Powerful suction-type sewer scavenger

A sewage suction truck, a powerful technology, applied in fixed filter elements, filtration separation, construction, etc., can solve the problems of low cleaning efficiency, increased traffic pressure and pollution, and affecting the treatment capacity of sewage plants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

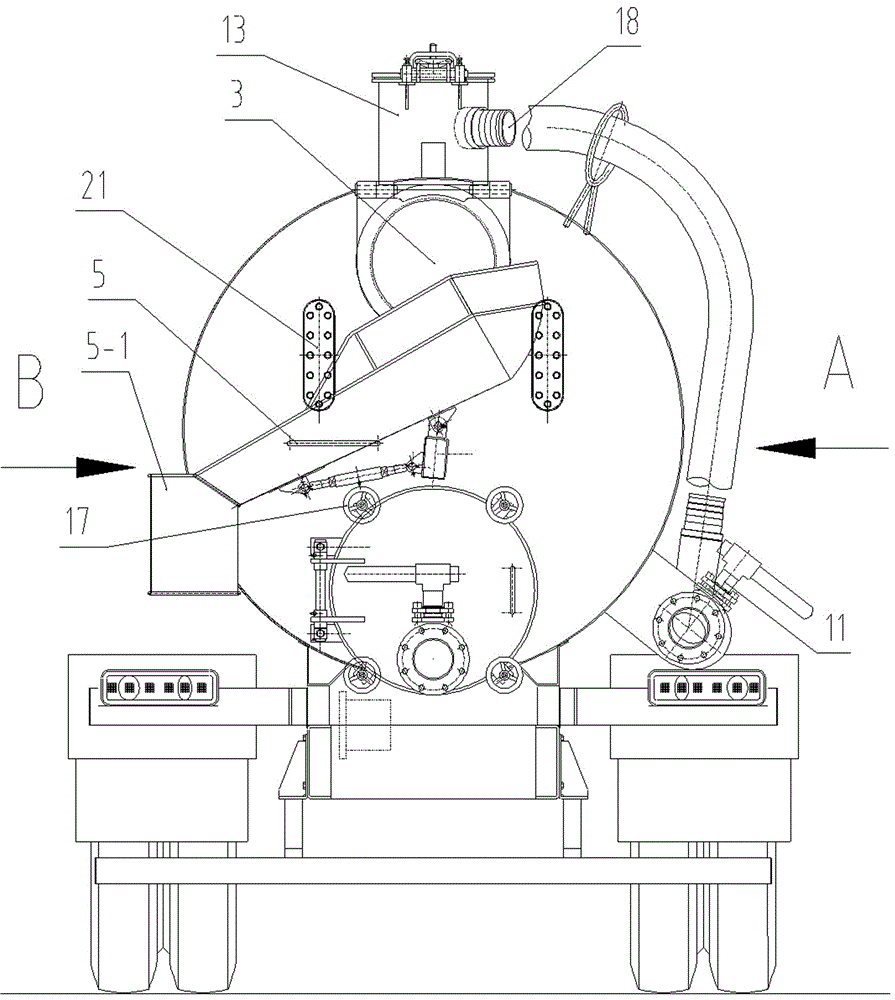

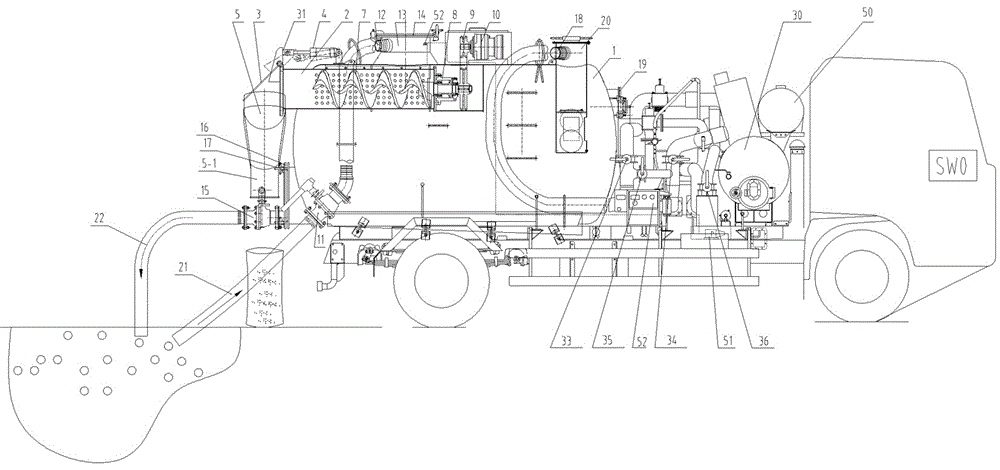

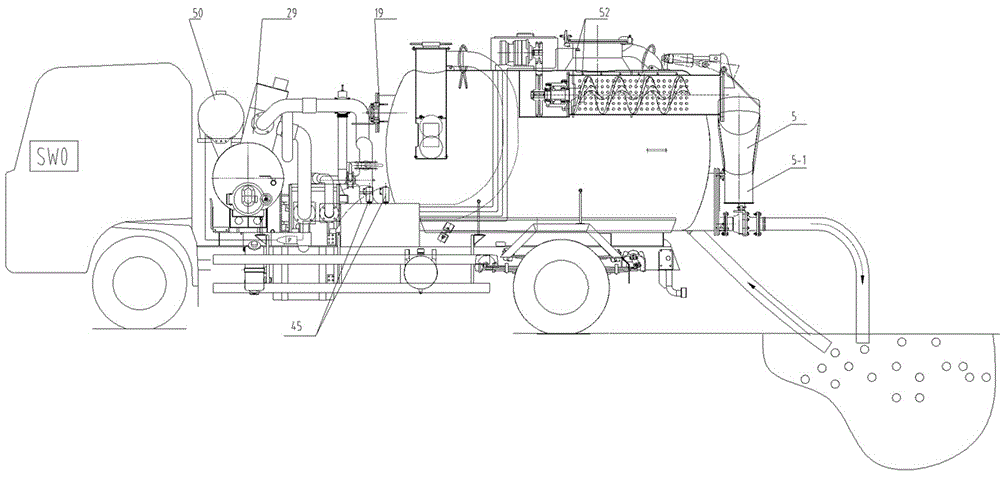

[0051] see Figure 1 to Figure 8 , a powerful sewage suction vehicle, comprising a sewage suction vehicle body, the chassis of the sewage suction vehicle body is provided with a tank body forming a closed space, the tank body is provided with a feeding port and a vent port, and the tank body is provided with There is a solid-liquid separation filter cartridge. The solid-liquid separation filter cartridge is fixed on the upper part of the tank body, one shaft end of the solid-liquid separation filter cartridge protrudes from the rear end of the tank body to form a discharge port, and the shaft end of the solid-liquid separation filter cartridge extends out of the tank body The end is provided with a sealing cover to seal the discharge port. The shaft end of the solid-liquid separation filter cartridge located in the tank is provided with an end plate. The solid-liquid separation filter cartridge is provided with a shaftless spiral body. The through hole provided on the end pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com