Remote control unit battery rear cover automatic assembly machine

A technology of remote control and assembly machine, which is applied in the field of automatic assembly machine for battery back cover of remote control, which can solve the problems of low production efficiency and high labor cost, and achieve the effect of high assembly efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] For the convenience of those skilled in the art to understand, below in conjunction with embodiment and appended Figure 1-Figure 13 To further illustrate the present invention, the content mentioned in the embodiment is not to limit the present invention.

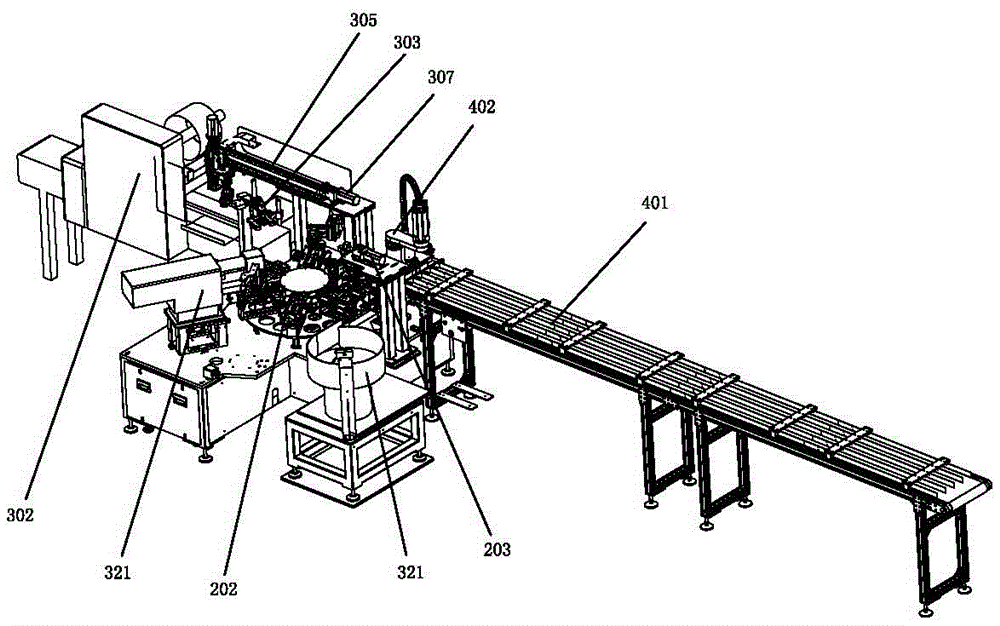

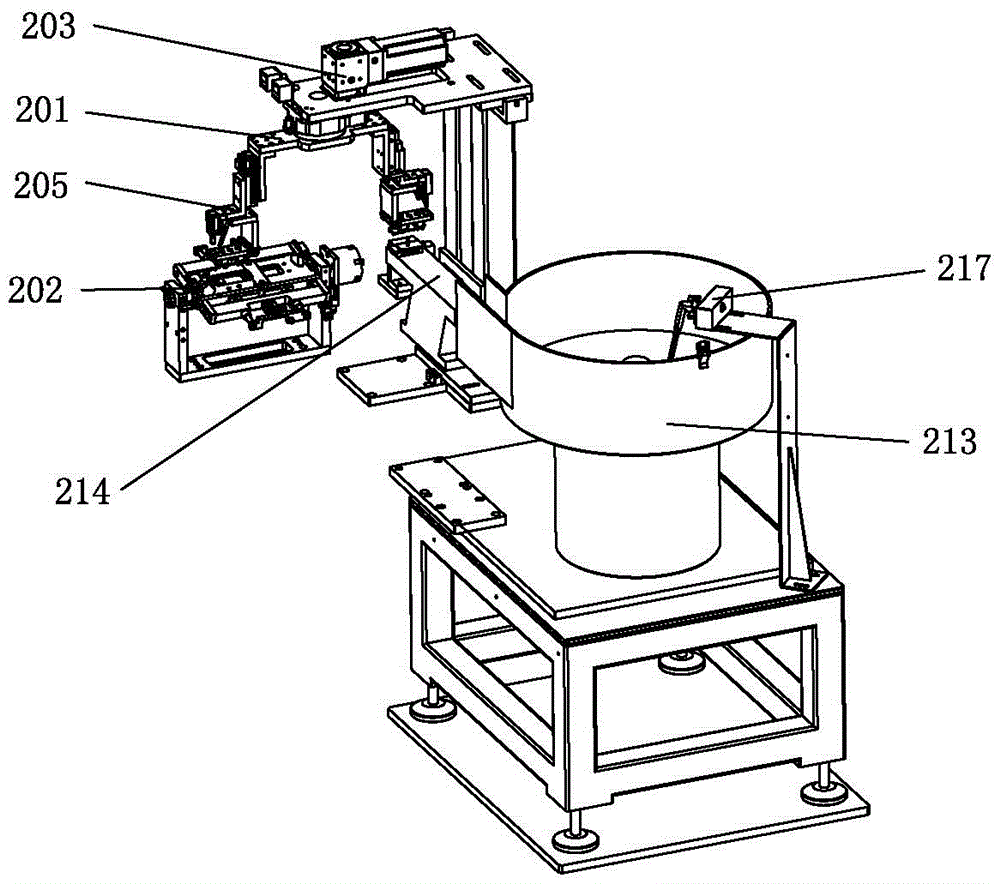

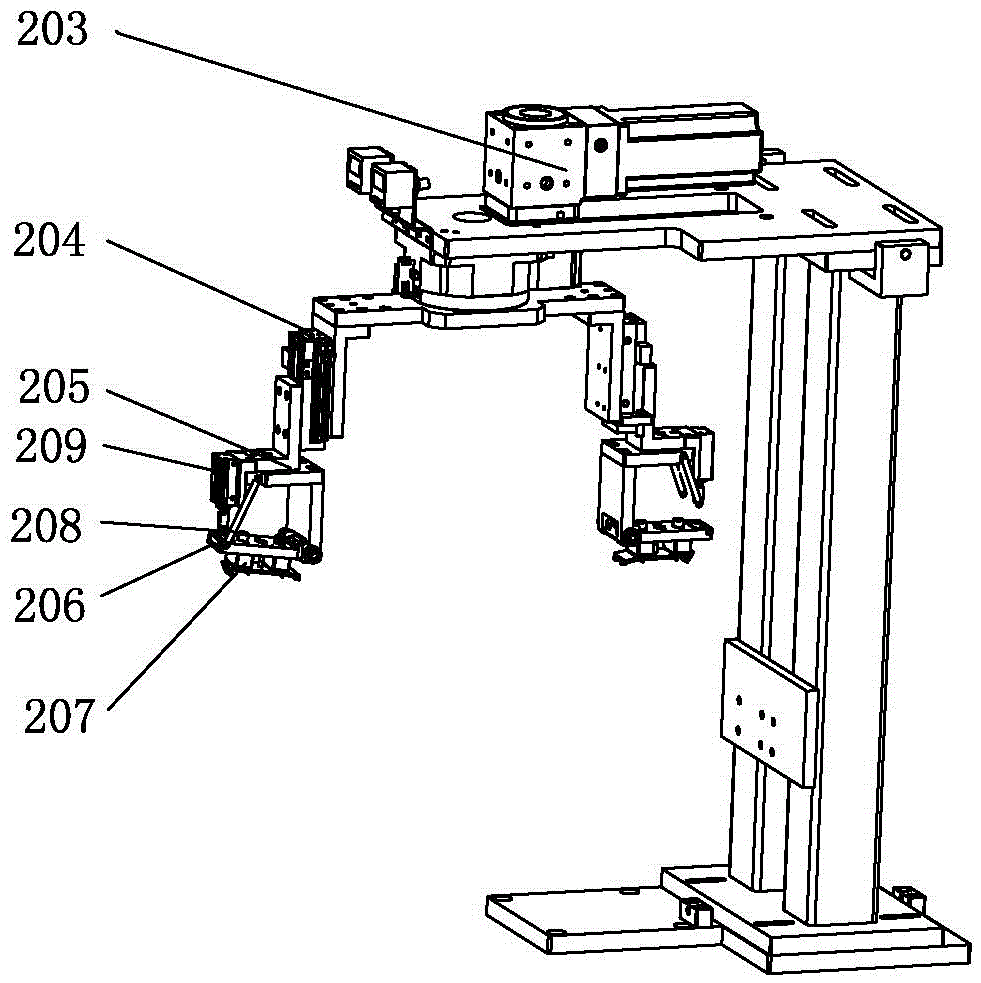

[0030] See Figure 1-5 , a remote control battery back cover automatic assembly machine, including a rotating disc 301, a circular array on the rotating disc 301 for carrying a plurality of automatic flip jigs 202 for the remote control to be separated, for driving the rotating disc 301 to rotate The disc motor, the incoming material feeding mechanism for placing the remote controller on the automatic turning jig 202, and the automatic assembly device for the rear cover arranged above the rotating disc 301, the automatic assembly device for the rear cover includes a rotating bracket 201 , the automatic turning fixture 202 for storing the remote controller to be assembled, and the rotating mechanism 203 for driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com