Primer-topcoat paint used for steel structures and allowing painting on rusty surfaces

A steel structure and coating technology, applied in coatings, anti-corrosion coatings, etc., can solve problems such as unfavorable energy consumption, labor cost and material cost, non-rust coating, early rust adhesion, etc., to achieve good anti-rust Effect, strong anti-rust ability, strong anti-rust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

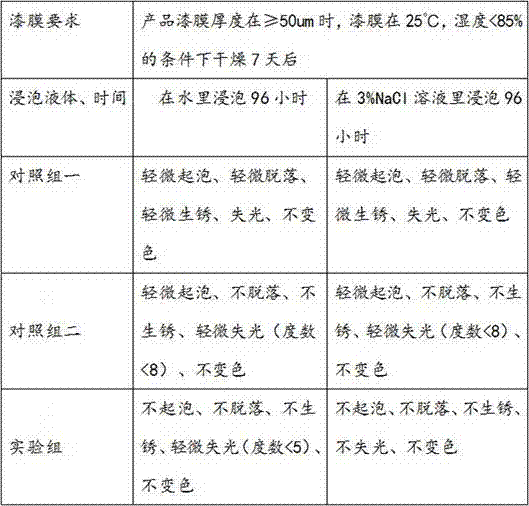

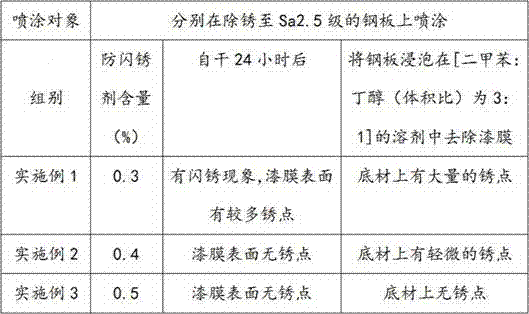

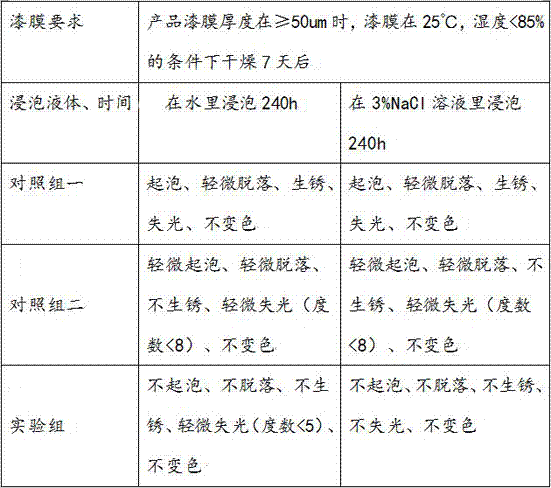

Embodiment 1

[0022] A steel structure paint with rusty coating bottom surface, including the following raw materials in weight percentage: 58% of acrylic polymer emulsion, 0.2% of defoamer, 0.15% of substrate wetting agent, 0.2% of wetting and dispersing agent, titanium dioxide 20%, zinc phosphate 6%, anti-flash rust agent 0.3%, dipropylene glycol butyl ether 3%, ammonia 0.15%, thickener 0.5%, preservative 0.1% and deionized water 11.35%.

[0023] A method for preparing a rust-coated bottom-surface-integrated steel structure paint, comprising the following steps:

[0024] 1) Take 8.5% of deionized water and put it into the dispersing tank, disperse at a speed of 1000r / min, and add 0.2% of wetting and dispersing agent and 0.1% of defoamer in sequence, then adjust the dispersing speed to 1200r / min, and disperse for 10 minutes , to obtain the first dispersion mixture, for subsequent use;

[0025] 2) Add 20% of titanium dioxide, 6% of zinc phosphate and 0.05% of preservative to the mixed disp...

Embodiment 2

[0036] A steel structure paint with rusty coating base, including the following raw materials in weight percentage: 58% of acrylic polymer emulsion, 0.2% of defoamer, 0.2% of substrate wetting agent, 0.2% of wetting and dispersing agent, titanium dioxide 20%, zinc phosphate 6%, anti-flash rust agent 0.4%, dipropylene glycol butyl ether 3%, ammonia 0.15%, thickener 0.5%, preservative 0.1% and deionized water 11.25%.

[0037] A method for preparing a rust-coated bottom-surface-integrated steel structure paint, comprising the following steps:

[0038] 1) Take 8.5% of deionized water and put it into the dispersing tank, disperse at a speed of 1000r / min, and add 0.2% of wetting and dispersing agent and 0.1% of defoamer in sequence, then adjust the dispersing speed to 1200r / min, and disperse for 10 minutes , to obtain the first dispersion mixture, for subsequent use;

[0039] 2) Add 20% of titanium dioxide, 6% of zinc phosphate and 0.05% of preservative to the mixed dispersion liquid...

Embodiment 3

[0050] A steel structure paint with rusty coating base, including the following raw materials in weight percentage: 58% of acrylic polymer emulsion, 0.2% of defoamer, 0.2% of substrate wetting agent, 0.2% of wetting and dispersing agent, titanium dioxide 20%, zinc phosphate 6%, anti-flash rust agent 0.5%, dipropylene glycol butyl ether 3%, ammonia 0.15%, thickener 0.5%, preservative 0.1% and deionized water 11.15%.

[0051] A method for preparing a rust-coated bottom-surface-integrated steel structure paint, comprising the following steps:

[0052] 1) Take 8.5% of deionized water and put it into the dispersing tank, disperse at a speed of 1000r / min, and add 0.2% of wetting and dispersing agent and 0.1% of defoamer in sequence, then adjust the dispersing speed to 1200r / min, and disperse for 10 minutes , to obtain the first dispersion mixture, for subsequent use;

[0053] 2) Add 20% of titanium dioxide, 6% of zinc phosphate and 0.05% of preservative to the mixed dispersion liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com