Automatic veneer drying device

A drying device and veneer technology, which is applied in drying, drying machine, wood drying, etc., can solve the problems of large area occupied by drying sites, increased production costs, and large labor costs, and achieve fast and accurate veneer delivery, production Satisfied efficiency and effective drying rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

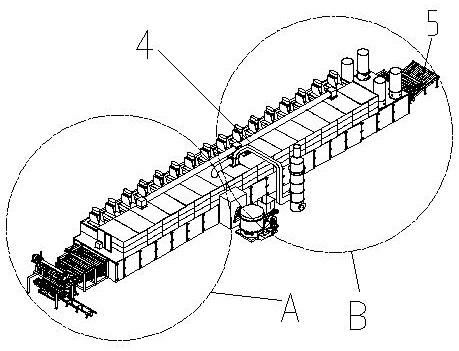

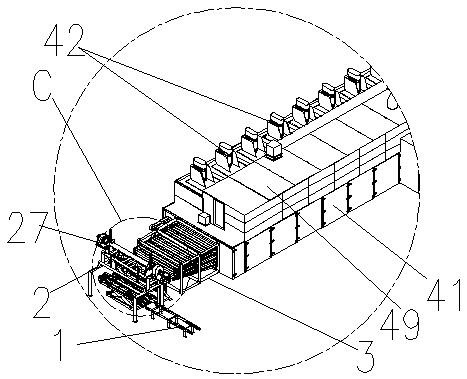

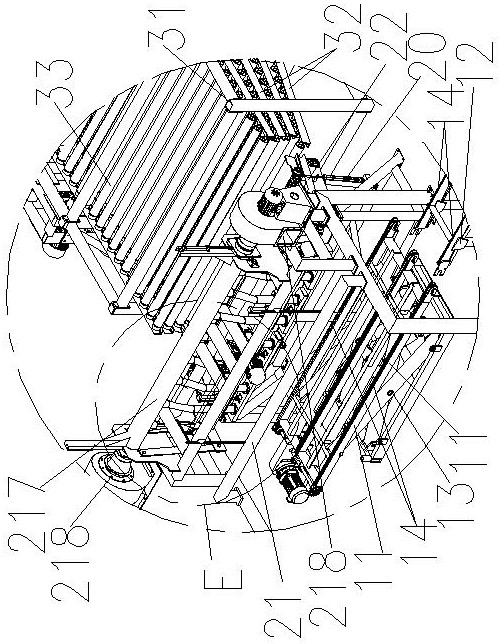

[0077] Example 1. Such as Figure 1-29 As shown, an automatic veneer drying device is characterized in that it includes: a feeding unit 1, a feeding unit 2, a transition guide frame 3, a drying unit 4, and a discharging unit 5;

[0078] The drying unit 4 comprises a hot smoke system, a heat exchange system, a drying box 41, and several heat extraction fans 42; , in the right two ends, it is provided with the veneer inlet that links to each other with transition guide frame 3 near transition guide frame 3 end, is provided with the veneer outlet that links to each other with discharge unit 5 near discharge unit 5 end; Several horizontal drying layers 43, each horizontal drying layer 43 is provided with several horizontal drying layer longitudinal transmission rollers 44 with the top surface level, each horizontal drying layer longitudinal transmission roller 44 is connected with the horizontal drying layer longitudinal transmission roller driving motor 45 are connected; the ho...

Embodiment 2

[0107] Example 2. Such as Figure 21 As shown, the difference between this embodiment and Embodiment 1 is that no pallet lifting device is provided below the veneer conveyor belt 14 located in the frame body 11 of the feeding unit 1 of the feeding unit 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com