Vacuum oven and circulation water removing system thereof

A vacuum oven and heating system technology, applied in lighting and heating equipment, drying, drying solid materials, etc., can solve the problems of poor uniformity of heating, excessive local heating, no gas, etc., to achieve convenient removal, nitrogen saving, effect obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

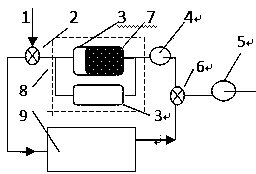

[0029] A single-door vacuum oven, the inner tank is made of 4mm thick stainless steel, the heating method is 4+1, the door is assisted in heating, and the heating element adopts a serpentine electric heating tube. An exhaust hole is opened on its rear wall, and an air intake hole is opened on the side. According to attached figure 1 In the best way, connect the vacuum pump, two-way valve, water removal unit, and nitrogen input pipeline with pipelines with good sealing performance. The water removal unit is a sealed stainless steel tank loaded with 4A molecular sieve. This constitutes the vacuum oven of the present invention.

Embodiment 2

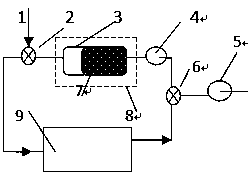

[0031] Replace the water removal unit with two parallel sealed stainless steel tanks loaded with 4A molecular sieves, according to the attached figure 2 The mode is connected, and all the other are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com