Trace lubricating oil and preparation method thereof

A lubricating oil and micro-quantity technology, which is applied in the direction of lubricating compositions, petroleum industry, additives, etc., can solve the problems of not being able to adapt to stainless steel processing, reduce the service life of tools, and general corrosion resistance, so as to improve the cleanliness and dispersibility. Anti-rust performance, strong corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

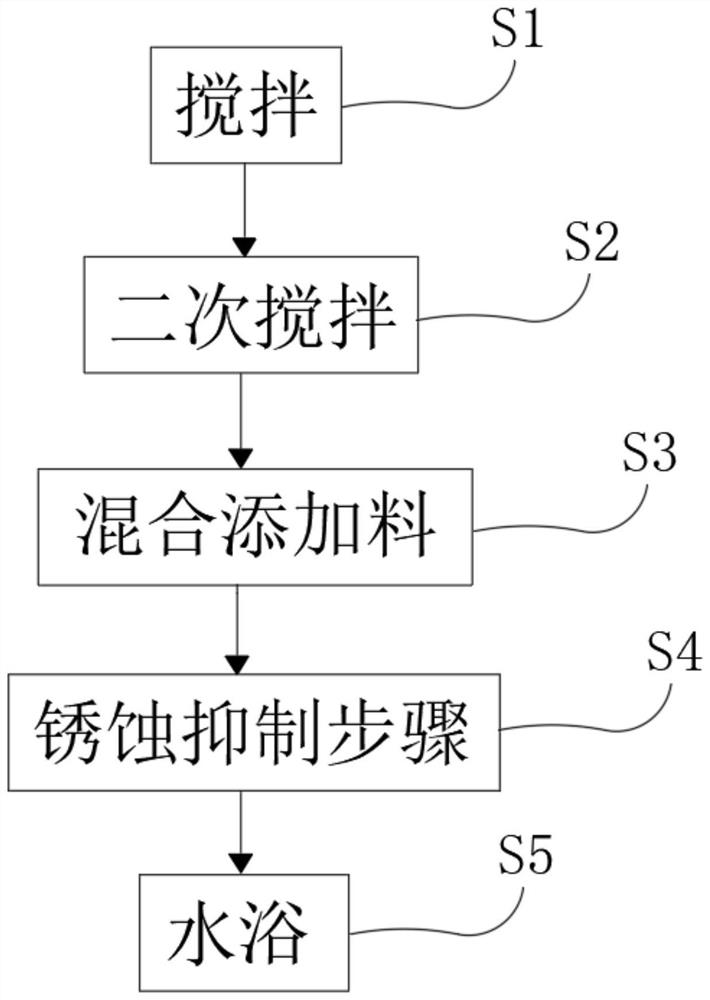

[0029] Embodiment one, refer to figure 1 , a micro-quantity lubricating oil and a preparation method thereof, wherein the micro-quantity lubricating oil comprises the following components in parts by weight:

[0030] 10 parts of extreme pressure agent, 5 parts of vulcanized lard, 10 parts of ultra-alkaline calcium sulfonate, 5 parts of antiwear agent, 0.6 part of antioxidant additive, 0.6 part of detergent, 0.1 part of rust inhibitor, and the rest is non-drying Oil.

[0031] In this embodiment, the antiwear agent includes one or both of thiocarbamate, alkyl zinc thiophosphate and alkyl phosphoric acid ester, and the antiwear agent can effectively reduce the wear rate during cutting, Improved service life.

[0032] In this embodiment, the non-drying oil is any one or more of palm oil, castor oil and olive oil, and the iodine value of the non-drying oil must be less than 100. Various parameters of lubricating oil.

[0033] In this embodiment, the antioxidant additive is comp...

Embodiment 2

[0045] Embodiment two, refer to figure 1 , a micro-quantity lubricating oil and a preparation method thereof, wherein the micro-quantity lubricating oil comprises the following components in parts by weight:

[0046] 5 parts of extreme pressure agent, 3 parts of vulcanized lard, 7 parts of ultra-alkaline calcium sulfonate, 3 parts of anti-wear agent, 0.3 part of anti-oxidation additive, 0.5 part of detergent, 0.02 part of rust inhibitor, and the rest is non-drying Oil.

[0047] In this embodiment, the antiwear agent includes one or both of thiocarbamate, alkyl zinc thiophosphate and alkyl phosphoric acid ester, and the antiwear agent can effectively reduce the wear rate during cutting, Improved service life.

[0048] In this embodiment, the non-drying oil is any one or more of palm oil, castor oil and olive oil, and the iodine value of the non-drying oil must be less than 100. Various parameters of lubricating oil.

[0049] In this embodiment, the antioxidant additive is c...

Embodiment 3

[0061] Embodiment three, refer to figure 1 , a micro-quantity lubricating oil and a preparation method thereof, wherein the micro-quantity lubricating oil comprises the following components in parts by weight:

[0062] 7 parts of extreme pressure agent, 4 parts of vulcanized lard, 8 parts of ultra-alkaline calcium sulfonate, 5 parts of anti-wear agent, 0.6 part of antioxidant additive, 0.6 part of detergent, 0.02 part of rust inhibitor, and the rest is non-drying Oil.

[0063] In this embodiment, the antiwear agent includes one or both of thiocarbamate, alkyl zinc thiophosphate and alkyl phosphoric acid ester, and the antiwear agent can effectively reduce the wear rate during cutting, Improved service life.

[0064] In this embodiment, the non-drying oil is any one or more of palm oil, castor oil and olive oil, and the iodine value of the non-drying oil must be less than 100. Various parameters of lubricating oil.

[0065] In this embodiment, the antioxidant additive is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com