Hydraulic pressure differential controller and application thereof

A technology of controller and pressure difference, which is applied in the direction of chemical instruments and methods, fixed filter elements, functional valve types, etc., can solve the problems of solenoid valve power consumption, inability to achieve sewage discharge effect, etc., to reduce investment and low cost , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

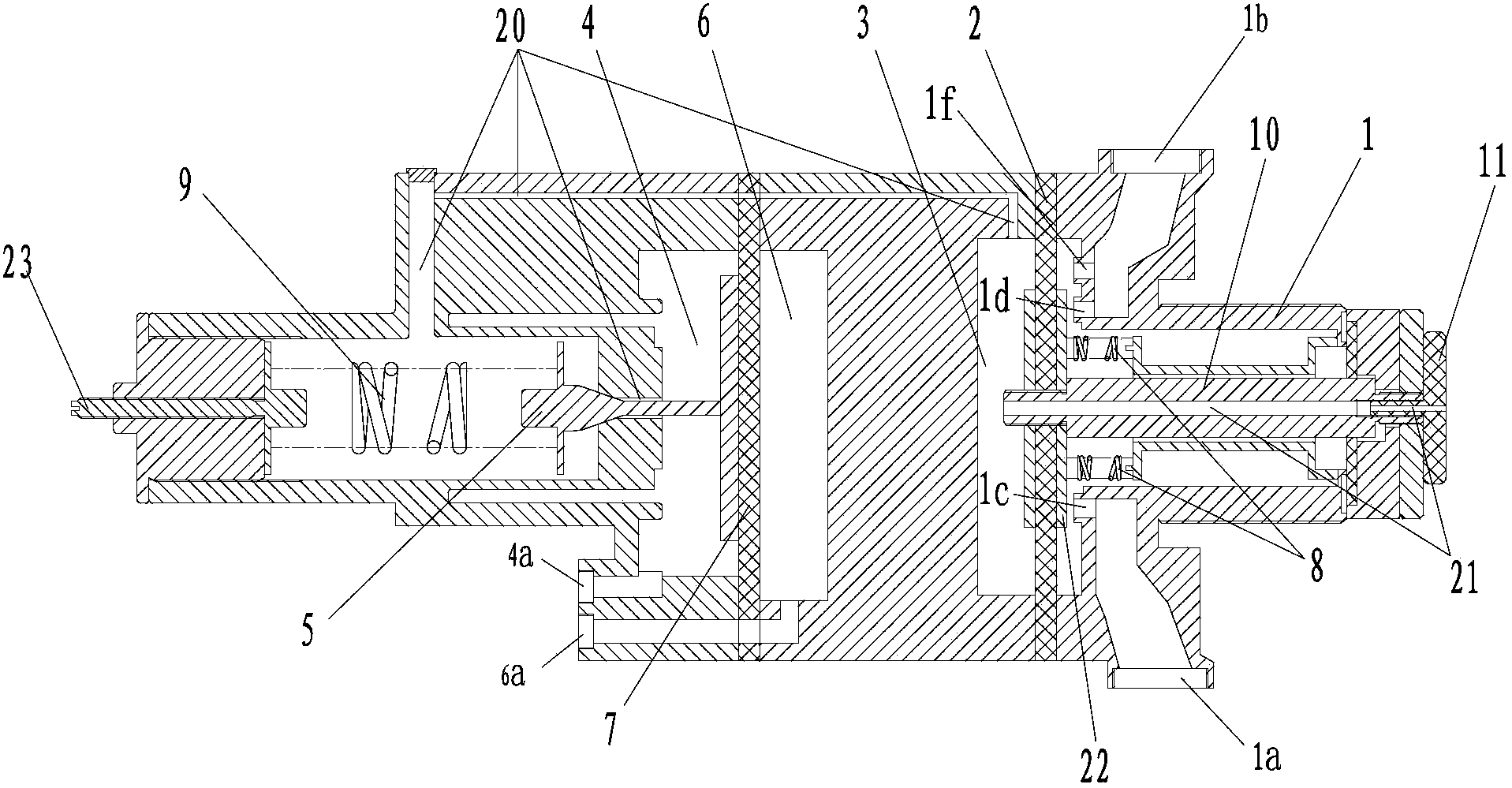

[0026] Refer to attached figure 1 , 2 , 3, 4: This hydraulic differential pressure controller includes a valve body 1, and the front end of the valve body 1 is provided with a water inlet 1a, a water outlet 1b, and a sewage valve return port 1f that communicate with each other. The first water inlet 1a, the second The rear side of a water outlet 1b is provided with a first elastic member 2 for blocking the communication between the first water inlet 1a and the first water outlet 1b, and the rear side of the first elastic member 2 is provided with a pressurized chamber 3. The pressurized chamber 3 communicates with the low-pressure chamber 4 through the passage 20, and the passage 20 is provided with a valve stem 5 for controlling the opening and closing of the passage; The two elastic parts 7 are separated, and the valve stem 5 is connected to the second elastic part 7 (there are many ways to connect, as long as the second elastic part 7 can be pushed to move when the second ...

Embodiment 2

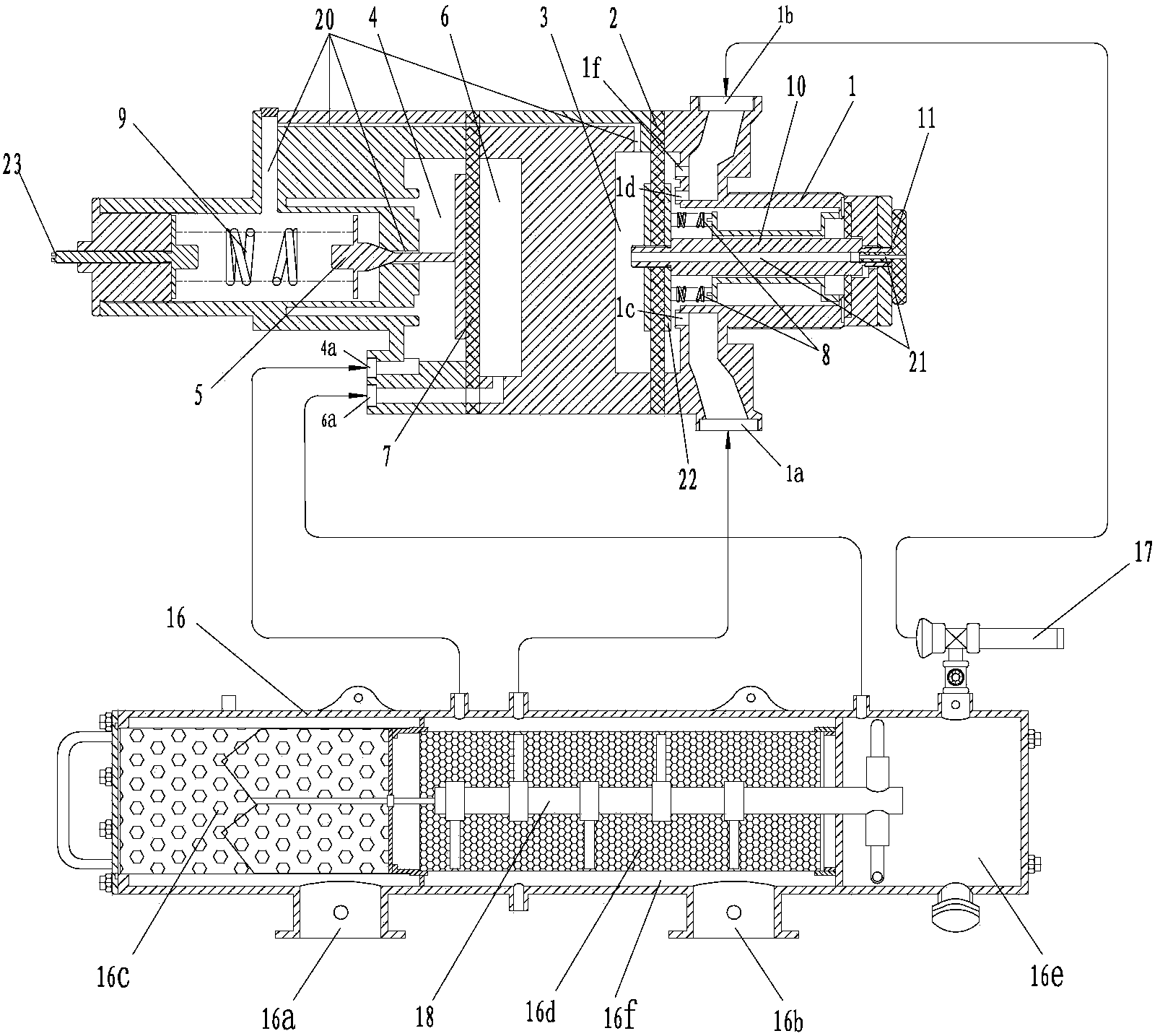

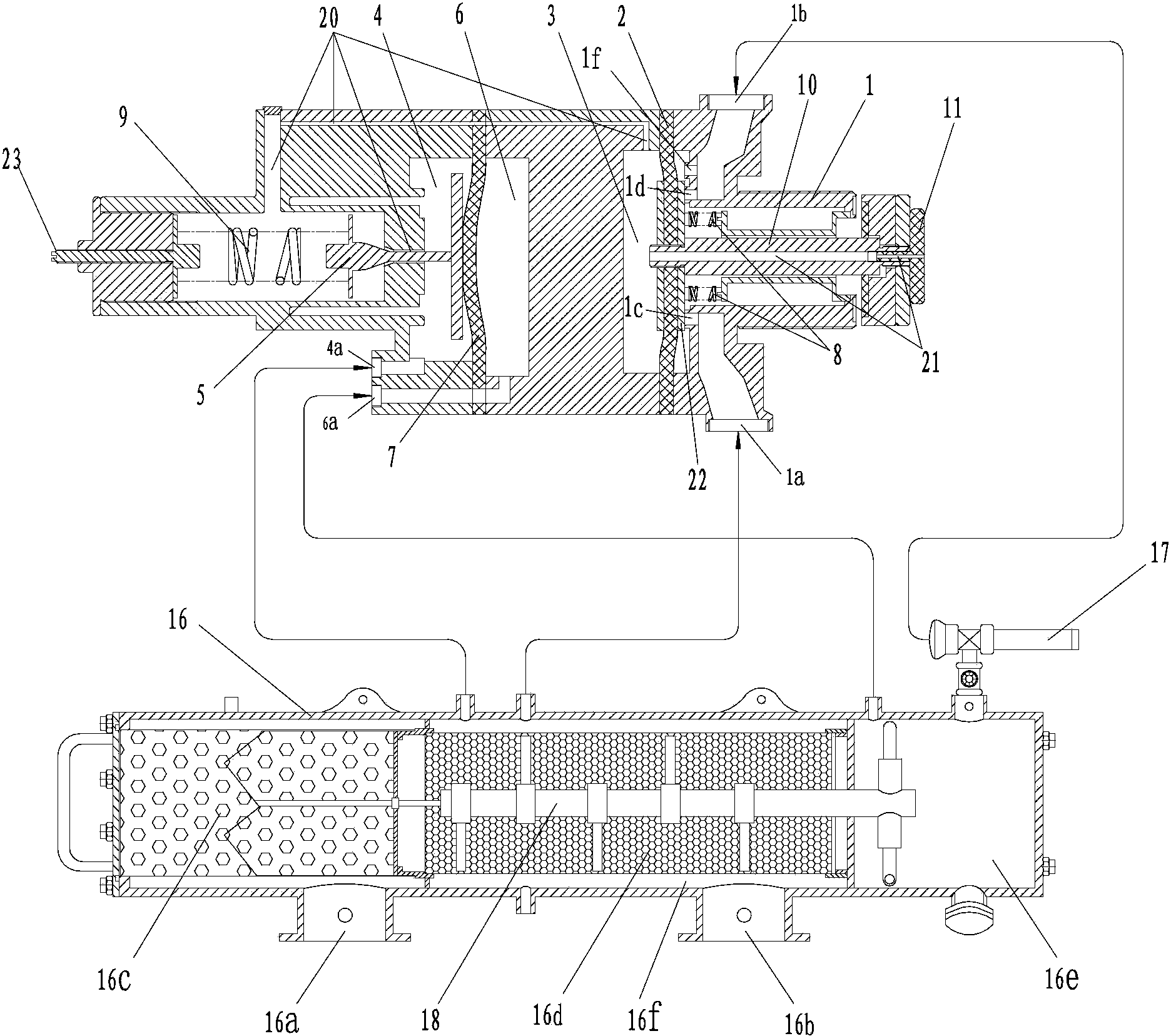

[0030] Refer to attached Figure 4 , 5 6. This hydraulic differential pressure controller is different from Embodiment 1 in that: the front end of the valve body 1 is provided with a hydraulic cylinder water inlet 1e. The rear side of the pressurization chamber 3 is provided with a return chamber 13, which is separated from the pressurization chamber 3 by a third elastic member 14, and the third elastic member 14 and the first elastic member 2 are separated by a connecting rod 15 Connection; the backwater chamber 13 is provided with a water inlet 13a of the backwater chamber.

[0031] This water processor equipped with the above-mentioned hydraulic differential pressure controller includes a housing 16, a second water inlet 16a, a second water outlet 16b, a coarse filter 16c, a fine filter 16d, and a clean water cavity outside the fine filter. 16f, sewage chamber 16e with sewage valve 17, hydraulically driven sewage suction device 18, low-pressure water inlet 4a of hydraulic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com