Self-made heat conductor and heating equipment into which insulating heat conduction material is embedded and implementation method of self-made heat conductor and heating equipment

A technology of insulation and heat conduction and heat conductor, which is applied in the direction of cable installation, heating element shape, overhead installation, etc., and can solve the problems of high requirements and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] The anti-icing and melting of ice is accomplished by using the power-transmitting heating equipment on the self-made thermal conductor embedded in the insulating and thermally conductive material.

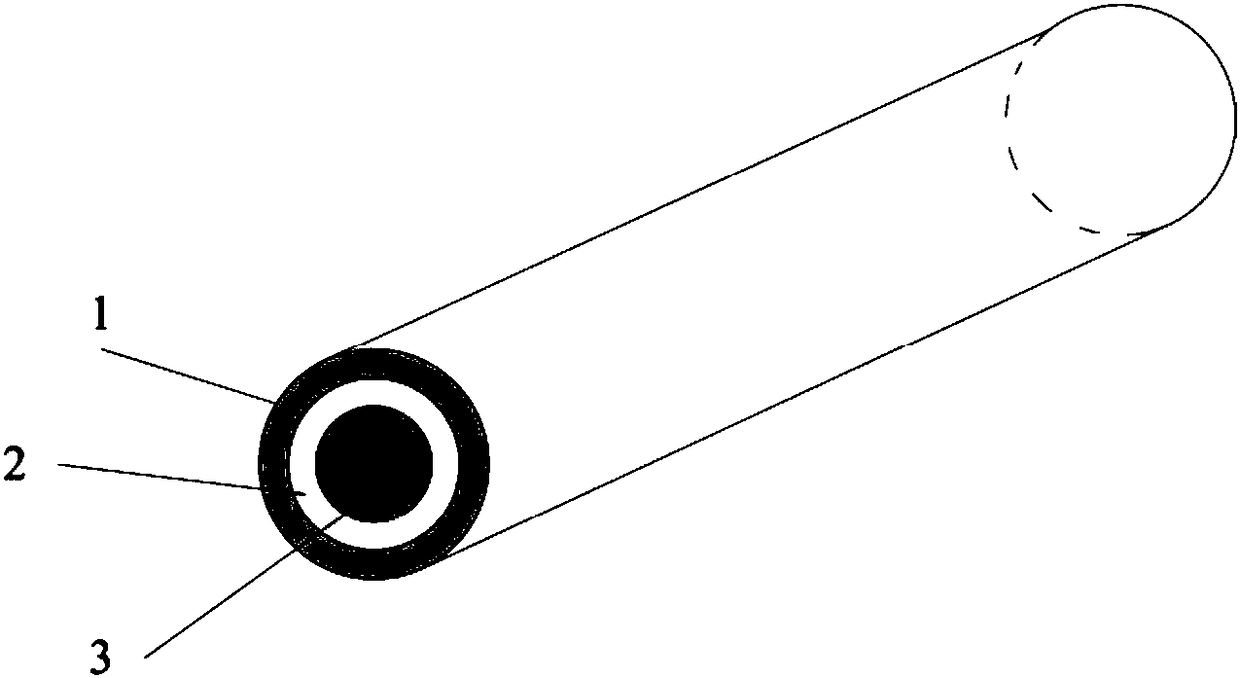

[0094] see attached figure 1 , 2 .

[0095] The self-made thermal conductor is a coaxial cable, including an outer conductor 1, an insulating and heat-conducting material 2 and an inner conductor 3; the insulating and heat-conducting material is a material with good heat conduction and insulating ability. This embodiment adopts the thermally conductive insulating material produced by Hefei AVIC Nanotechnology Development Co., Ltd.: Model: ZH-HCM-A.

[0096] The insulating and heat-conducting material 2 surrounds the outer side of the inner conductor, completely surrounds the outer periphery of the inner conductor, and completely isolates the inner and outer conductors to avoid short circuit of the inner and outer conductors. When alternating current or direct current is a...

Embodiment 2

[0160] The anti-icing and melting ice is completed by using the heating equipment at the power receiving end on the self-made thermal conductor embedded in the insulating and heat-conducting material.

[0161] See attached Figure 23 .

[0162] The heating equipment at the power receiving end is divided into two types: heating equipment using conventional transformers and heating equipment using anti-icing and ice-melting load transformers. In this embodiment, a heating device at the receiving end using a conventional transformer is used.

[0163] The heating equipment at the power receiving end that adopts a conventional transformer is composed of the fifth switch circuit 19-5, the sixth switch circuit 19-6, the power receiving microprocessor 72, the power receiving communication module 71, the power receiving conductor icing sensing module 73, steel Core load transformer 62 constitutes. The inner conductor and the outer conductor of the power transmission end are short-ci...

Embodiment 3

[0166] See attached Figure 24 .

[0167] This embodiment uses the heating equipment using the anti-icing and melting ice load transformer.

[0168]The heating equipment at the power receiving end adopting the anti-icing and melting load transformer is composed of the fifth switch circuit 19-5, the sixth switch circuit 19-6, the power receiving microprocessor 72, the power receiving communication module 71, and the power receiving conductor icing induction Module 73 is composed of anti-icing and melting ice-transmission load transformer 63. The inner conductor 3 and the outer conductor 1 of the power transmitting end are short-circuited and connected to the output of the power transmission power supply. The outer conductor 1 of the power receiving end is connected to the aluminum stranded wire winding of the anti-icing and melting load transformer 63, and the secondary winding of the anti-icing and melting load transformer 63 is connected to the electric load. The inner con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com