Purification system and purification method for volatile pollutants

A volatile pollutant and purification system technology, applied in the field of purification, can solve the problems of high economic cost, complex process, low efficiency, etc., and achieve the effect of saving electric energy, simple structure and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

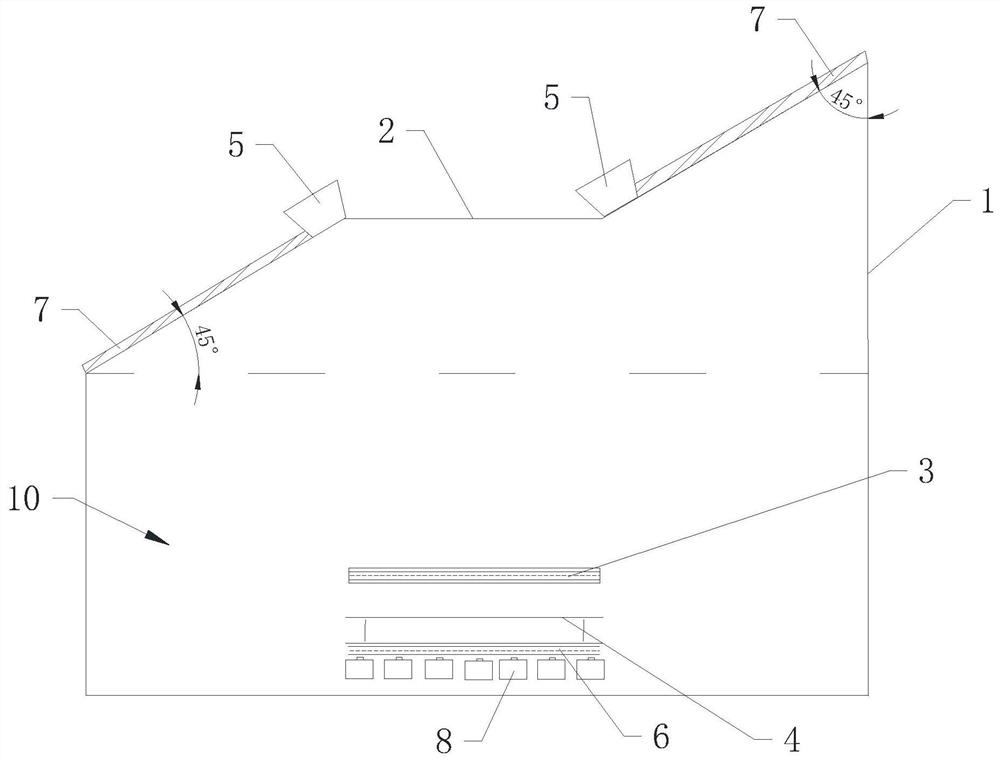

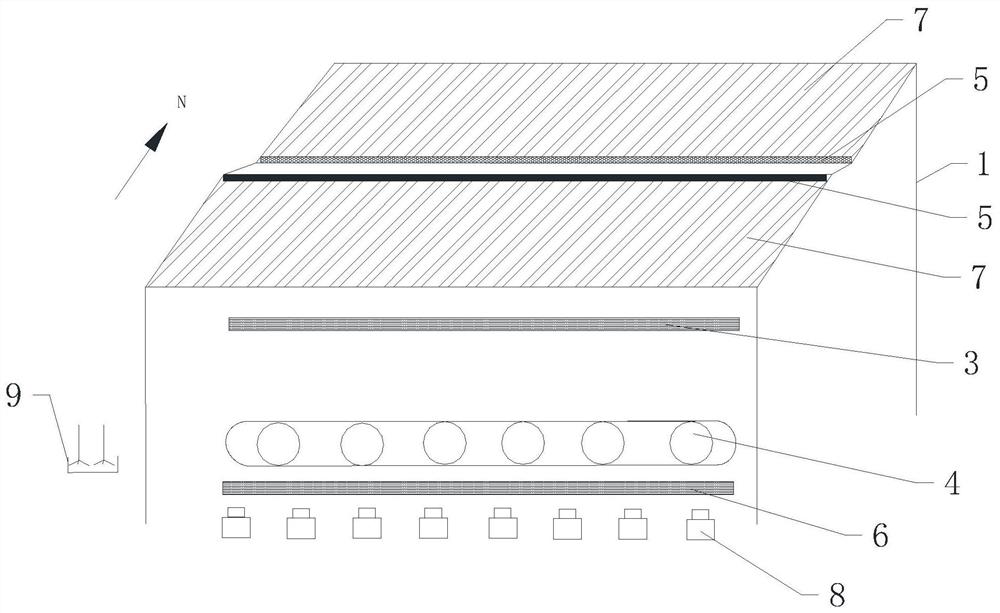

[0044] Reference manual attached Figure 1 to Figure 4 , the present invention provides a purification system of volatile pollutants, the purification system of said volatile pollutants can directly convert light radiation into heat energy or convert light radiation into electric energy first and then into heat energy, so as to remove volatile pollution in soil The process is simple and efficient. Preferably, the pollutant is polluted soil. It can be understood that the pollutant can also be other solid or liquid pollutants, and the specific type of the pollutant should not limit the present invention.

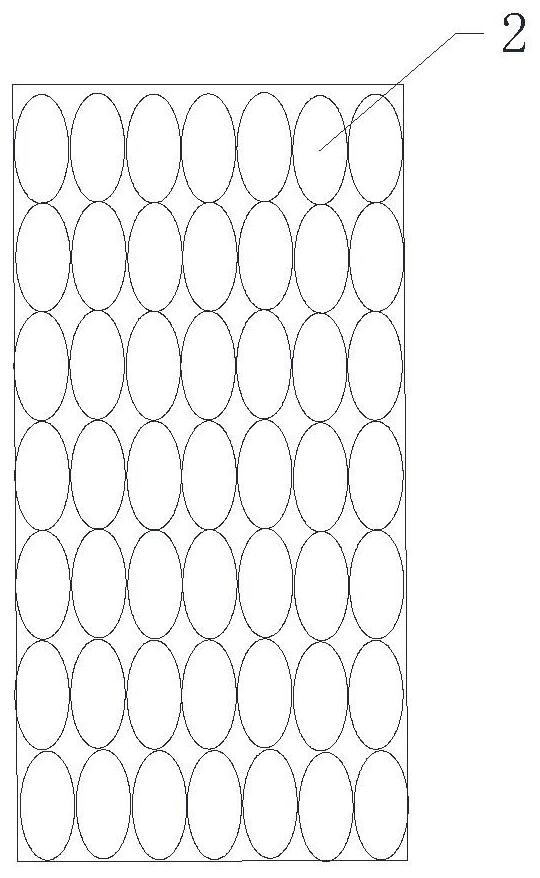

[0045] Reference manual attached figure 1 with figure 2 , specifically, the purification system for volatile pollutants includes a skeleton 1 , a convex lens group 2 , a heat distribution plate 3 , a conveying device 4 and a negative pressure purification device 5 . The frame 1 surrounds and forms a clean space 10; the convex lens group 2 is installed on the frame 1; the h...

Embodiment 2

[0067] According to another aspect of the present invention, the present invention further provides a purification method for volatile pollutants, comprising:

[0068] 101: Transport the pollutants to a preset position through the conveying device 4;

[0069] 102: Heat the pollutants delivered to a preset location, so that volatile pollutants in the pollutants are heated and left;

[0070] 103: extract the volatile pollutants volatilized by the pollutants by heating through the negative pressure purification device 5, and introduce the outside air;

[0071] Wherein, heating the pollutants delivered to the preset position includes:

[0072] Through the convex lens group 2 arranged in the middle position of the top of the frame 1, the light is converged to the heat distribution plate 3 arranged at the focal point of the convex lens group 2, and the heat distribution plate 3 can heat the transmission device 4 in the form of thermal radiation. pollutants; and / or, the pollutants ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com