Chemical impurity-removing method and equipment for graphene thin film during transfer

A graphene film and graphene technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve problems such as difficult cleaning, limited output, increased time cost, etc., to improve cleaning effect and improve corrosion Speed, achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

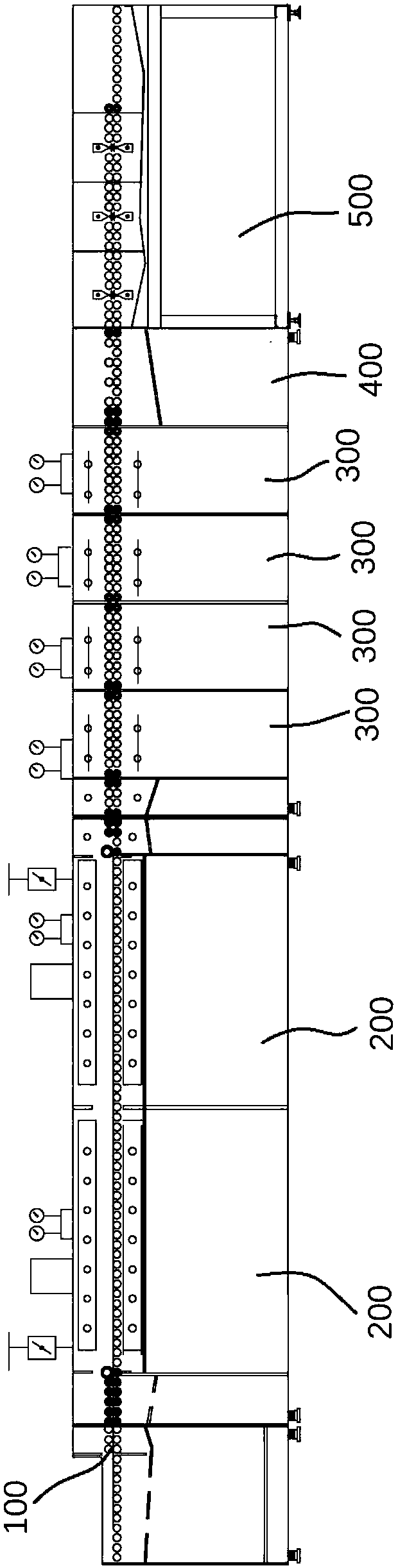

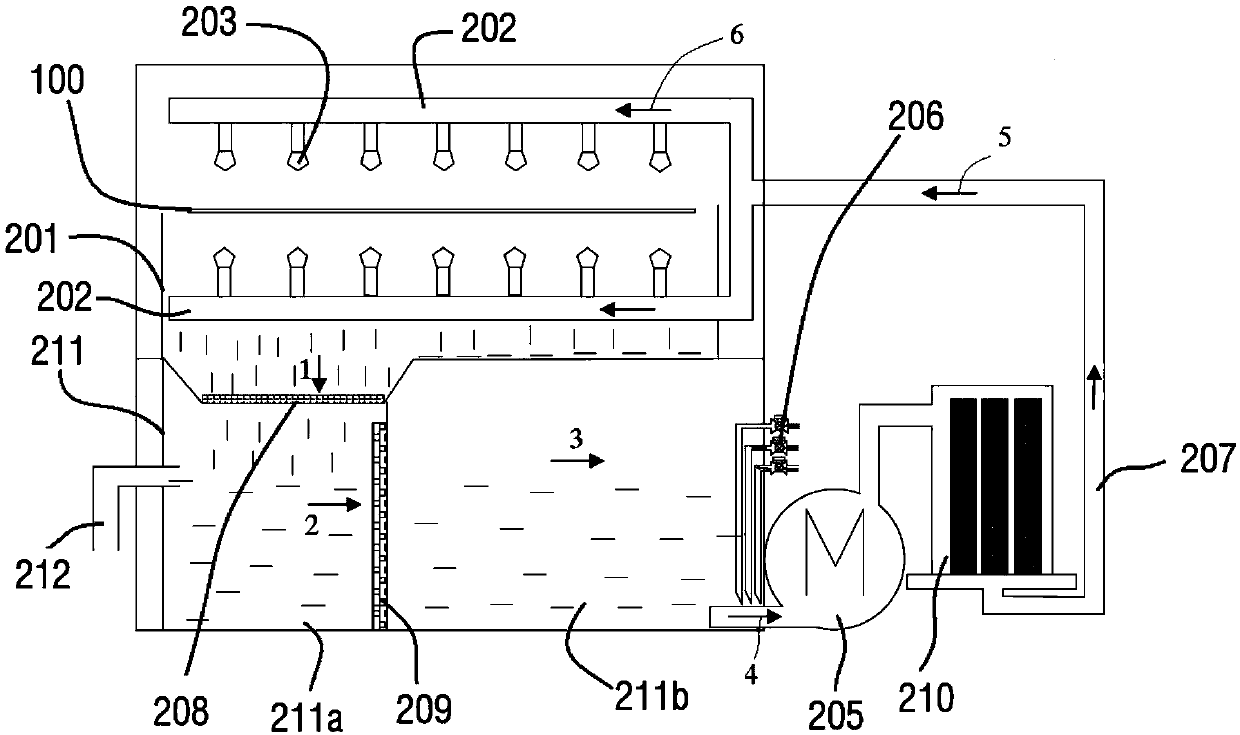

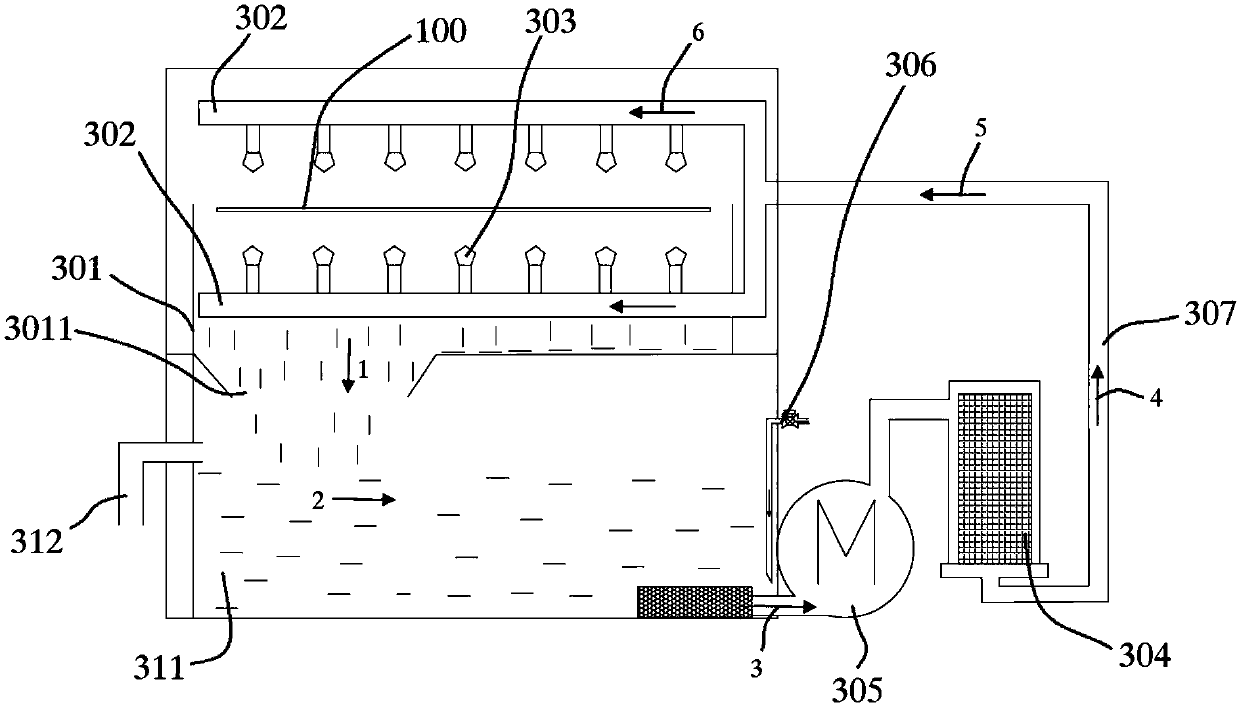

[0064] Such as figure 1 As shown, the present embodiment provides a continuous impurity removal device for graphene film transfer, including: transmission device 100, two continuous chemical corrosion sections 200, four continuous water washing sections 300, a water reducing section 400, and the drying section 500, the transmission device 100 runs through the chemical corrosion section 200, the water washing section 300, the water reduction section 400, and the drying section 500, and the chemical corrosion from the upstream to the downstream of the driving direction of the transmission device 100 is sequentially Section 200, washing section 300, water reducing section 400, and drying section 500.

[0065] The base of this embodiment takes copper foil as an example. After graphene is prepared by CVD, a layer of dense graphene with regular arrangement of C atoms will be deposited on one surface of the copper foil, and graphene will be deposited or adsorbed on the other surface....

Embodiment 2

[0086] Embodiment 2 is a further improvement to Embodiment 1. The main improvement is that a temperature control system is also provided in the chemical corrosion section 200, and the temperature control system includes a heating rod and a heat dissipation pipe. The heating rod and the heat dissipation pipe are arranged on In the medicine tank, it is used to control the temperature of the medicine in the medicine tank.

Embodiment 3

[0088] A chemical impurity removal method for a graphene film in transfer, comprising:

[0089] First cover the side of the graphene-grown substrate with the graphene film that needs to be retained with a protective film;

[0090] Then add the impurity-removing potion for chemical corrosion;

[0091] After the chemical corrosion is completed, the liquid medicine is filtered and recycled;

[0092] The substrate after impurity removal is washed with water and dried.

[0093] The chemical etching is carried out by spraying impurity-removing potion on the surface of the substrate on which the graphene grows.

[0094] The substrate is a metal substrate, preferably a copper substrate or a nickel substrate.

[0095] The impurities-removing potion is a mixed system of hydrochloric acid plus hydrogen peroxide, a mixed system of sulfuric acid plus hydrogen peroxide, a mixed system of sulfuric acid plus sodium persulfate or a nitric acid system. The HCL content in the mixed system of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com