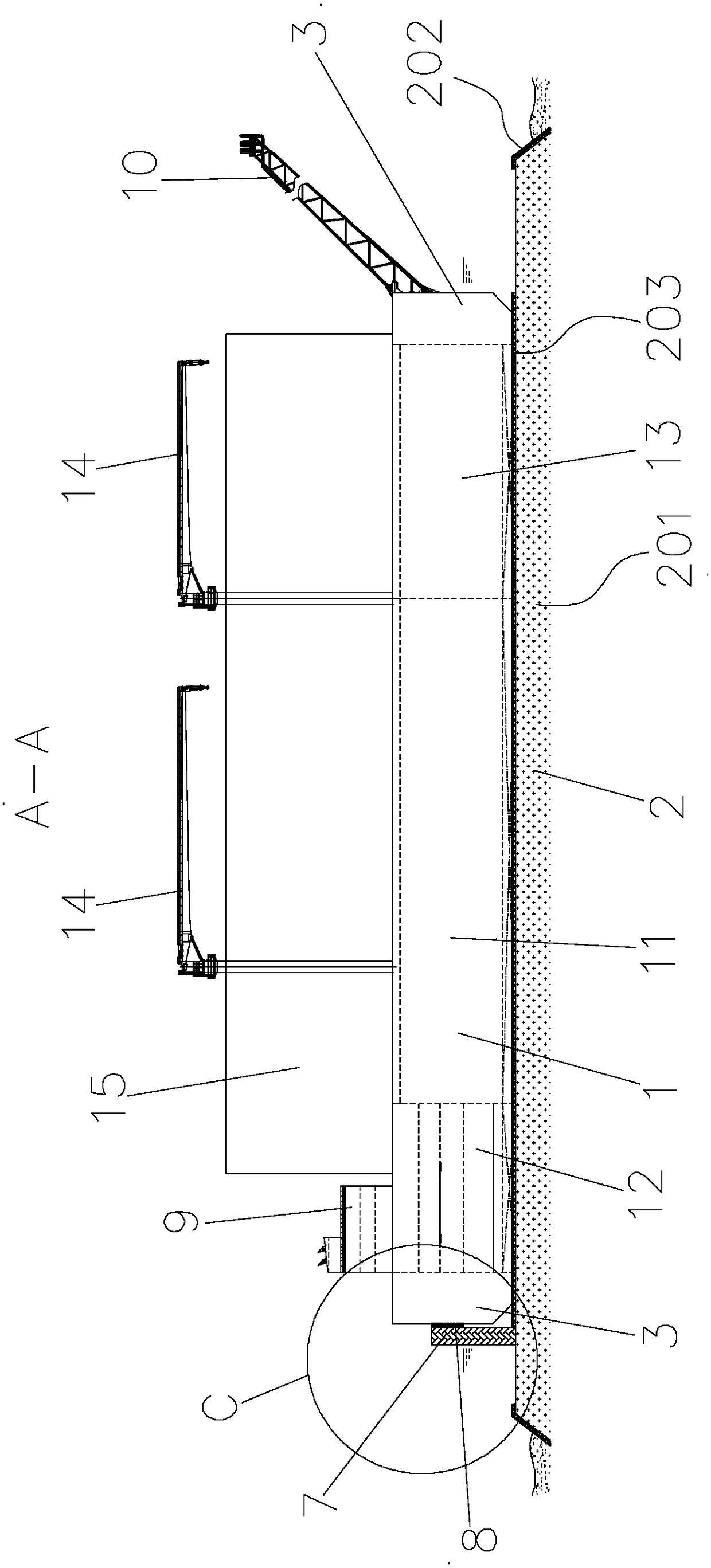

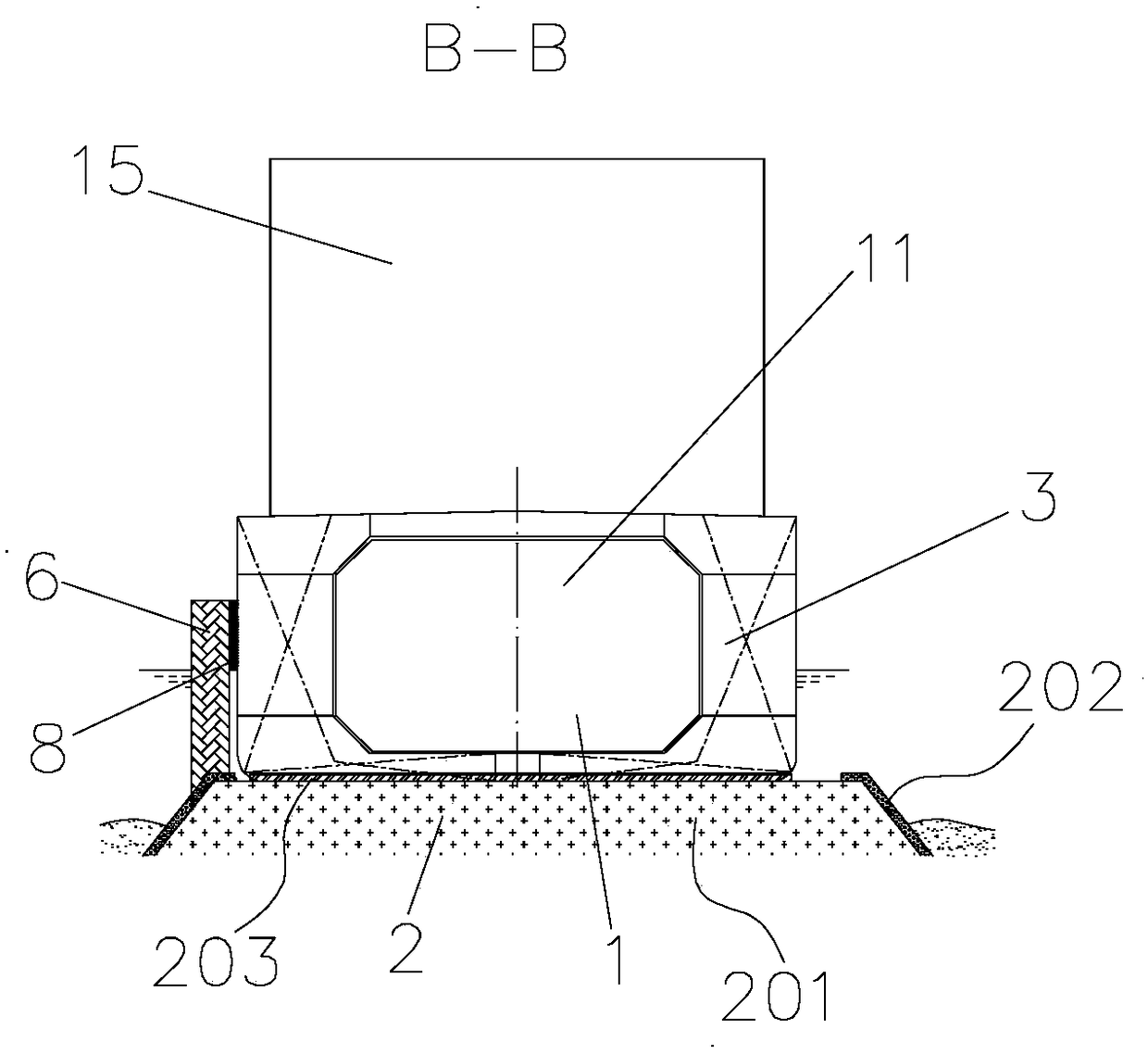

Maritime bottom-sitting type natural gas treatment device

PendingCN108298034ASit down and stabilizeNo sloshing load effectsFloating buildingsMooring systemNatural-gas processing

The invention belongs to the technical field of LNG production and particularly relates to a maritime bottom-sitting type natural gas treatment device. The maritime bottom-sitting type natural gas treatment device comprises a main hull and an underwater foundation, a natural gas treatment facility and a liquefied natural gas storage system are arranged on the main hull, multiple ballast tanks arearranged on the hull bottom and the periphery of the main hull, and the top face of the underwater foundation is used for bearing the main hull. Ballast water is injected in or drained out of the ballast tanks through ballast pumps so that the main hull can be adjusted to sink or float, and bottom-sitting installation of the device is achieved. A rubber cushion board can be arranged between a bottom board of the hull bottom of the main hull and the top face of the underwater foundation so as to increase the friction coefficient. The maritime bottom-sitting type natural gas treatment device hasthe beneficial effects that no mooring system needs to be arranged, under the effect of wind, waves and streams, a setting type bottom-sitting mode can guarantee that the device does not move at all,LNG stored on the device cannot shake, and continuity and safety of natural gas production and treatment are guaranteed.

Owner:SHANGHAI WISON OFFSHORE & MARINE CO LTD

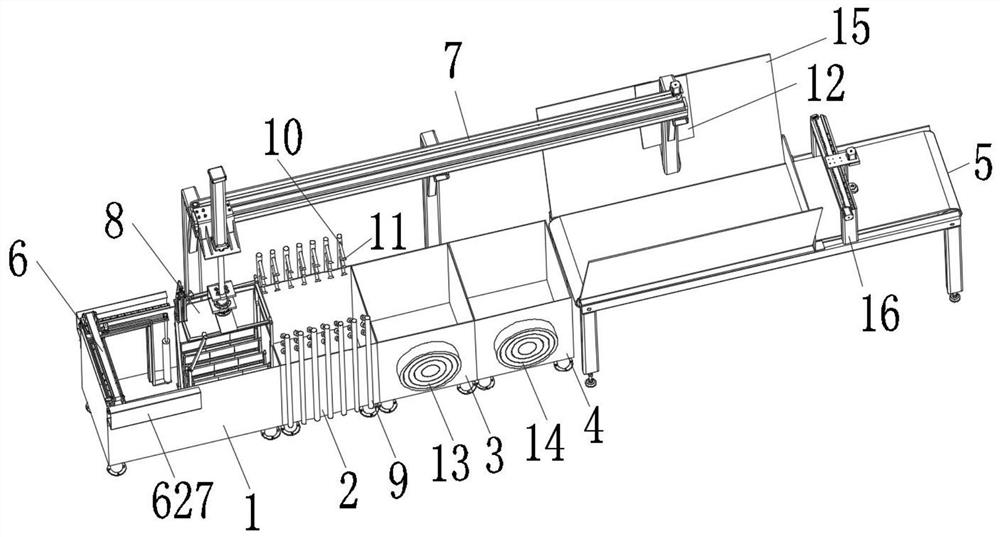

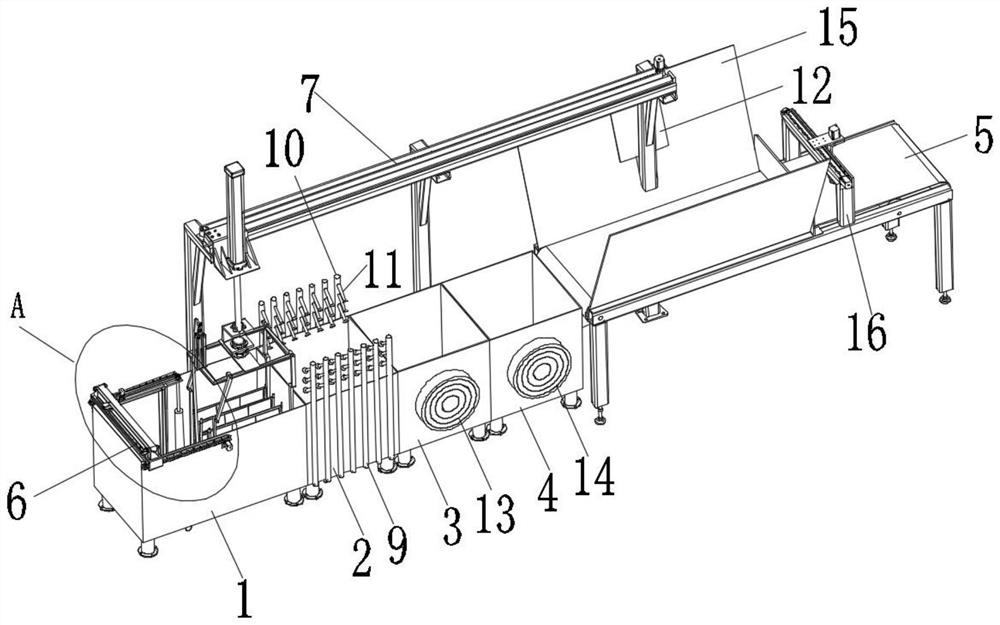

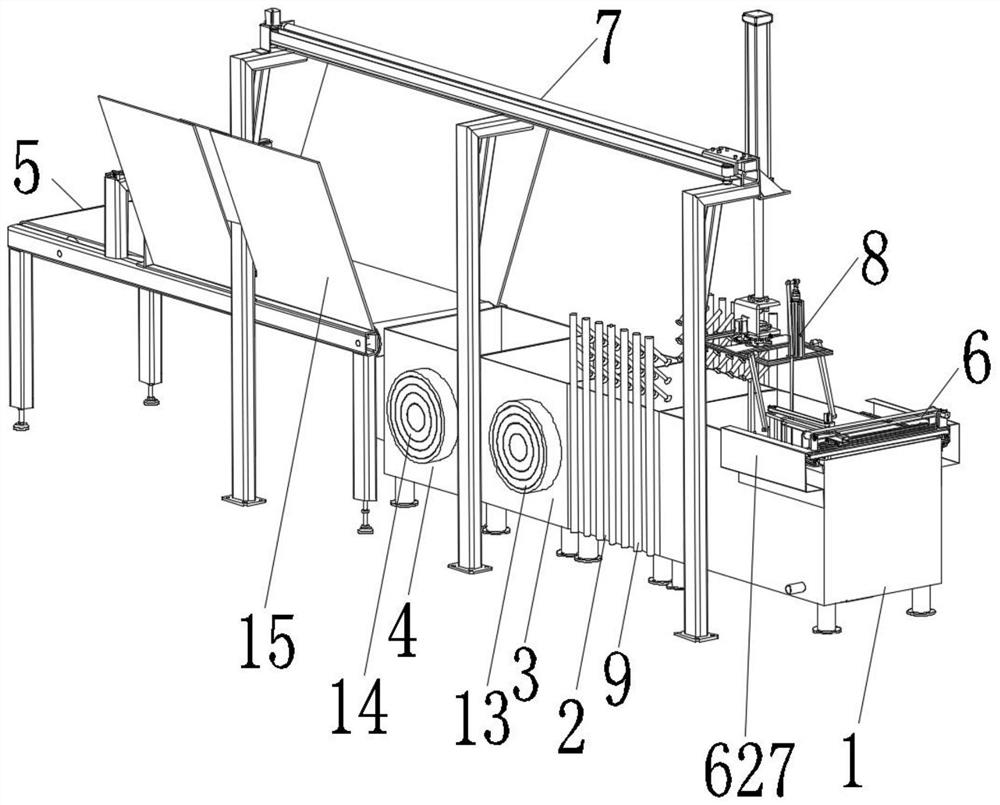

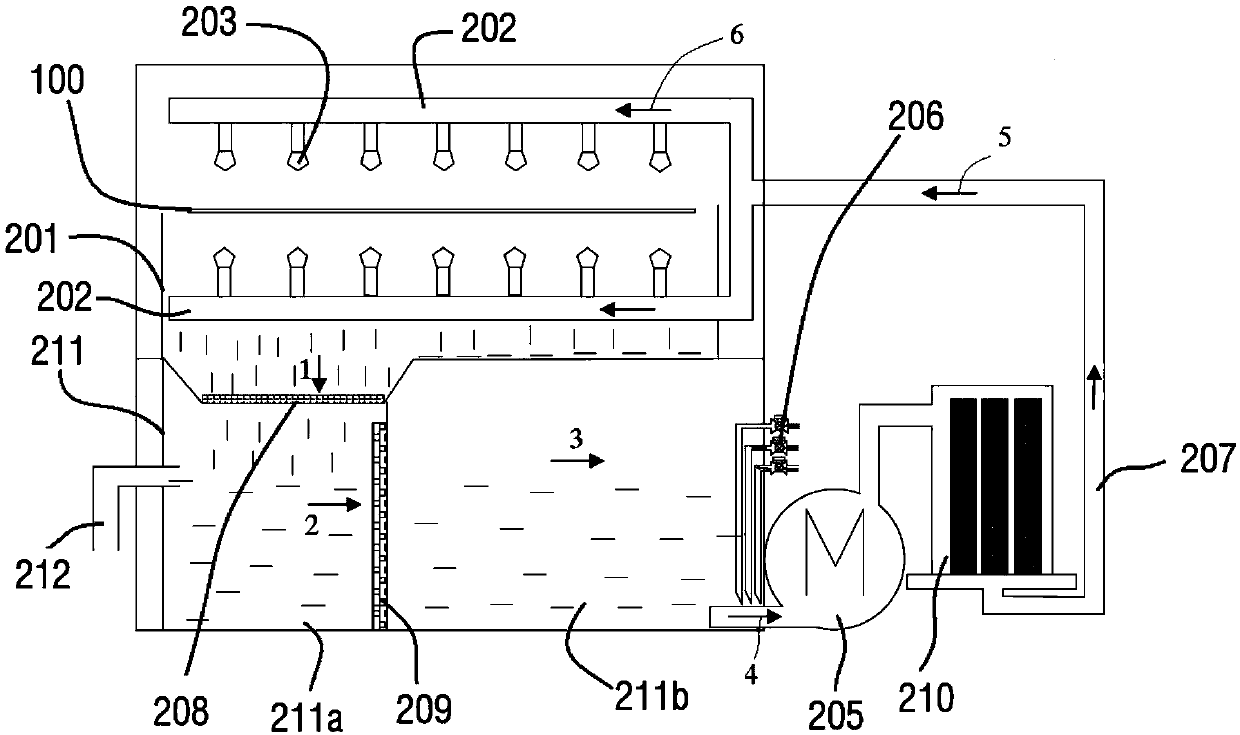

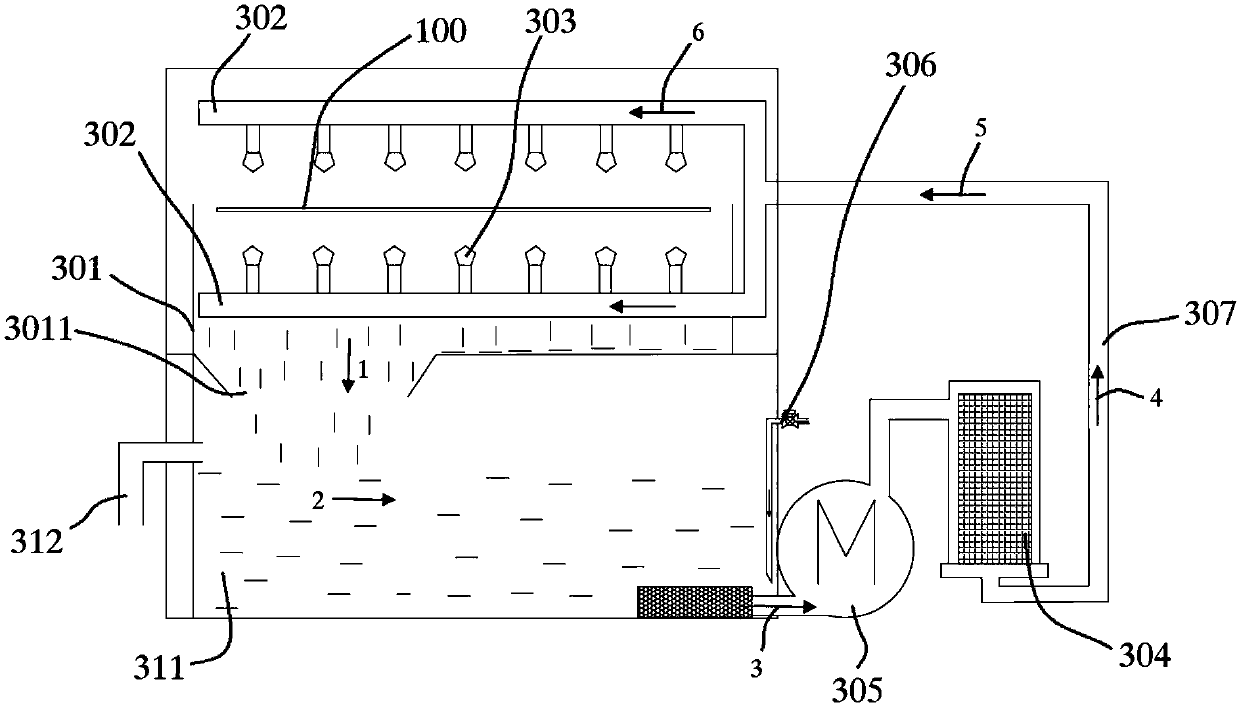

Integrated cleaning, drying and conveying device for chip production

InactiveCN112317407AEasy to placeImprove cleaning qualitySemiconductor/solid-state device manufacturingCleaning using toolsCold airStructural engineering

The invention discloses an integrated cleaning, drying and conveying device for chip production. The integrated cleaning, drying and conveying device comprises a cleaning box, a spraying box, a cold air box, a drying box and a conveying line which are sequentially arranged from left to right, wherein a cleaning mechanism is mounted at the top end of the cleaning box; a driving mechanism is arranged on the back side of the cleaning box; a chip storing mechanism is mounted on the driving mechanism; water pipes are mounted on the front face and the back face of the spraying box at equal intervals; inclined pipes are welded to the water pipes at equal intervals; and spraying heads are mounted at the tail ends of the inclined pipes. The integrated cleaning, drying and conveying device is provided with the cleaning mechanism, and compared with a traditional device, the cleaning quality is better; the chip storing mechanism is arranged and is arranged to be a chip storing plate capable of being taken out, thus chips on the chip storing plate are sprayed and dried in all directions, and the problems that in the traditional mode, the chips are stored on the conveying line, consequently, thedrying effect of one face is poor, and watermarks exist are solved; and a correcting mechanism is arranged, the center distance of the chips is conveniently corrected, and thus the integrated cleaning, drying and conveying device can be well connected with the next technological process.

Owner:安徽晟东科技有限公司

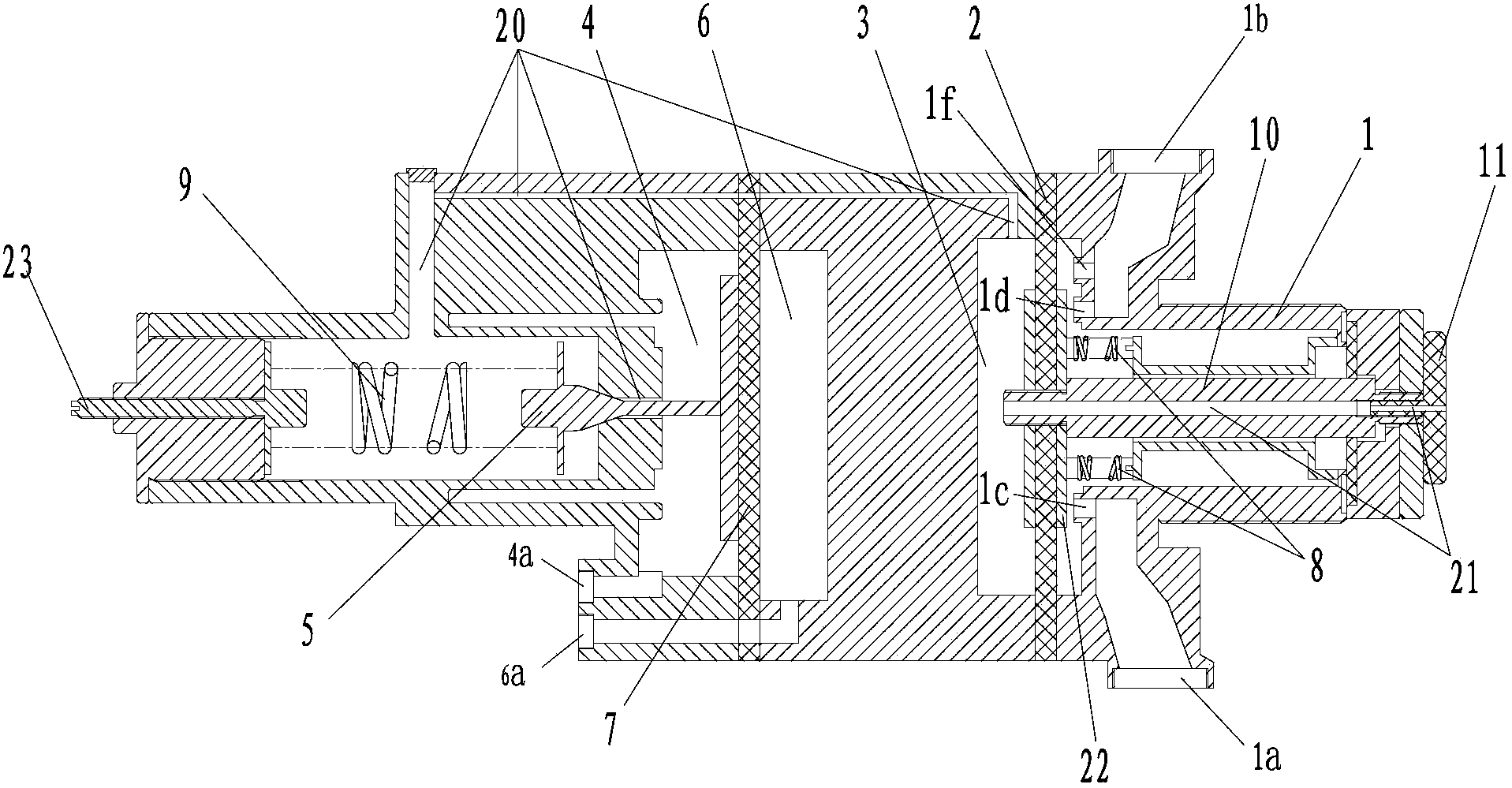

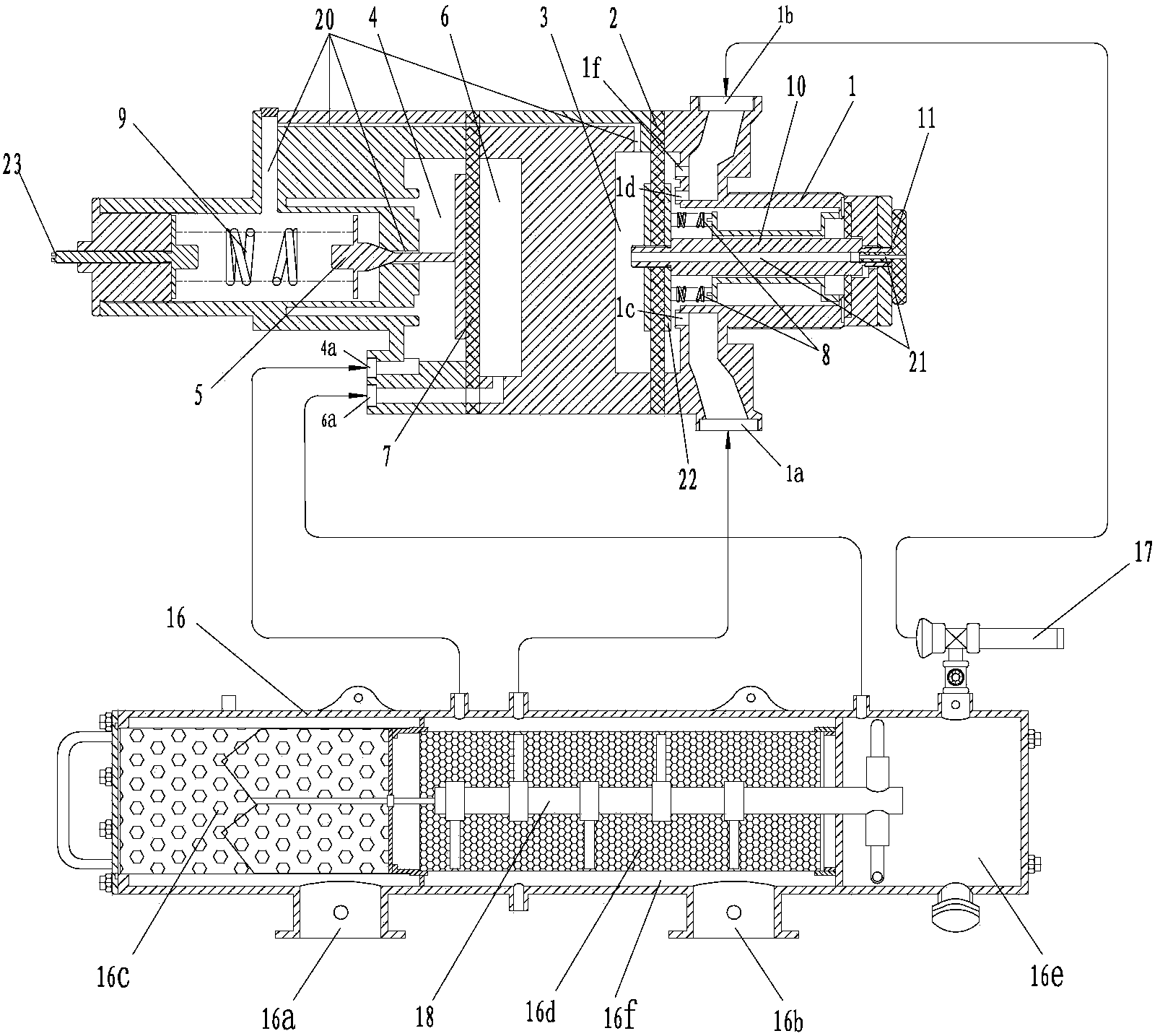

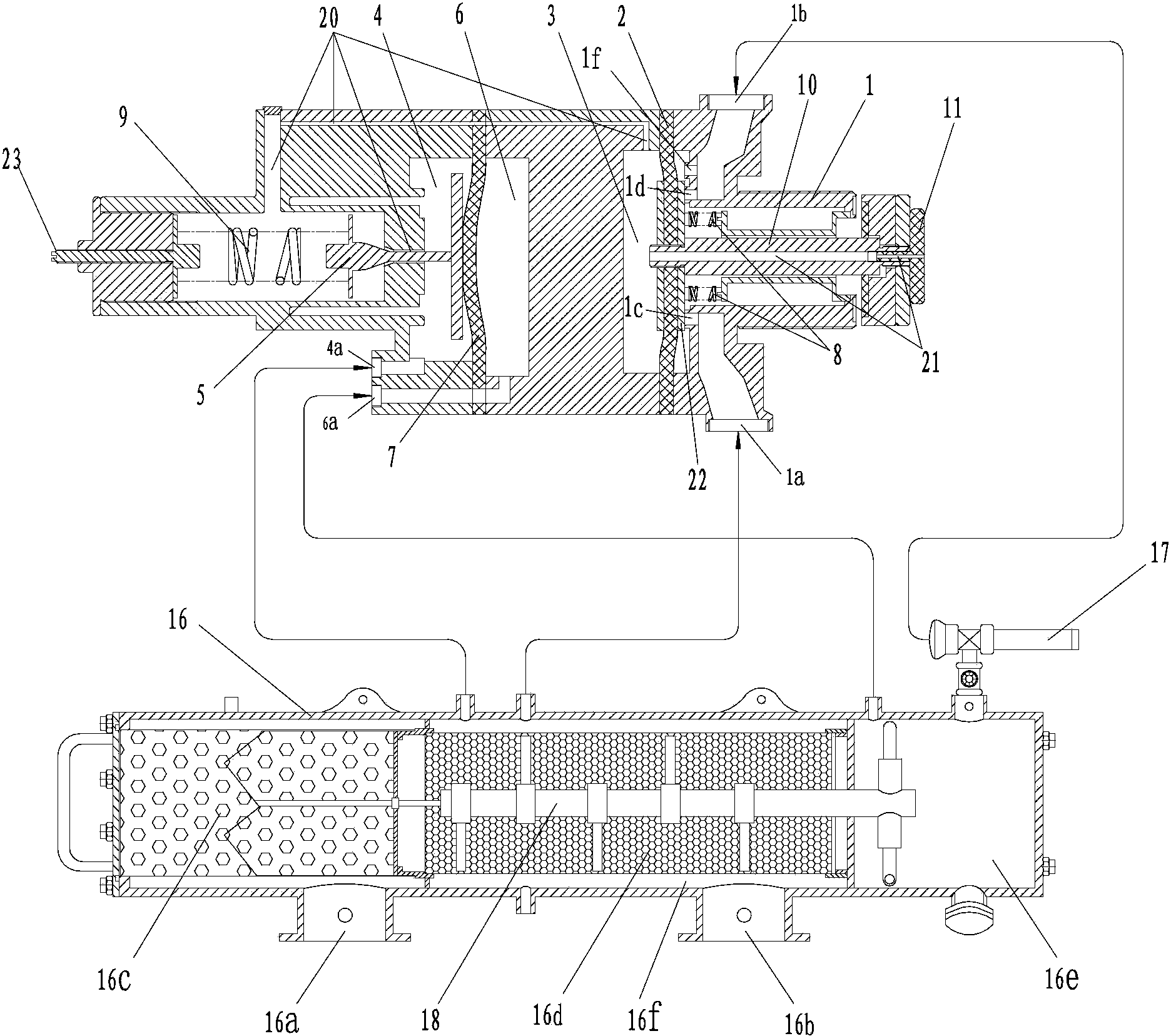

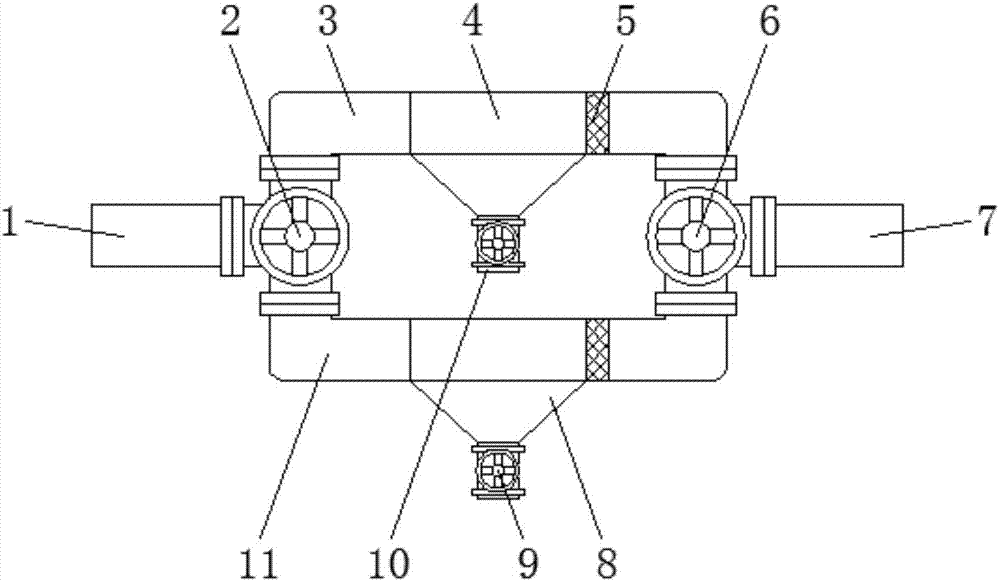

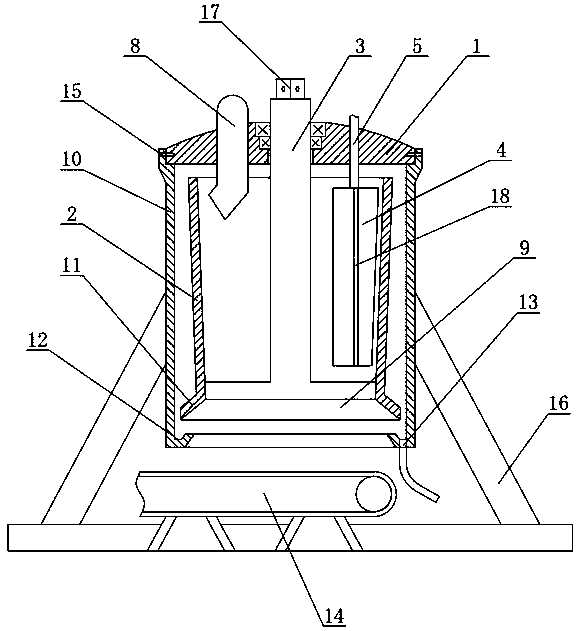

Hydraulic pressure differential controller and application thereof

ActiveCN103438247AUninterrupted workReduce consumptionEqualizing valvesMultiple way valvesElectricitySewage

The invention discloses a hydraulic pressure differential controller and application thereof. The hydraulic pressure differential controller comprises a valve body, wherein a first water inlet and a first water outlet communicated with each other are arranged at the front end of the valve body, a first elastic part used for blocking the communication of the first water inlet and the first water outlet is arranged at the rear sides of the first water inlet and the first water outlet, a pressure boosting cavity is arranged at the rear side of the first elastic part, the pressure boosting cavity is communicated with a low pressure cavity through a first channel, and a valve stem used for controlling the opening and closing of the channel is arranged on the channel; the low pressure cavity is connected with the high pressure cavity, the low pressure cavity and the high pressure cavity are separated through a second elastic part, the valve stem is connected with the second elastic part, and a low pressure water inlet and a high pressure water inlet are respectively arranged in the low pressure cavity and the high pressure cavity; a first reset spring and a second reset spring are respectively arranged on the first elastic part and the valve stem. The hydraulic pressure differential controller and the application thereof solve the defects that when traditional water processors are used for treating sewage, filter nets are blocked by dirt and cannot be cleaned automatically, and people need to dismount the water processors to carry out manual cleaning. Besides, the hydraulic pressure differential controller adopts the purely physical working principle, consumes no electricity and is energy-saving.

Owner:ZHEJIANG LYUGU ENVIRONMENT PROTECTION TECH CO LTD

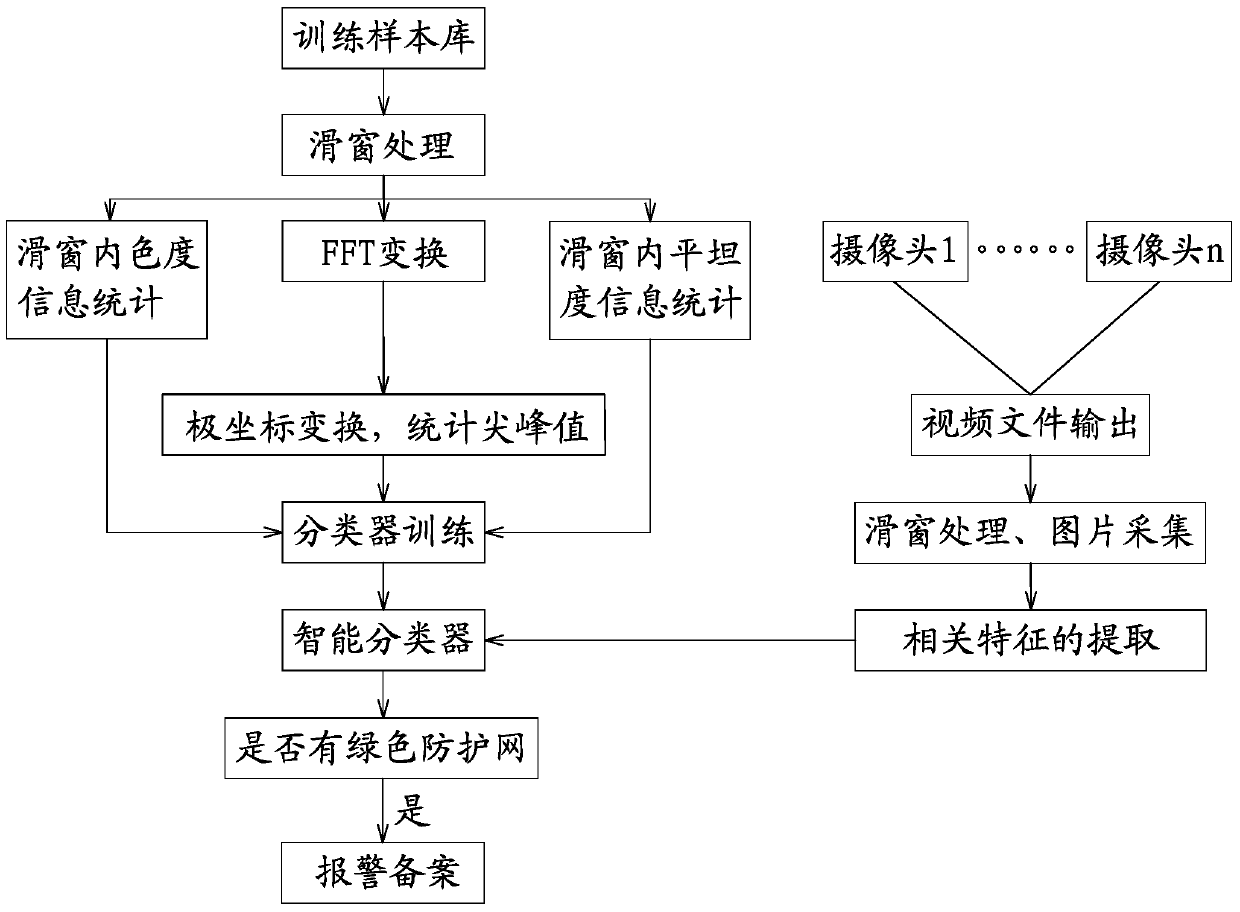

Guard net detection method based on Fourier spectrum under polar coordinates

InactiveCN103996050AGood indicationEasy to handleData processing applicationsCharacter and pattern recognitionFrequency spectrumTraining phase

The invention discloses a guard net detection method based on the Fourier spectrum under polar coordinates. The detection method comprises the following steps that S1) a guard-net training sample library is established; S2) sliding window is carried out on images in a major sample image library, and Fourier transform is carried out on each image after sliding window; S3) polar coordinate transformation is carried out on the images after Fourier transform, and peak values are used as texture features of the guard net, S4) the extracted texture features are transmitted into a classifier to obtain an intelligent classifier based on the guard-net training sample library; and S5) guard net detection after a training phase is completed. According to the method, guard net detection is used as basis for determining illegal construction, a computer is combined with a camera to automatically monitor state-owned land and automatically identify guard nets to determine whether illegal construction occurs, the instantaneity and timeliness are high, discovery of illegal construction is not lagged, monitoring is stable and uninterrupted, consumed energy and material are low, and time and labor are saved.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV +1

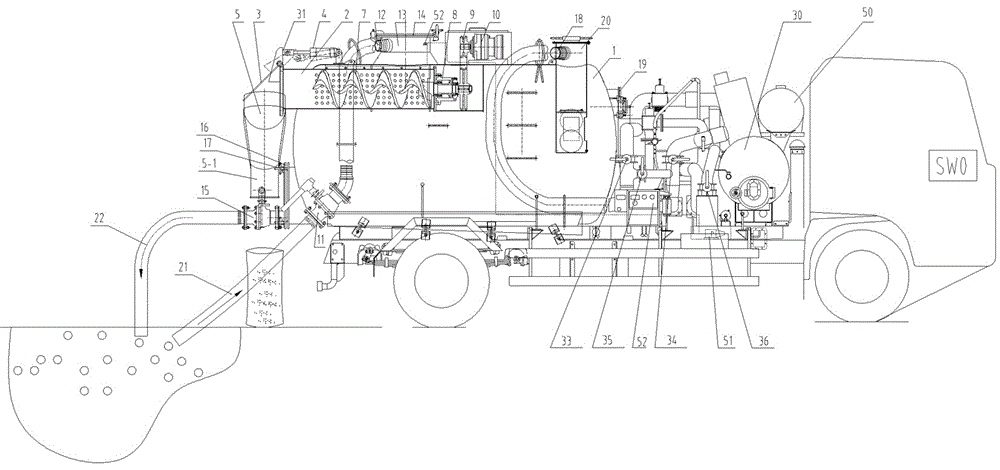

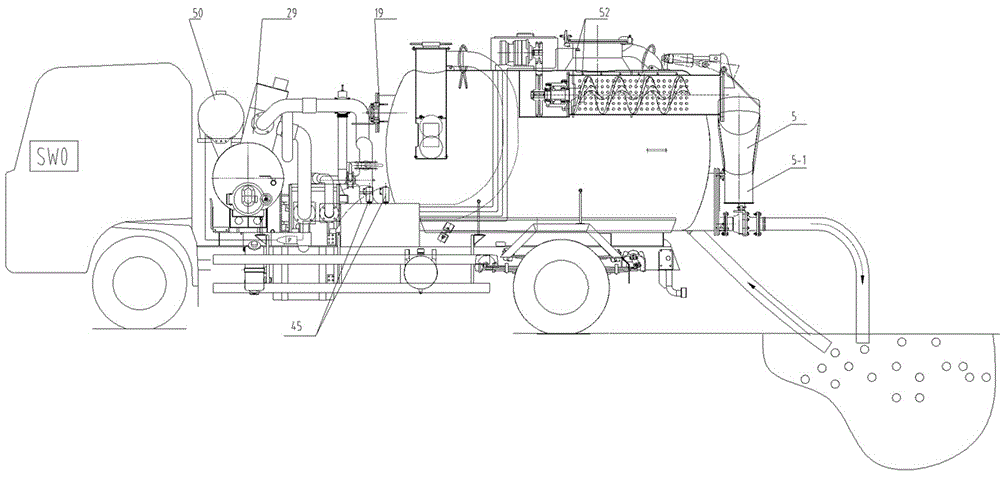

Powerful suction-type sewer scavenger

InactiveCN105971108AUninterrupted workImprove cleaning efficiencySewer systemsStationary filtering element filtersVacuum pumpingScavenger

The invention relates to a powerful suction-type sewer scavenger. The powerful suction-type sewer scavenger comprises a suction-type sewer scavenger body, wherein a tank body forming closed space is arranged on a chassis of the suction-type sewer scavenger body and provided with a feeding port I, a vent nozzle and a vacuum pumping port; a solid-liquid separation filter cartridge is arranged in the tank body; one axial end of the solid-liquid separation filter cartridge extends out of the rear end of the tank body; a seal cover is arranged at the axial end, extending out of the tank body, of the solid-liquid separation filter cartridge; an end plate is arranged at the axial end, located in the tank body, of the solid-liquid separation filter cartridge; a shaftless screw body is arranged in the solid-liquid separation filter cartridge; a support end of the shaftless screw body penetrates a via hole formed in the end plate of the solid-liquid separation filter cartridge, extends out of the solid-liquid separation filter cartridge and is connected with a power driving device through a transmission mechanism; a plurality of filter holes and a feeding port II are formed in the body, located in the tank body, of the solid-liquid separation filter cartridge; the feeding port II allowing entry of sewage is communicated with the feeding port I of the tank body; a liquid level control device is arranged in the tank body; a first filter device is communicated between the vacuum pumping port and a first vacuum pump through a pipeline.

Owner:重庆耐德山花特种车有限责任公司

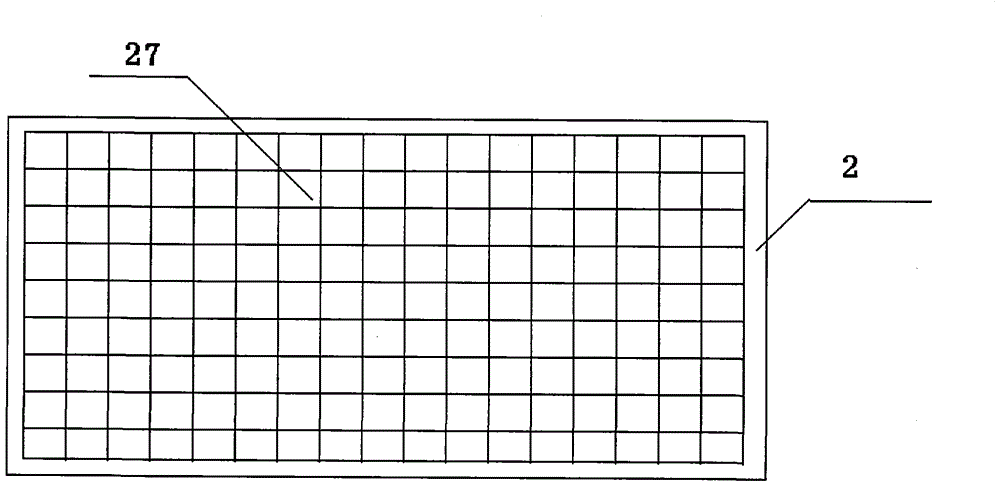

Underwater walking dredging device

The invention provides an underwater walking dredging device, and belongs to desludging devices. The underwater walking dredging device comprises a device body which is a closed shell, and a sludge inlet is formed in the bottom of the closed shell. Two gridding type drive belts are symmetrically arranged on the outer wall of the body, and the gridding type drive belts are driven through a drive shaft. A driving mechanism and a sludge pump are arranged in the device body, and the driving mechanism is connected with a driving shaft. The sludge pump is connected with a sludge conveying pipe, and the upper end of the sludge conveying pipe extends out of the device body. A control table is further included, and the control table is electrically connected with the driving mechanism and the sludge pump respectively through lines. The underwater walking dredging device is simple in structure, reasonable in design, widely applicable to desludging of ponds, reservoirs and city moats, capable of achieving quickness and high efficiency, low in energy consumption and ceaseless in operation. Water in the ponds does not need to be swabbed off, blockage can not happen, the sludge swabbing concentration is high, and good practicability is achieved.

Owner:李德兵

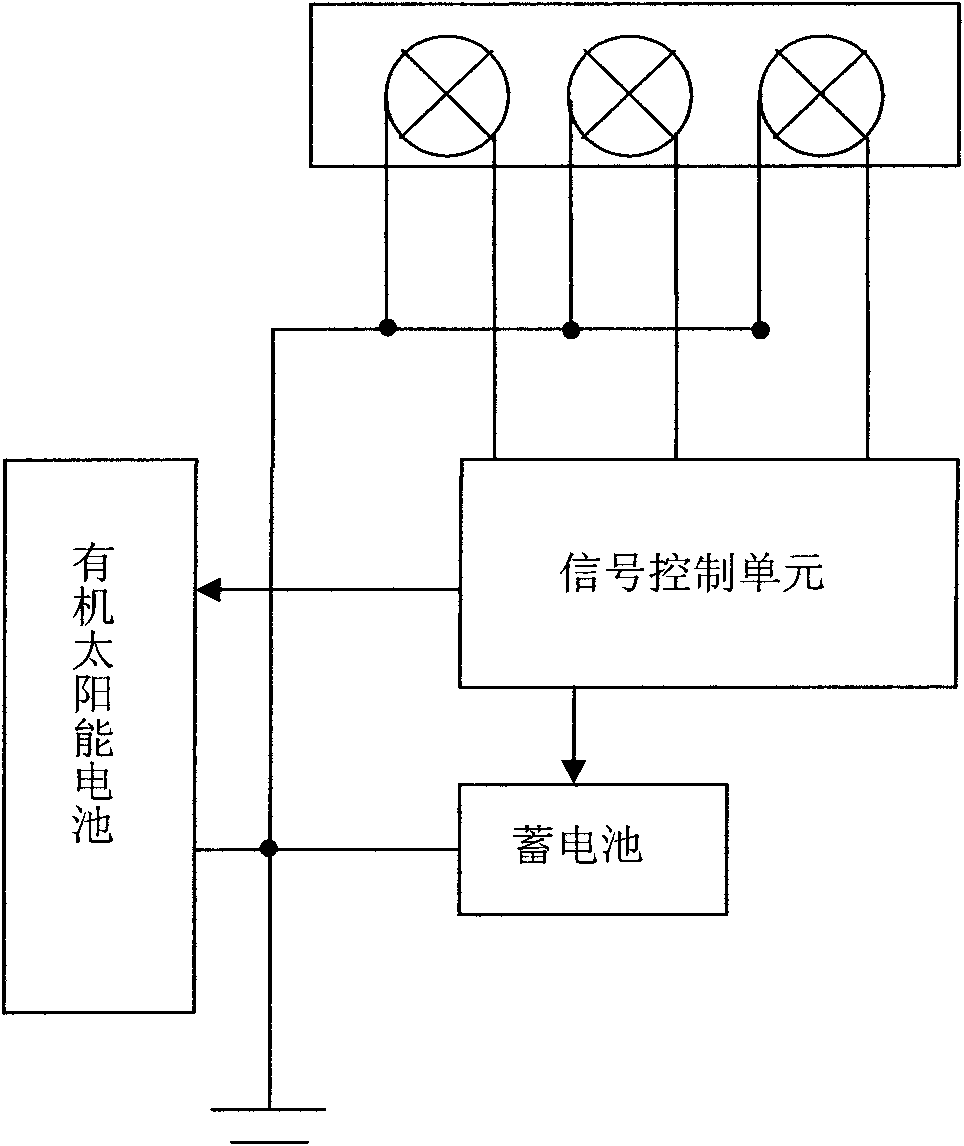

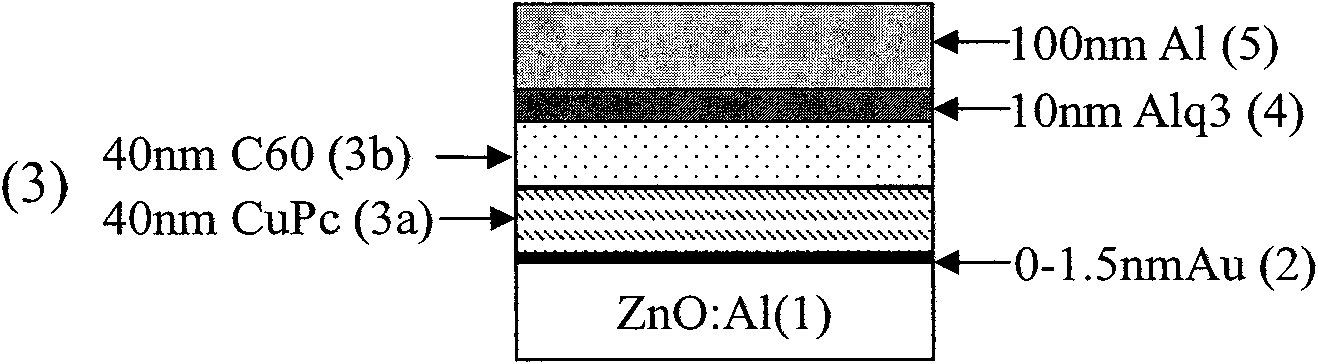

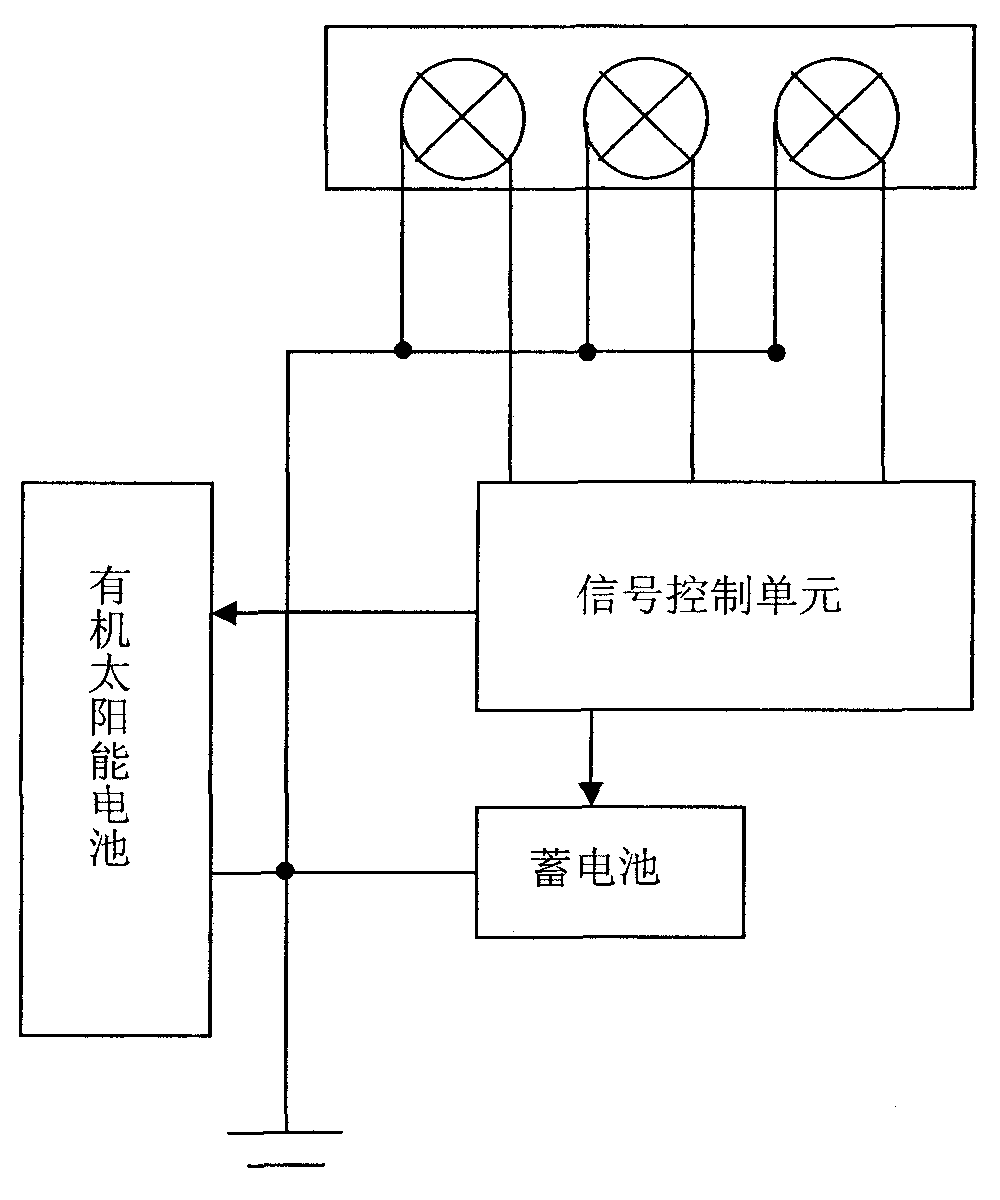

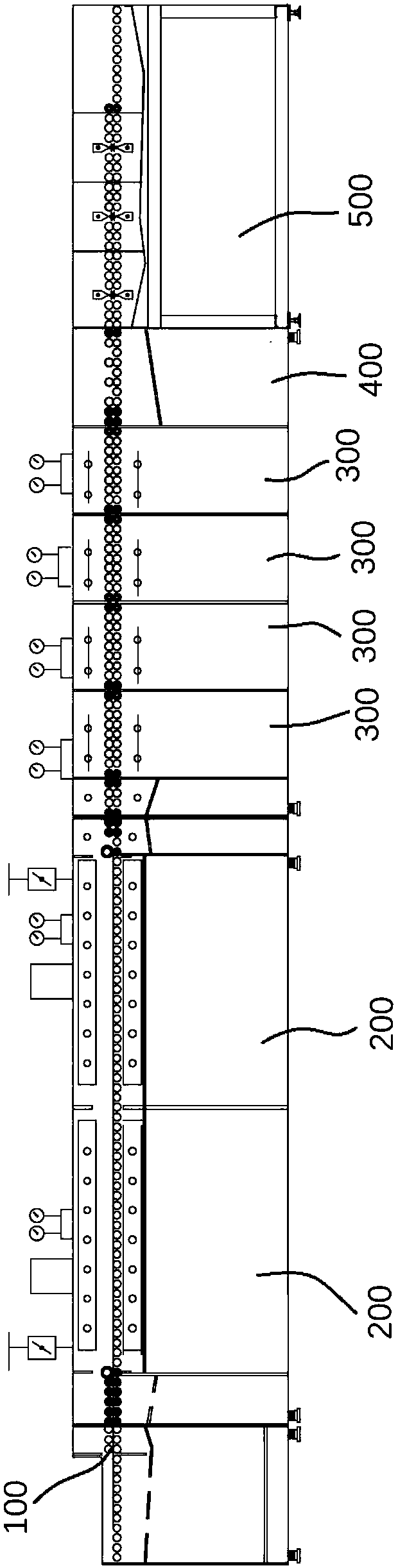

Organic solar traffic light

InactiveCN101923785ASolve the problem of power supplySolve the saving problemRoad vehicles traffic controlSolid-state devicesOrganic solar cellDaylight

The invention belongs to the technical field of solar cell application, in particular relates to an organic solar traffic light comprising a signal light, a solar cell, a storage cell and a control unit, wherein the solar cell is connected with the signal light; the storage cell is connected between the solar cell and the signal light; the signal light is formed by an OLED (Organic Light-Emitting Diode) array; an active layer of the solar cell is formed by stacking organic materials CuPo / C60; an ultrathin Au layer (0.5+ / -0.2nm) is modified on a ZnO:Al anode, and therefore, compared with the energy conversion efficiency of a solar cell without an Au modifying layer, the energy conversion efficiency of the organic solar cell is increased by about 10 times. The organic solar traffic light has low cost and convenient and simple facilities and is especially suitable for a crossing without an alternating current area. In addition, the organic solar traffic light can work by directly using solar energy to supply electric energy in a sunny day and stores electric energy into the storage cell and can also work by using the electric energy stored in the storage cell at night or an overcast and rainy day, thus the organic solar traffic light can work uninterruptedly throughout the year.

Owner:甄玉凤

Chemical impurity-removing method and equipment for graphene thin film during transfer

The invention relates to a continuous impurity-removing method and equipment for a graphene thin film during transfer and a graphene transfer method. The equipment comprises a transmission device, a chemical corrosion section, a washing section, a water reducing section and a drying section, wherein the transmission device penetrates the chemical corrosion section, the washing section, the water reducing section and the drying section which are sequentially arranged from upstream to downstream along the traveling direction of the transmission device.

Owner:WUXI GRAPHENE FILM +1

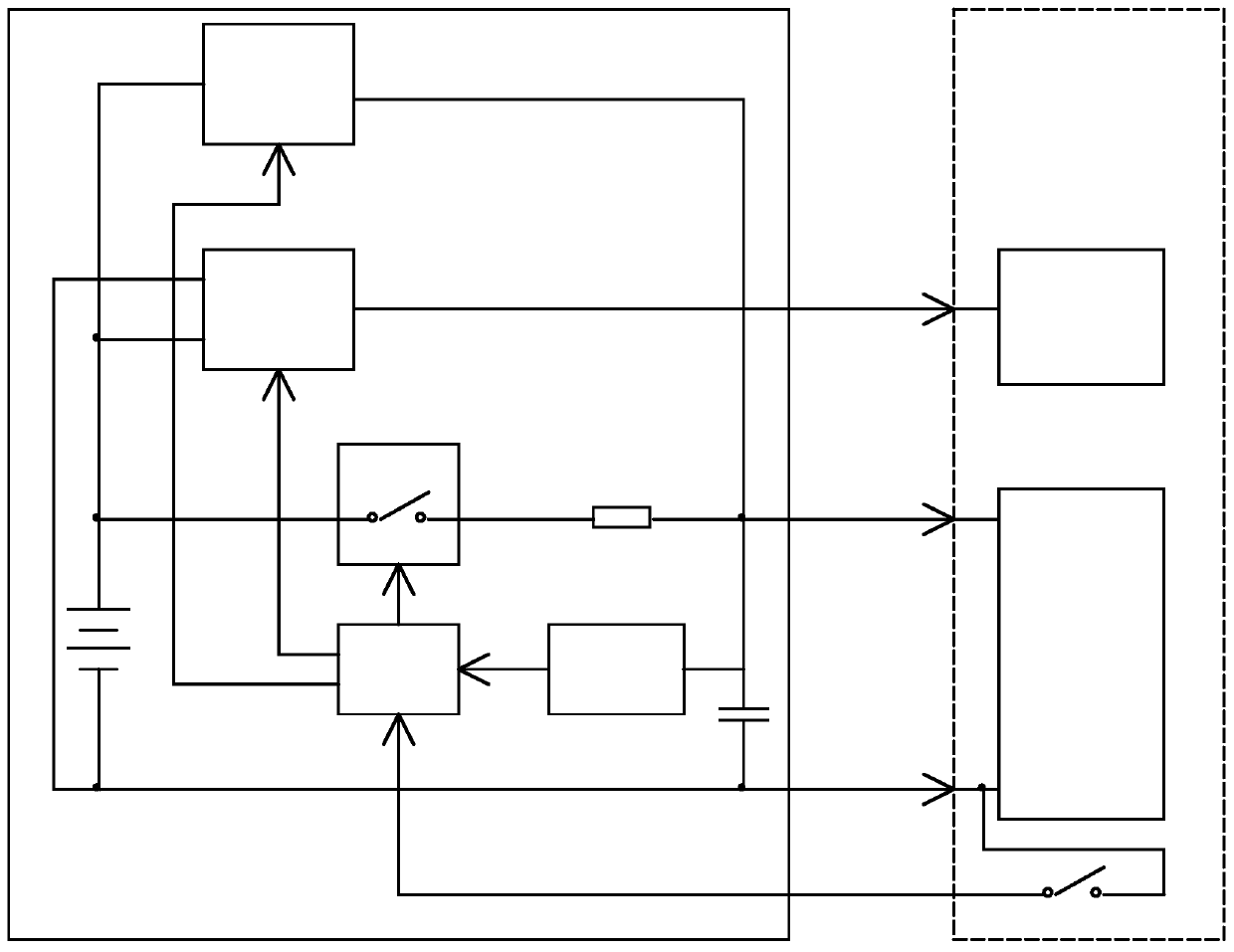

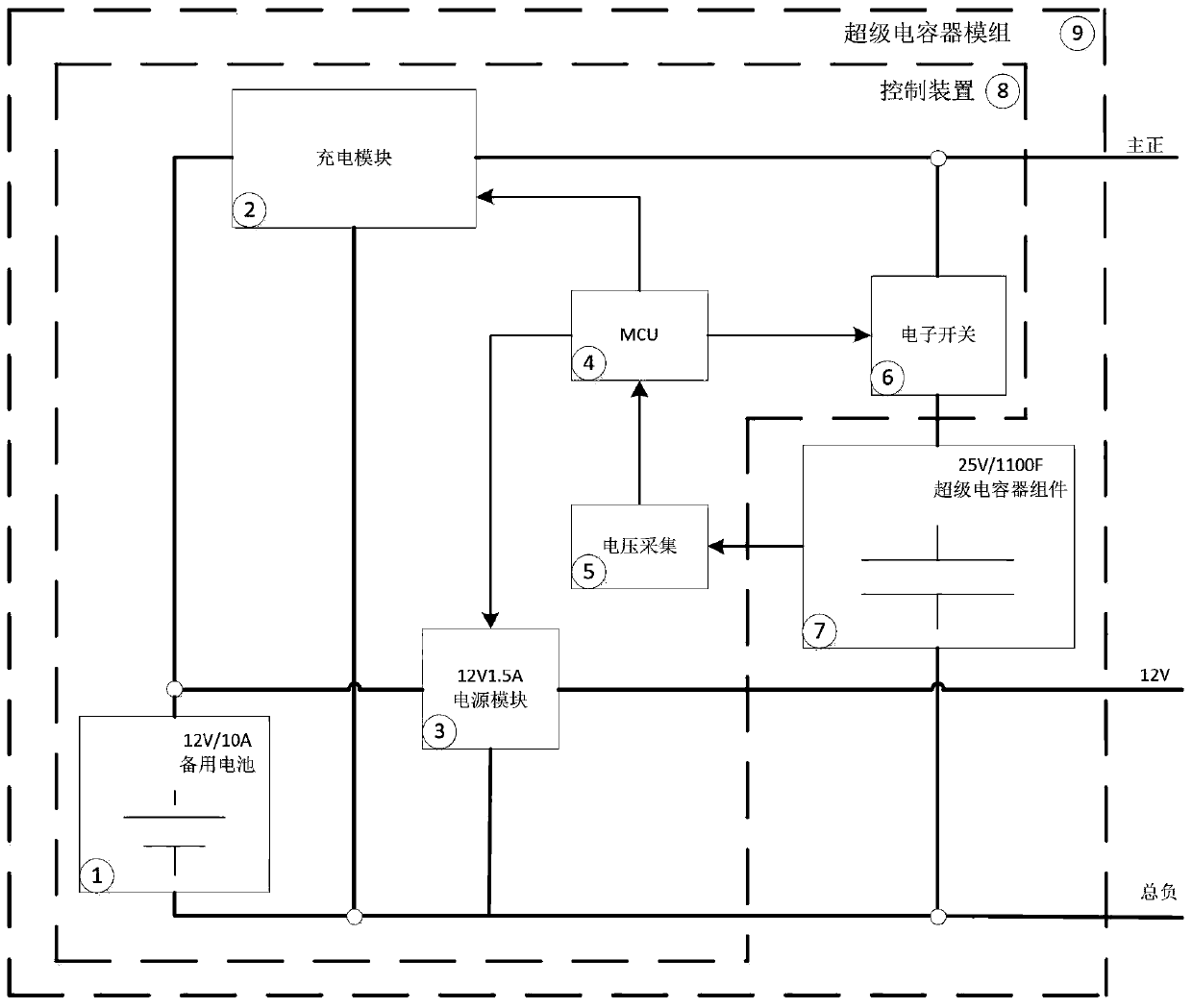

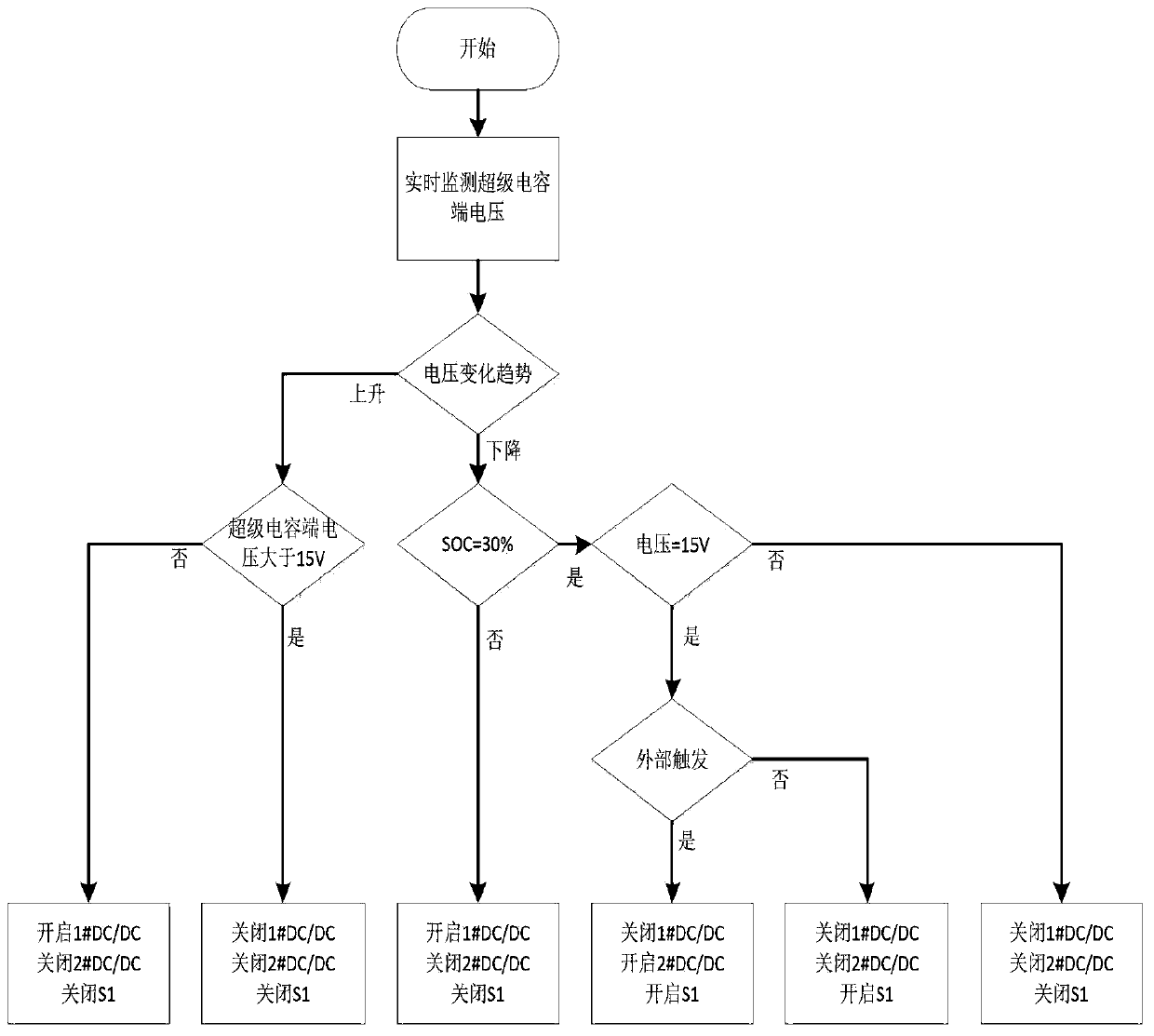

Super-capacitor and battery parallel control system

PendingCN111391676AAvoid failureUninterrupted workElectric devicesPropulsion by capacitorsElectrical batteryElectric capacity

The invention relates to a super capacitor and battery parallel control system, and belongs to the field of electronic components. The system comprises a super capacitor module; the super capacitor module comprises a control device and a super capacitor assembly. The control device comprises a standby battery, an electric charging module, a power supply module, an MCU, a voltage acquisition unit and an electronic switch. The standby battery is electrically connected with the power supply module, the charging module and the super capacitor assembly. The MCU is in signal connection with a voltage acquisition module, the power supply module, the charging module and the electronic switch. The super capacitor assembly is in signal connection with the voltage acquisition and the electronic switch. When the control system on an AGV fails, the AGV stops running; the standby battery is automatically started to provide power for the wireless charging system, so that a problem that the wireless charging control system fails after the super capacitor discharges and is as low as the working range of the main power supply is effectively solved, and thus the whole super capacitor can continuouslywork in the AGV wireless charging control system.

Owner:重庆中科超容科技有限公司

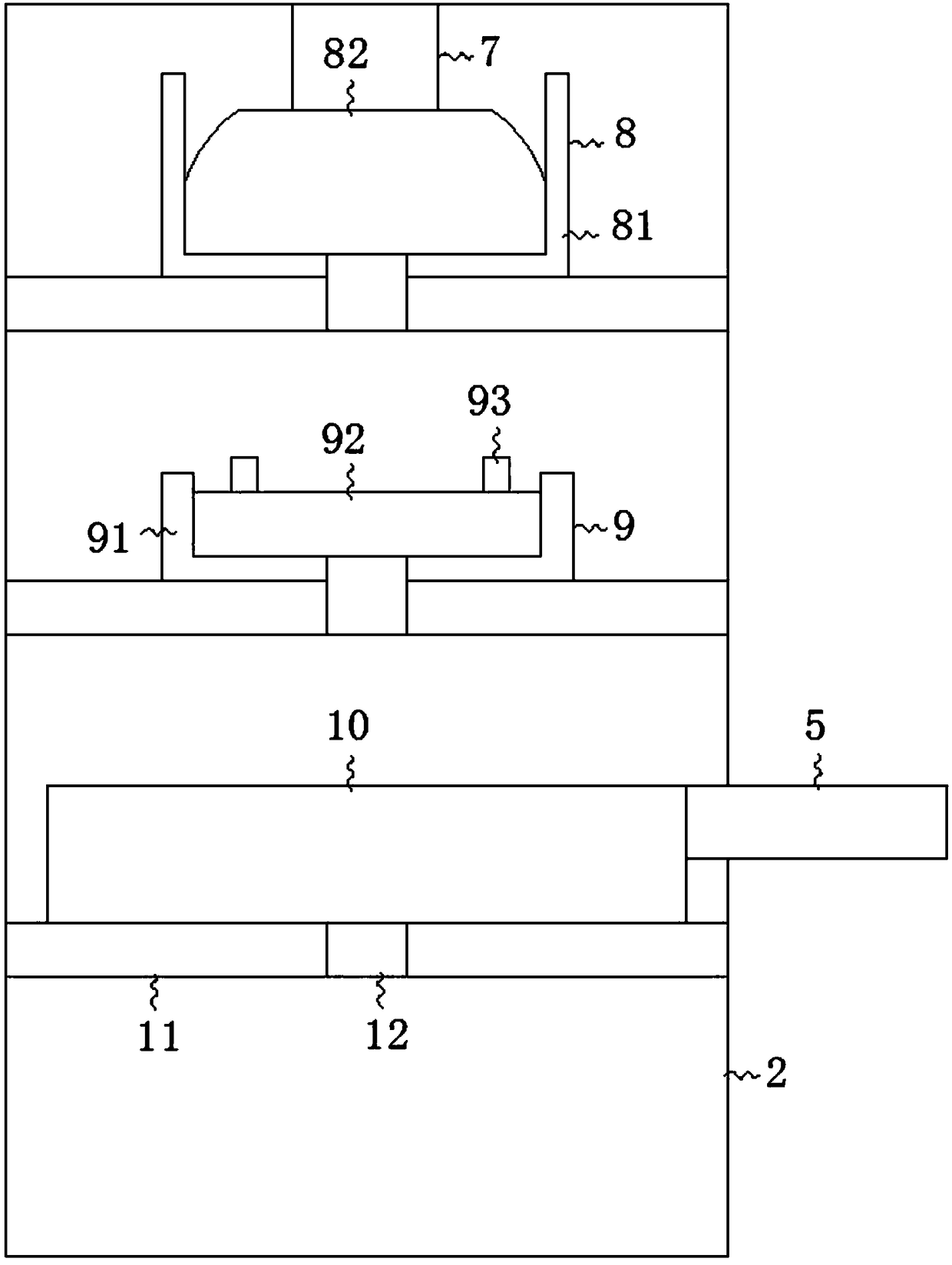

Industrial flue gas desulfurization and denitrification dust remover

InactiveCN111773842AReduce contentImprove dust removal effectGas treatmentDispersed particle filtrationActivated carbonFlue gas

The invention relates to the field of industrial flue gas dust removal, in particular to an industrial flue gas desulfurization and denitrification dust remover. The dust remover includes a table plate, a desulfurization barrel is fixedly mounted at the top end of the table plate; a built-in bracket is fixedly mounted in the desulfurization barrel; a built-in filter cartridge is mounted at the topend of the built-in bracket in a clamping manner; an oxygen inlet pipe is fixedly mounted at the top end of the desulfurization barrel; a water inlet pipe is inserted into the desulfurization barrel;a denitration box is fixedly mounted at the top end of the table plate; a filter screen cover is mounted on the lower surface of a top cover of the denitration box through threads; a filter plate ismounted in the denitration box in a clamping manner; an air pump is fixedly mounted at the top end of the platen; a discharge pipeline is fixedly suspended at the bottom end of the bedplate; a first dust filtering mechanism and a second dust filtering mechanism are movably mounted on the discharge pipeline; the air cylinder is fixedly installed on the lower surface of the table plate, the transmission mechanism is installed at the bottom end of the table plate, the filter screen cover, the activated carbon plate, the first dust filtering mechanism and the second dust filtering mechanism are arranged, dust can be treated in an interception and adsorption combined mode, and the dust removal effect of the dust removal device is greatly improved.

Owner:沈春丰

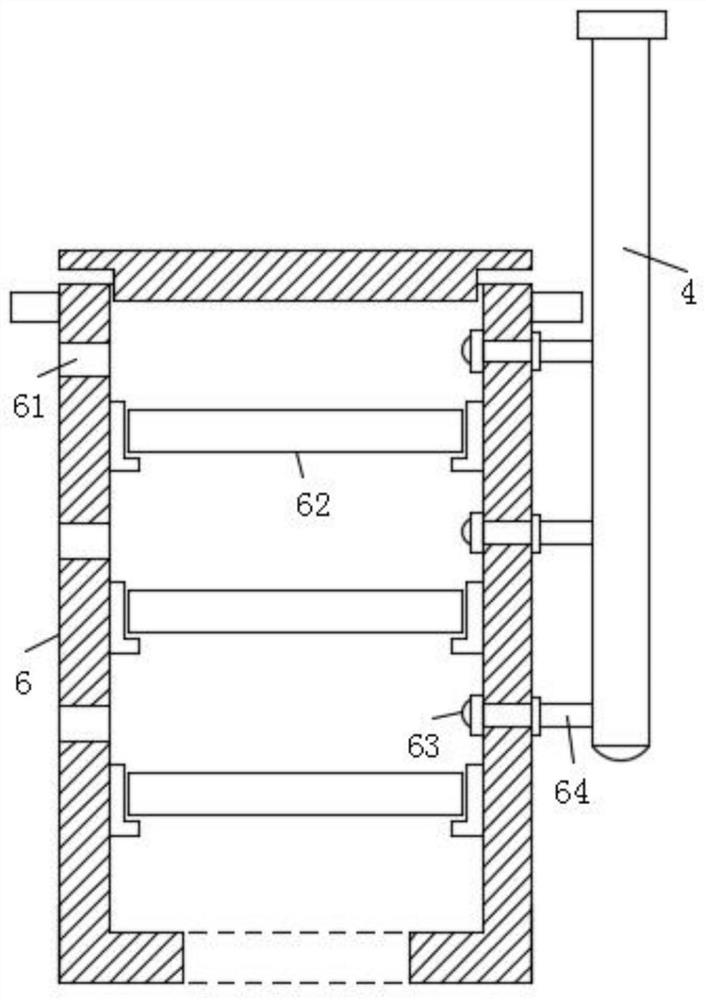

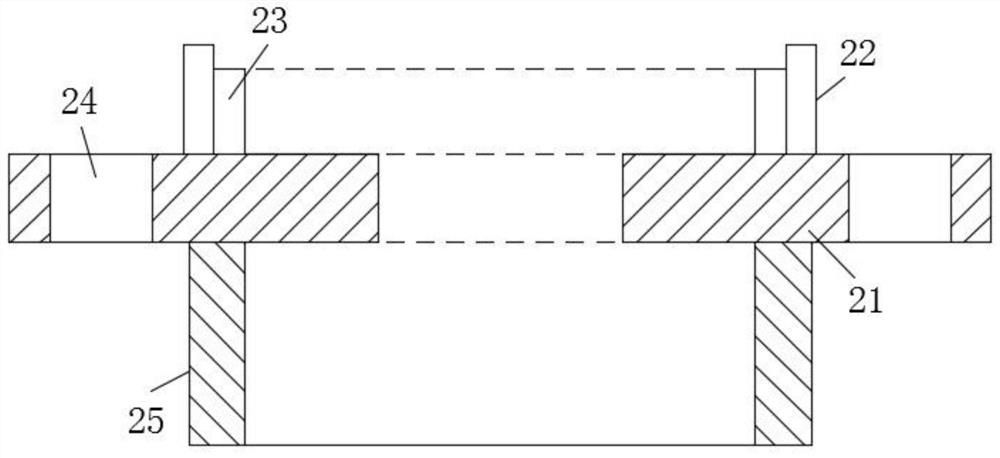

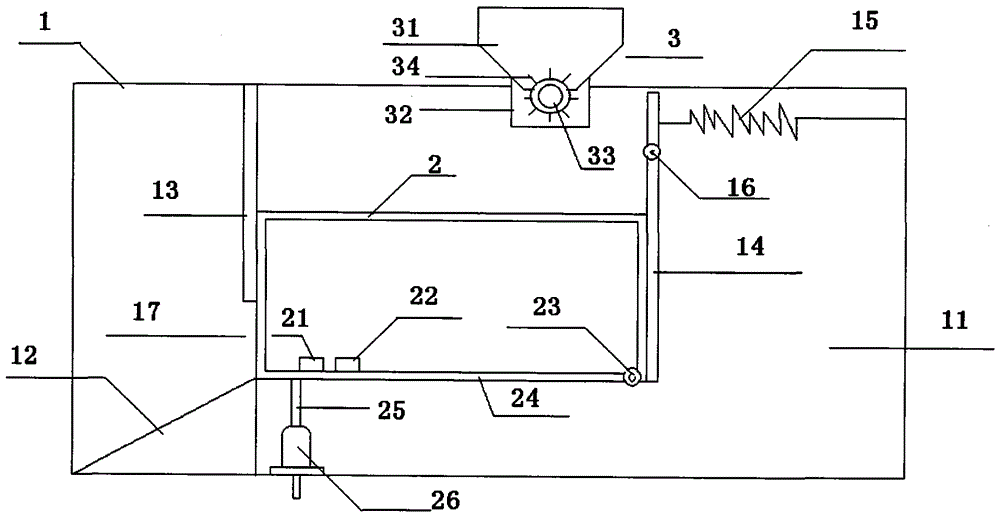

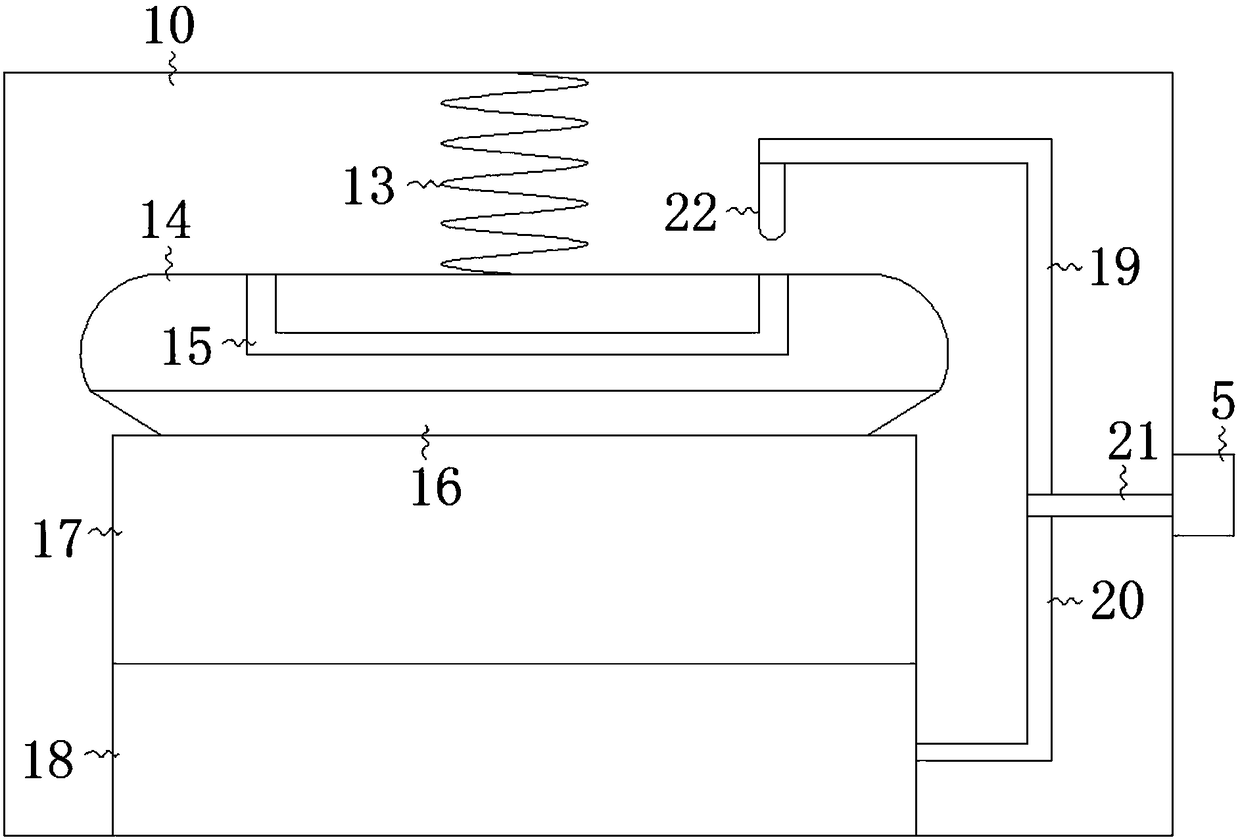

Vacuum oven and circulation water removing system thereof

InactiveCN107917580AGood removal effectOvercome the Difficulty of HeatingDrying using combination processesDrying solid materials without heatNitrogenEnvironmental engineering

The invention proposes a vacuum oven with a circulating dewatering system, and proposes the circulating dewatering system of the vacuum oven. A circulating water removal system is set outside the inner tank of the oven, which is mainly composed of a pipeline, a circulating pump and a water removal unit. Back to the interior of the liner, the technical solution of the present invention does not need to be continuously maintained in a high vacuum state, which overcomes the difficulty of heating in a vacuum state, can effectively and conveniently remove trace moisture from the baking object, and saves a lot of nitrogen. The invention is convenient to implement and has obvious effects.

Owner:柯国平

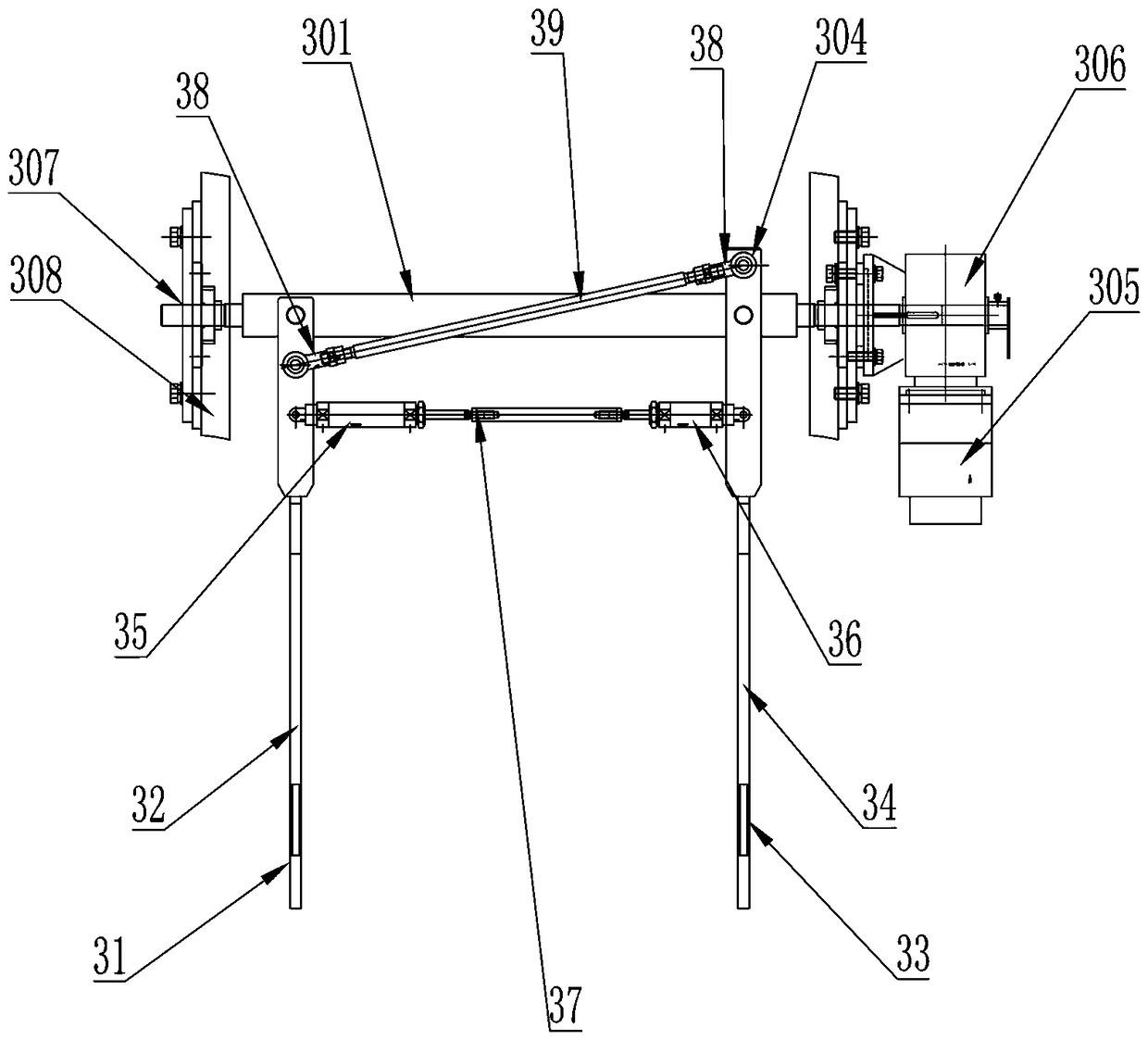

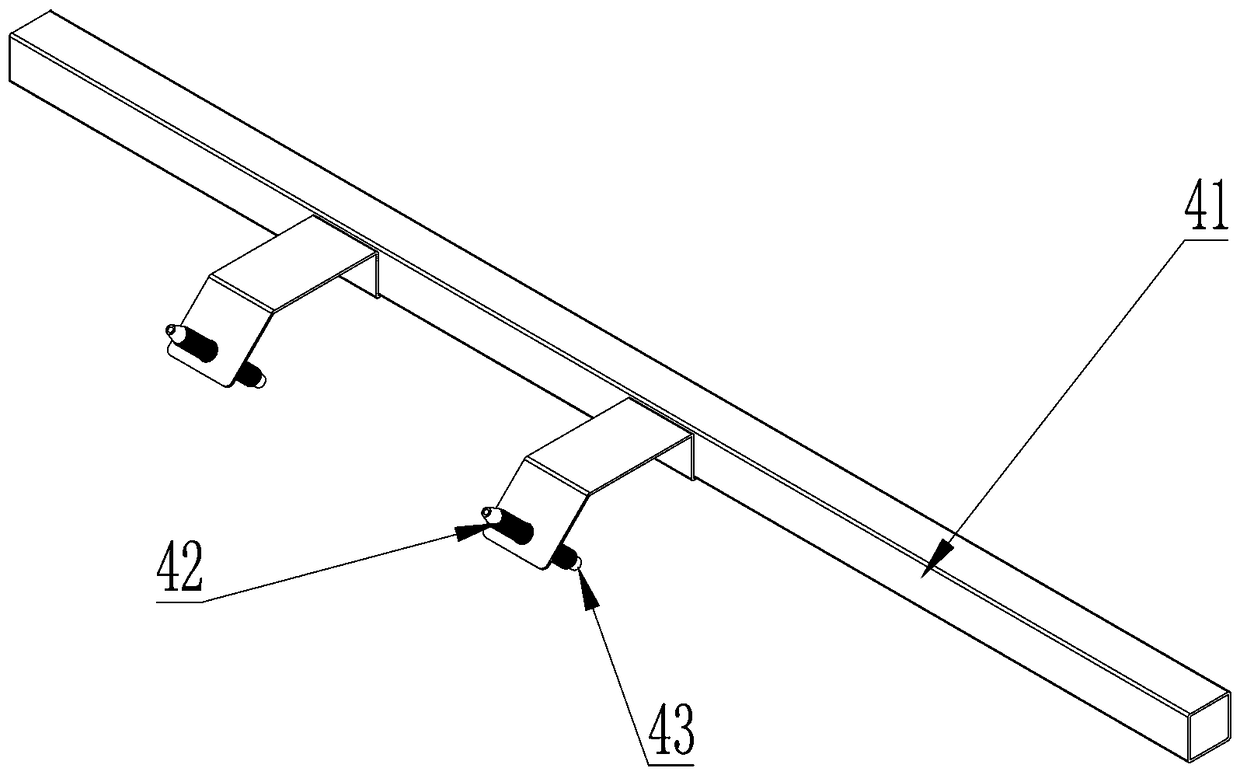

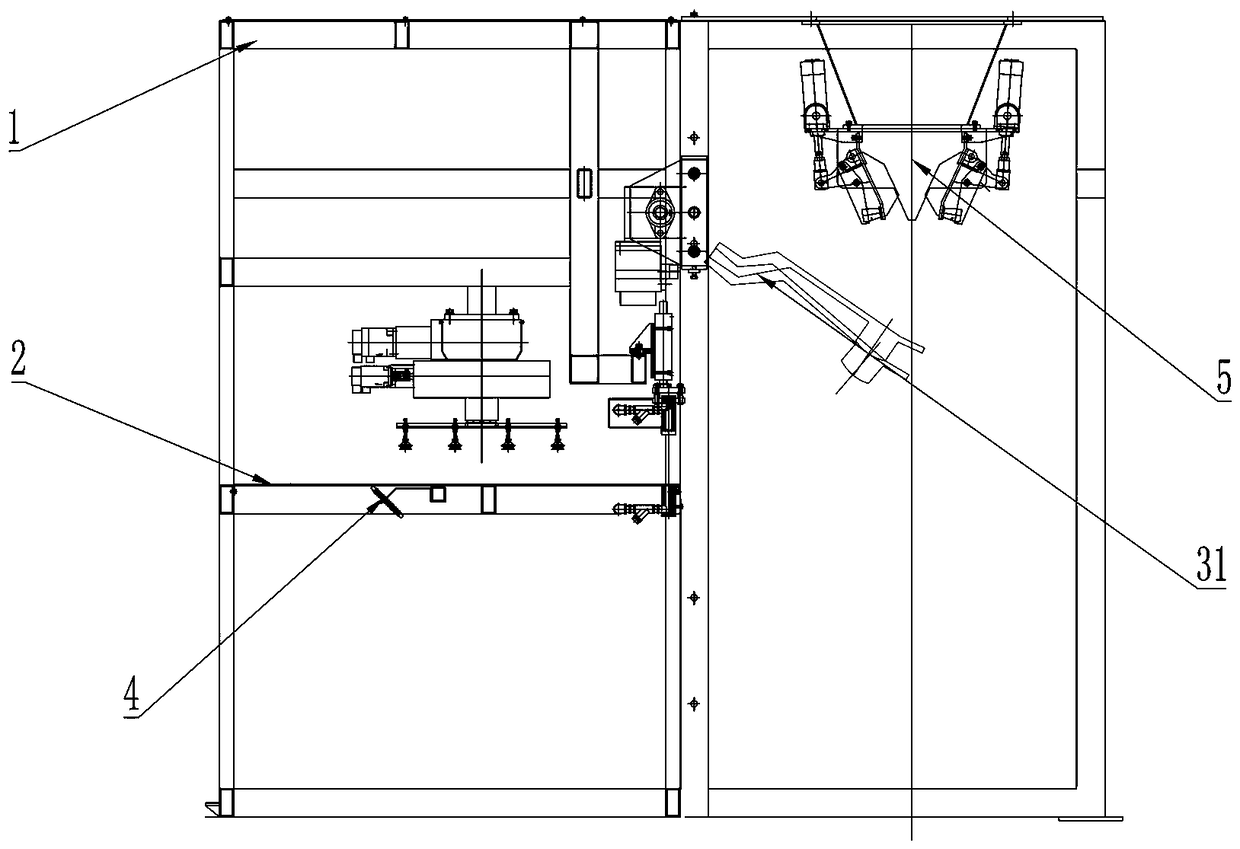

Mouth expanding and bag opening device for woven bags

PendingCN108792045AOpen smoothlyMeet the hanging bag requirementsPackaging automatic controlEngineeringManipulator

The invention relates to the technical field of automatic filling equipment for bulk materials, and specifically relates to a mouth expanding and bag opening device for woven bags. The mouth expandingand bag opening device comprises a bag opening mechanism, a mouth expanding device and a cleaning device for the woven bags, wherein the mouth expanding device is used for sucking-expanding the mouths of the woven bags; the bag opening mechanism is used for opening the sucked-expanded woven bags and loading the woven bags; and the cleaning device for the woven bags eliminates the woven bags whichare not successfully subjected to bag opening to avoid influence on the subsequent procedures. The mouth expanding and bag opening device is capable of realizing automatic mouth expanding for the woven bags, and carrying out bag opening for the woven bags on the woven bags with different specifications, capable of accurately identifying the action of grabbing failure of a manipulator, reasonablein design, reliable in working, high in practicability, and capable of timely removing and cleaning the woven bags with failed bag hanging, so that the mouth expanding and bag loading efficiency for the woven bags is increased.

Owner:ZHENGZHOU JINGU GRAIN MECHANICAL ENG EQUIP

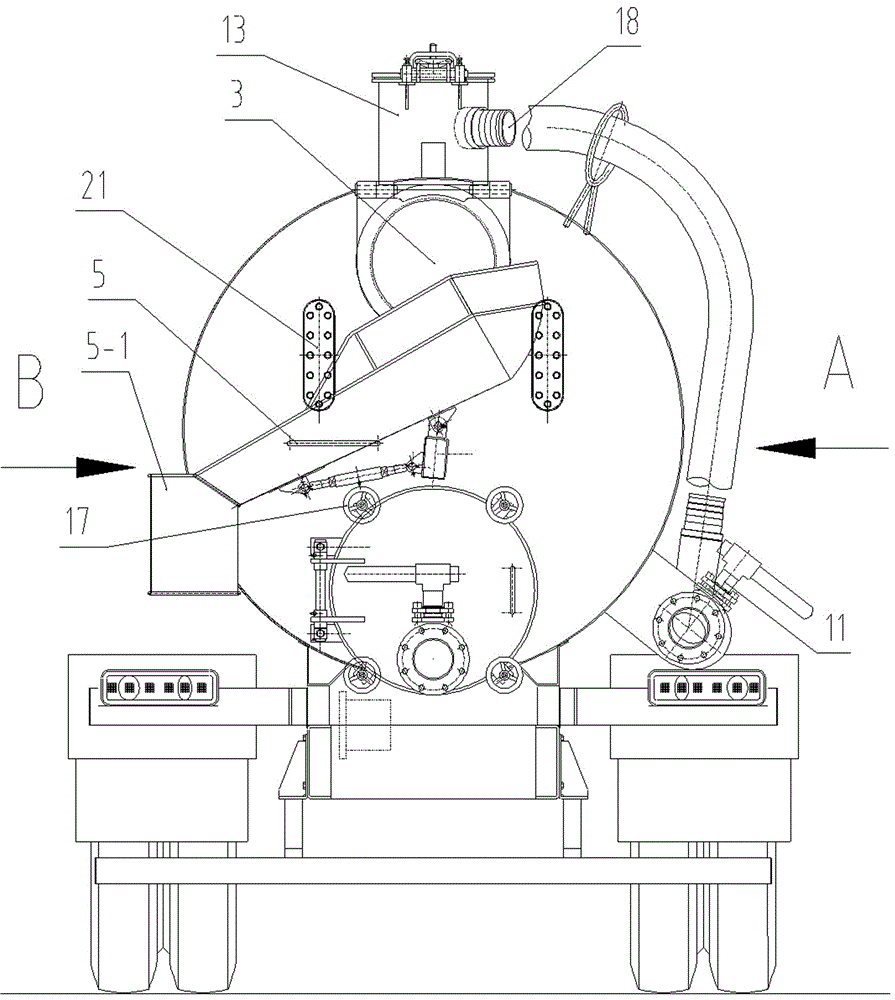

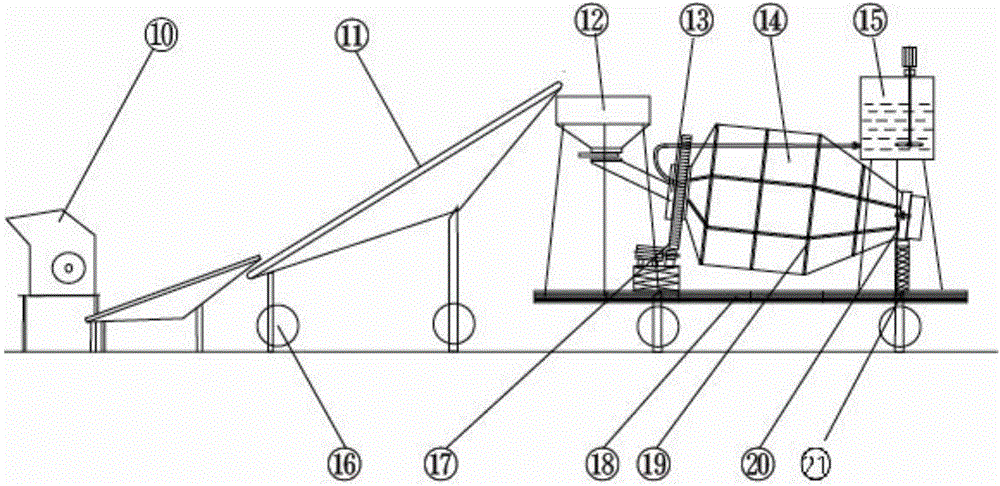

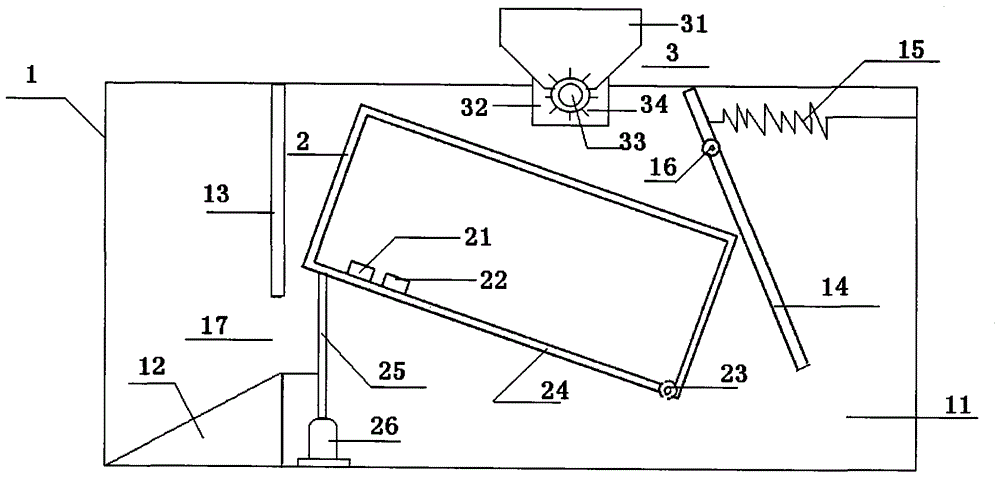

Harmless remediation method and device of electrolytic aluminum waste slag and contaminated soil of electrolytic aluminum waste slag

The invention belongs to the field of environment protection, and relates to a soil remediation technology and device, in particular to a harmless remediation treatment technology and device of electrolytic aluminum waste slag and contaminated soil of the electrolytic aluminum waste slag. According to a harmless treatment method of the electrolytic aluminum waste slag and the contaminated soil of the electrolytic aluminum waste slag, cyanide, soluble fluoride and other harmful substances can be removed simply, economically and efficiently, and green harmless treatment of the electrolytic aluminum waste slag and contamination therefore is achieved. According to the harmless treatment device of the electrolytic aluminum waste slag and the contaminated soil of the electrolytic aluminum waste slag, a rotary stirring tank is used as a stirring system for the first time to carry out harmless treatment of the electrolytic aluminum waste slag and the contaminated soil thereof, the walking speed of materials is adjusted by adjusting the tilt angle of the rotary stirring tank, and therefore the mixing effect is adjusted, the design length of the rotary stirring tank is reduced, the device is simple, and the equipment manufacturing cost is greatly reduced.

Owner:XINZHONGTIAN ENVIRONMENTAL PROTECTION

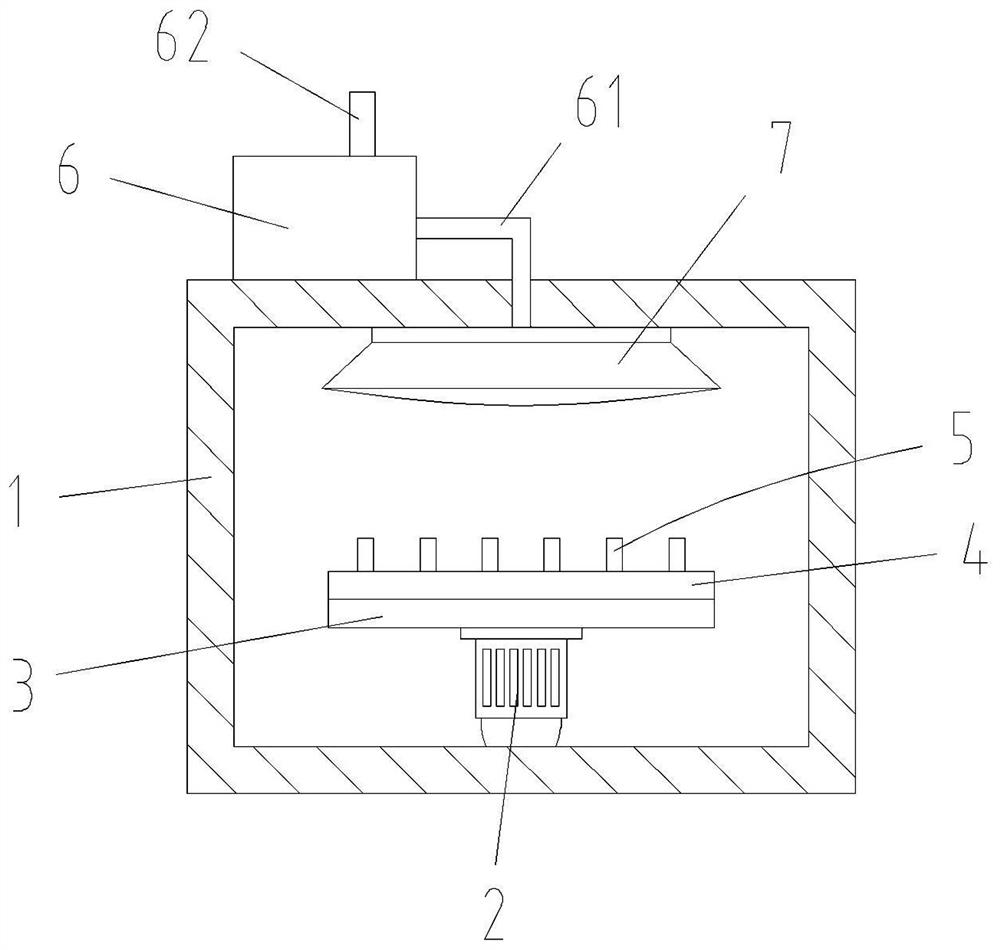

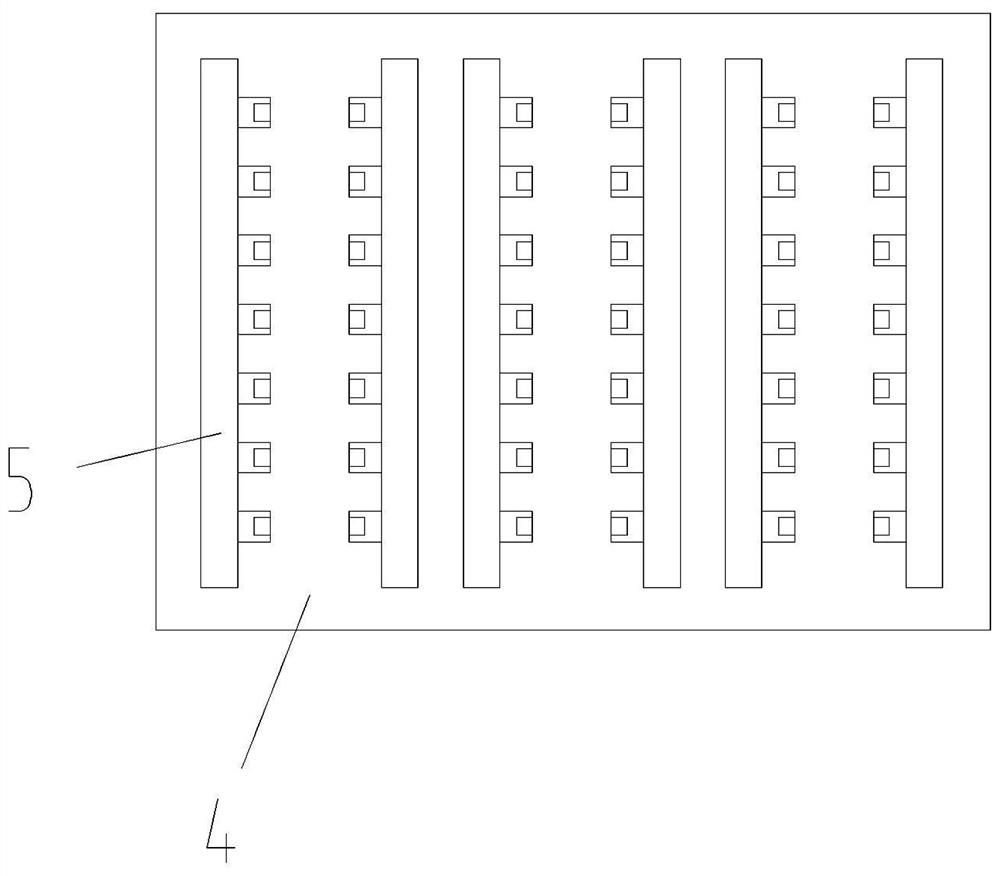

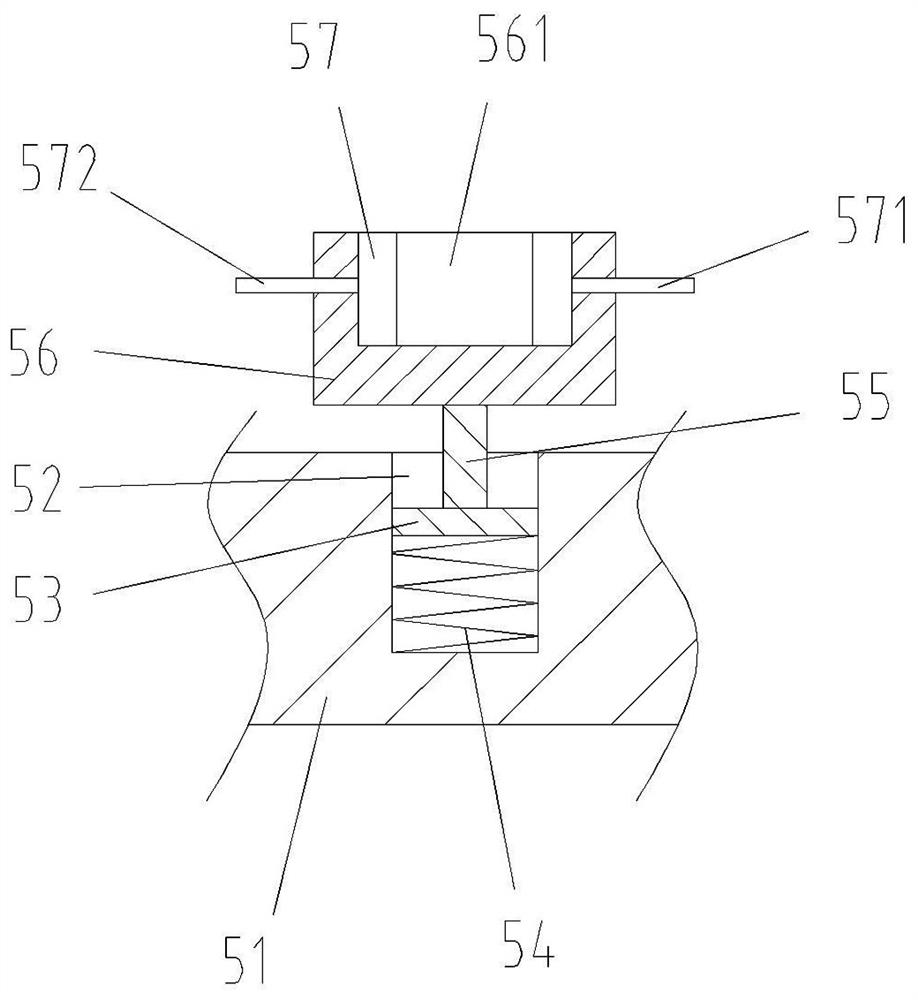

Resistor insulating layer spraying equipment

The invention discloses resistor insulating layer spraying equipment. A box is included. A box door is arranged on one side of the box. A spraying device is arranged on the top of the inner side of the box. The bottom of the inner side of the box is fixedly connected with a motor. A main shaft of the motor is vertically upwards arranged and fixedly connected with a flat plate. The upper side of the flat plate is detachably connected with a base plate. The base plate is provided with a plurality of clamping devices. Each clamping device comprises two vertical plates arranged in parallel, wherein each vertical plate is provided with a plurality of sliding holes, the sliding holes in the two vertical holes are coaxially arranged in a one-to-one correspondence manner, and each sliding hole isinternally in sliding connection with a pin seal device. The resistor insulating layer spraying equipment has the advantages that an air bag is expanded and deforms through inflation, accordingly, pins of a resistor are wrapped, pin spraying is avoided in the spraying process, the detachable connection manner is adopted in the base plate and the flat plate, resistor mounting and resistor dismounting can be conducted outside, and a plurality of base plates and seal devices can be prepared so that the spraying device can constantly work.

Owner:蚌埠市欧利特电子科技有限公司

An electronic mousetrap and its automatic control method

ActiveCN104068010BHigh mouse catching efficiencyReduce electricity costsAnimal trapsAutomatic controlDecoy

Owner:HUNAN XINNANFANG CULTURE SERVICE CO LTD

Pond filter

InactiveCN107232119AWon't leakUninterrupted workPisciculture and aquariaTubular articlesFilter systemSewage

The invention discloses a pond filter, which comprises a water inlet pipe and a water outlet pipe. A first three-way valve is arranged on one side of the water inlet pipe, and the upper part of the first three-way valve is fixedly connected with a first connecting pipe. , and the bottom of the first three-way valve is fixedly connected with the second connecting pipe, one side of the first connecting pipe is connected with the first filter chamber, and one side of the second connecting pipe is connected with the second filter chamber, so Sewage outlets are arranged below the first filter chamber and the second filter chamber. In the present invention, two parallel filter chambers are used to connect between the water inlet pipe and the water outlet pipe through a connecting pipe. When in use, a single filter chamber works, and another filter chamber can be adjusted to use for a period of time or when the filter chamber is blocked, and The clogged filter chamber is cleaned and discharged, so as to ensure the uninterrupted operation of the entire filter system, and at the same time avoid the impact on the filter work of the pond due to clogging.

Owner:CHENGDU YANXINGGUO TECH CO LTD

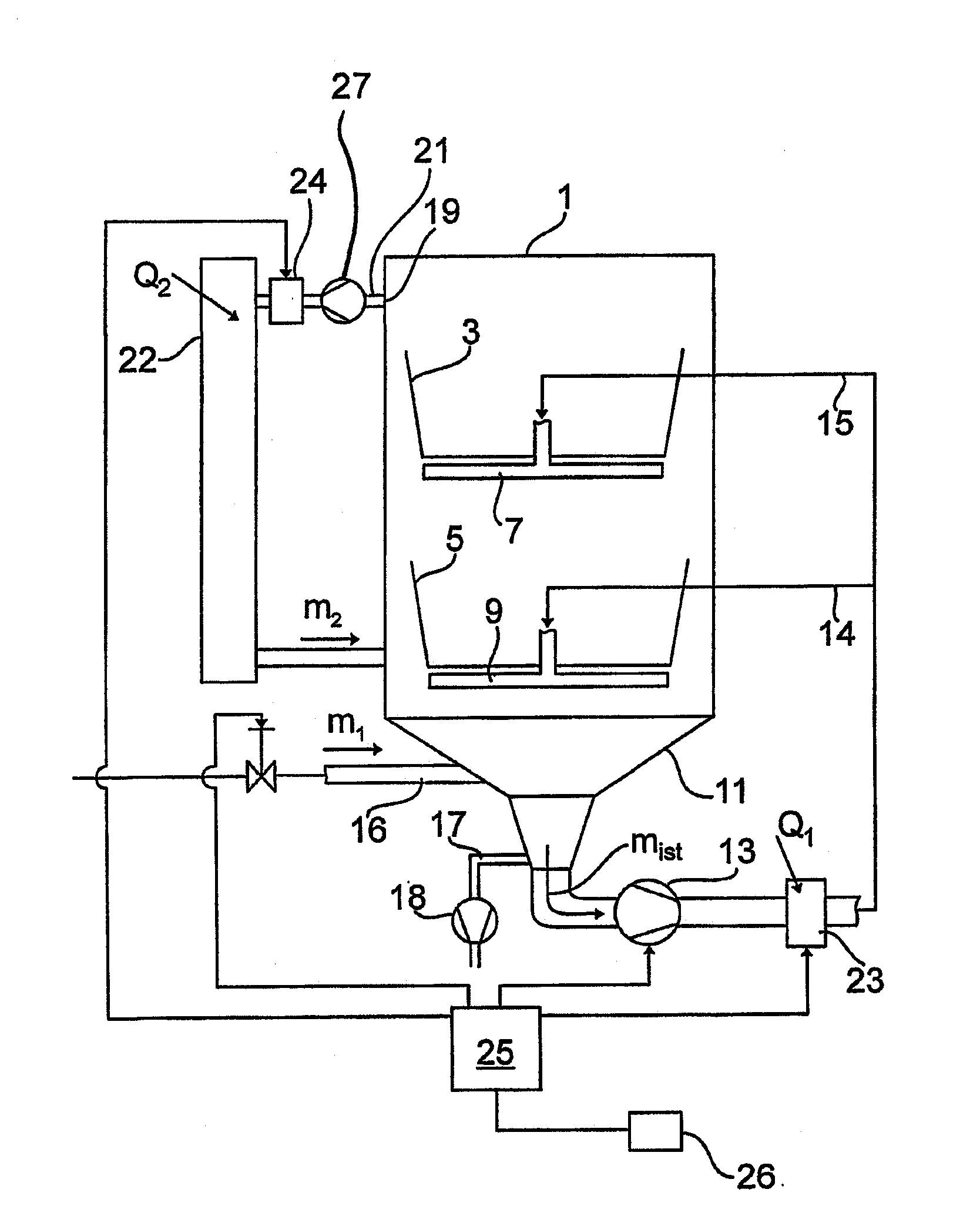

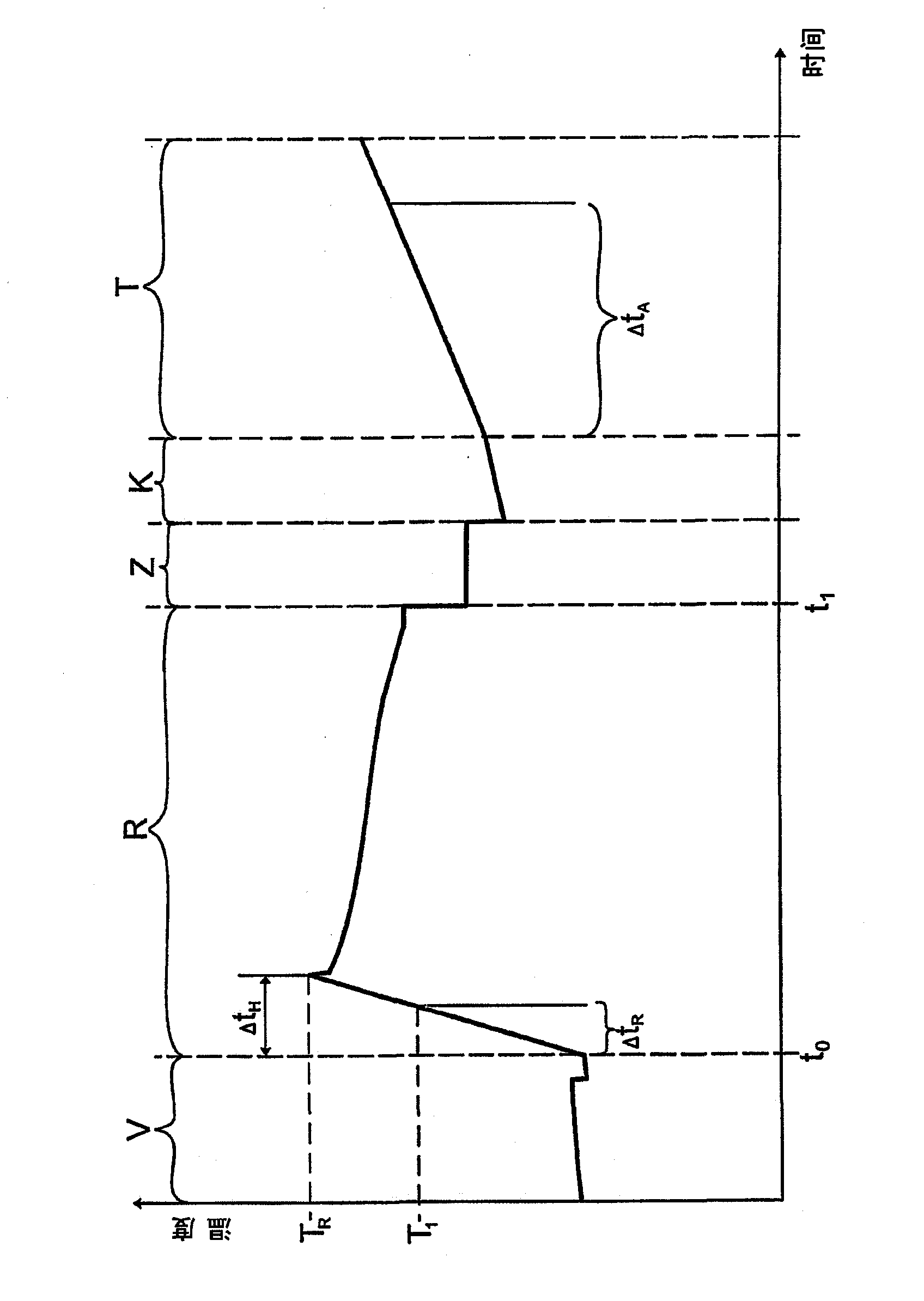

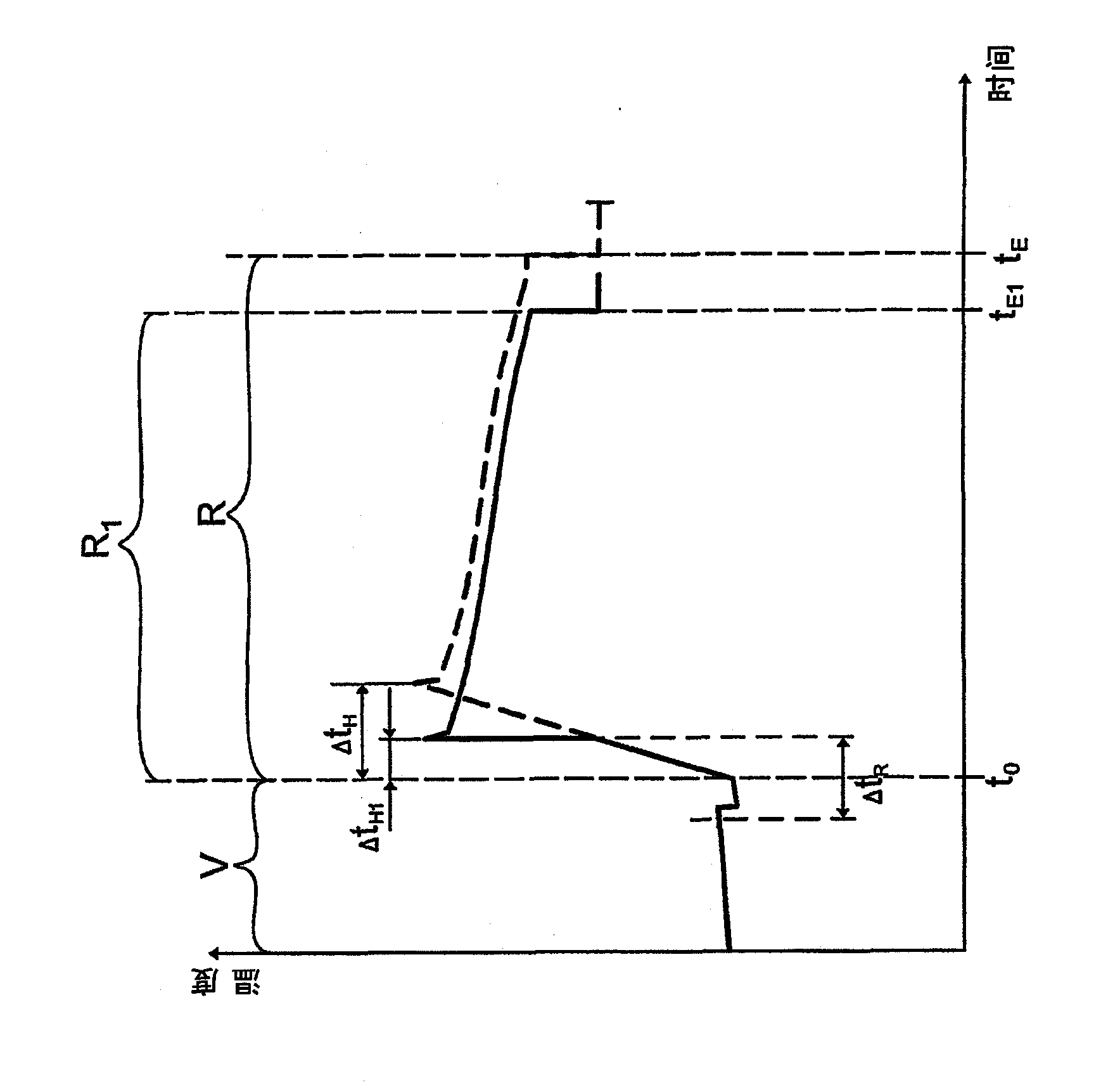

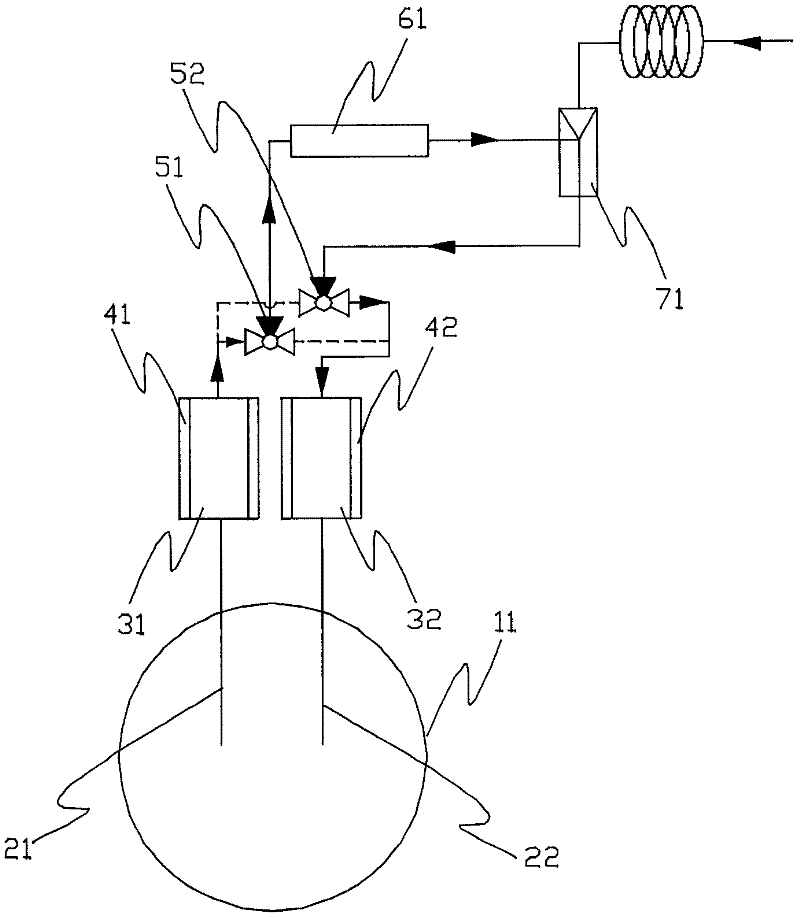

Method for operating a water-carrying household appliance

ActiveCN102112032AReduce power consumptionUninterrupted workTableware washing/rinsing machine detailsTextiles and paperHome useThermodynamics

Owner:BOSCH SIEMENS HAUSGERATE GMBH

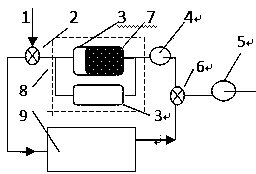

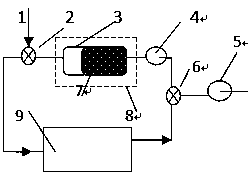

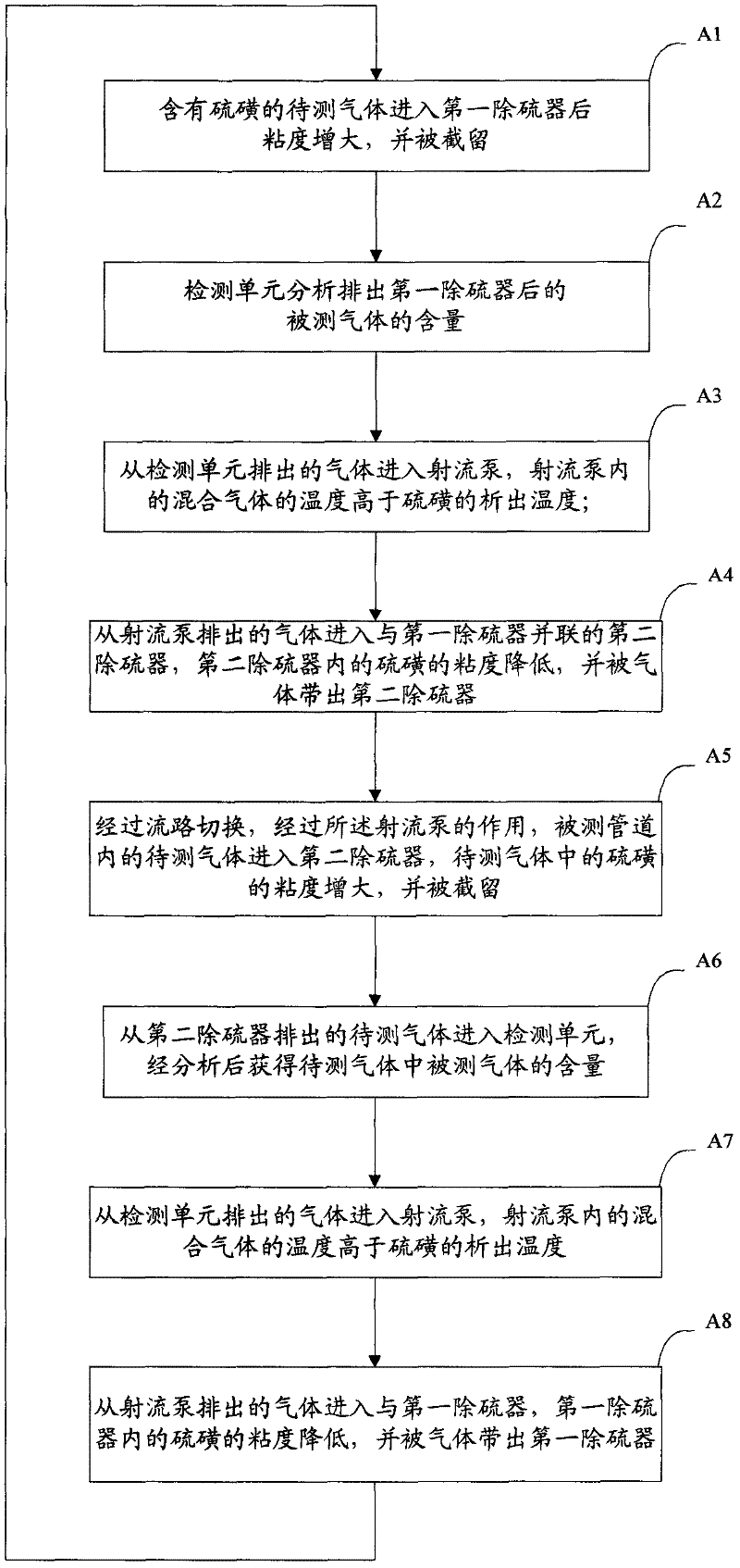

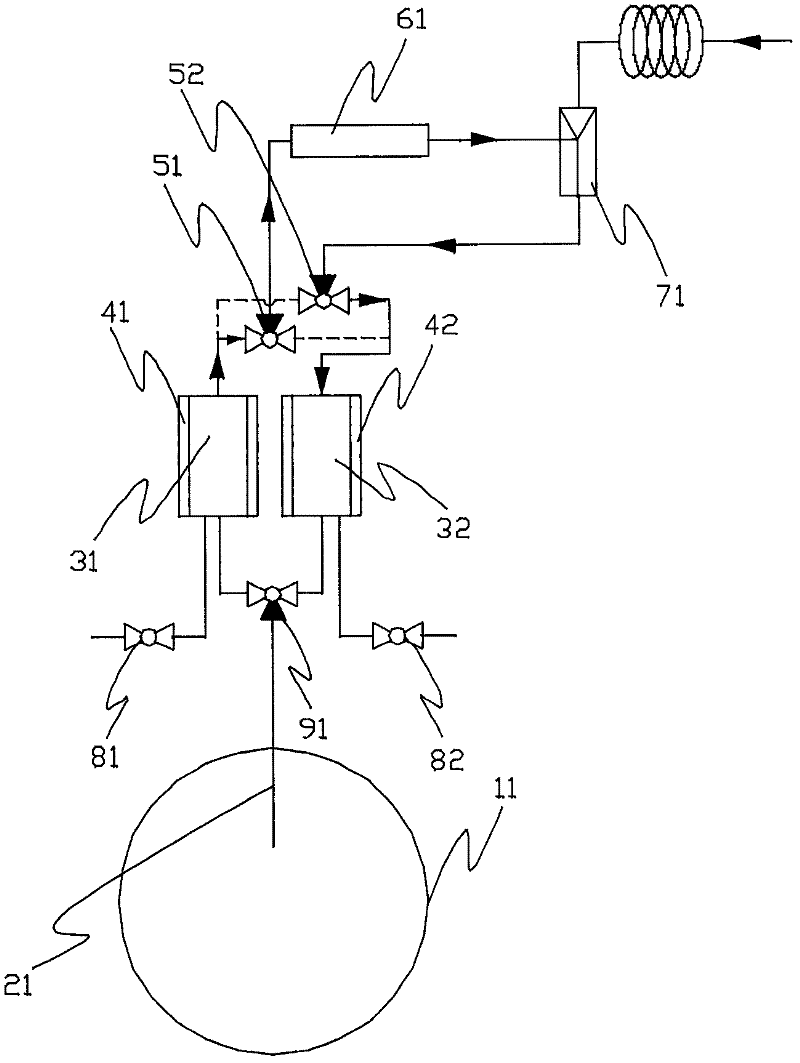

Sulphur ratio on-line monitor and monitoring method

ActiveCN102410945AUninterrupted workNo manual maintenanceWithdrawing sample devicesPreparing sample for investigationTemperature controlEngineering

The invention provide a sulphur ratio instrument which comprises a sampling pipe used for conveying gas to be measured in a measured pipeline to a first desulphurization device and a second desulphurization device which are in parallel connection, a temperature control module used for selectively lowering down temperature in the first desulphurization device and the second desulphurization deviceso as to enable sulphur in the gas to be measured to be precipitated, a flow path switching module used for selectively allowing a detection unit and an injection pump to respectively communicate with the first desulphurization device and the second desulphurization device, wherein, the detection unit is arranged at the lower reaches of the first desulphurization device and the second desulphurization device, an injection inlet of the injection pump communicates with the detection unit, and an injection outlet of the injection pump is connected with the flow path switching module, and a heating module used for enabling temperature of gas in pipelines of the upper reaches and the lower reaches of the first desulphurization device and the second desulphurization device and mixed gas in the injection pump to be higher than precipitation temperature of sulphur. The invention has the advantages of high desulphurization efficiency, low cost, etc.

Owner:FOCUSED PHOTONICS

Purification system and purification method for volatile pollutants

InactiveCN112404117AReduce usageSave heatContaminated soil reclamationOptical radiationPurification methods

The present invention discloses a purification system and purification method for volatile pollutants. The purification system for the volatile pollutants comprises a skeleton surrounding to form a purification space, a convex lens group arranged on the framework, a heat distribution plate which is located in the purification space and located at the focal point of the convex lens group, a conveying device located below the heat distribution plate and is opposite to the heat distribution plate, and a negative pressure purification device used for extracting volatile pollutants volatilized by heated pollutants and introducing external air into the purification space; light penetrating through the convex lens group irradiates the heat distribution plate, wherein the heat distribution plate is used for heating pollutants on the conveying device in a heat radiation mode, so that volatile pollutants in the pollutants are heated to leave. Light radiation can be directly converted into heat energy or light radiation is firstly converted into electric energy and then converted into heat energy, so that volatile pollutants in soil are removed, and the process is simple and efficient.

Owner:SHANGHAI PUDONG ROAD & BRIDGE GRP CO LTD

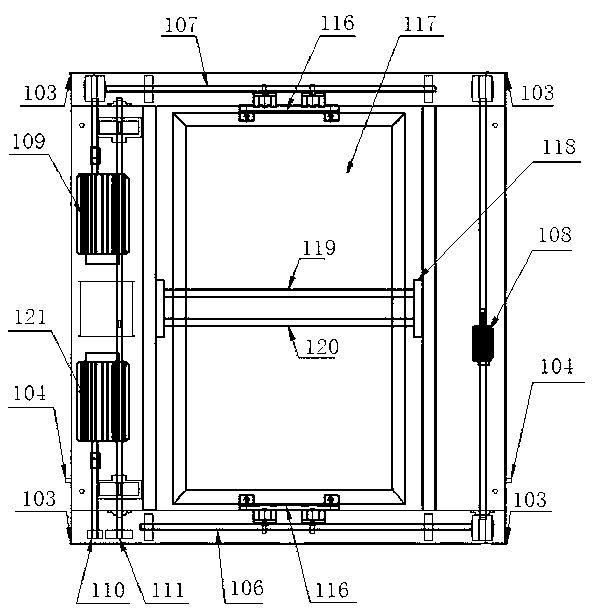

Ultrasonic welding machine and its ultrasonic welding control method

ActiveCN106271022BUninterrupted workImprove welding efficiencyNon-electric welding apparatusUltrasonic weldingEngineering

The invention discloses an ultrasonic welding machine and an ultrasonic welding control method thereof. The ultrasonic welding machine comprises a machine frame, a main controller, an ultrasonic welding mechanism, a first workpiece pressing and fixing mechanism, a first CCD image pickup mechanism, a second workpiece pressing and fixing mechanism and a second CCD image pickup mechanism. The ultrasonic welding mechanism comprises a transverse translation mechanism, a vertical lifting mechanism and an ultrasonic welding head. The first workpiece pressing and fixing mechanism comprises a first longitudinal translation mechanism and a first rotary platform. The second workpiece pressing and fixing mechanism comprises a second longitudinal translation mechanism and a second rotary platform. The ultrasonic welding machine has the beneficial effects that the ultrasonic welding mechanism can weld a workpiece on the first rotary platform and a workpiece on the second rotary platform in sequence, welding is circulated and repeated, and the ultrasonic welding machine works intermittently, so that the welding efficiency can be greatly improved. By means of the ultrasonic welding control method provided by the invention, welded positions are accurate and free of deviation, thus, defective welded products can be greatly decreased, and the welding quality also can be greatly improved.

Owner:SHENZHEN TECHSON AUTOMATION SYST

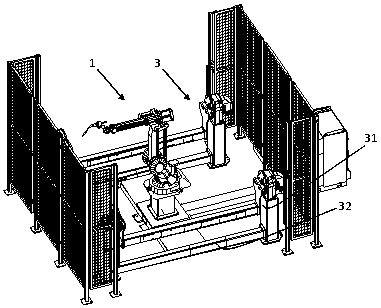

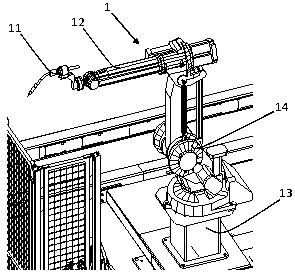

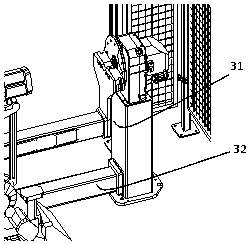

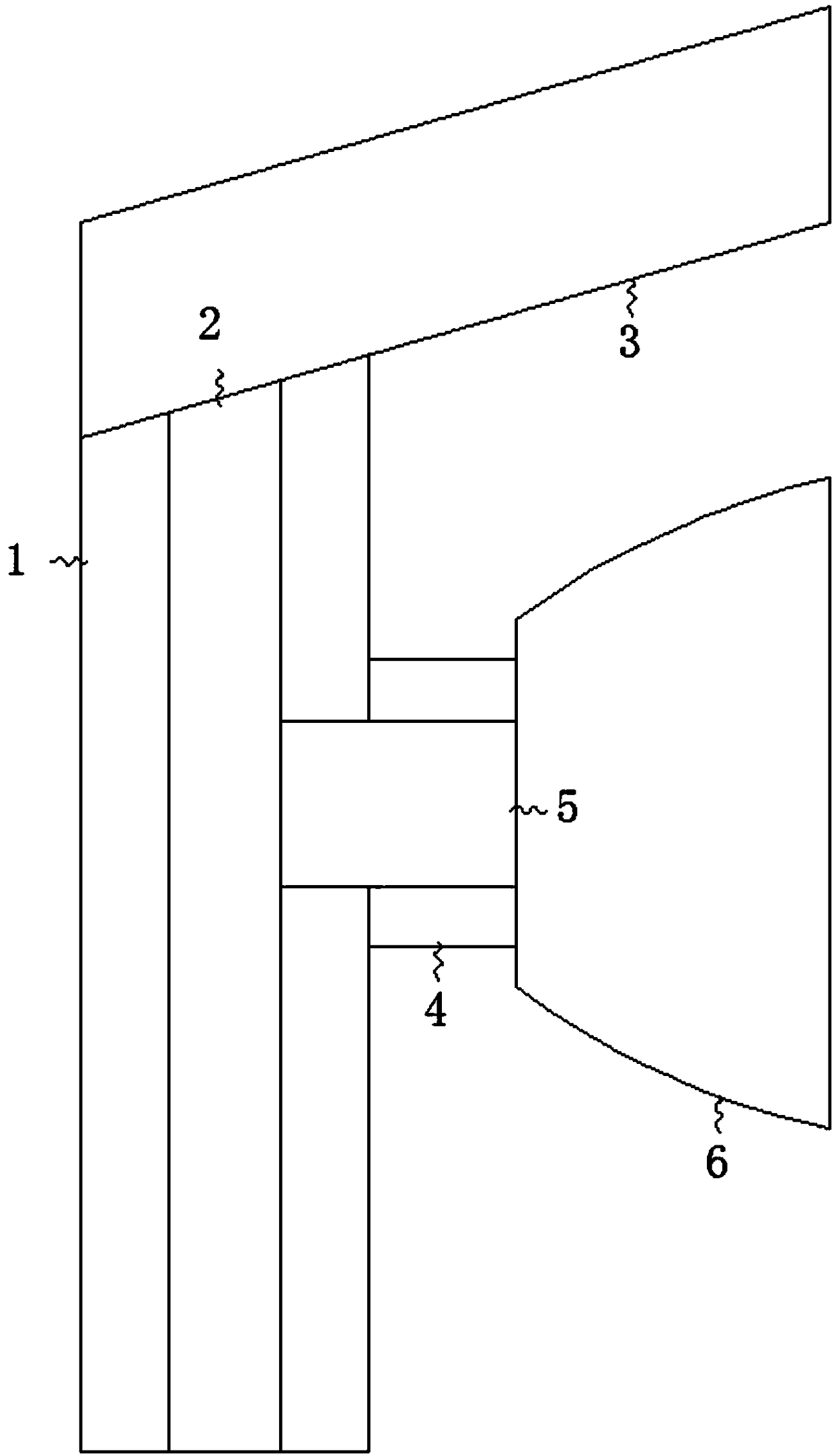

Automatic welding system for framework of automobile dash board

InactiveCN107790932ASolve efficiency problemsSolve the high scrap rateProgramme-controlled manipulatorWelding/cutting auxillary devicesDashboardWelding power supply

The invention relates to the field of electrowelding or automation and provides an automatic welding system for a framework of an automobile dash board. The automatic welding system comprises a welding robot and clamp work stations. The welding robot comprises a welding gun head, a connecting arm and a base. The welding head is arranged on the base by the connecting arm. Each clamp work station comprises a clamp end, a clamp frame and a clamp base. The clamp ends are arranged on the clamp bases by the clamp frames. The welding robot and the clamp work stations are arranged correspondingly andmatched with an externally connected welding power source for welding operation. The automatic welding system is provided with the welding robot and the clamp work stations and is operated by the cooperation of both, such that the problems of low efficiency, high rejection rate and incomplete welding in manual welding are solved.

Owner:上海岩灵自动化工程有限公司

Anti-power-off monitoring device

PendingCN108461978AFix not workingUninterrupted workEngagement/disengagement of coupling partsEngineeringRubber ring

The invention discloses an anti-power-off monitoring device, comprising a bottom plate, wherein a battery is installed in the middle of the upper end of the bottom plate, electrode columns are connected to the left and right sides of the upper end of the battery, a movable plate that is installed at the left end of the battery includes a plate, a blind hole and a heat dissipation hole, a screw isfixedly connected to the left end of the movable plate, a stopper is connected to the left end of the screw, an adjustment plate is mounted on the left side of the movable plate, first circular holesare respectively opened on the upper, middle and lower ends of the adjustment plate, and a rubber ring is mounted on the right end of the adjusting plate. Due to the structure provided with a first spring, a second spring, a buffer plate and an elastic rubber rod, the anti-power-off monitoring device is capable of reducing the impact of external force on the battery, and avoiding the phenomenon that the battery is damaged after the external force hits the battery, which leads to the spontaneous combustion of the battery.

Owner:福州艾弗斯智能科技有限公司

Automatic vertical centrifugal dewatering machine

InactiveCN109612233AUninterrupted workImprove work efficiencyDrying machines with non-progressive movementsDrying solid materialsPulp and paper industryConveyor belt

The invention relates to the field of powder material dewatering equipment, in particular to an automatic vertical centrifugal dewatering machine. Continuous dewatering work of the vertical centrifugal dewatering machine can be achieved. The automatic vertical centrifugal dewatering machine comprises a dewatering cylinder, a shell, a top cover, a rotating shaft and a scraping plate; the dewateringcylinder and shell are arranged below the top cover, the dewatering cylinder is arranged in the shell and fixedly connected with the rotating shaft, the rotating shaft is rotatably connected with thecenter of the top cover, the scraping plate is arranged in the dewatering cylinder, and a control shaft is arranged at the top of the scraping plate, rotatably connected with the top cover, and connected with a driving device; the upper part and the lower part of the dewatering cylinder are open, the bottom of the shell is inwards bent to form a water receiving tank, a water draining opening is formed in the bottom of the water receiving tank, and a conveyor belt is arranged at the bottom of the dewatering cylinder; when the scraping plate rotates by different angles, the distances between the scraping plate and the inner wall of the dewatering cylinder are different, the dewatering cylinder has taper, and the top diameter of the dewatering cylinder is larger than the bottom diameter of the dewatering cylinder; a connecting shaft part is arranged at the top of the rotating shaft; and the shell and the top cover are detachably connected through a connecting device.

Owner:李文博

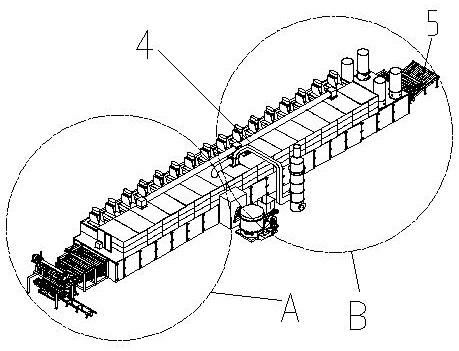

Automatic veneer drying device

PendingCN112082359APrecise deliveryReduce harmDrying solid materials without heatDrying gas arrangementsEngineeringMechanical engineering

The invention discloses an automatic veneer drying device. The automatic veneer drying device comprises a feeding unit, a loading unit, a transition guide frame, a drying unit and a discharging unit,wherein the drying unit comprises a hot smoke system, a heat exchange system, a drying box and multiple heat extraction fans; the gap between the left end and the right end of the drying box is largerthan the gap between the front end and the back end of the drying box; the hot smoke system comprises a combustion furnace, a hot smoke pipe and a chimney; the transition guide frame comprises a transition guide frame body; frame plates as many as feed ends of horizontal drying layers of the drying unit are arranged on the transition guide frame body; the loading unit comprises a loading unit frame body, a guide plate frame arranged on the loading unit frame body, a suction module and a suction lifting adjusting module; the feeding unit is arranged below the suction module; and the discharging unit is connected with a veneer outlet of the drying unit. The drying device can absorb soft, light and thin veneers, quickly and accurately feeds the veneers into each horizontal drying layer of the drying unit for drying and automatic collection, and has the characteristics of high drying efficiency and continuous operation.

Owner:山东利森智能装备有限公司

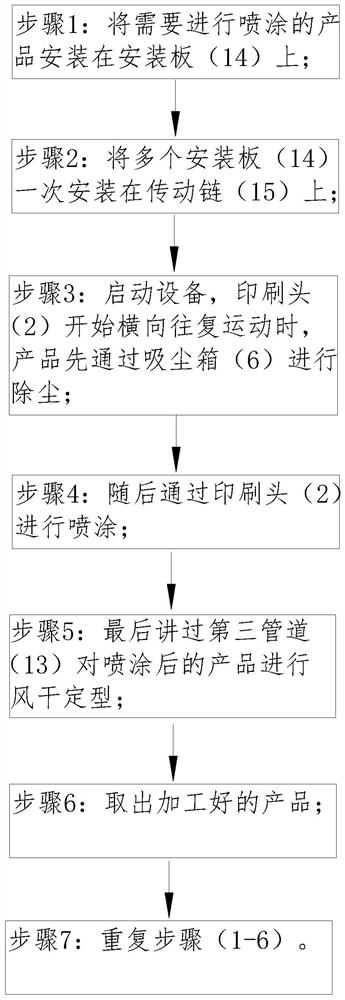

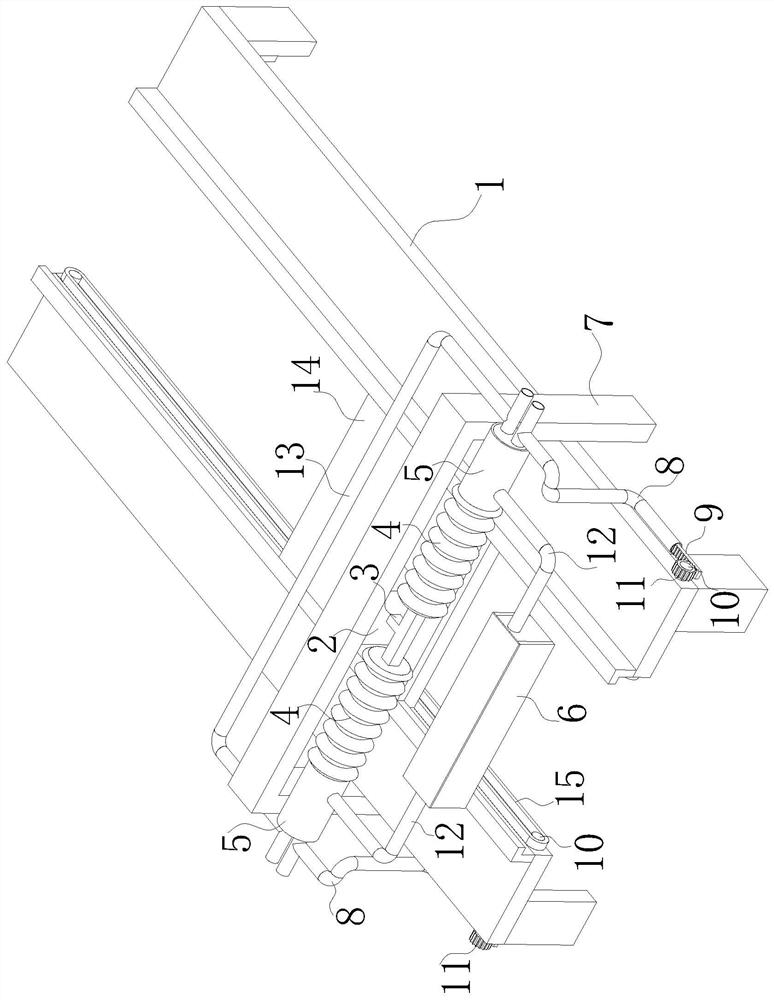

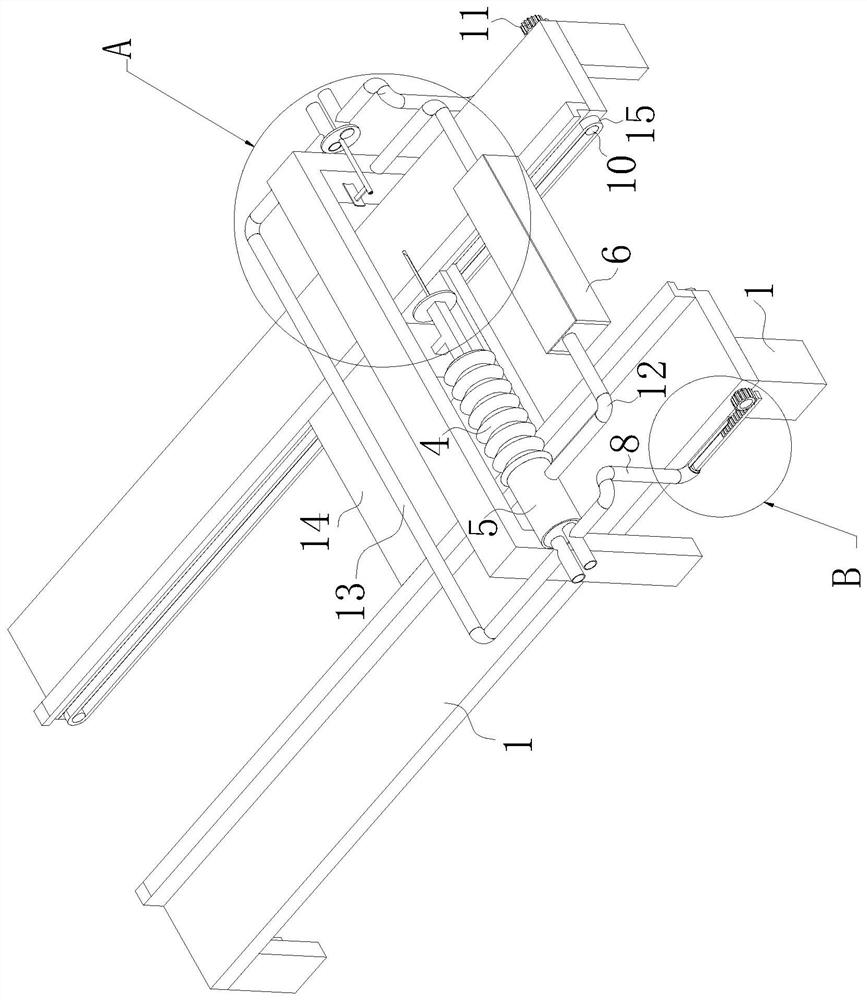

Digital direct injection printing equipment and printing process thereof

ActiveCN113635676AUninterrupted workStable and accurate workTypewritersOther printing apparatusTextile printerReciprocating motion

The invention discloses digital direct injection printing equipment and a printing process thereof, and belongs to the field of printing and spraying. Air bags symmetrically arranged on the two sides are driven to work through reciprocating motion of printing cloth of a printing head, the air bags on the two sides are alternately stretched and compressed, so that uninterrupted work of a dust suction box and air injection of a third pipeline is achieved, and the production efficiency is guaranteed; the communication states of all pipelines are switched through a torsion shaft to control movement of a rack, and therefore it is guaranteed that after the printing head conducts printing on cloth every time, the cloth can be driven by a mounting plate to be fed forwards by one unit in time, and it is guaranteed that the printing head can work accurately and stably; and the problem that in the prior art, when small and medium-sized enterprises spray cloth, efficient work is difficult on the premise that the quality is guaranteed is solved.

Owner:ZHEJIANG SCI TECH UNIV SHAOXING KEQIAO RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com