Sulphur ratio on-line monitor and monitoring method

A monitoring instrument, sulfur technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of short duration, sulfur pollution in the detection pool, incomplete backflushing, etc., and achieve the effect of small engineering maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

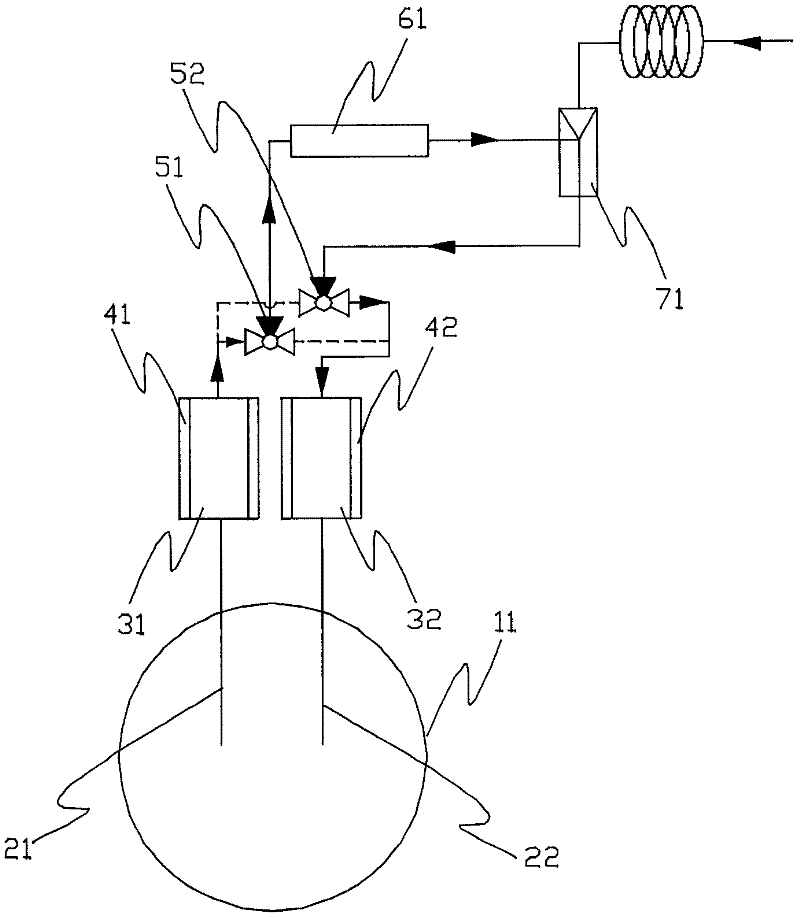

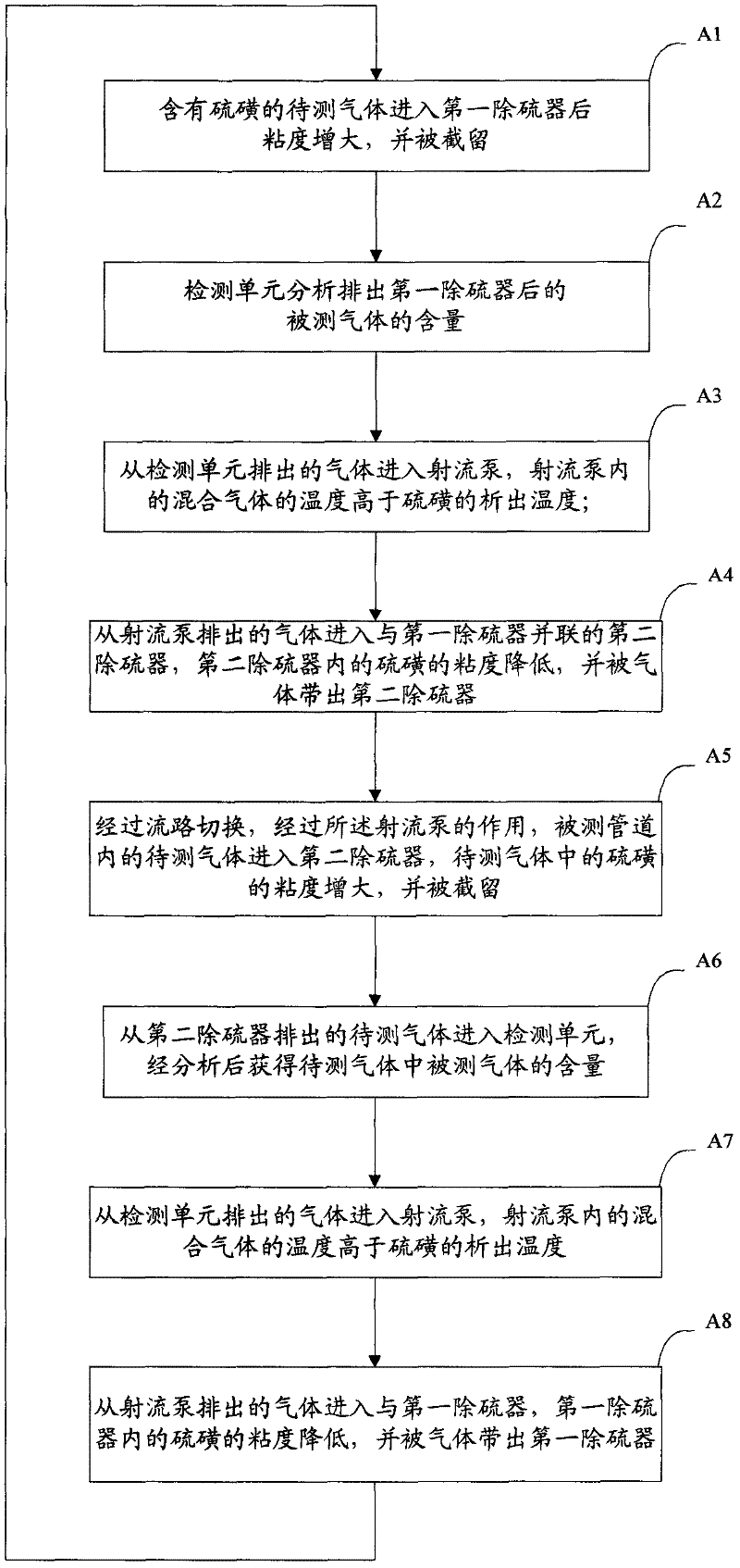

[0053] figure 1 , 3 The basic structure diagram of the sulfur ratio on-line monitor of the embodiment of the present invention is schematically given. Such as figure 1 , 3 As shown, the sulfur ratio on-line monitor includes:

[0054] Sampling pipe 21, which is used to transport the gas to be tested in the pipeline to be tested to the first desulfurizer 31 and the second desulfurizer 32;

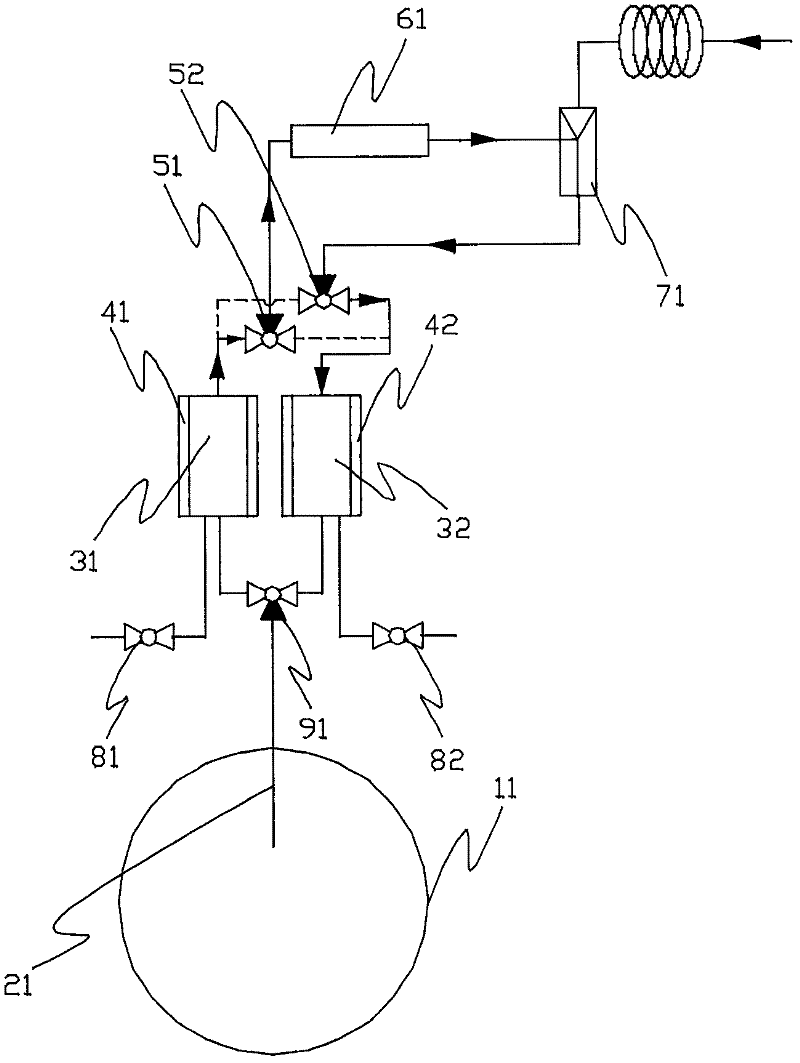

[0055]The sampling pipe can adopt one 21 or two 21, 22. If one 21 is used, a switching device 91, such as a three-way valve, should be provided on the sampling pipe, so that the gas in the pipeline under test can selectively enter The first desulfurizer 31 or the second desulfurizer 32 also needs to be provided with waste discharge pipes at the inlet ends of the first desulfurizer and the second desulfurizer respectively, and waste discharge pipes and sampling pipes are also provided with Switch modules such as valves 81, 82, so that the sulfur in the first desulfurizer 31 and the second...

Embodiment 2

[0083] An application example of the on-line monitor and monitoring method according to Embodiment 1 of the present invention in the detection of coking sulfur tail gas. The temperature in the gas to be tested in the pipeline to be tested is 160°C, the pressure is 0.025MPa, the measuring range of hydrogen sulfide is 0-2%, and the measuring range of sulfur dioxide is 0-1%, using two sampling tubes, two sampling tubes The sampling end is on the same radial section of the pipeline under test, and the sampling pipes are respectively connected to the first desulfurizer and the second desulfurizer, and no switch module is arranged on the sampling pipes. The temperature control module can not only heat the first desulfurizer and the second desulfurizer, but also reduce the temperature of the first desulfurizer and the second desulfurizer.

[0084] While the first sulfur remover (internal temperature is 130°C; of course, it can also be at [160°C, 190°C], at this time, the viscosity of...

Embodiment 3

[0086] An application example of the on-line monitor and monitoring method according to Embodiment 1 of the present invention in the detection of coking sulfur tail gas. The temperature in the gas to be tested in the pipeline to be tested is 160°C, the pressure is 0.025MPa, the measuring range of hydrogen sulfide is 0-2%, and the measuring range of sulfur dioxide is 0-1%, using a sampling tube, such as a Y-shaped tube , setting a first valve and a second valve on the sampling pipe so as to selectively connect the measured pipeline with the first desulfurizer and the second desulfurizer. The first waste discharge pipe and the second waste discharge pipe are arranged at the inlet ends of the first desulfurizer and the second desulfurizer, and the third valve and the fourth valve are respectively arranged on the first waste discharge pipe and the second waste discharge pipe. The valve is used to control whether the first desulfurizer, the second desulfurizer are connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com