Separated type prefabricated reinforced concrete cow-leg pillar and construction method thereof

A technology of reinforced concrete and construction method, applied in the direction of columns, piers, pillars, etc., can solve problems such as reducing work efficiency, damage to corbels and columns, and increasing indentation resistance, so as to improve work efficiency, reduce processes, and reduce adhesion. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

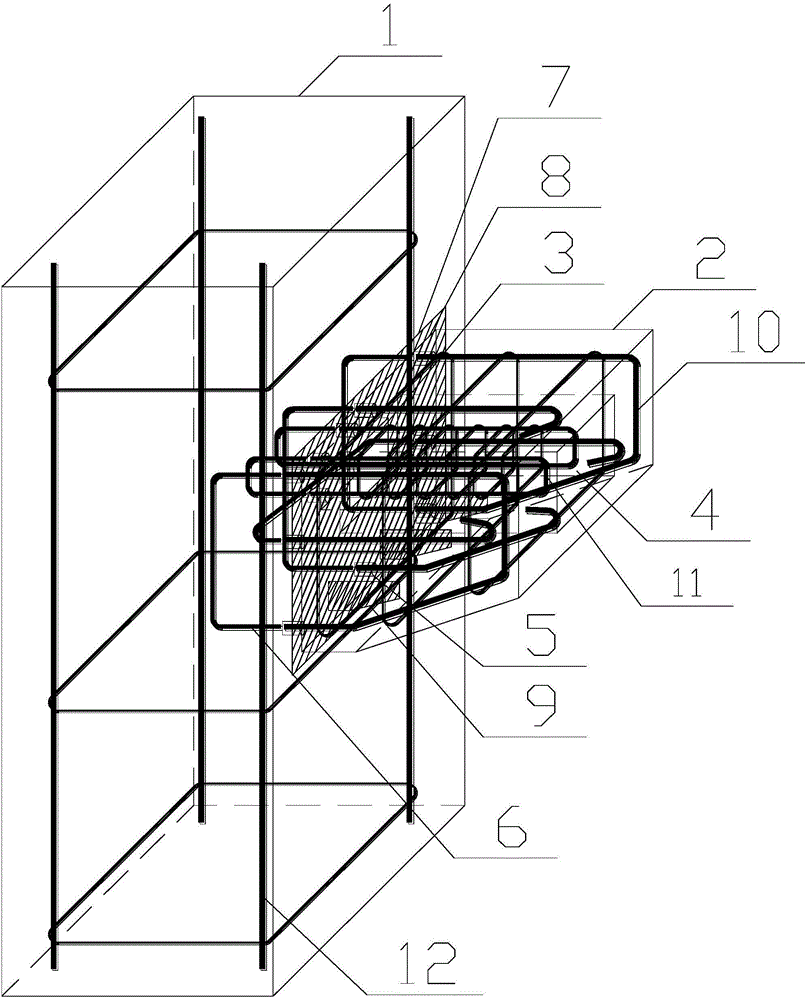

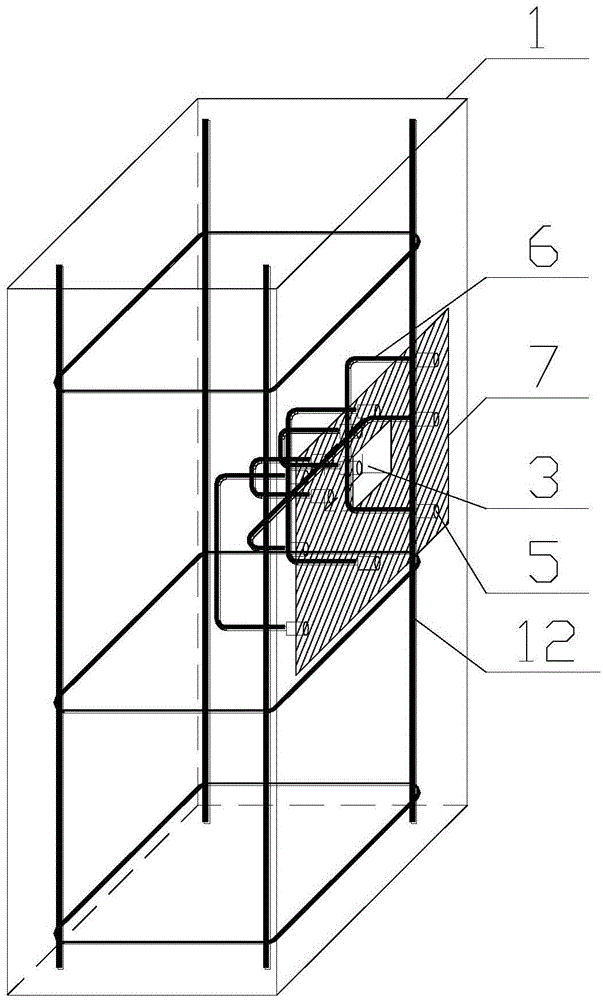

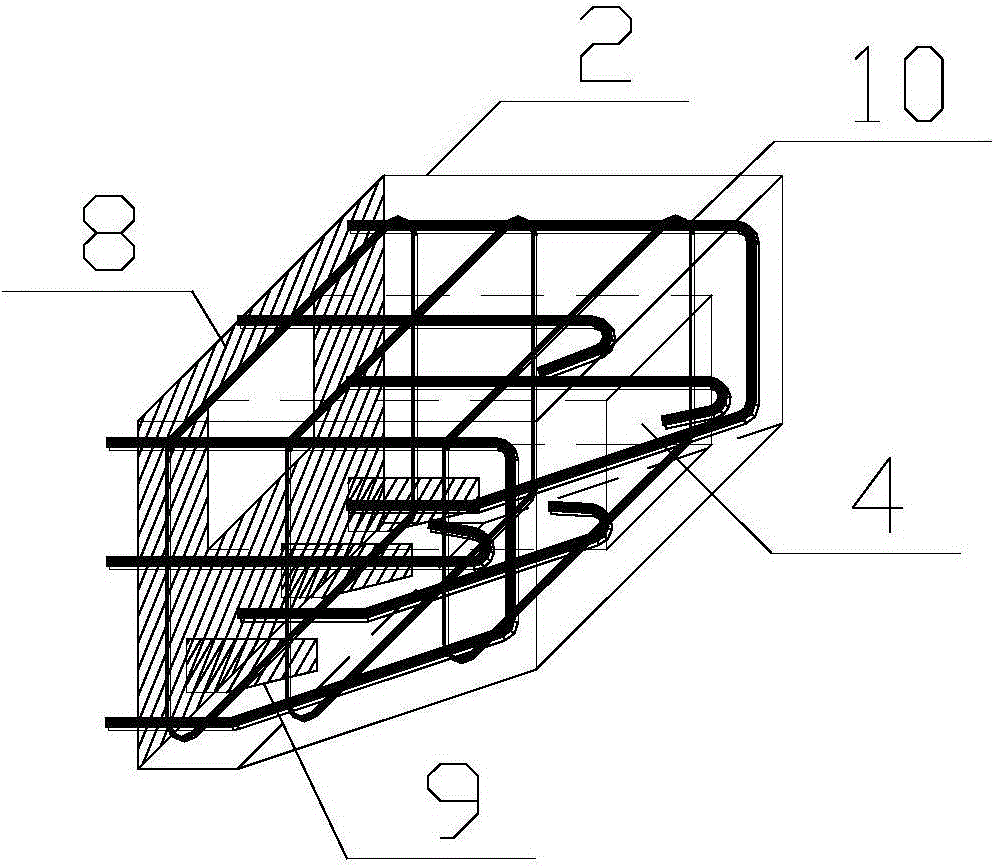

[0035] The present invention is described in detail below in conjunction with accompanying drawing:

[0036] This separated prefabricated reinforced concrete corbel column includes a prefabricated column body 1 and a prefabricated corbel 2 that can be installed on the column body later, and square holes are reserved on the prefabricated column body and the corbel.

[0037] The reserved square hole 3 of the column is a non-through long hole, and the reserved square hole 4 of the corbel is a through long hole. The reserved square hole 3 of the column is 20mm shorter than the 4 side lengths of the reserved square hole of the corbel. The different sizes of the two holes provide conditions for pre-embedding steel plates with different sizes of holes, ensuring that the two steel plates can be welded effectively.

[0038] A pre-embedded steel casing 5 is arranged in and around the reserved square hole 3 of the column. One end of the steel casing is connected with a pre-embedded steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com