Ultrasonic welding machine and its ultrasonic welding control method

An ultrasonic welding machine and ultrasonic welding technology, applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problems of long welding processing cycle, low operation efficiency, and inaccurate rotation angle, etc. Efficiency improvement, good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

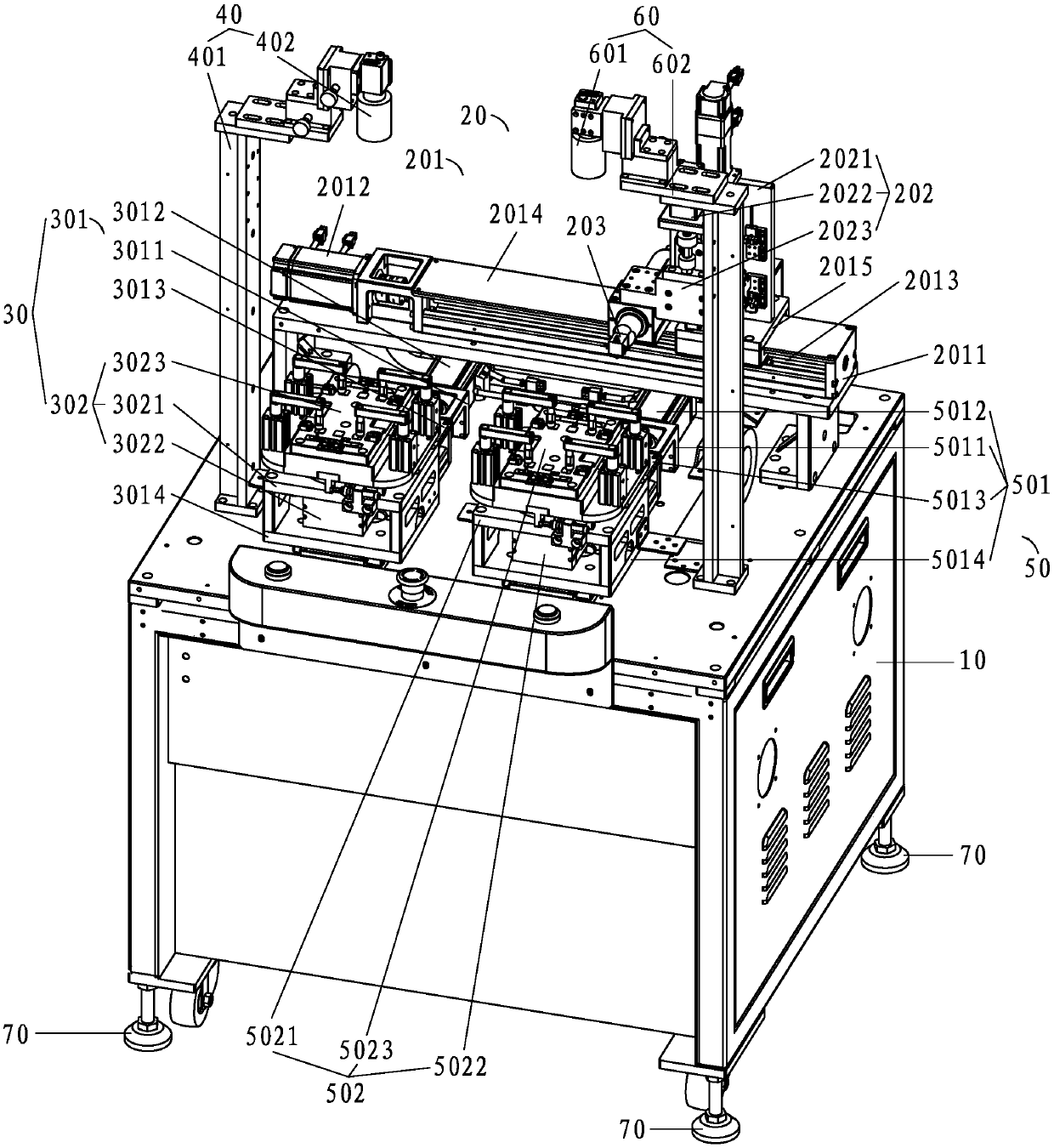

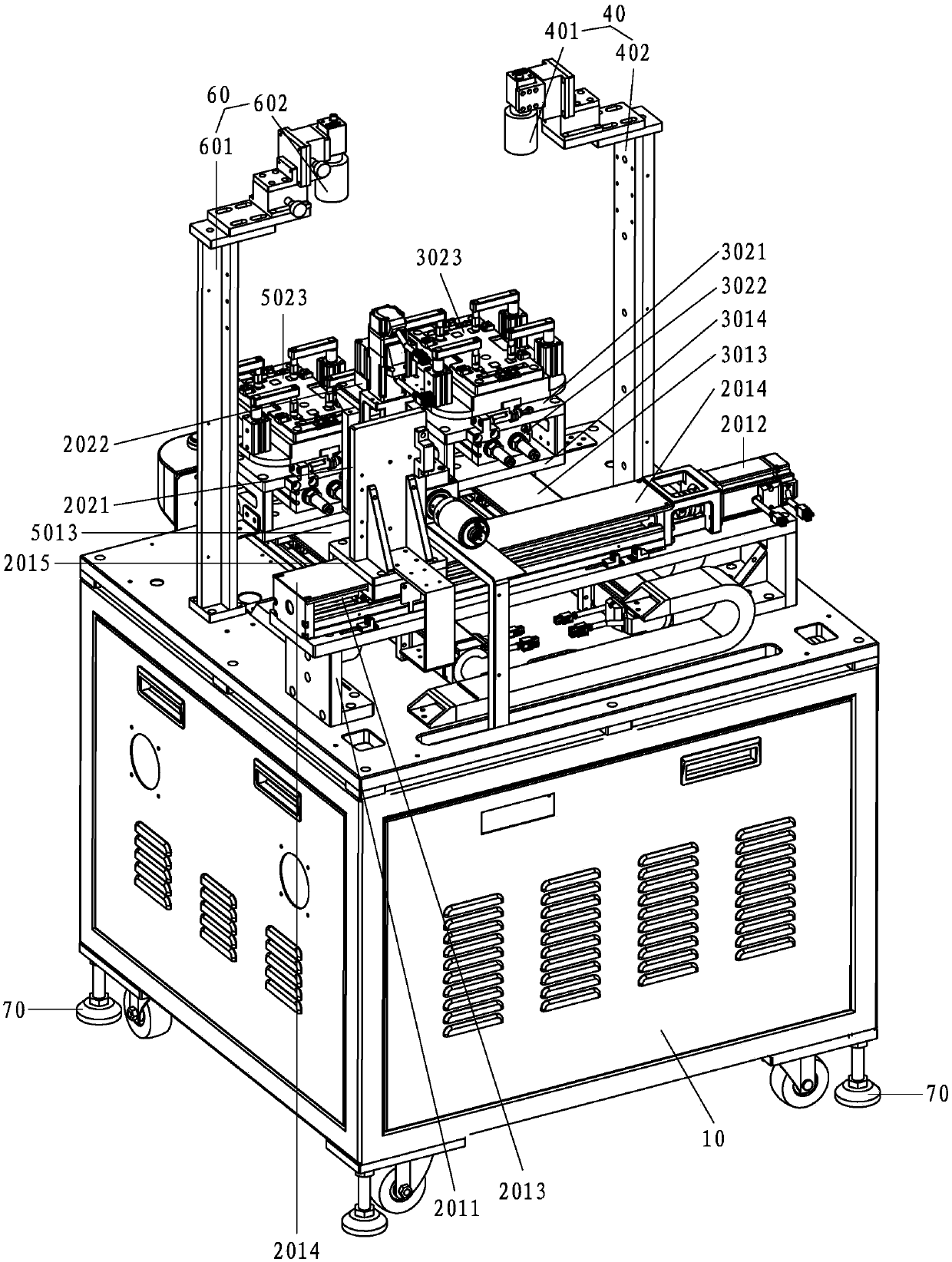

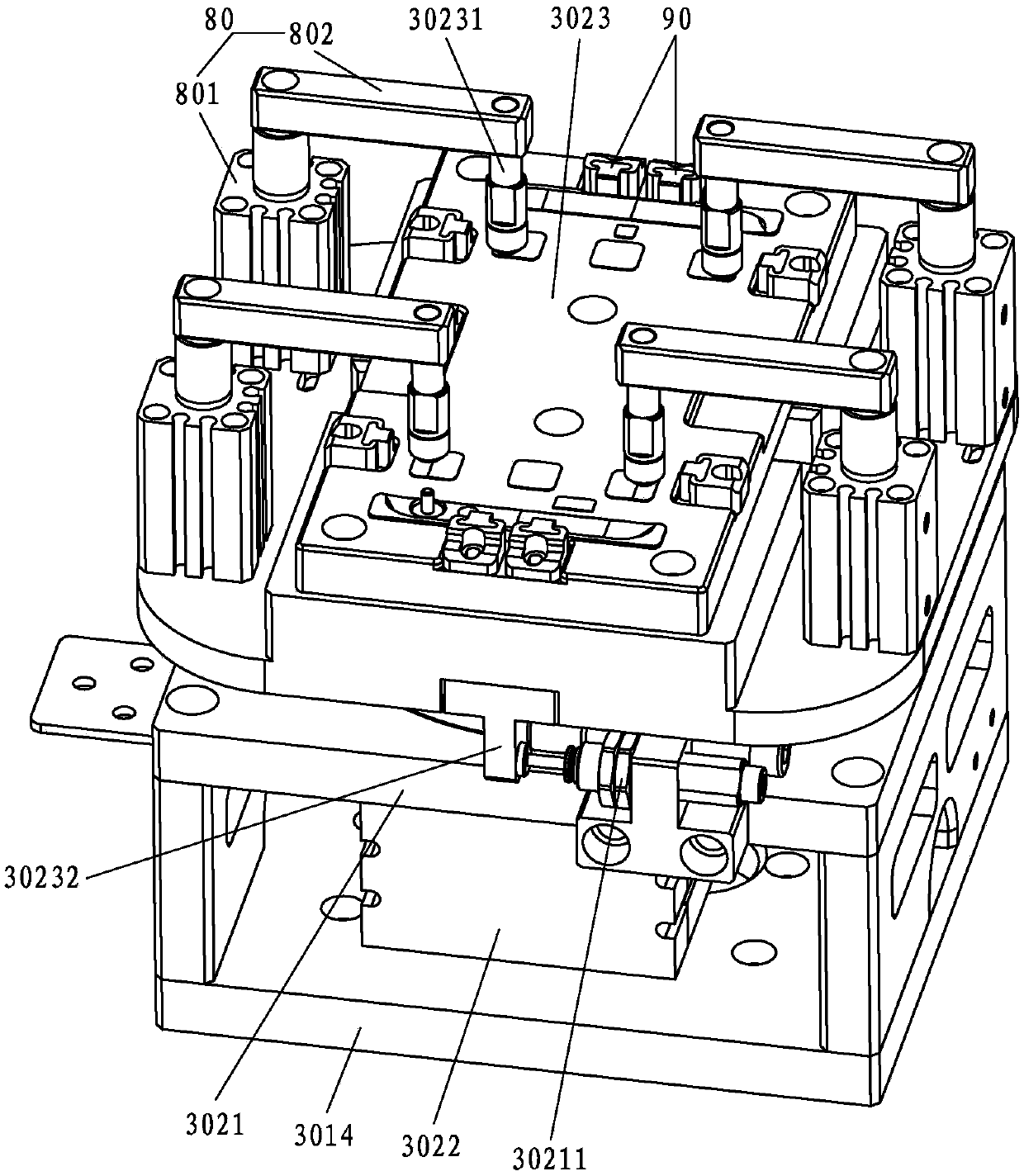

[0081] combine figure 1 , figure 2 , image 3 , Figure 4 shown;

[0082] An ultrasonic welding machine provided by the present invention includes a frame 10 and a main controller arranged in the frame 10. The improvement of the present invention is that it also includes:

[0083]The ultrasonic welding mechanism 20, the ultrasonic welding mechanism 20 includes a horizontal translation mechanism 201 arranged on the rear end of the upper end surface of the frame 10 along the horizontal direction, and a vertical lifting mechanism fixed on the horizontal translation mechanism 201 along the vertical direction 202 and the ultrasonic welding head 203 fixed on the vertical lifting mechanism 202 along the longitudinal direction; the horizontal translation mechanism 201, the vertical lifting mechanism 202 and the ultrasonic welding head 203 are respectively connected with the main controller signal , and the ultrasonic welding head 203 faces to the front and upper side of the frame...

Embodiment 2

[0120] refer to Figure 1-Figure 4 shown;

[0121] An ultrasonic welding control method provided by the present invention is applied to the ultrasonic welding machine described in Embodiment 1, which includes the following steps:

[0122] S1. Control the first longitudinal translation mechanism 301 through the main controller, so that the first rotating platform 302 moves along the first longitudinal translation mechanism 301 to directly below the first CCD camera;

[0123] S2. Use the first CCD camera 402 to photograph and locate the welding position of the rear side of the workpiece clamped on the first rotating platform 302, and send the welding position information after photographing and positioning the rear side of the relevant workpiece to the the main controller;

[0124] S3. Control the first longitudinal translation mechanism 301 through the main controller, so that the first rotating platform 302 moves along the first longitudinal translation mechanism 301 to dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com