Automatic vertical centrifugal dewatering machine

A vertical centrifuge and dehydrator technology, applied in non-progressive dryers, dryers, drying solid materials, etc., can solve the problems of affecting the dehydration effect, fixed distance, waste of power, etc., to optimize the drying effect and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

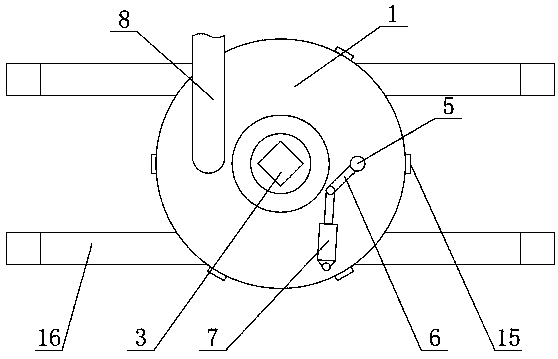

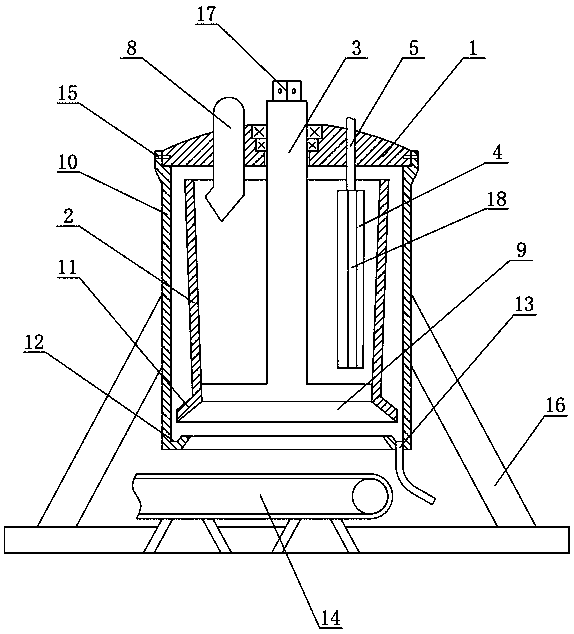

[0034] Such as Figure 1~Figure 3 As shown, an automatic vertical centrifugal dehydrator includes a top cover 1, a dehydration cylinder 2, a casing 10, a rotating shaft 3 and a scraper 4, the dehydration cylinder 2 and the casing 10 are located under the top cover 1, and the dehydration cylinder 2 is arranged on the casing 10 Inside, it is fixedly connected with the rotating shaft 3, the rotating shaft 3 is rotationally connected with the top cover 1, and the scraper 4 is arranged in the dehydration cylinder 2, and is rotationally connected with the top cover 1. A conveyer belt 14 is arranged at the bottom of the dehydration cylinder 2 , the top cover 1 and the shell 10 are connected through a connecting device 15 , and the connecting shell 10 is set on a bracket 16 . The connecting device 15 is a connecting plate evenly distributed on the joint of the top cover 1 and the casing 10 , one end is fixedly connected to the casing 10 , and the other end is bolted to the top cover 1...

Embodiment 2

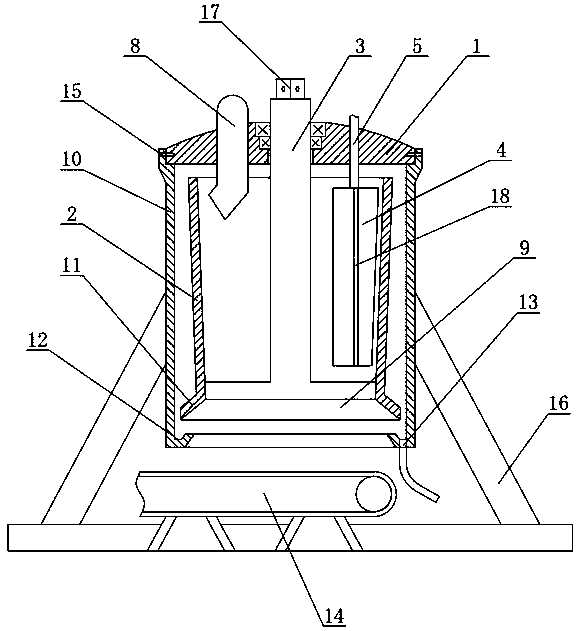

[0043] Such as Figure 4 As shown, in this embodiment, the top cover 1 is provided with two scrapers 4, and the centers of the two scrapers 4 are arranged symmetrically, and the center of symmetry is the rotating shaft 3, and the rotation directions of the scrapers 4 are also opposite. The two scrapers 4 rotate at the same time, and the dehydration barrel 2 is cleaned simultaneously, so that the dehydration barrel 2 rotates more stably when cleaning. Other parts in this embodiment are basically the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com