Harmless remediation method and device of electrolytic aluminum waste slag and contaminated soil of electrolytic aluminum waste slag

A technology of electrolytic aluminum waste slag and repair method, which is applied in the restoration of polluted soil, etc., and can solve problems such as unconsidered anti-seepage, difficult government supervision, and no protective measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

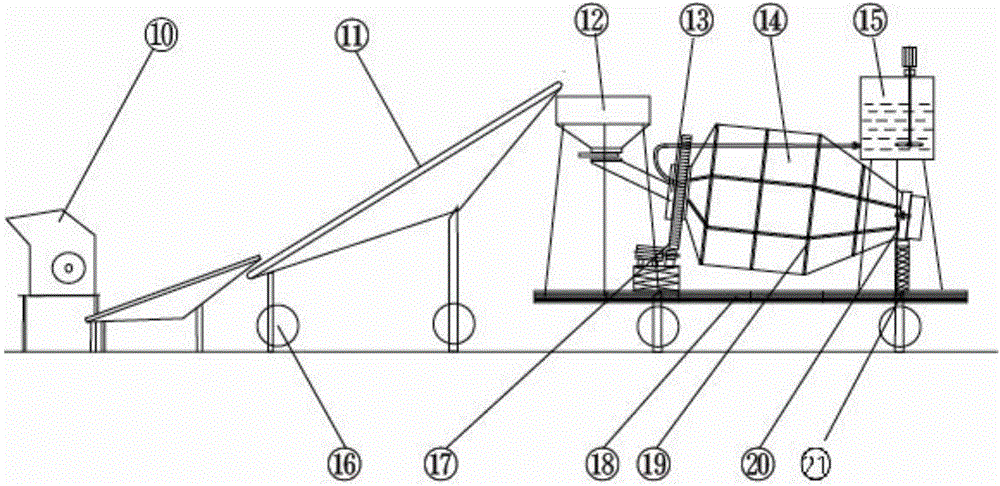

Image

Examples

Embodiment 1

[0064] Example 1 The harmless restoration method of electrolytic aluminum waste slag and its polluted soil

[0065] Step 1: Sorting out easily identifiable, bulky reusable materials including anode and cathode carbon blocks, iron blocks, aluminum blocks, sintered and dissolved alumina cryolite blocks, silicon carbide and nitride Silicon refractory bricks, etc.;

[0066] Step 2: Apply artificial impact hammer or wheeled mechanical impact hammer to the large material that cannot directly enter the hopper of the crushing system for crushing and pretreatment into small pieces that can enter the crushing system;

[0067] Step 3: Send the coarsely crushed material in step 2 to the crushing system with a conveyor belt for crushing, and the crushed particle size is ≤10mm;

[0068] Step 4: Take coarse samples evenly at multiple points, grind them, and weigh 100g after intercepting the test product by the method of quartering the round cake multiple times, add 100ml of water, stir, fil...

Embodiment 2

[0072] Example 2 The harmless restoration method of electrolytic aluminum waste slag and its polluted soil

[0073] Step 1: Sorting out easily identifiable, bulky reusable materials including anode and cathode carbon blocks, iron blocks, aluminum blocks, sintered and dissolved alumina cryolite blocks, silicon carbide and nitride Silicon refractory bricks, etc.;

[0074] Step 2: Apply artificial impact hammer or wheeled mechanical impact hammer to the large material that cannot directly enter the hopper of the crushing system for crushing and pretreatment into small pieces that can enter the crushing system;

[0075] Step 3: Send the coarsely crushed material in step 2 to the crushing system with a conveyor belt for crushing, and the crushed particle size is ≤10mm;

[0076] Step 4: Take coarse samples evenly at multiple points, grind them, and weigh 100g after intercepting the test product by the method of quartering the round cake multiple times, add 100ml of water, stir, fil...

Embodiment 3

[0081] Example 3 The harmless restoration method of electrolytic aluminum waste slag and its polluted soil

[0082] Step 1: Sorting out easily identifiable, bulky reusable materials including anode and cathode carbon blocks, iron blocks, aluminum blocks, sintered and dissolved alumina cryolite blocks, silicon carbide and nitride Silicon refractory bricks, etc.;

[0083] Step 2: Apply artificial impact hammer or wheeled mechanical impact hammer to the large material that cannot directly enter the hopper of the crushing system for crushing and pretreatment into small pieces that can enter the crushing system;

[0084] Step 3: Send the coarsely crushed material in step 2 to the crushing system with a conveyor belt for crushing, and the crushed particle size is ≤10mm;

[0085] Step 4: Take coarse samples evenly at multiple points, grind them, and weigh 100g after intercepting the test product by the method of quartering the round cake multiple times, add 100ml of water, stir, fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com