Water-borne rusty anticorrosive primer and preparation method thereof

A technology with rust anti-corrosion and primer, applied in anti-corrosion coatings, coatings, polyester coatings, etc., can solve the problems of unrequired paint film thickness, poor water resistance, poor adhesion and roller coating leveling, and achieve good initial water resistance, Good salt spray resistance and good metal adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

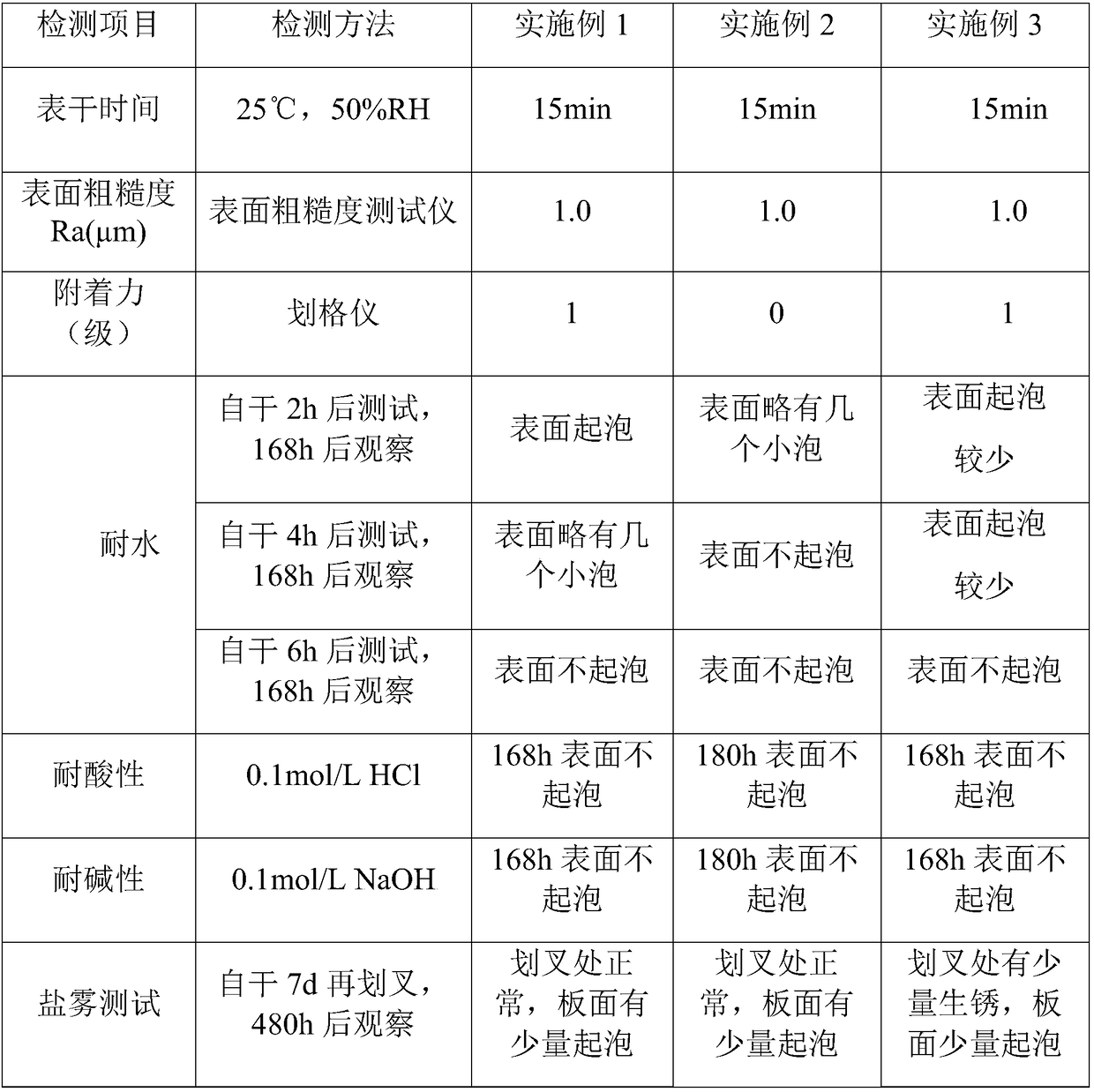

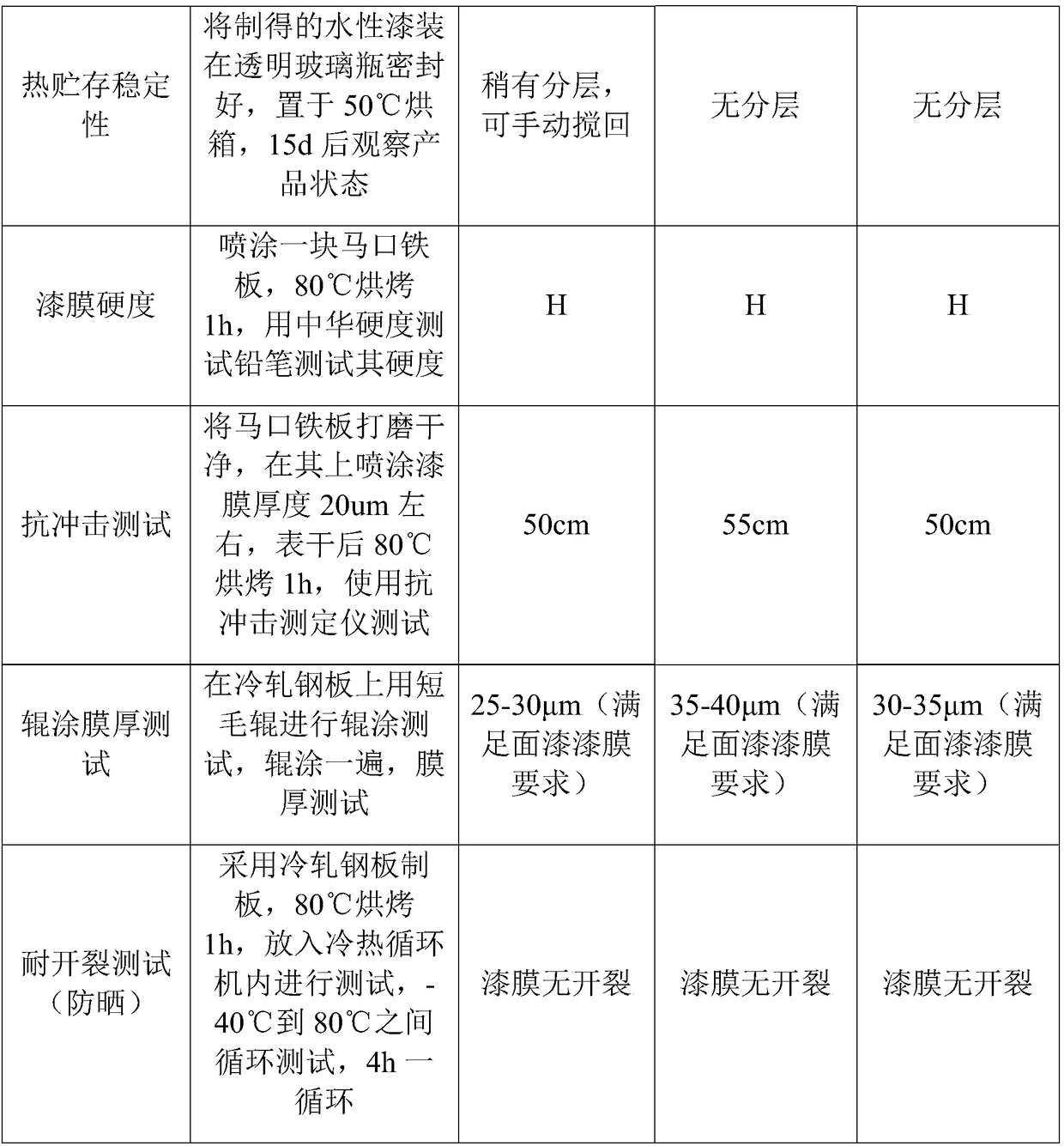

Examples

Embodiment 1

[0042] The embodiment of the present invention provides a kind of water-based anticorrosion primer with rust, and described water-based anticorrosion primer with rust comprises the following components by weight:

[0043] 1.5 parts of water-based acrylic modified alkyd resin, 18.5 parts of water-based epoxy modified alkyd resin, 1 part of defoamer, 0.1 part of dispersant, 1 part of anti-flash rust agent, 0.5 part of thickener, 0.1 part of dimethylethanolamine , 0.1 part of leveling agent, 1 part of drier, 0.1 part of wetting agent, 2 parts of rust conversion agent, 0.5 part of anti-mildew thixotropic agent, 15 parts of iron red, 8 parts of talcum powder, 17 parts of barium sulfate, butyl propylene glycol 1 part of ether and 32 parts of deionized water.

[0044] The above-mentioned water-based acrylic modified alkyd resin is 3EA42Y resin of Foshan Gaoming Tongde Chemical Co., Ltd.; the water-based epoxy-modified alkyd resin is 3AK25B resin of Foshan Gaoming Tongde Chemical Co.,...

Embodiment 2

[0050] The embodiment of the present invention provides a kind of water-based anticorrosion primer with rust, and described water-based anticorrosion primer with rust comprises the following components by weight:

[0051] 2 parts of water-based acrylic modified alkyd resin, 23 parts of water-based epoxy modified alkyd resin, 0.4 part of defoamer, 0.6 part of dispersant, 0.4 part of anti-flash rust agent, 0.8 part of thickener, 0.2 part of dimethylethanolamine , 0.3 parts of leveling agent, 0.6 parts of drier, 0.4 parts of wetting agent, 1 part of rust conversion agent, 0.3 parts of anti-mildew thixotropic agent, 10 parts of iron red, 9 parts of talcum powder, 14 parts of barium sulfate, propylene glycol butyl 2 parts of ether and 34 parts of deionized water.

[0052] The models of the above-mentioned components are the same as those in Example 1, and will not be repeated here.

[0053] The preparation steps of above-mentioned water-based band rust anticorrosion primer are as ...

Embodiment 3

[0058] The embodiment of the present invention provides a kind of water-based anticorrosion primer with rust, and described water-based anticorrosion primer with rust comprises the following components by weight:

[0059] 2 parts of water-based acrylic modified alkyd resin, 28 parts of water-based epoxy modified alkyd resin, 0.2 part of defoamer, 1 part of dispersant, 0.1 part of anti-flash rust agent, 2 parts of thickener, 0.5 part of dimethylethanolamine , 0.5 parts of leveling agent, 0.1 parts of drier, 1 part of wetting agent, 0.5 parts of rust conversion agent, 0.1 part of anti-mildew thixotropic agent, 8 parts of iron red, 12 parts of talcum powder, 10 parts of barium sulfate, propylene glycol butyl 2.5 parts of ether and 36 parts of deionized water.

[0060] The models of the above-mentioned components are the same as those in Example 1, and will not be repeated here.

[0061] The preparation steps of above-mentioned water-based band rust anticorrosion primer are as fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com