Mouth expanding and bag opening device for woven bags

A bag holding device and woven bag technology, which is applied in the field of automatic filling equipment for bulk materials, can solve the problems of low working efficiency of automatic filling equipment, lower bag holding efficiency and filling efficiency, and inability to open the opening of woven bags. Easy to popularize and implement, maximize work efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

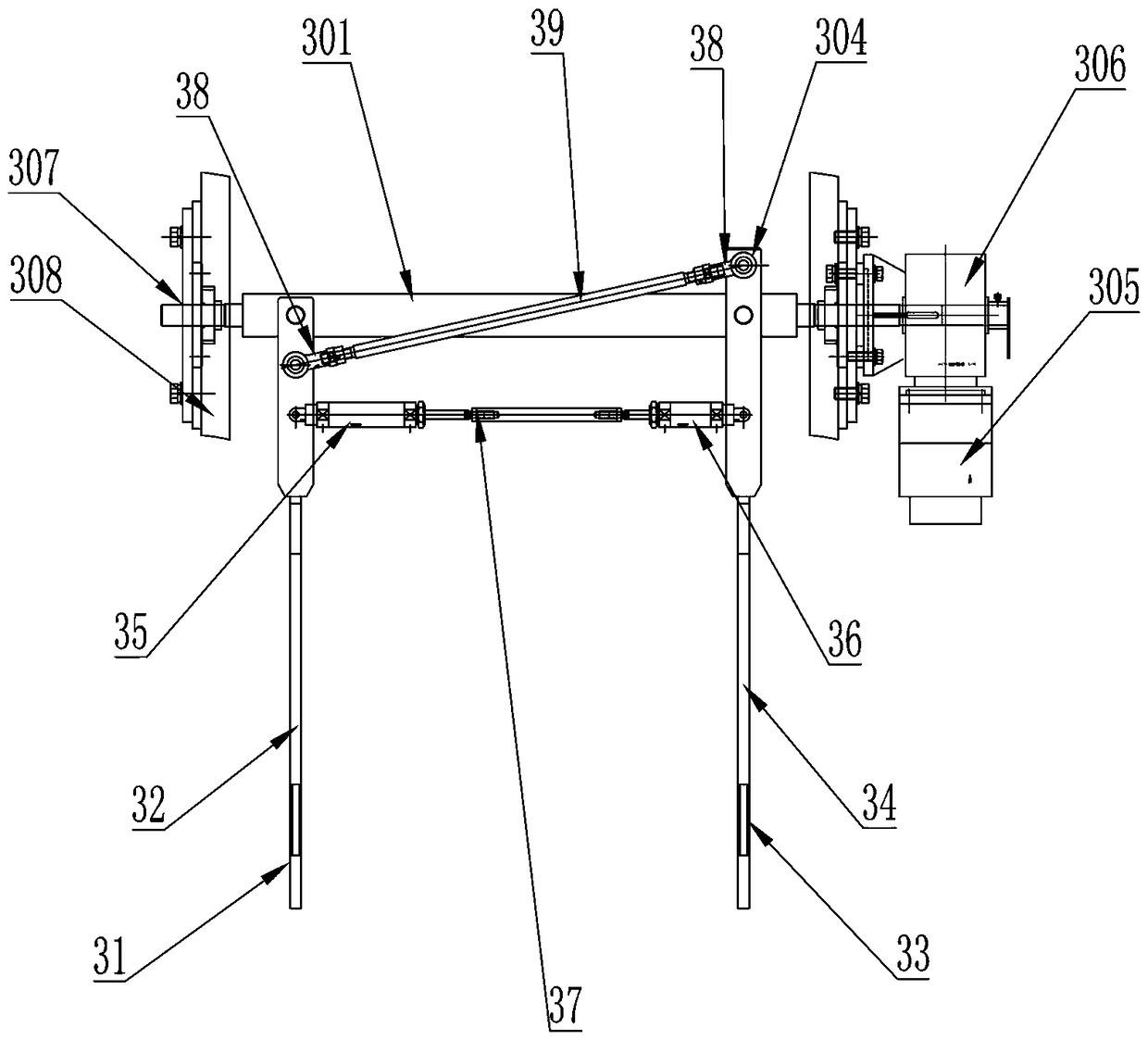

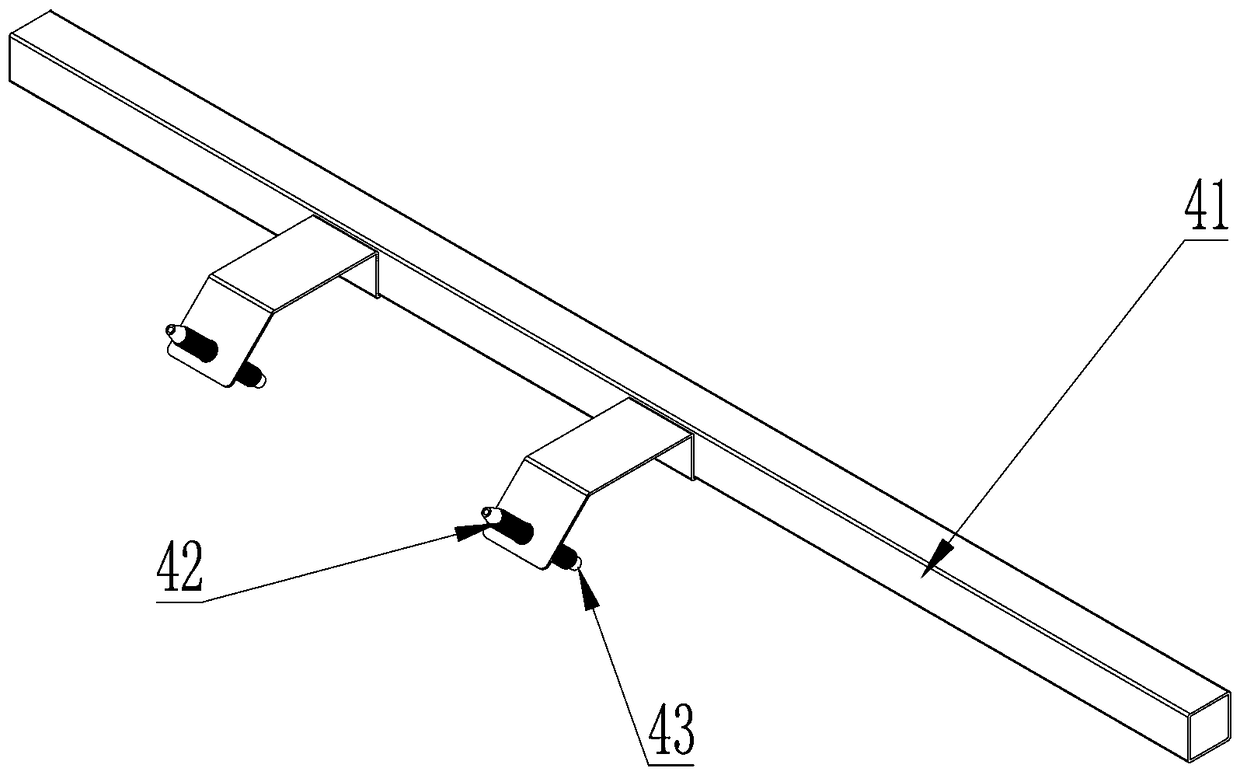

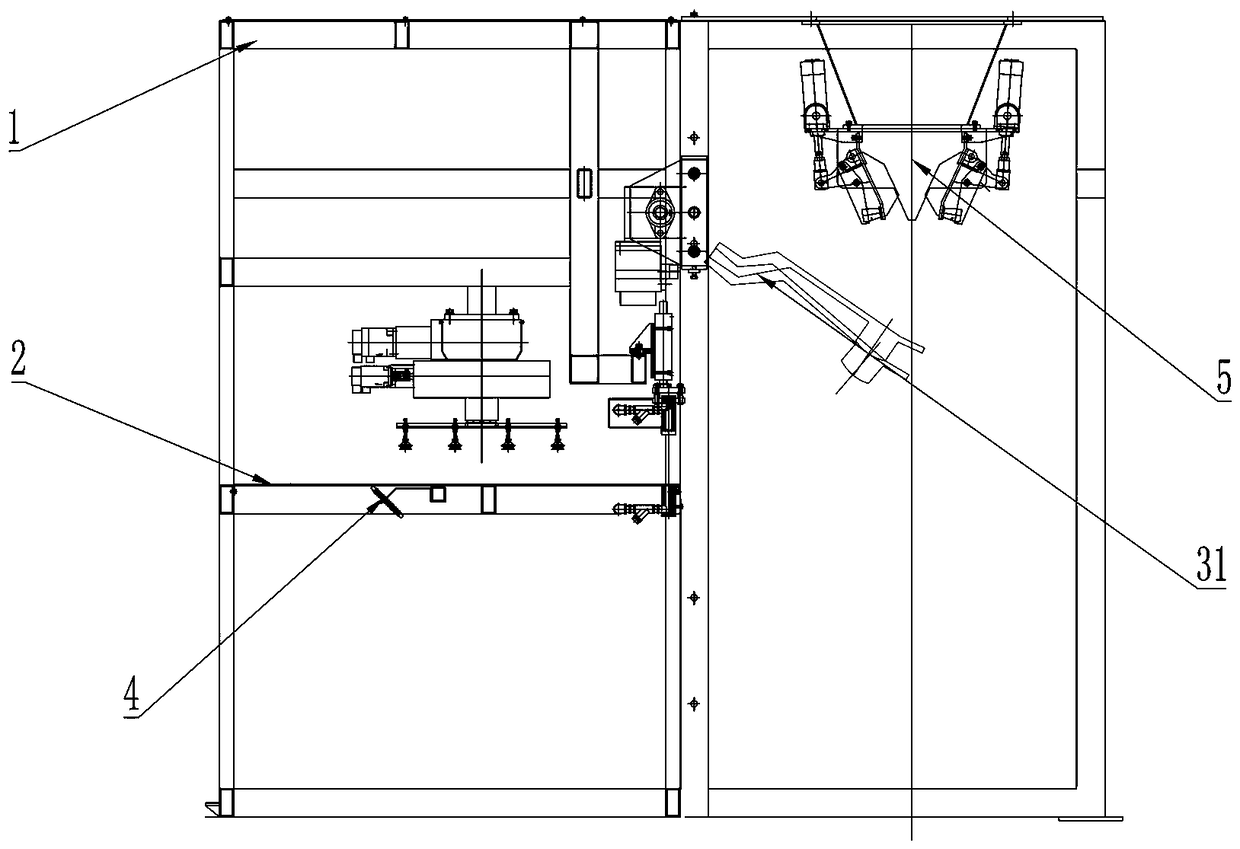

[0018] Embodiment 1 of the woven bag opening and bag supporting device of the present invention, as Figure 1~4 As shown, it includes a frame 1, the left side of the frame 1 is provided with a working platform 2 for placing woven bags horizontally, and the frame is provided with an opening device 6 and a bag supporting mechanism 3; the opening device 6 includes a set The lower vacuum chuck body 62 on the work platform, the upper vacuum chuck body 61 arranged on the frame, the upper and lower vacuum chuck bodies are respectively provided with at least two relative vacuum suction ports 610, and the upper vacuum chuck body There is also an execution cylinder 63 for driving the upper vacuum chuck body to move up and down; a buffer device is arranged between the upper vacuum chuck body 61 and the execution cylinder 63, and the buffer device includes two connecting screws 68 respectively connected to the upper vacuum The suction cup body 61 and the connecting plate 69 of the actuato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com