Maritime bottom-sitting type natural gas treatment device

A technology for processing equipment and natural gas, which is applied in the field of LNG production, and can solve problems such as shutdown of floating equipment, high requirements for mooring systems, and inability to ensure that the equipment does not move, achieving the effect of ensuring continuity, safety, and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

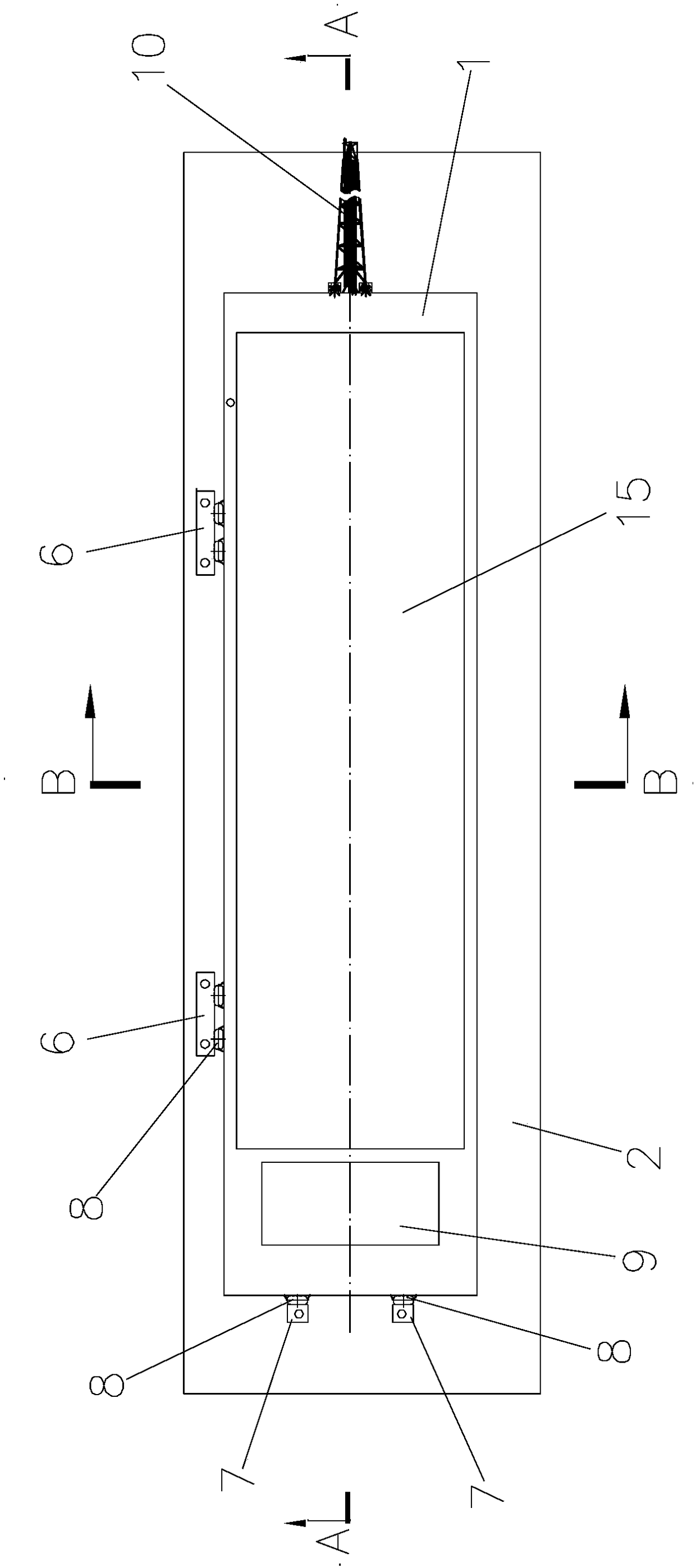

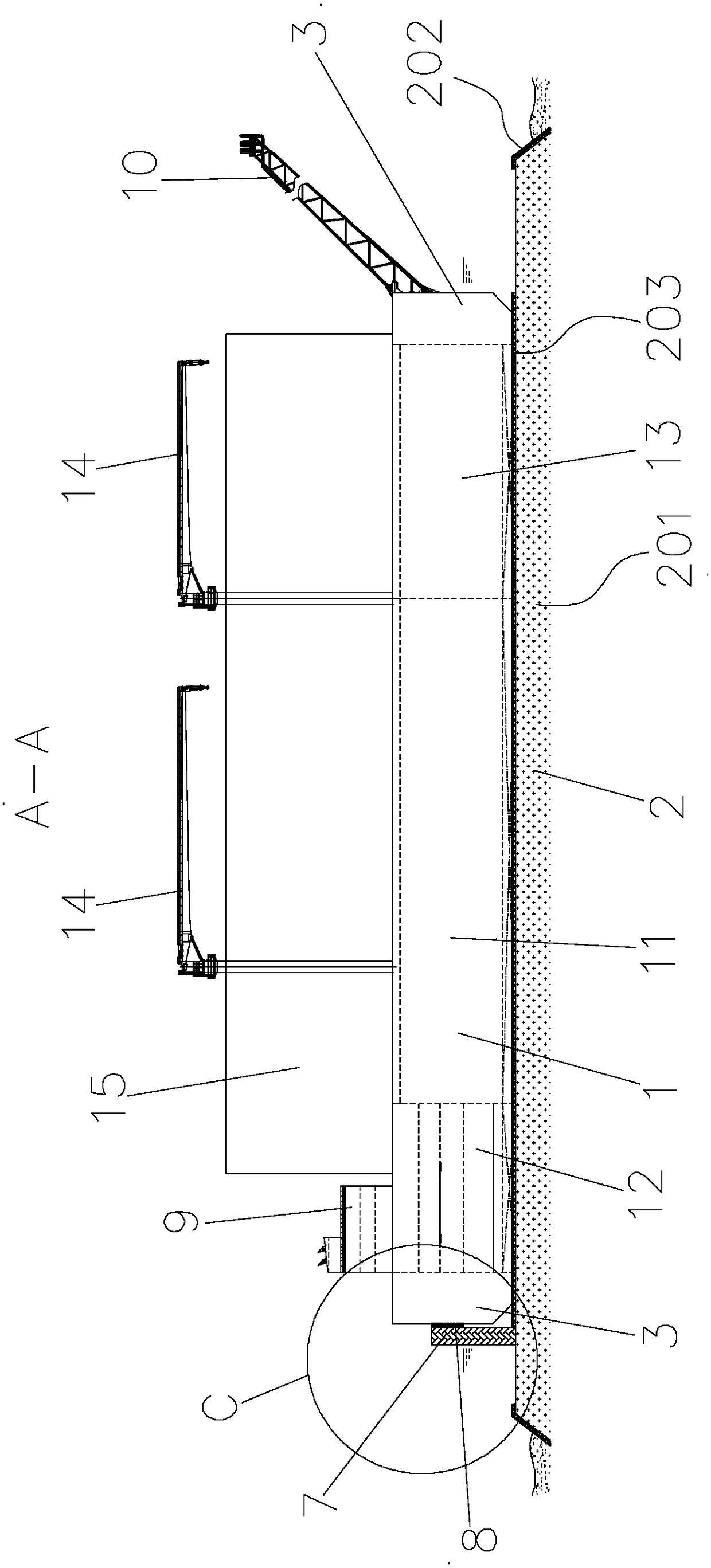

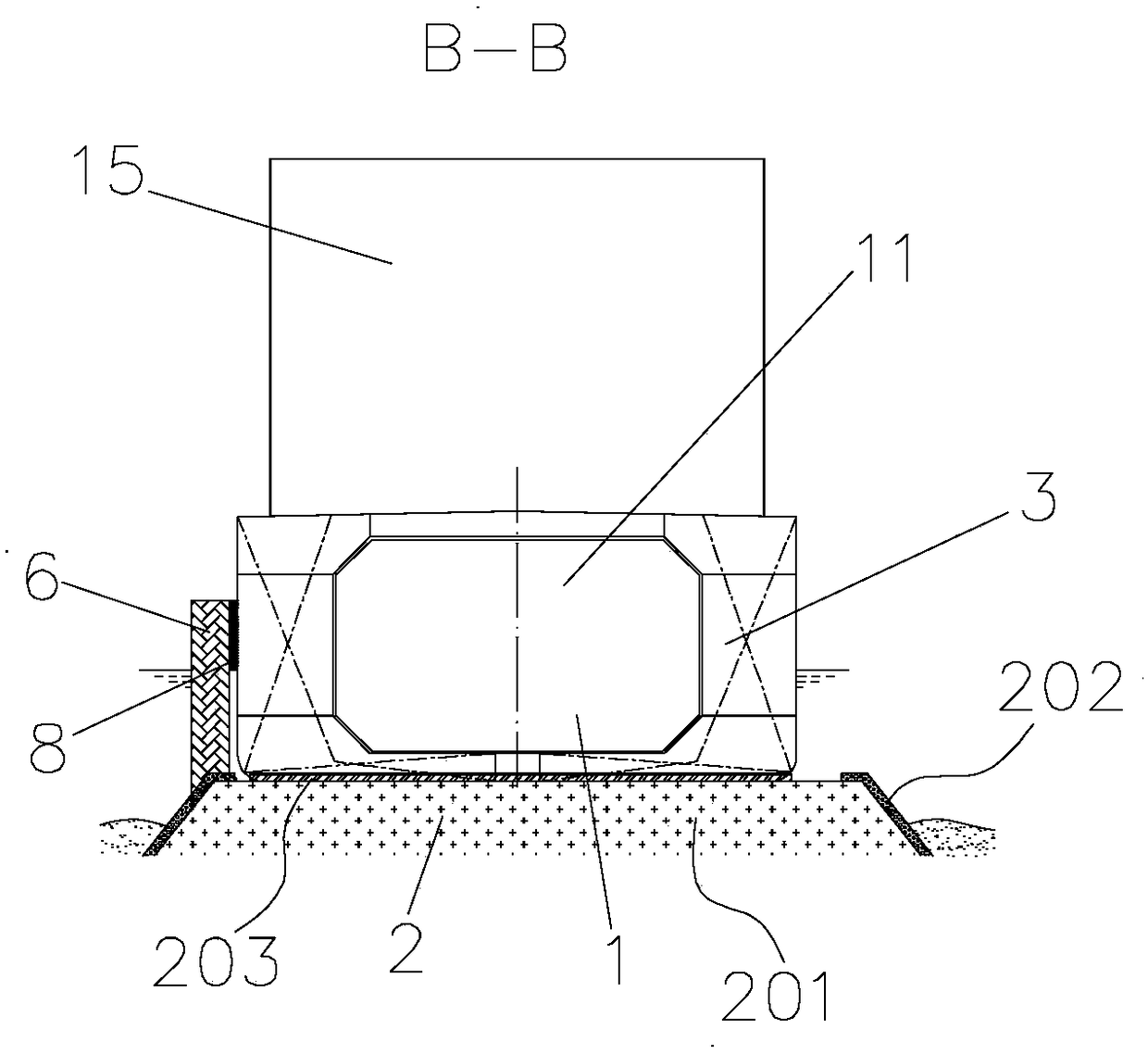

[0044] Such as Figure 1-Figure 4 The shown embodiment one of an offshore bottom-mounted natural gas processing device of the present invention includes a main hull 1 and an underwater foundation 2. The main hull 1 is provided with a natural gas processing facility 15 and a liquefied natural gas storage system 11. The main hull 1 is provided with a plurality of ballast tanks 3 around the bottom of the ship, and the top surface of the underwater foundation 2 is used to carry the main hull 1. The ballast water pump is used to inject or discharge ballast water into the ballast tank 3, so that the sinking or floating of the main hull 1 can be adjusted, and the installation of the device on the bottom can be realized. A rubber backing plate can be set between the bottom plate of the main hull 1 and the top surface of the underwater foundation 2 to increase the coefficient of friction.

[0045] Before installation, since the inside of the ballast tank 3 is empty, the draft of the m...

Embodiment 2

[0061] Such as Figure 5-Figure 7 Shown is the second embodiment of an offshore bottom-mounted natural gas processing device of the present invention. The difference between this embodiment and the first embodiment is that a plurality of liquefied natural gas storage systems 11 are installed on the deck of the main hull 1, and the liquefied natural gas The natural gas storage system 11 is a C-type tank, which further increases the LNG storage capacity; other structures are the same as in the first embodiment.

[0062] To sum up, the integration of power station, storage, loading and unloading, and LNG processing of the offshore bottom-mounted natural gas processing device, the optimized layout and compact design of the upper equipment can minimize the occupied area; there is no need to build roads and long pipelines There is no need to be equipped with numerous onshore auxiliary systems and expensive mooring systems. The underwater foundation, main hull, cargo tank and upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com