Method of preparing hydrophobic nano-titanium dioxide powder

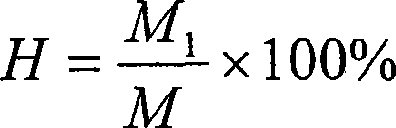

A nano-titanium dioxide, hydrophobic technology, applied in the field of nanomaterials, can solve the problems of unsatisfactory inorganic surface treatment effect, no mention of nano-titanium dioxide organic surface treatment, limitations in the application field of nano-titanium dioxide, etc., to achieve excellent light stability and easy control. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Specifically follow the steps below to implement:

[0026](1) Take 1000 g of nano-titanium dioxide aqueous dispersion with a mass percentage of 10% and place it in a 3000 mL three-necked flask, start the stirring device, adjust the temperature of nano-titanium dioxide aqueous dispersion to 40° C. 4% sodium aluminate aqueous solution and 5% phosphoric acid aqueous solution were added to the mixture, and the pH value of the system was maintained at 8.0. Amount of sodium aluminate to generate AlPO 4 The mass meter accounts for 4% of the mass of nano-titanium dioxide. After adding the aqueous sodium aluminate solution, continue stirring and aging at 40° C. for 10 minutes.

[0027] (2) The temperature of the nano-titanium dioxide aqueous dispersion is raised to 95° C., adding a mass percentage of 10% sodium silicate aqueous solution and a mass percentage of 5% nitric acid aqueous solution to the nano-titanium dioxide aqueous dispersion respectively, and maintaining the sys...

Embodiment 2

[0032] Specifically follow the steps below to implement:

[0033] (1) Measure 1000 g of the nano-titanium dioxide aqueous dispersion that is 25% by mass and place it in a 3000 mL three-necked flask, start the stirring device, adjust the temperature of the nano-titanium dioxide aqueous dispersion to 80° C. A 10% aqueous solution of sodium aluminate and a 10% aqueous solution of phosphoric acid were added to the mixture, and the pH of the system was maintained at 10.0. Amount of sodium aluminate to generate AlPO 4 The mass meter accounts for 10% of the mass of nano-titanium dioxide. After adding the aqueous sodium aluminate solution, continue stirring and aging at 80° C. for 60 minutes.

[0034] (2) maintaining the temperature of the nano-titanium dioxide aqueous dispersion at 80°C, adding a mass percentage of 20% sodium silicate aqueous solution and a mass percentage of 10% hydrochloric acid aqueous solution to the nano-titanium dioxide aqueous dispersion, and maintaining the...

Embodiment 3

[0039] Specifically follow the steps below to implement:

[0040] (1) Take 1000 g of nano-titanium dioxide aqueous dispersion with a mass percentage of 15% and place it in a 3000mL three-necked flask, start the stirring device, adjust the temperature of nano-titanium dioxide aqueous dispersion to 60°C, and pour into nano-titanium dioxide aqueous dispersion respectively A 7% aqueous solution of sodium aluminate and a 7% aqueous phosphoric acid solution were added to maintain the pH value of the system at 9.0. Amount of sodium aluminate to generate AlPO 4 The mass meter accounts for 6% of the mass of nano-titanium dioxide. After adding the aqueous sodium aluminate solution, continue stirring and aging at 60° C. for 30 minutes.

[0041] (2) The temperature of the nano-titanium dioxide aqueous dispersion is raised to 90° C., adding a mass percentage of 15% sodium silicate aqueous solution and a mass percentage of 8% sulfuric acid aqueous solution to the nano-titanium dioxide aqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com